Metal casting machining and manufacturing process

A technology for processing and manufacturing castings, which is applied in the field of metal casting processing and manufacturing technology, can solve the problems of large noise, severe vibration, and inconvenient operation, and achieve the effect of high noise, severe vibration, and improved spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

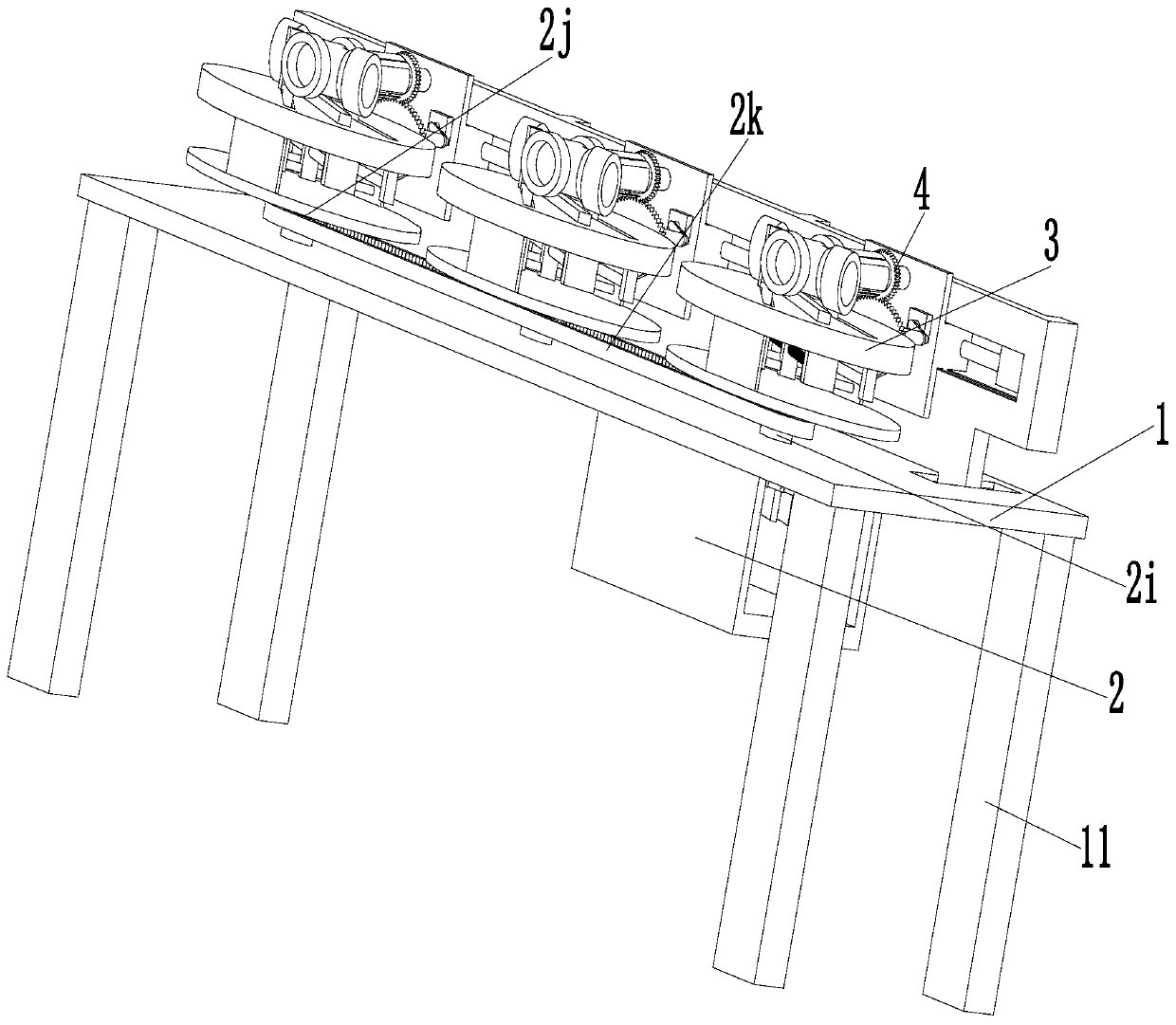

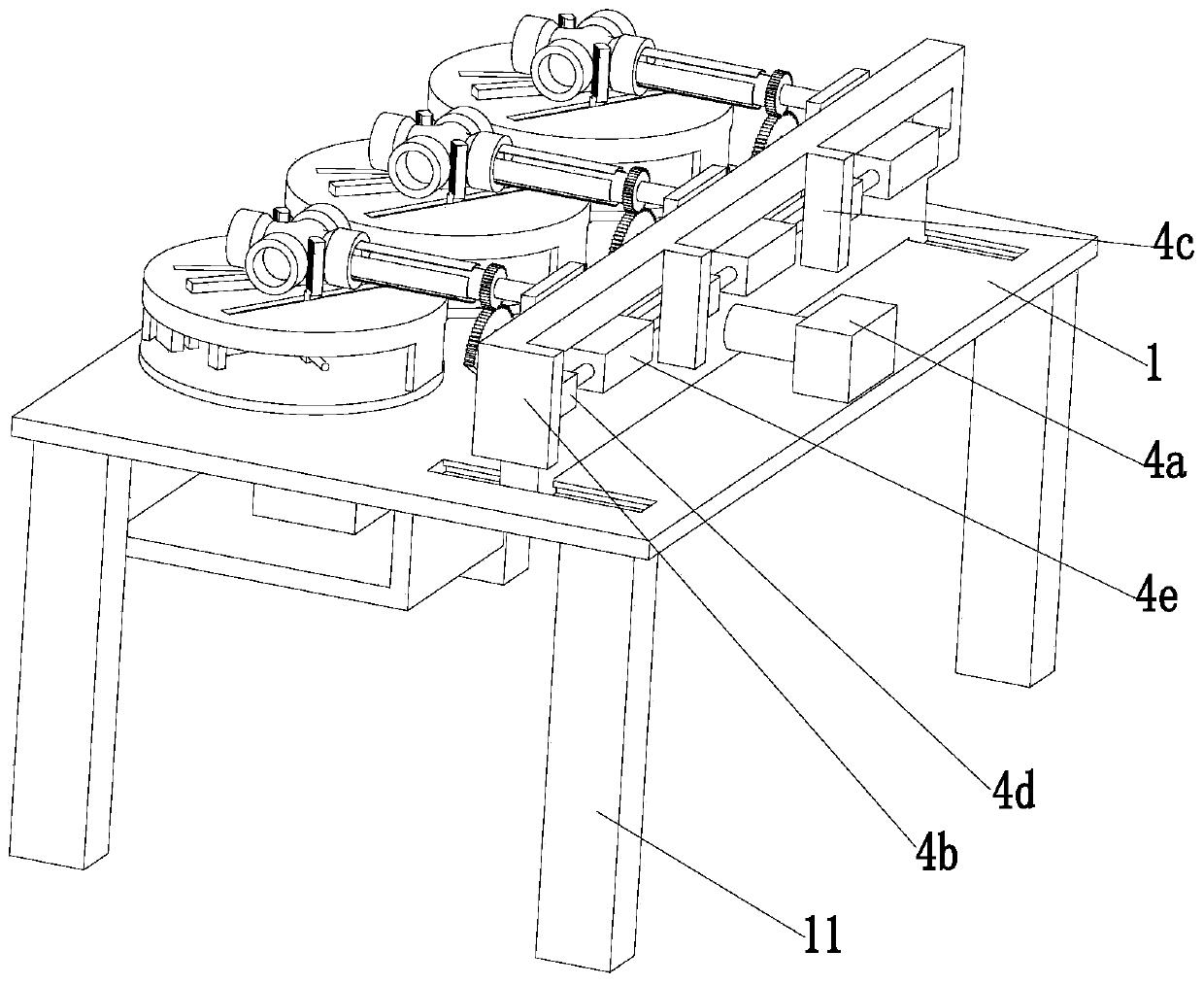

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

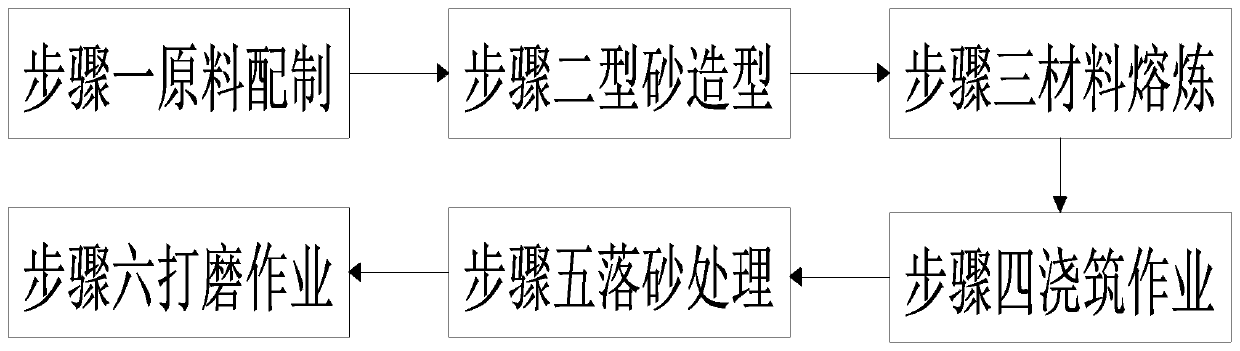

[0036] Such as Figure 1 to Figure 10 As shown, a metal product processing and manufacturing process mainly includes the following steps:

[0037] Step 1, raw material preparation: manual batching of raw materials according to weight percentage to obtain prepared raw materials;

[0038] Step 2, molding sand molding: according to the requirements of sand mold manufacturing and the shape of the casting, prepare qualified molding sand, put the prepared qualified molding sand in the molding machine for extrusion molding, and obtain the molding sand cavity;

[0039] Step 3, material smelting: put the raw materials prepared in step 1 into the intermediate frequency furnace for smelting operation, and obtain the smelted melt;

[0040] Step 4, pouring ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com