Patents

Literature

52results about How to "Low assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Human papillomaviruse type hybrid virus-like particles and preparation method thereof

ActiveCN102747047AIncrease production costProne to cross protectionViral antigen ingredientsInactivation/attenuationDiseaseHuman papillomavirus

The present invention relates to human papillomavirus (HPV) type hybrid virus-like particles and a preparation method thereof. The virus-like particles can be used for preventions two or more HPV infections and diseases caused by HPV infections. The present invention further relates to uses of the protein and the virus-like particles in preparations of drug compositions or vaccines, wherein the drug compositions or the vaccines are provided for preventions of HPV infections and diseases caused by HPV infections, and the diseases comprise cervical cancer, condyloma acuminatum, and the like.

Owner:XIAMEN UNIV +1

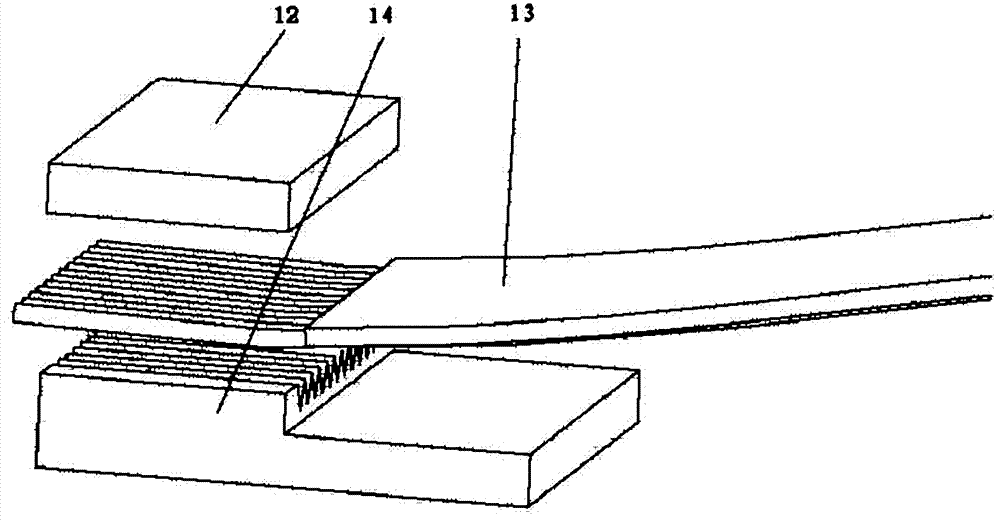

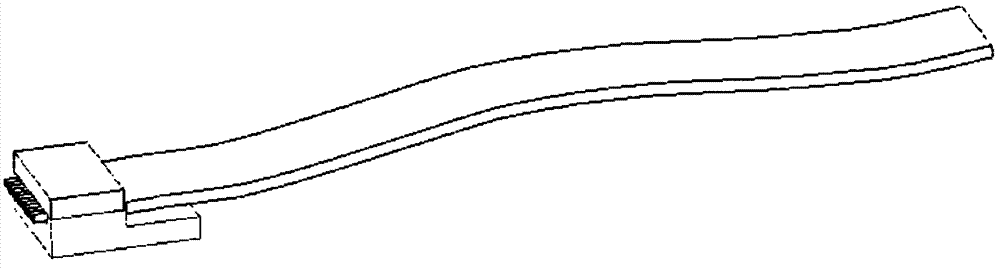

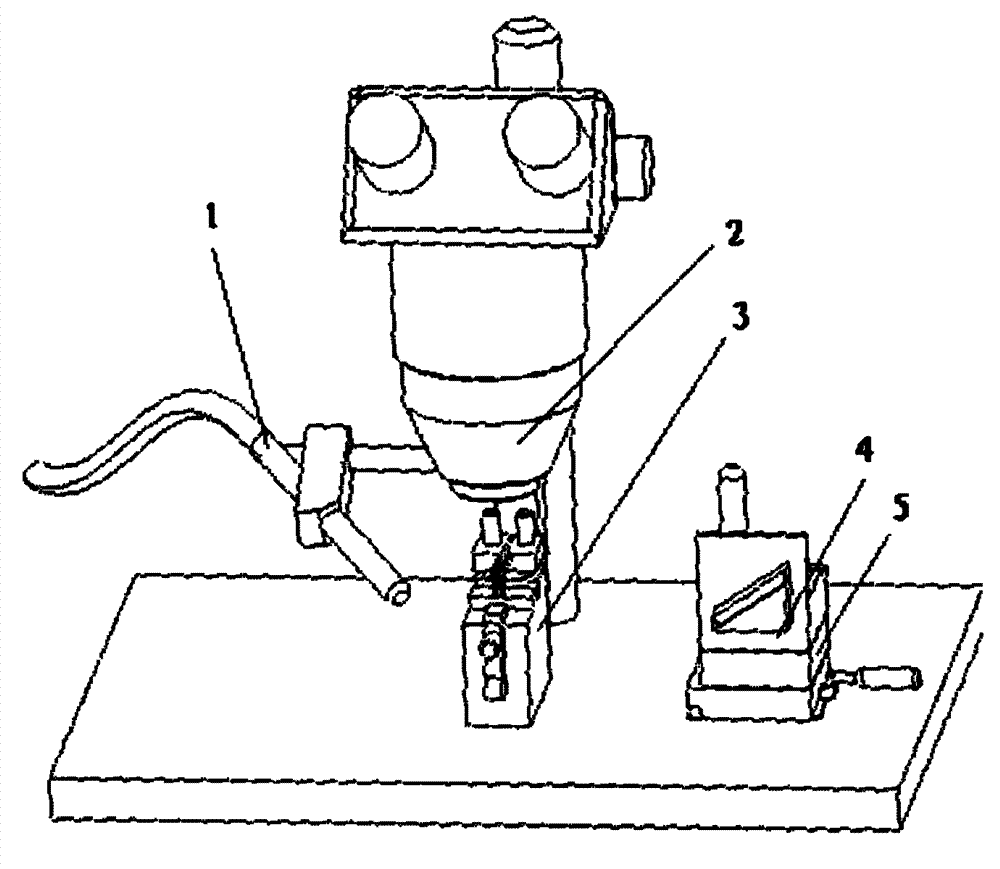

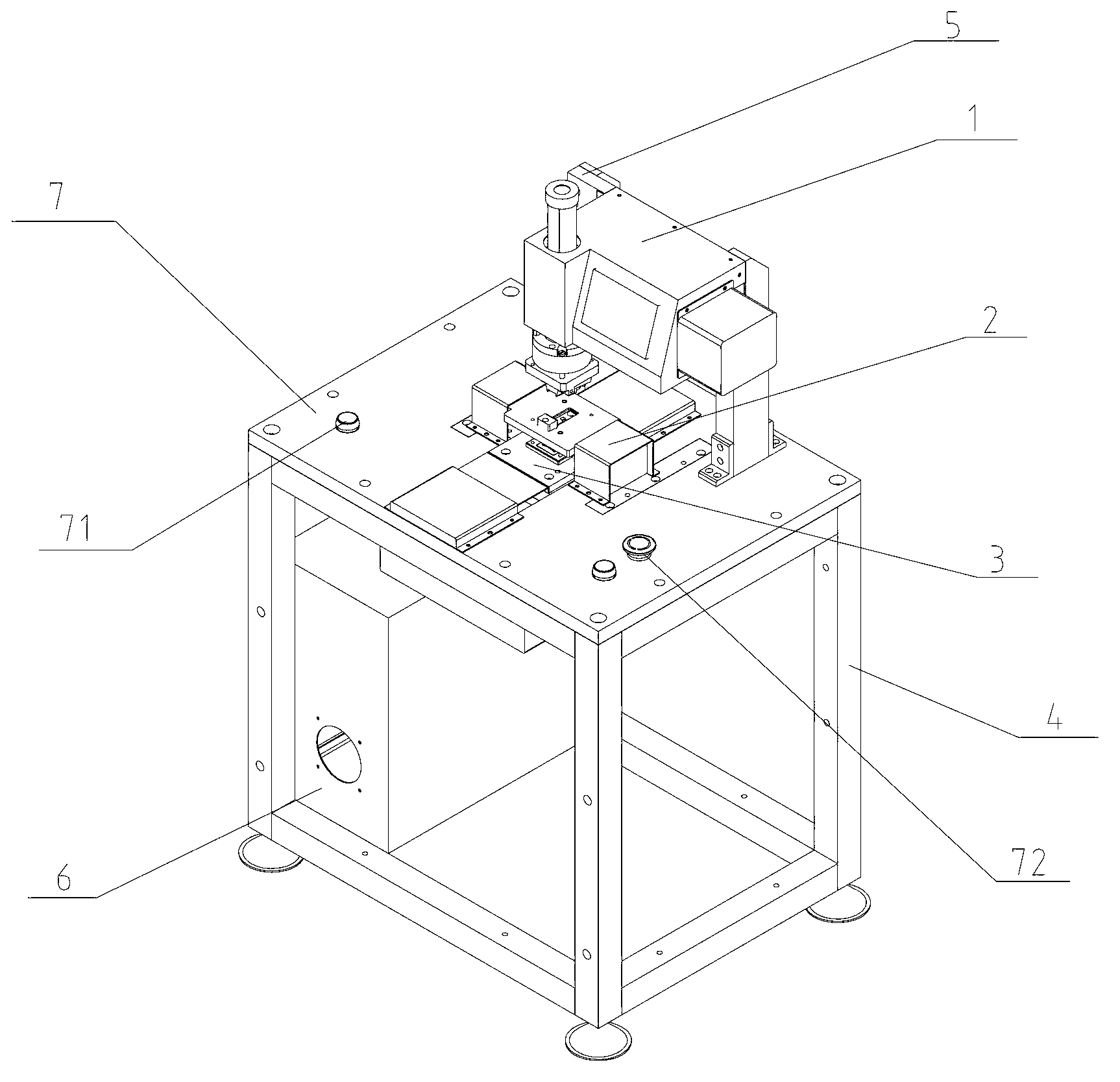

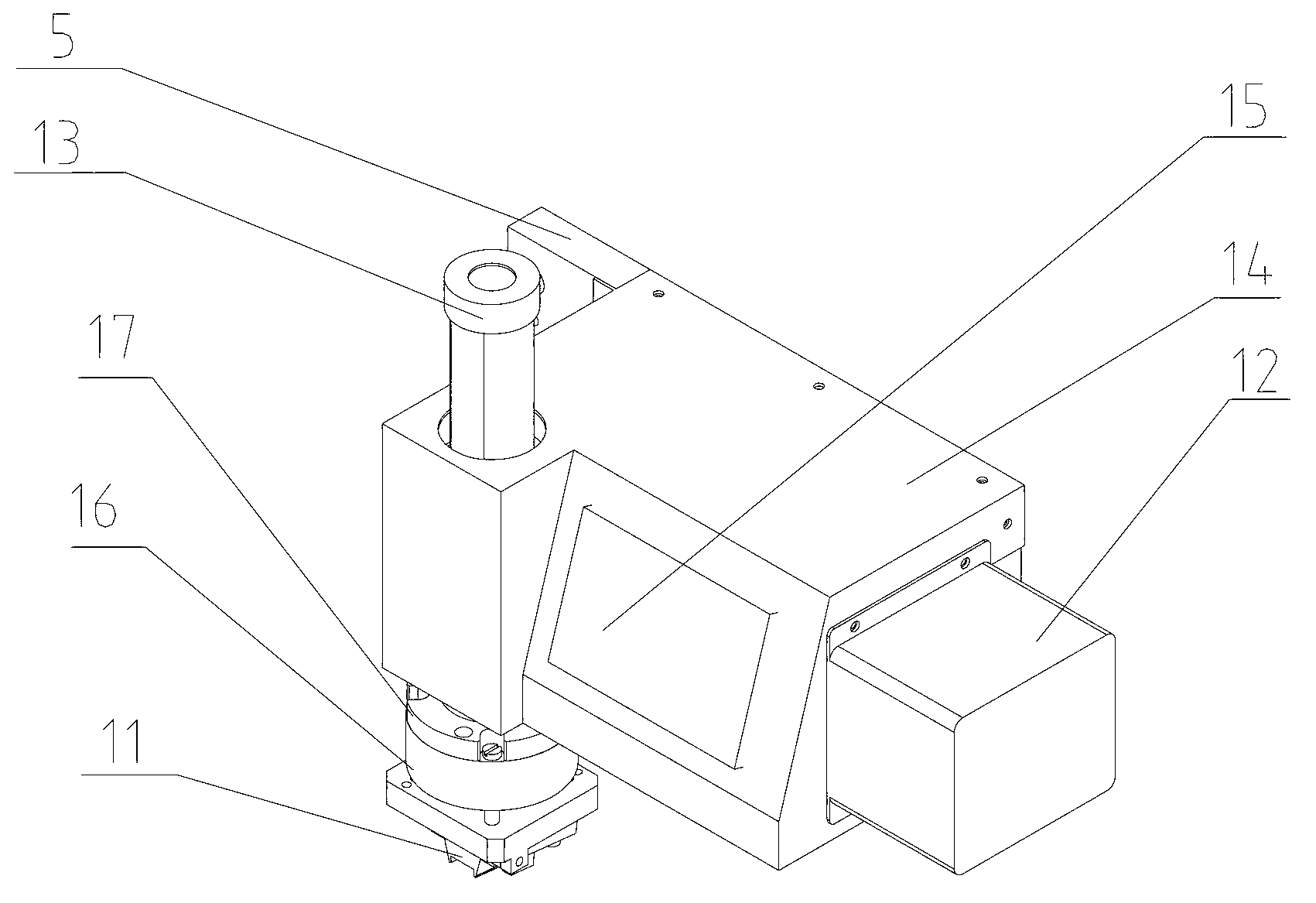

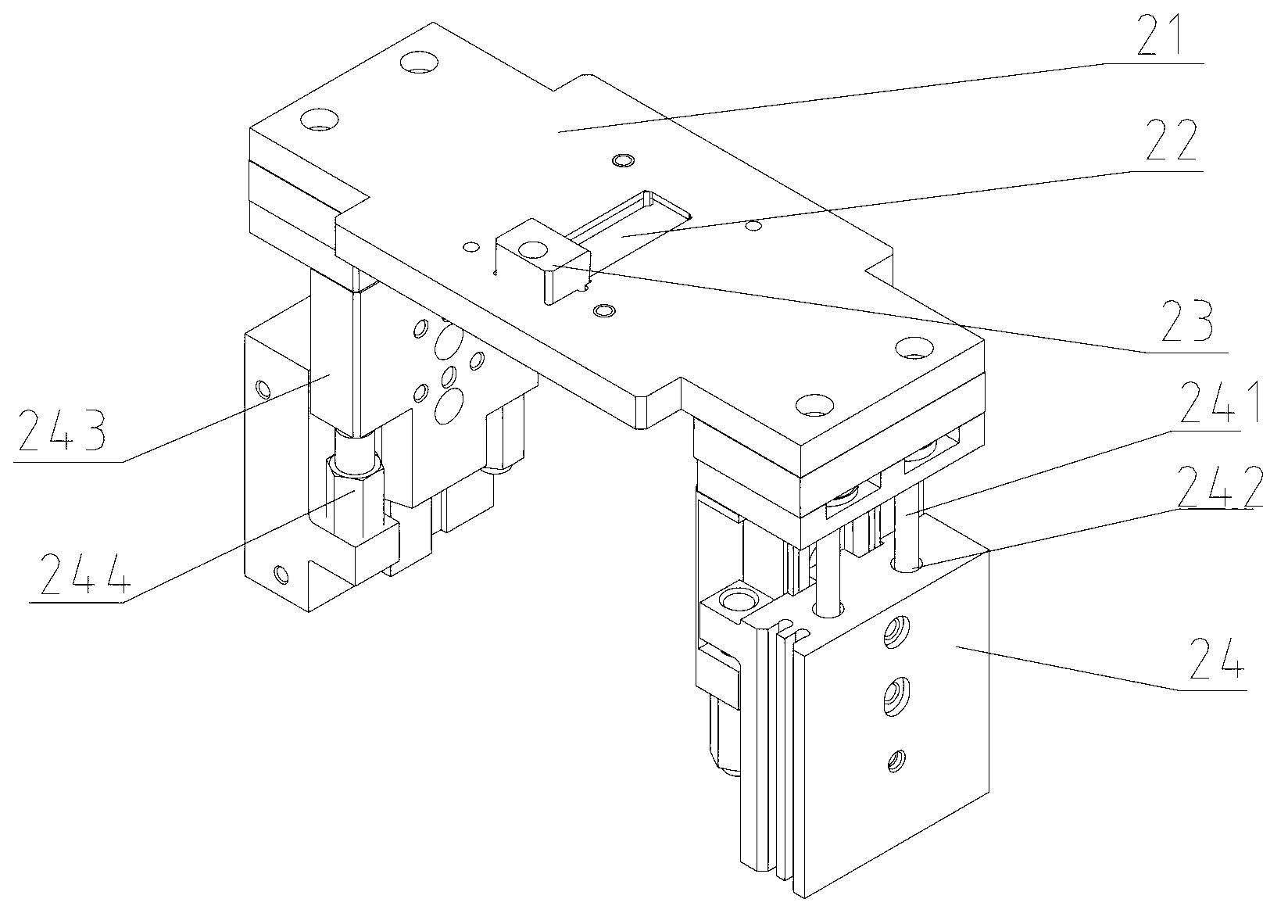

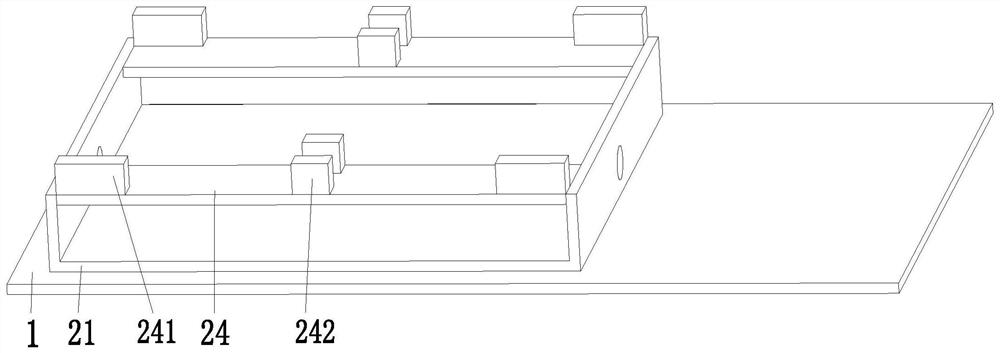

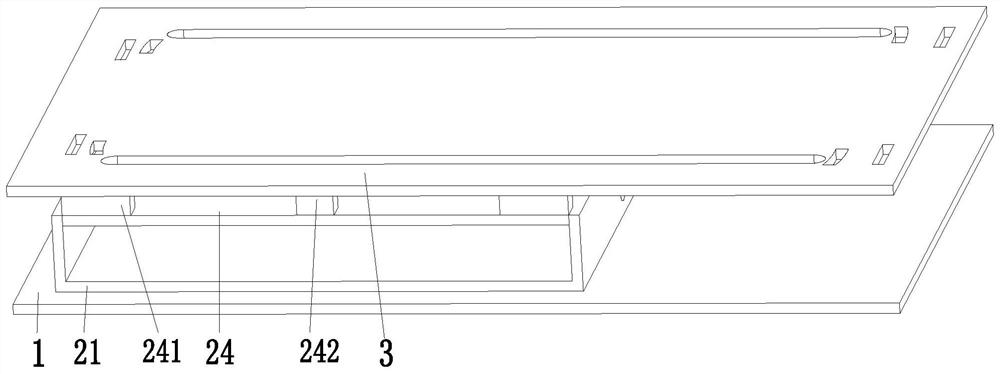

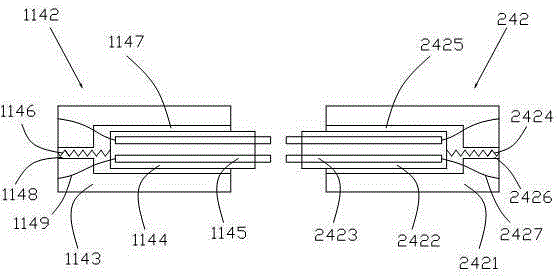

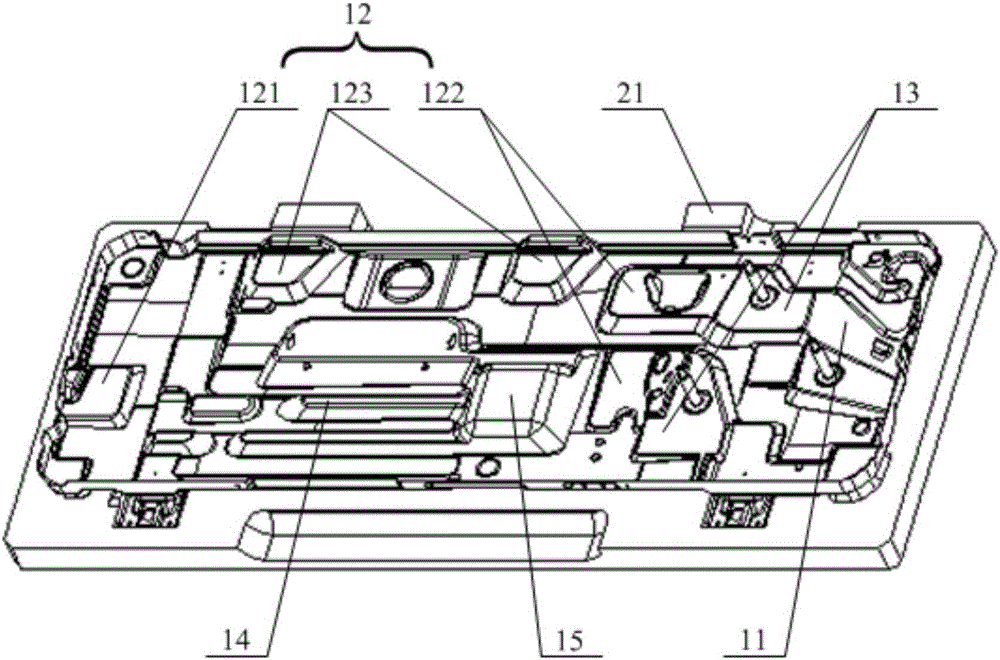

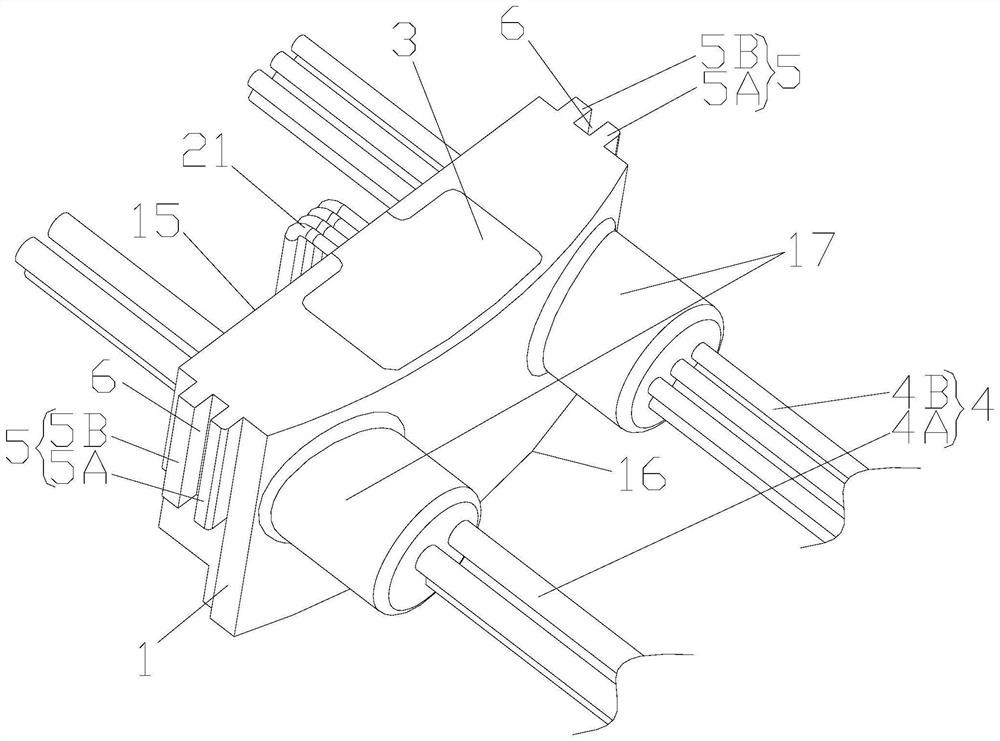

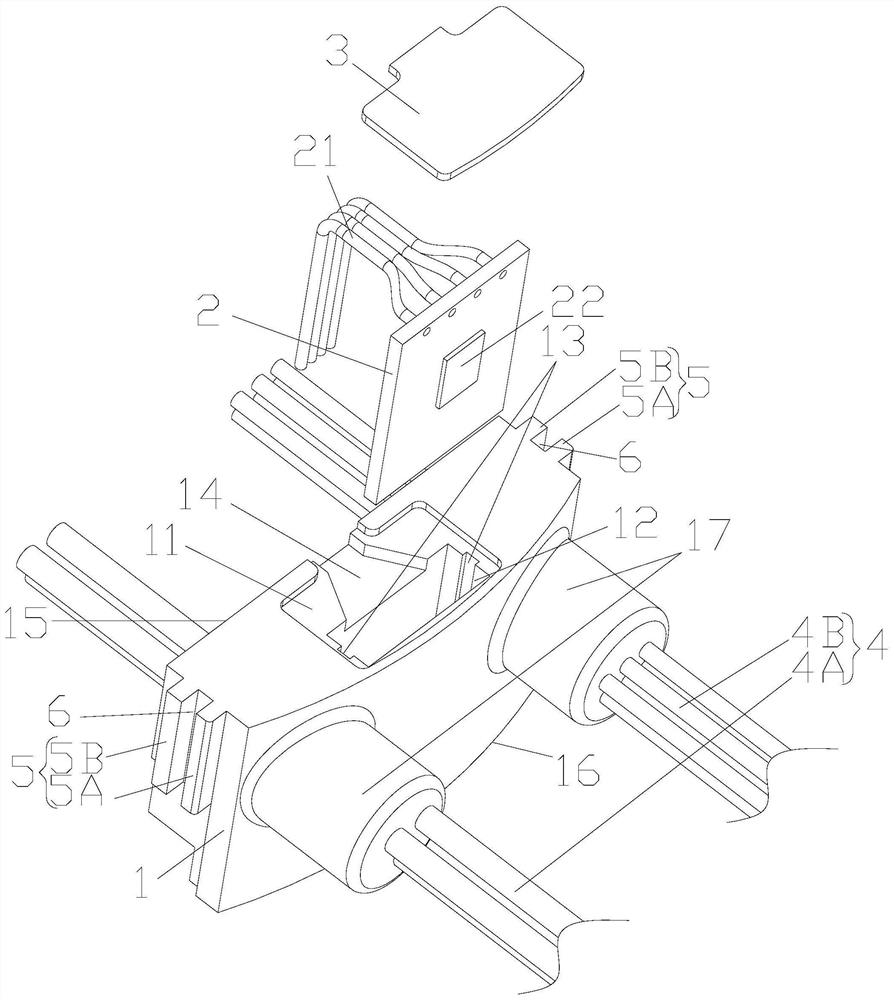

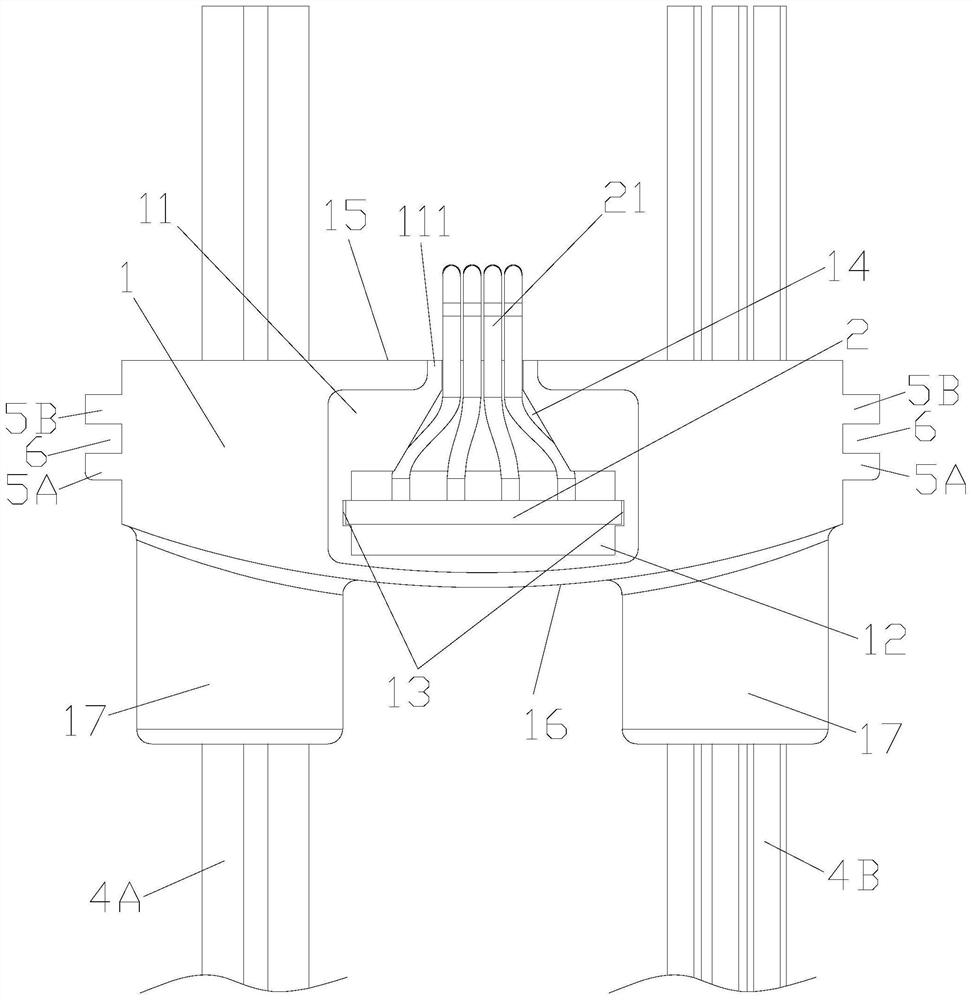

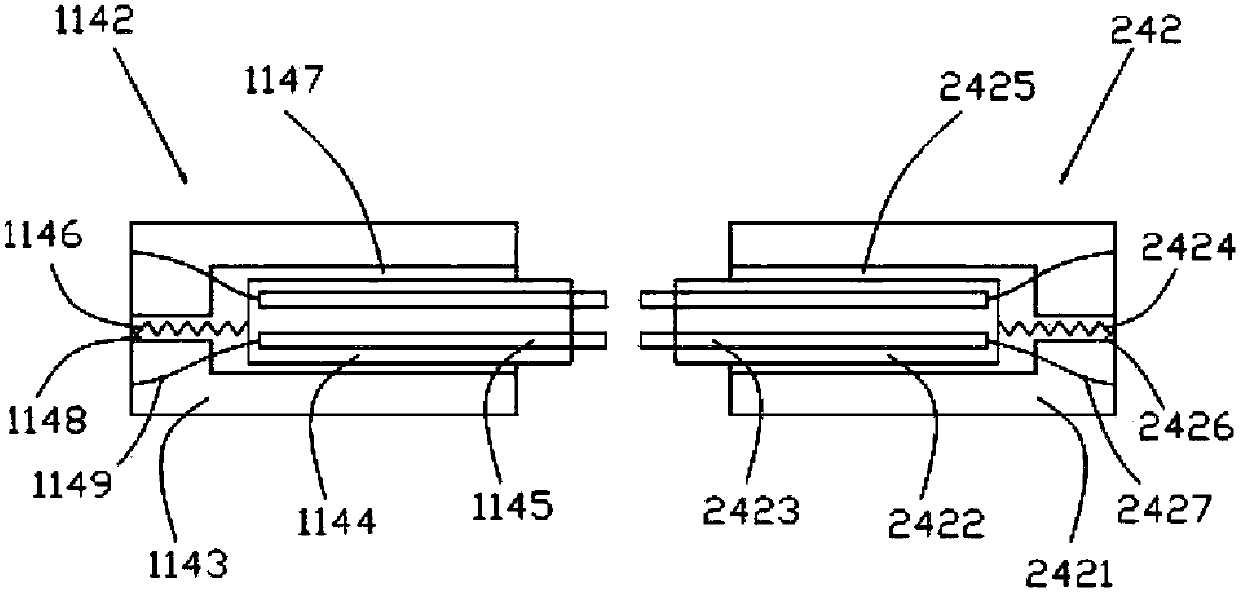

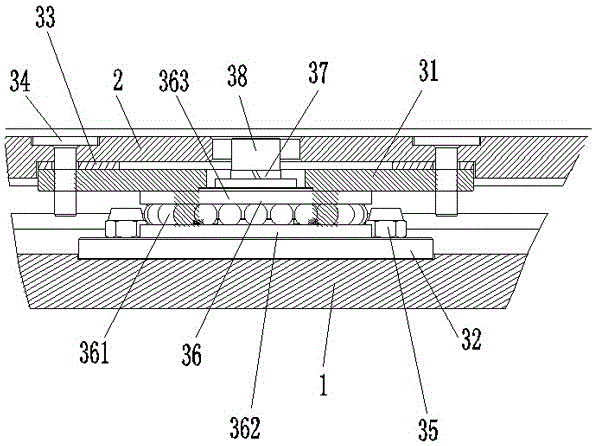

Fiber array board assembly device and fiber array board assembly platform using same

ActiveCN103358249AImprove assembly qualityIncrease profitWork holdersFastening meansFiber arrayMechanical engineering

The invention relates to a fiber array board assembly device and a fiber array board assembly platform using the same. The fiber array board assembly device comprises an L-shaped positioning base and a clamp component. The L-shaped positioning base comprises a side wall and a base. A positioning block is fixedly connected to the inner side of the side wall. A pressure block parallel to the positioning block is also movably connected to the inner side of the side wall. The pressure block can horizontally move along the inner side of the side wall. The inner side of the side wall is further provided with a clamp groove. The base is provided with a through hole. A lifting member and a support member are disposed in the through hole. A U-shaped support is disposed on two side walls of the clamp component. An elastic member is arranged between the bottom of the U-shaped support and the bottom of the clamp component. A glass pressure block is arranged between two ends of the U-shaped support. One end of the clamp component is provided with a protrusion which is clamped in the clamp groove. The lifting member controls the U-shaped support to ascend and descend through the support member.

Owner:广东安捷康光通科技有限公司

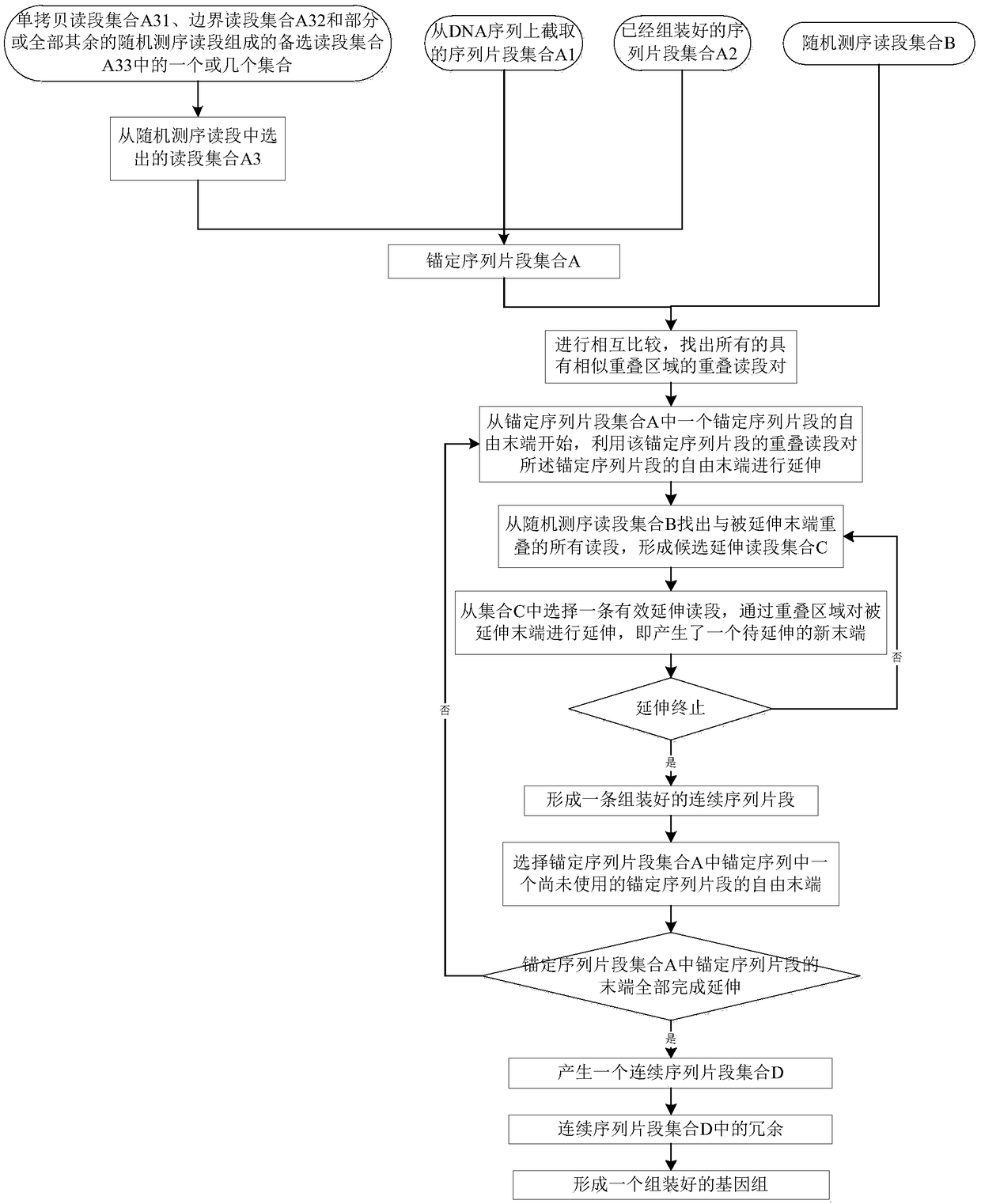

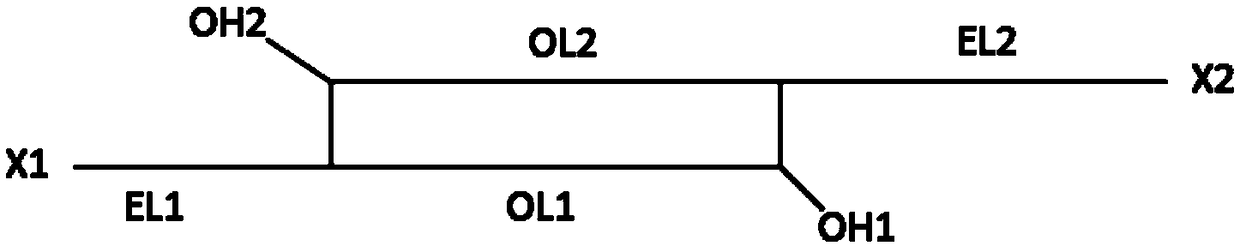

Genome assembling method

ActiveCN109234267AEfficient assemblySimplify the implementation process of assemblyDNA preparationComputational biologyChromosome

The invention discloses a genome assembling method, comprising the following four steps: sequence comparison, sequence extension, completion of extension and removal of redundancy. Genome-wide assembly is divided into two main steps: assembly of single copy sequence and assembly of remaining sequence, which simplifies the implementation process, makes the whole method fast, efficient and error-free, and greatly improves the continuity of the assembly sequence fragments and the assembly quality. By assembling the whole genome sequence with the method of the invention, the whole genome sequencecan be recovered quickly and efficiently, and the whole chromosome and the whole genome sequence can be recovered more easily. The genome assembling method of the invention can also be used for filling the sequence of the blank region in the genome sequence, in particular, the assembling effect can be greatly improved by combining the genome optical map information or the chromosome grouping sorting information. And for judging whether there is a connection between any two sequences or for estimating a distance between two adjacent sequences.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

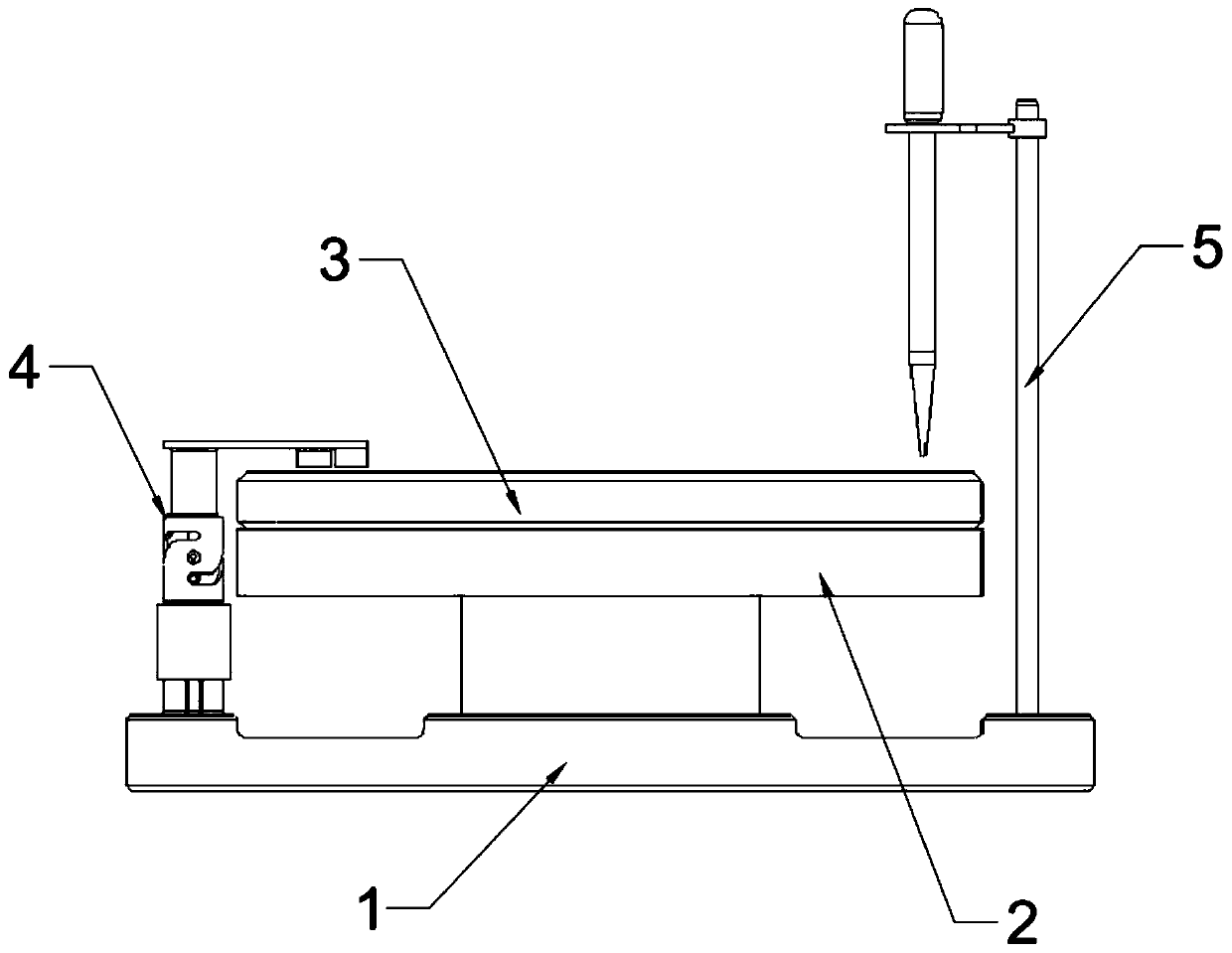

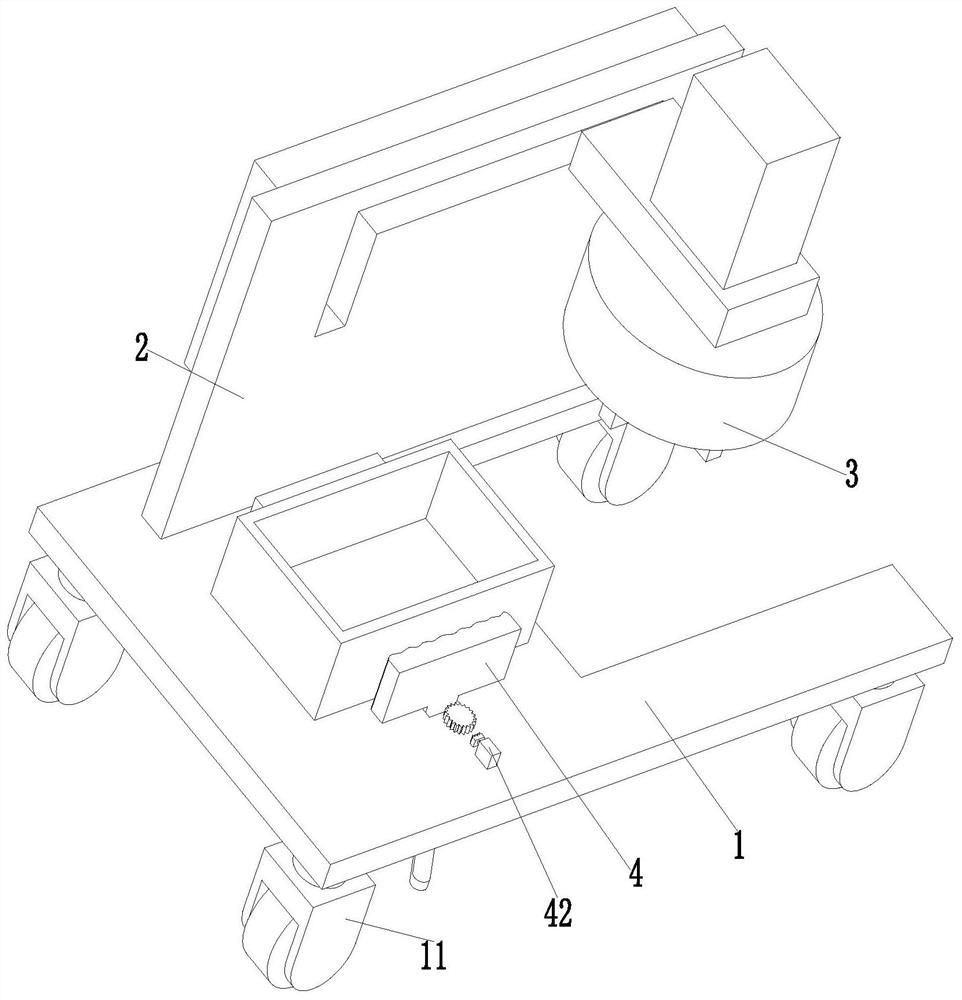

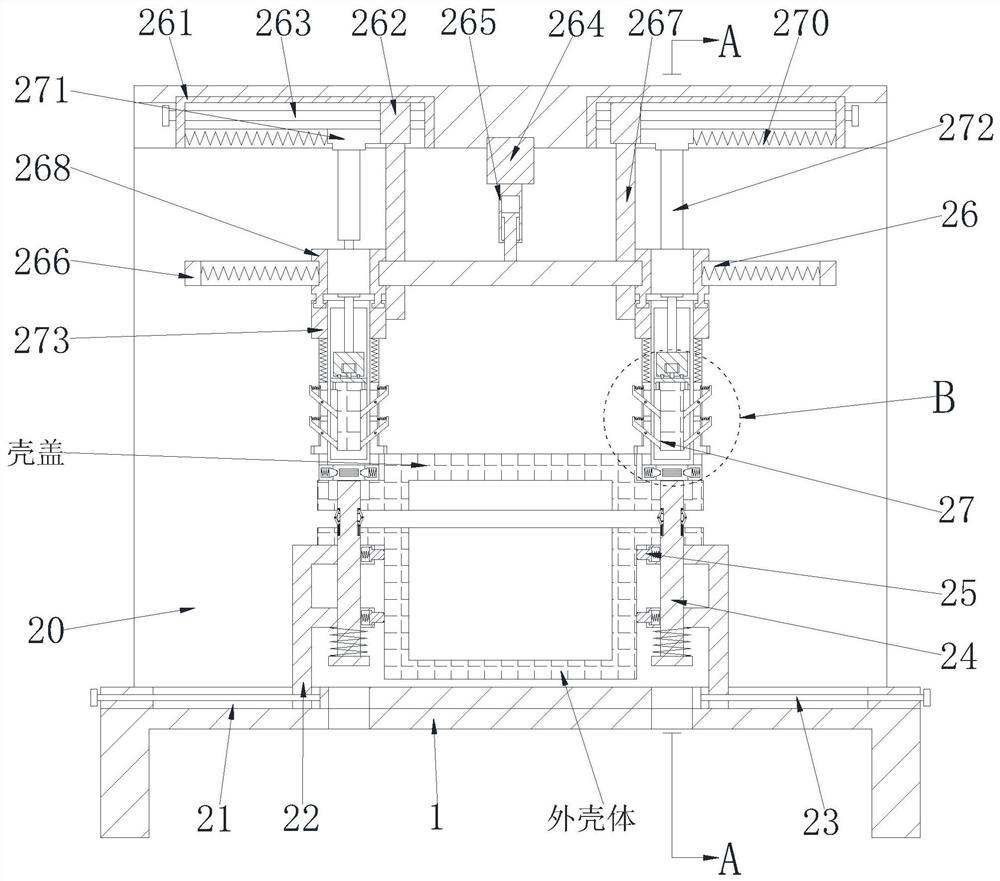

MP3 product shell pressing and assembling device

InactiveCN102794636AImprove assembly efficiencyImprove product qualityMetal working apparatusStructural engineeringVertical motion

The invention discloses an MP3 product shell pressing and assembling device, which is characterized by comprising a product input / output device, a pressing head pressing device and a pressing head, wherein the product input / output device is provided with a fixing base for fixing MP3 products, and a slide platform cylinder which can horizontally move front and back is arranged at the lower end of the fixing base; the pressing head pressing device is arranged at the upper end of the product input / output device; and the pressing head is fixedly connected with a vertical movement mechanism and is driven by the vertical movement mechanism to press and assemble the MP3 products which are not provided with shells in the fixing seat. The MP3 product shell pressing and assembling device disclosed by the invention can greatly improve the assembling efficiency, reduce safety accidents in the assembling process, and ensure the stable quality, uniformity and low reject ratio of the assembled products.

Owner:昆山市圣吉川工业自动化设备有限公司

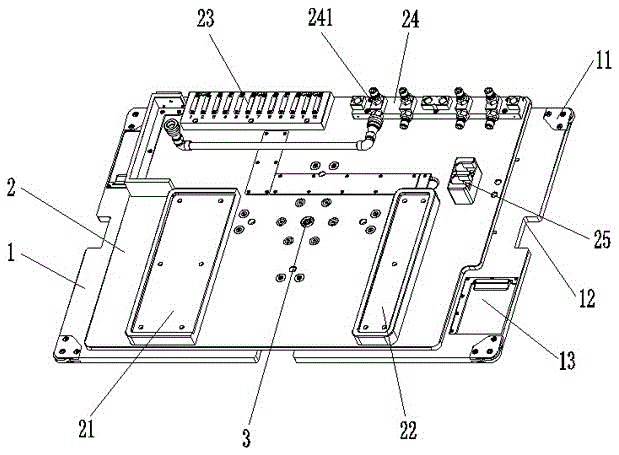

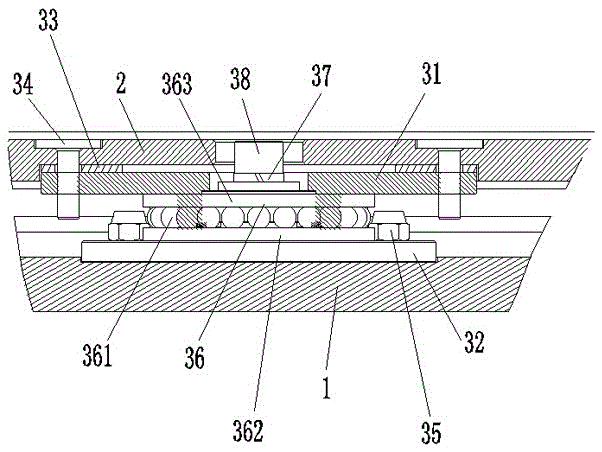

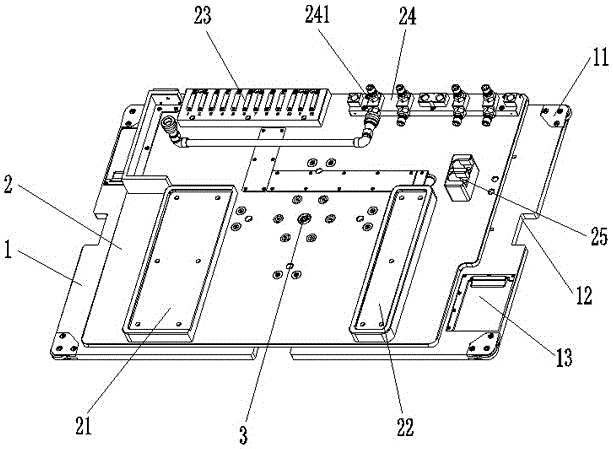

Intelligent tooling plate for assembling air conditioner

ActiveCN105479415AAvoid Composition CostsLow costAssembly machinesWork benchesElectricityEngineering

The invention relates to an intelligent tooling plate for assembling an air conditioner. The intelligent tooling plate comprises a bottom plate assembly, a rotating plate assembly, a rotary table assembly, guide pulleys, dog catch spacing openings, file folder grooves, one or more first die sets, one or more second die sets, connecting line assemblies, a connector mounting plate, coolant connectors, an electric connection terminal, an upper mounting plate, a fillister head screw, an elastic washer, a rotary table, a rotary table lower mounting plate, upper mounting plate screws, lower mounting plate screws and a rotating plate mat. The rotary table disclosed by the invention has the functions of automatic positioning and being capable of elastically adjusting rising or falling, so that more than two die sets can perform synchronous assembly or synchronous test simultaneously and accurately on air conditioner assemblies with a plurality of different faces placed on the rotary table, the problem that the operation of the next station of a conventional air conditioner mounting assembly line can be started only after the completion of the operation of the previous station so that time is wasted is solved, the disadvantages of being high in cost, large in volume, difficult to maintain and low in assembling efficiency in the conventional air conditioner mounting assembly line are avoided, and the intelligent tooling plate disclosed by the invention is high in intelligent degrees and low in cost.

Owner:GUANGDONG HUI LIXING SEIKO TECH

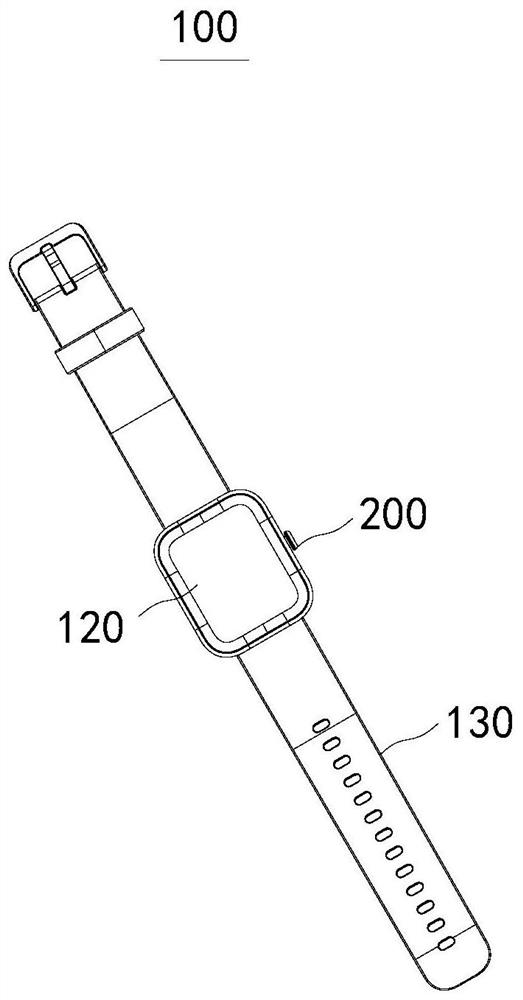

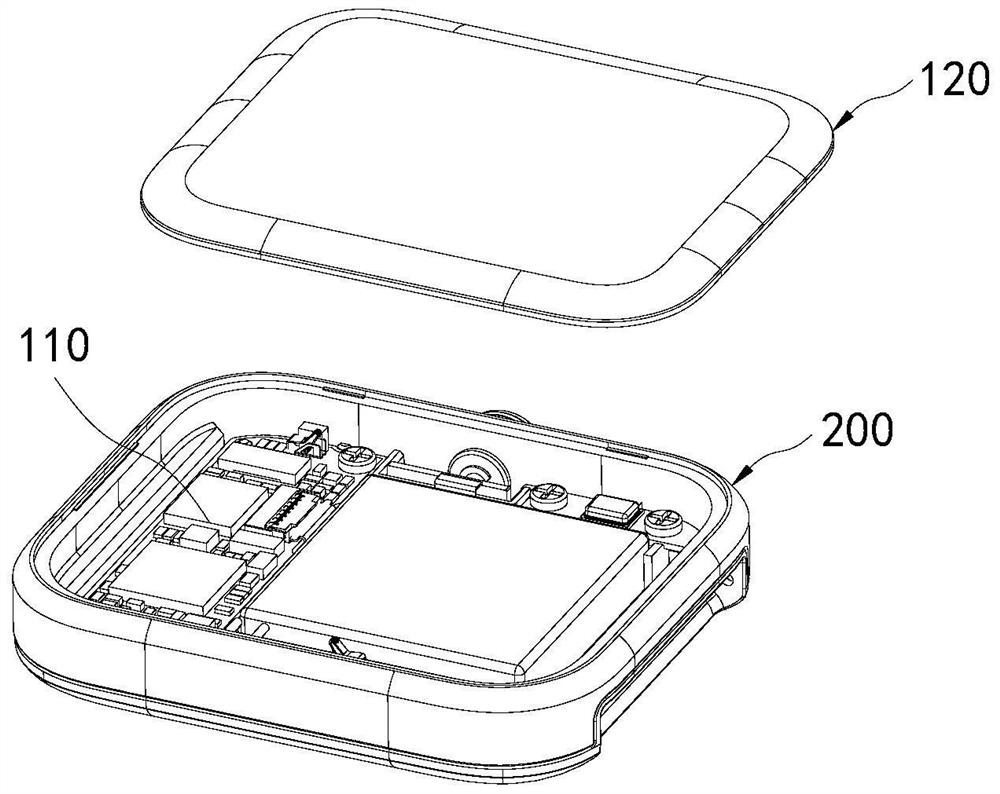

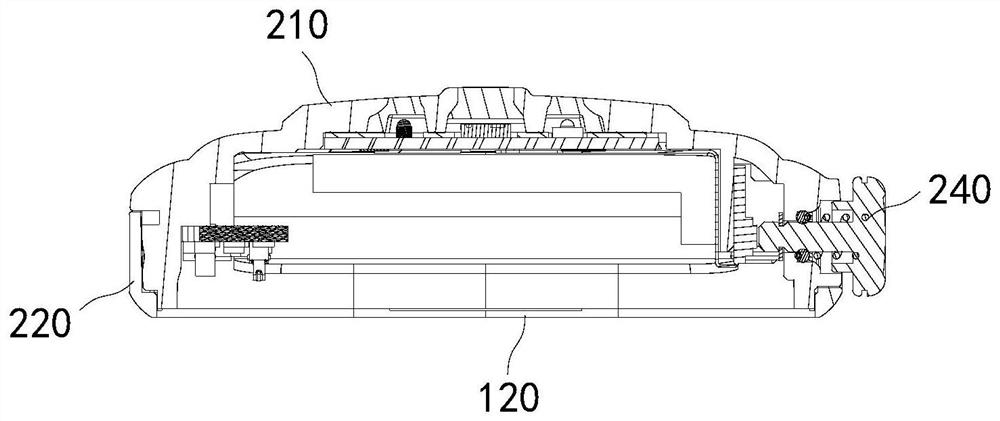

Watch body and smart watch

PendingCN112799294AGuaranteed aestheticsGuaranteed structural strengthElectronic time-piece structural detailsTime-pieces with integrated devicesEngineeringStructural engineering

The invention relates to the technical field of wearable equipment, in particular to a watch body and a smart watch. The watch body comprises a plastic seat body, a metal frame body and a display screen; a mounting groove is formed in the plastic seat body; the mounting groove is used for mounting electrical elements of a smart watch; the metal frame body is arranged on the outer side face of the plastic seat body in a sleeving mode; and the display screen is arranged on the mounting groove in a covering mode. The watch body is simple in structure, and the manufacturing and assembling difficulty and cost of the watch body can be reduced while the attractiveness and the structural strength of the watch body are guaranteed; and the metal frame body can be used as a communication antenna of the smart watch, so that the signal strength of the smart watch is improved.

Owner:SHENZHEN DO INTELLIGENT TECH CO LTD

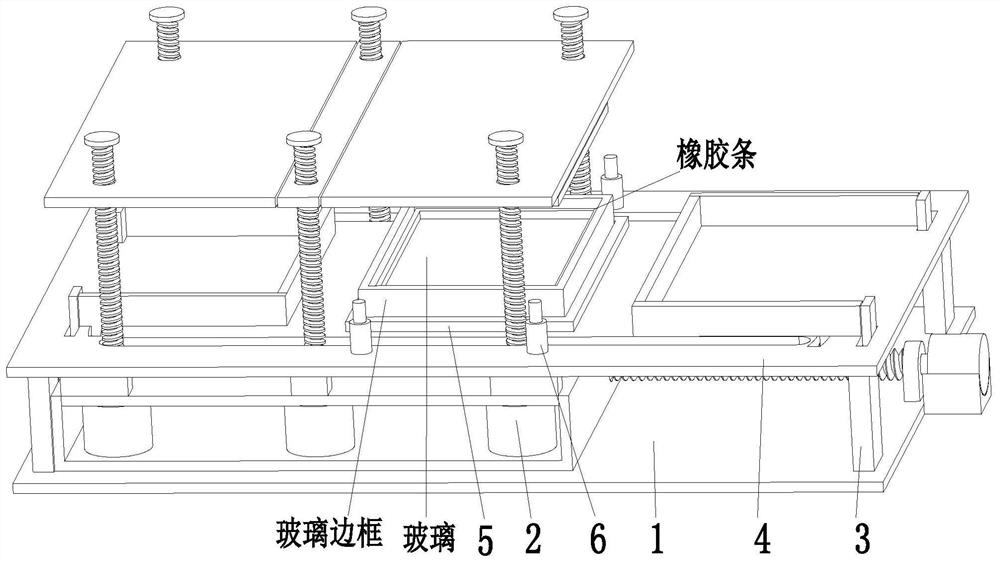

Automatic vacuum glass assembling machine and assembling method

ActiveCN111958542AHigh scrap rateReduce the pressing effectWork holdersMetal-working hand toolsEngineeringPressed glass

The invention relates to an automatic vacuum glass assembling machine. The automatic vacuum glass assembling machine comprises a base, a displacement mechanism, a supporting plate, a bearing plate, amaterial storage mechanism and a spring rod, and is characterized in that the displacement mechanism is installed on the upper end face of the base, the supporting plate is installed at the corner position of the upper end face of the base, the bearing plate is installed on the upper end face of the supporting plate, the material storage mechanism is installed on the upper end face of the bearingplate, spring rods are evenly arranged in the middle of the upper end face of the bearing plate, and scales are arranged on the outer side faces of the contraction ends of the spring rods. According to the automatic vacuum glass assembling machine and the assembling method, the problems that when an existing vacuum glass assembling machine is used for assembling vacuum glass, the corners of the pressed glass cannot be aligned, the unaligned parts of the corners of the glass are prone to being broken in the pressing process, when the glass surface is pressed, the stress is not uniform, so thatthe pressed glass surface is in an inclined state, and the effect of assembling the vacuum glass is reduced are solved.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

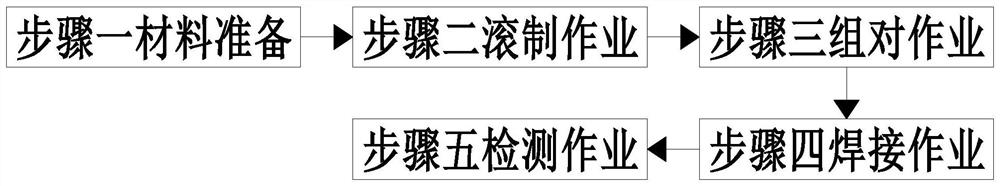

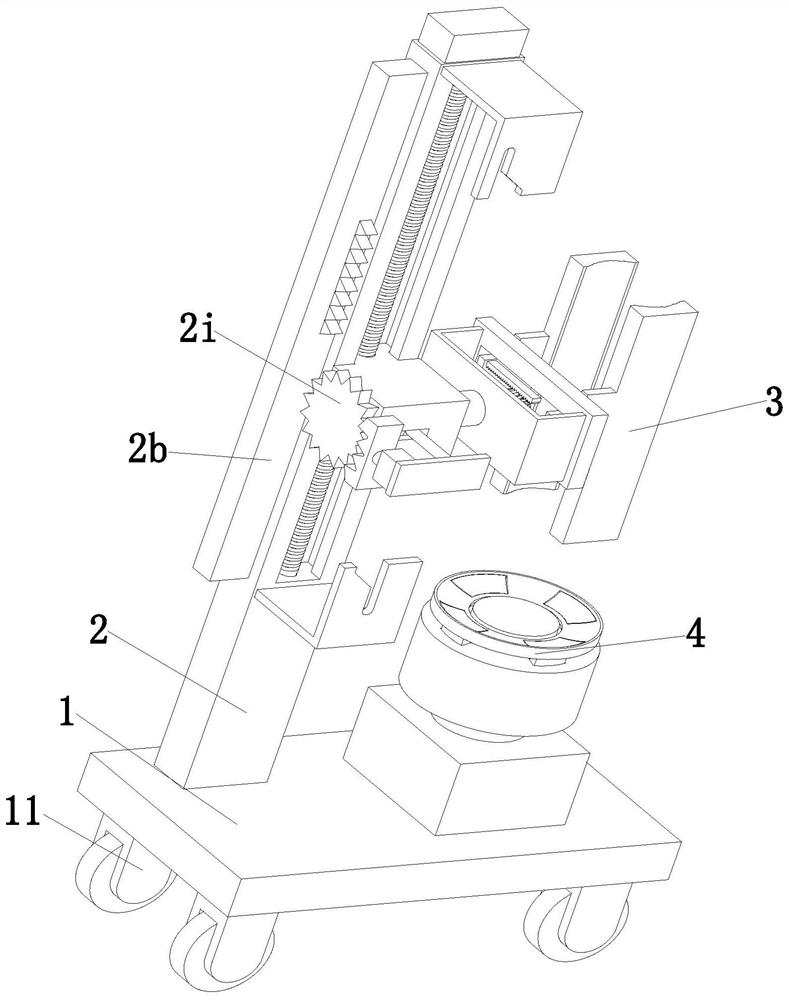

Chemical pressure vessel manufacturing and forming process

InactiveCN112676724ALow assembly efficiencyLight in massWelding/cutting auxillary devicesAuxillary welding devicesMaterials preparationStructural engineering

The invention relates to a chemical pressure vessel manufacturing and forming process. The chemical pressure vessel manufacturing and forming process mainly comprises the various procedures of material preparation, rolling operation, pairing operation, welding operation, detection operation and the like; and pressure vessel assembling equipment used in the chemical pressure vessel manufacturing and forming process comprises a bottom plate, a lifting device, a clamping device and an abutting device. The chemical pressure vessel manufacturing and forming process can solve the problems existing in butt joint assembly of an existing chemical pressure vessel that A, during the butt joint assembly of the traditional chemical pressure vessel, the stable butt joint operation cannot be performed on a pressure vessel barrel and a pressure vessel end socket, and the butt joint dislocation often occurs during the butt joint of the pressure vessel barrel and the pressure vessel end socket, so that the butt joint quality of the pressure vessel barrel and the pressure vessel end socket is reduced; and B, existing chemical pressure vessel butt joint assembling equipment cannot stably clamp and position the pressure vessel barrel, so that the pressure vessel assembling stability is affected, and the pressure vessel assembling efficiency is reduced.

Owner:南京系原商贸有限公司

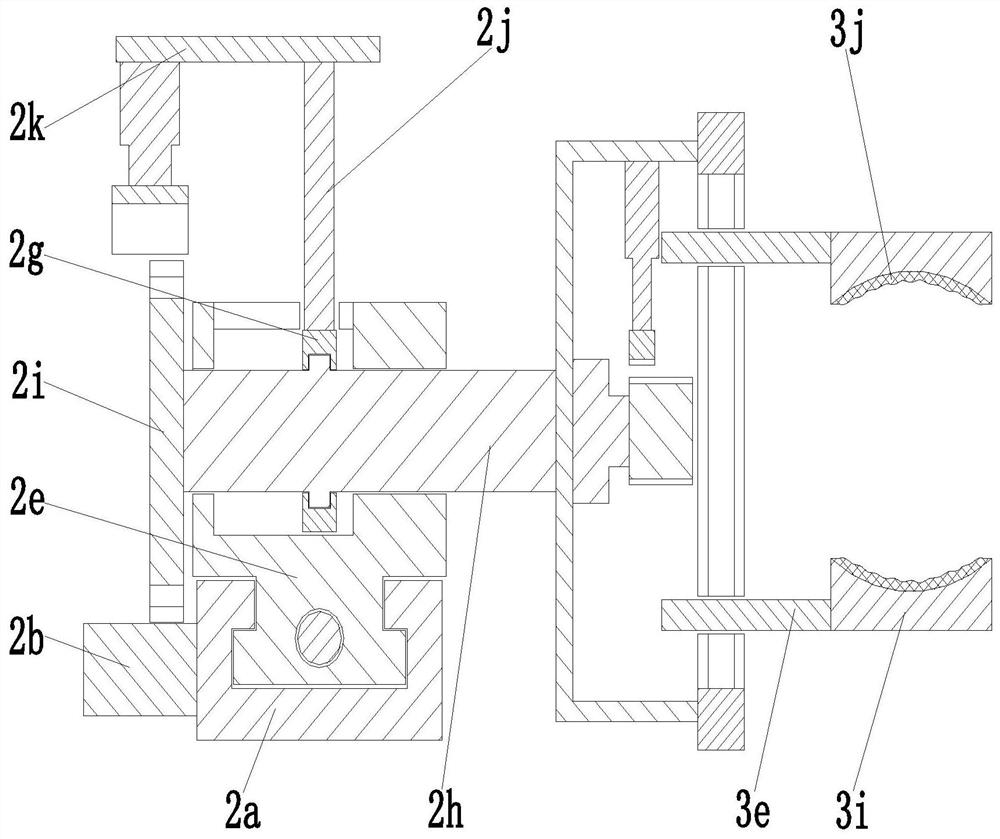

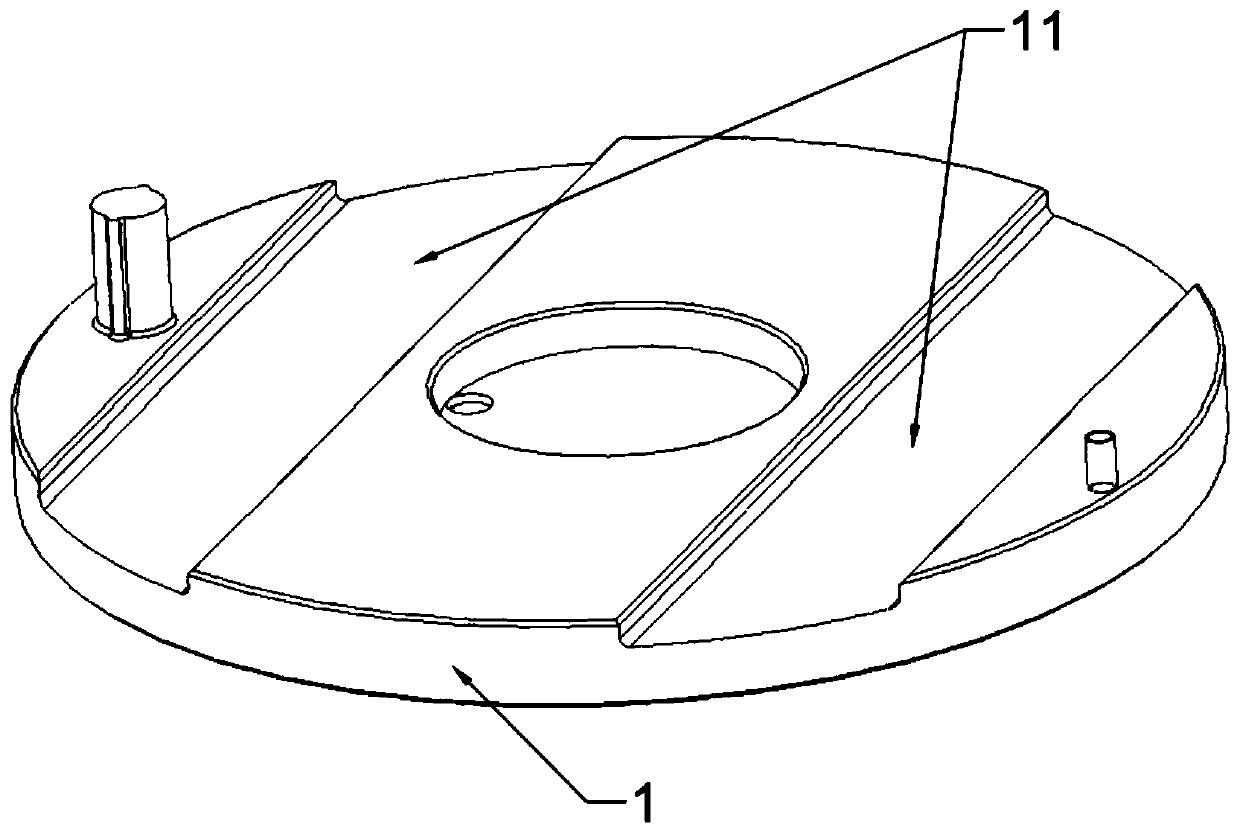

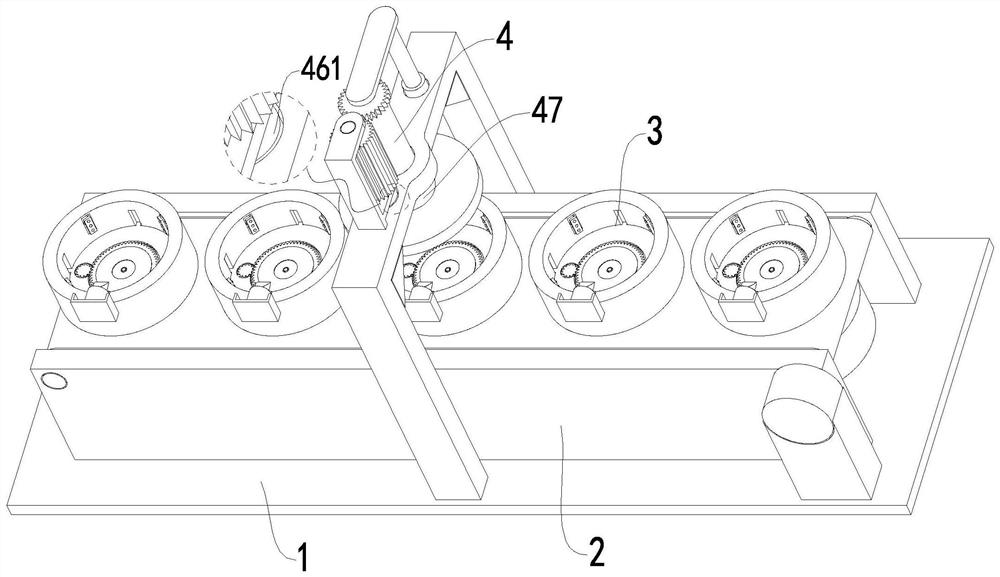

Rotary worktable for assembling button cell

PendingCN111261921AEasy to operateImprove labor efficiencyPrimary cell manufactureAssembling battery machinesPhysicsEngineering

The invention provides a rotary worktable for assembling a button cell. The rotary worktable comprises a base; a rotating mechanism, a rotating disc, a positioning mechanism and a liquid dropping mechanism are arranged on the base; a plurality of circular grooves are uniformly formed in the top surface of the rotating disc; the rotating mechanism is connected with the base; the positioning mechanism comprises a lifting mechanism and a positioning plate; the lifting mechanism comprises a connecting rod, a fixed sleeve and a cylindrical cam which are sleeved with one another from inside to outside; a shaft pin is arranged at one end of the connecting rod; a vertical sliding groove is formed in the fixed sleeve; a spiral sliding groove and a handle are arranged on the side wall of the cylindrical cam; the shaft pin penetrates through the vertical sliding groove and the spiral sliding groove; the cylindrical cam is rotated through the handle; the spiral sliding groove drives the shaft pinto slide along the vertical sliding groove, so that the positioning plate is driven to limit the position of the circular grooves and assist electrode plates and gaskets in being guided into the circular grooves; the liquid dropping mechanism injects electrolyte into the button cell. The rotary worktable for assembling the button cell, provided by the invention, is simple in structure, can realizeaccurate alignment and assembly, improve labor efficiency and reduce labor intensity.

Owner:HUNAN UNIV OF ARTS & SCI

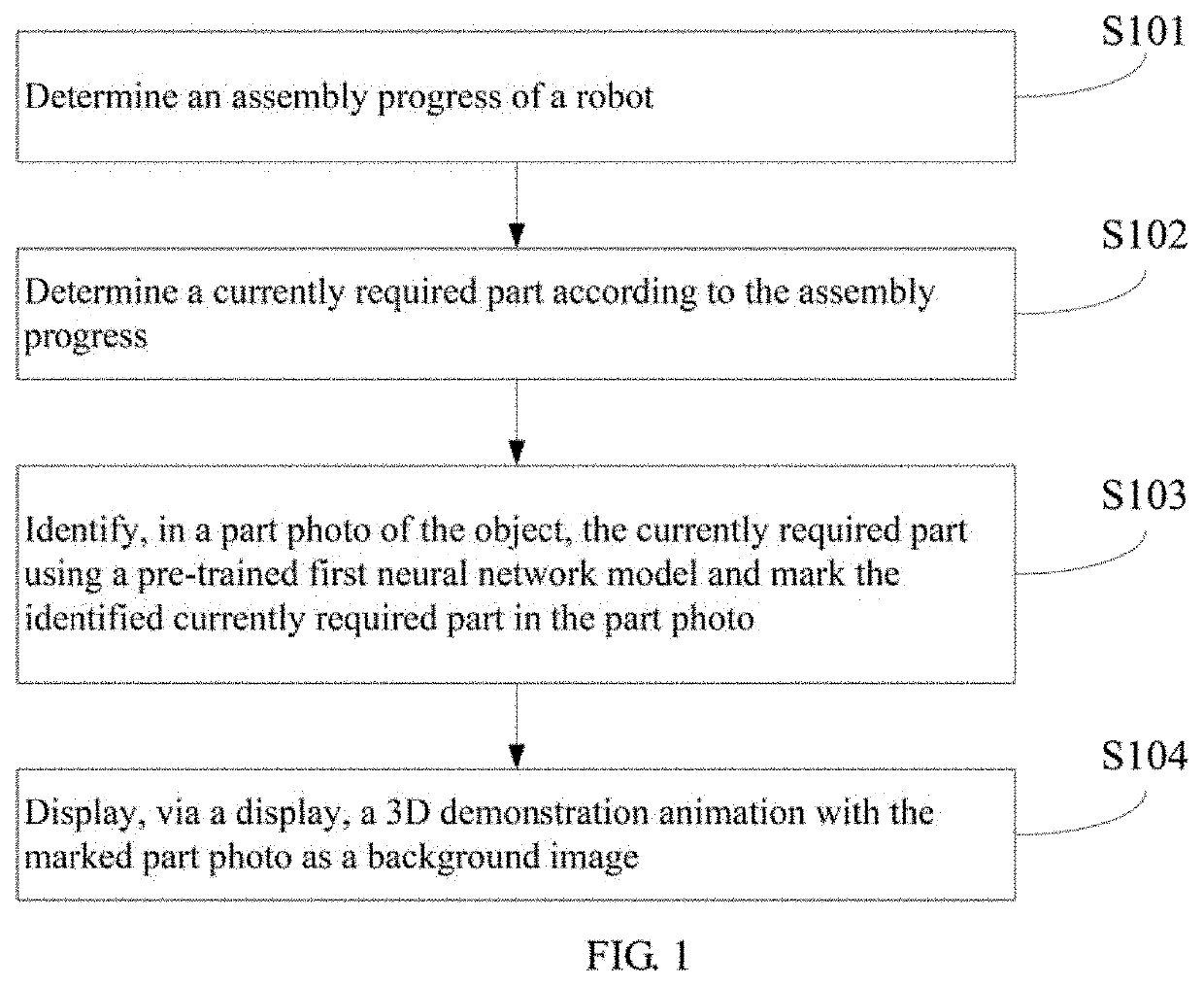

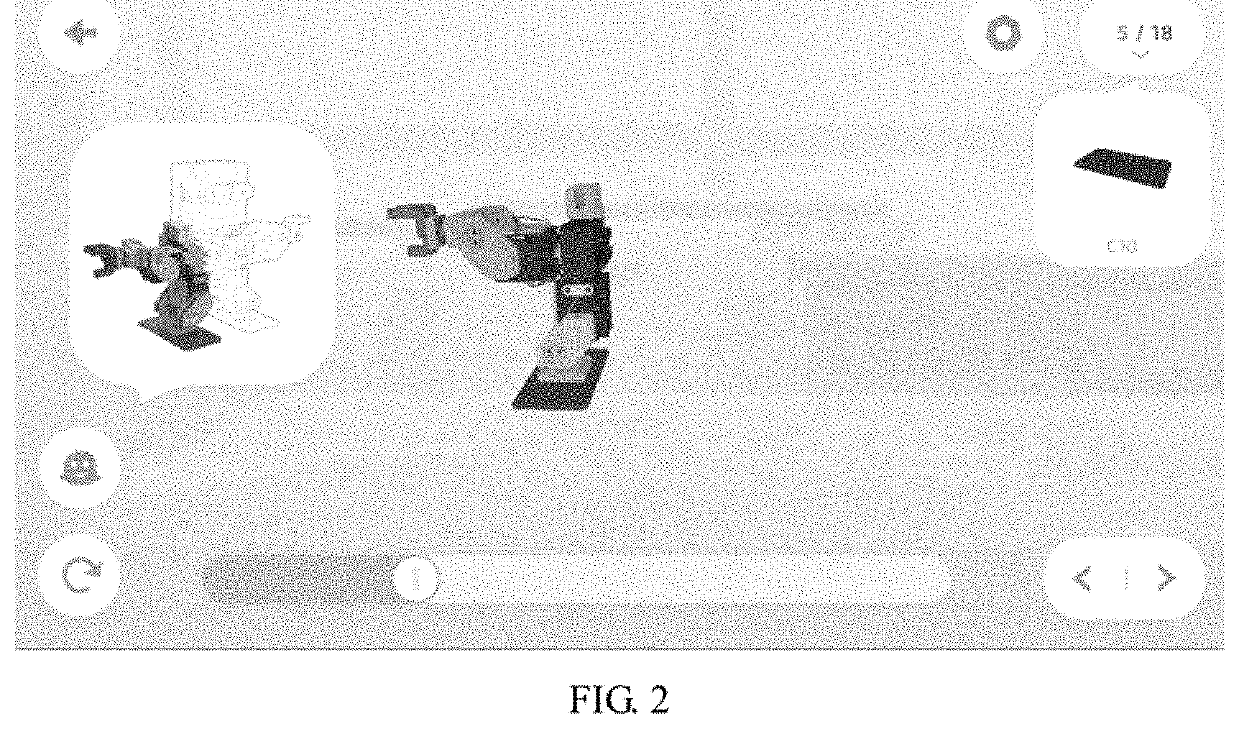

Method, apparatus and terminal device for constructing parts together

The present disclosure is provides a method, an apparatus and a terminal device for constructing parts together. The method includes: determining an assembly progress of an object constructed of parts; determining a currently required part according to the assembly progress; identifying, in a part photo of the object, the currently required part using a pre-trained first neural network model and marking the one or more identified currently required parts in the part photo; and displaying, via a display, a 3D demonstration animation with the marked part photo as a background image. The method is based on the existing 3D demonstration animation, which identifies the currently required part in the captured part photo and marks the identified currently required part in the part photo, and then displays the marked part photo as the background image of the 3D demonstration animation, thereby adding a prompt for the real part.

Owner:UBTECH ROBOTICS CORP LTD

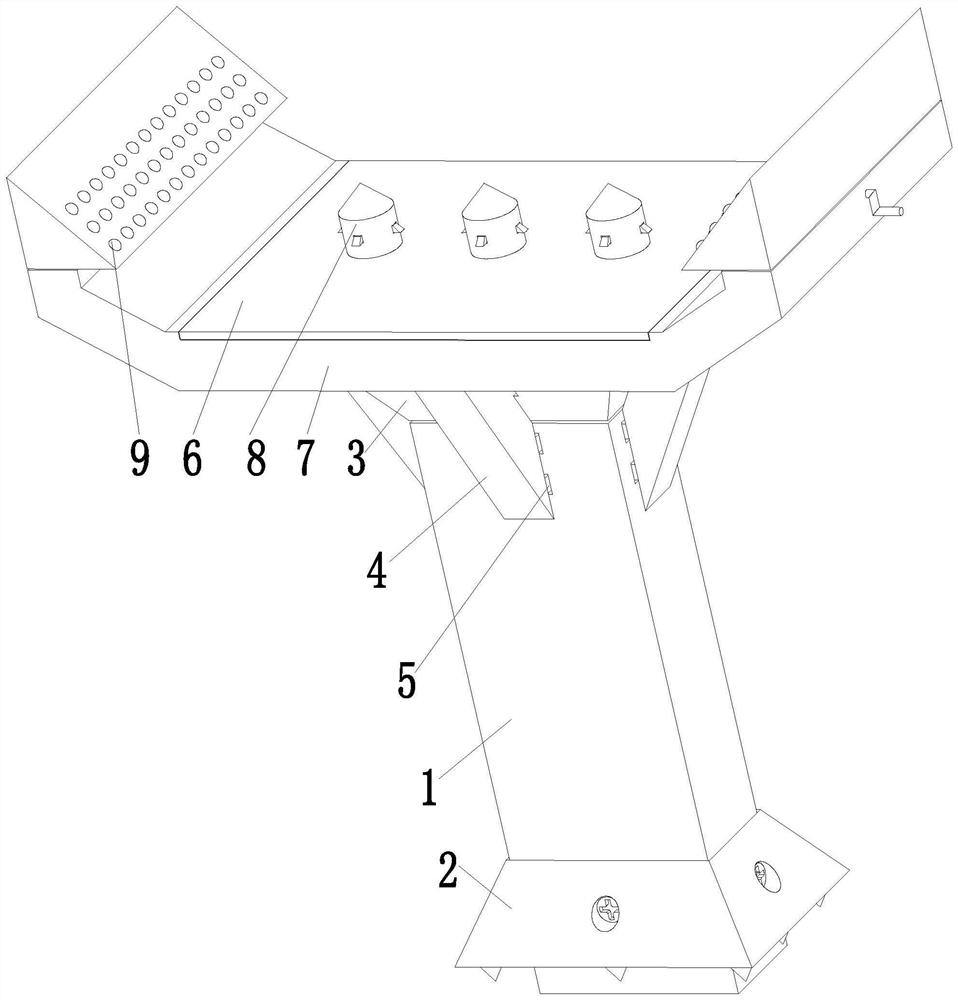

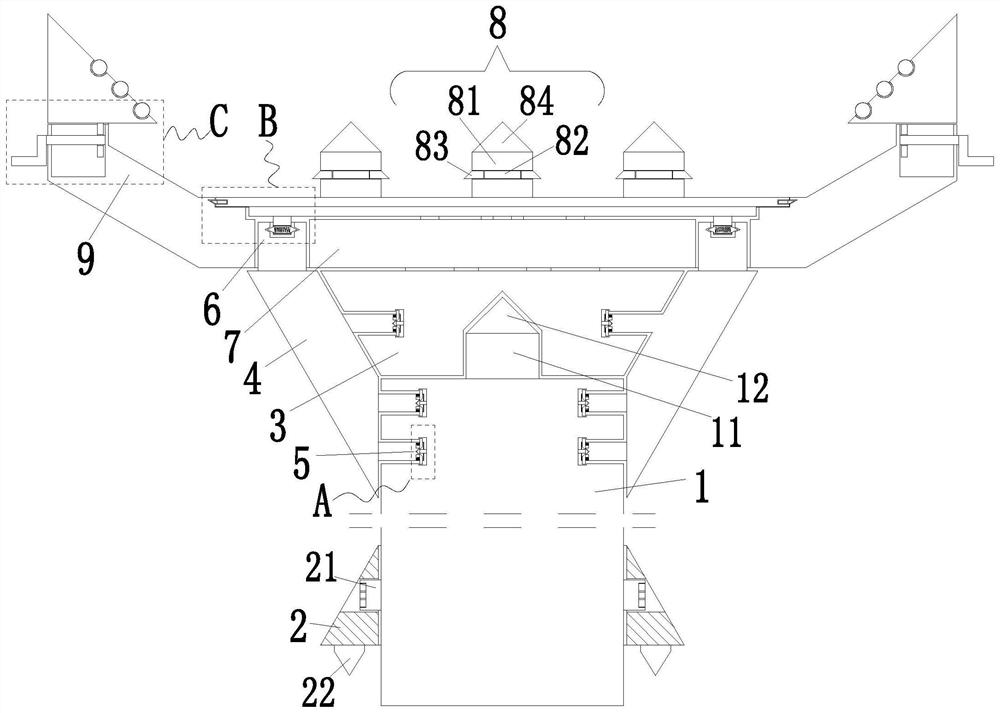

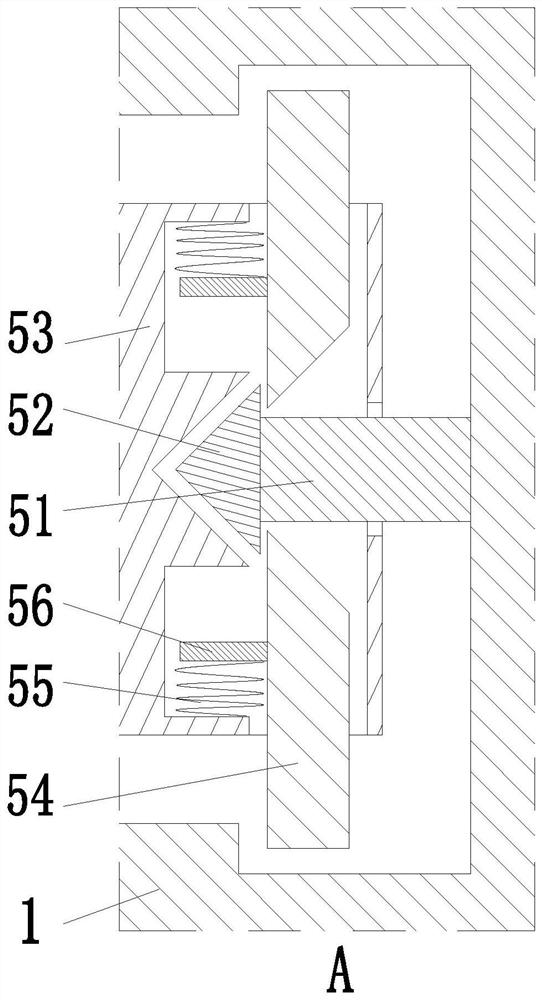

Reinforced steel structure bridge prefabricated assembly

ActiveCN112921796AReduce transport efficiencyLow assembly efficiencyBridge structural detailsBridge materialsEngineeringMechanical engineering

The invention relates to a reinforced steel structure bridge prefabricated assembly which comprises a column body, a base, a supporting block, fixing blocks, fixing mechanisms, locking mechanisms, supporting plates, limiting mechanisms and guiding mechanisms. The base is arranged on the outer side face of the column body in an up-down sliding fit mode, and the supporting block of a trapezoidal structure is installed at the upper end of the column body; the fixing blocks are evenly arranged on the outer side faces of the supporting block and the column body, the fixing mechanisms are arranged between the fixing blocks and the column body and between the fixing blocks and the supporting block, the supporting plates are arranged between the fixing blocks and the upper ends of the supporting block through locking mechanisms, the limiting mechanisms are arranged at the upper ends of the middles of the supporting plates, and the guiding mechanisms are arranged at the upper ends of the left sides and the right sides of the supporting plates. The problems that in the prior art, in the steel structure bridge building process, a common transport vehicle cannot transport bridge supporting columns conveniently, and the transport efficiency of the bridge supporting columns is reduced, the assembling steps of all the assemblies are tedious, and the assembling efficiency of the bridge supporting column is reduced are solved.

Owner:湖北交投建设集团有限公司

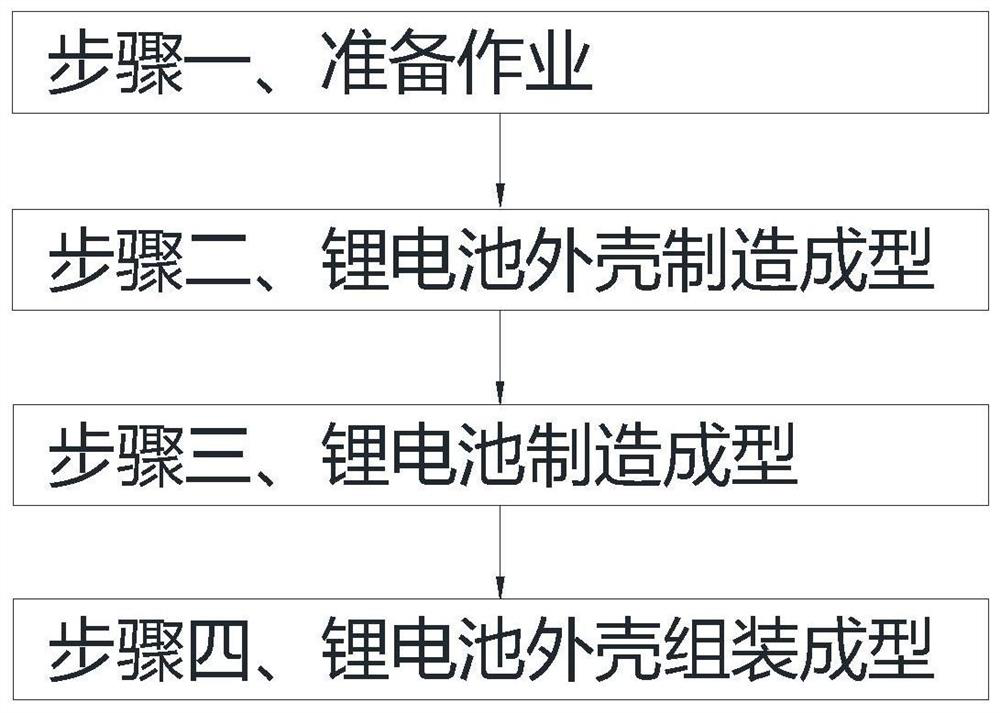

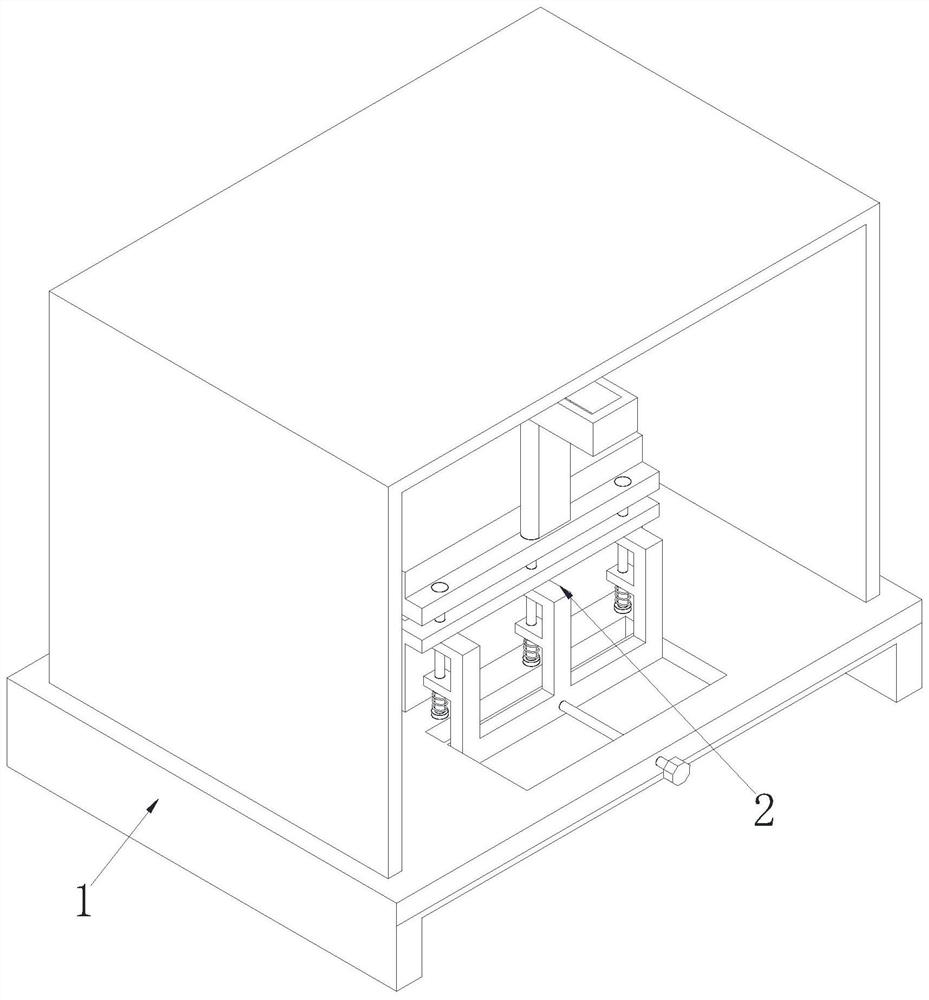

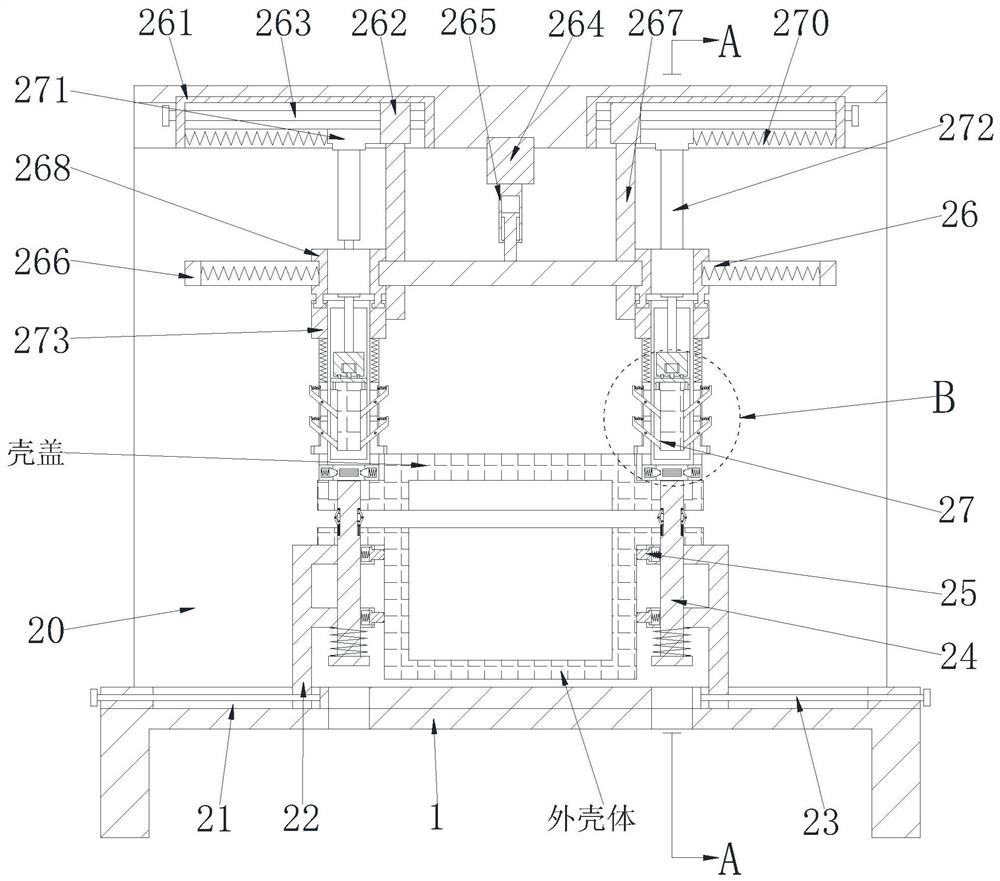

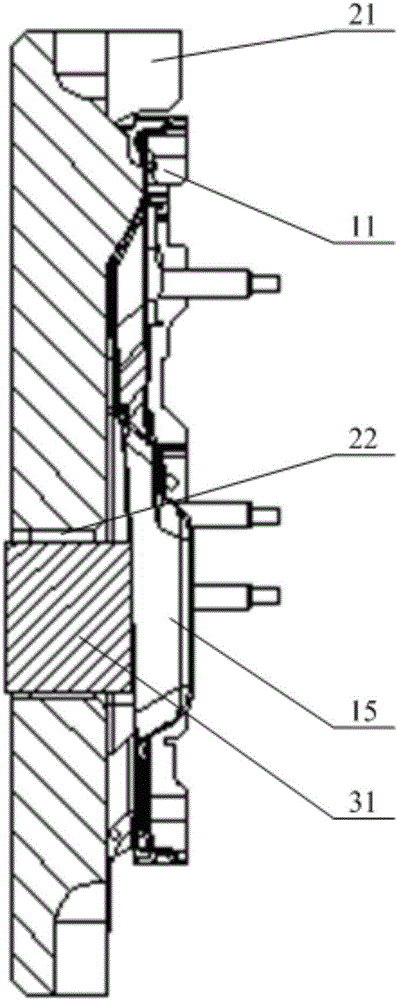

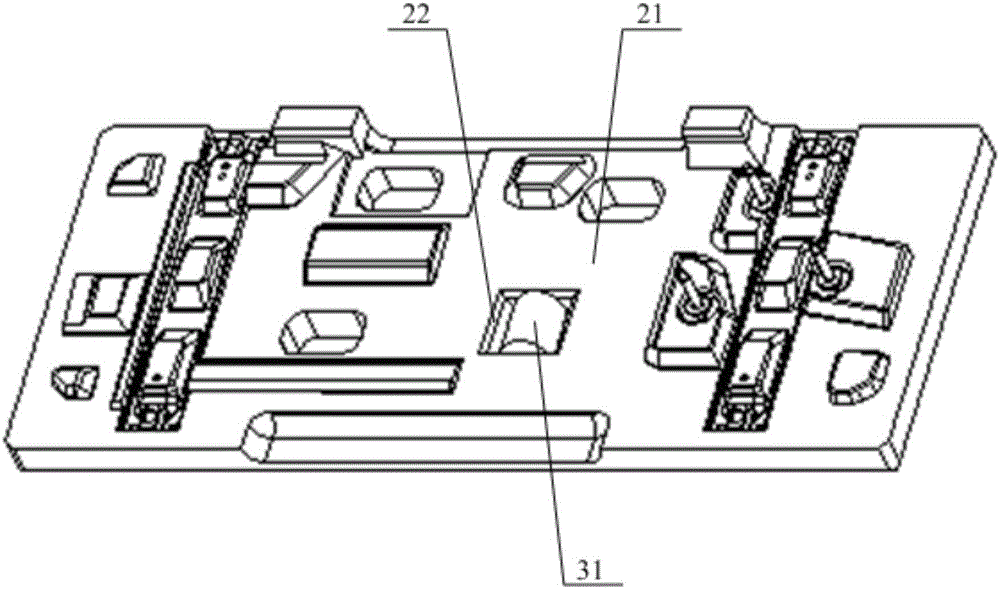

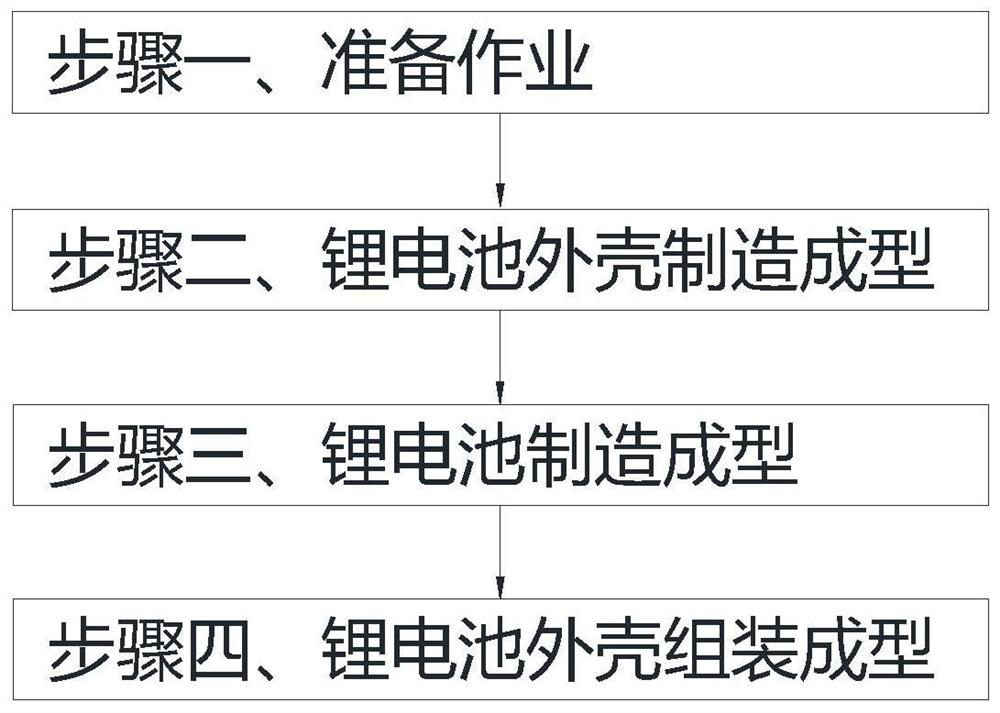

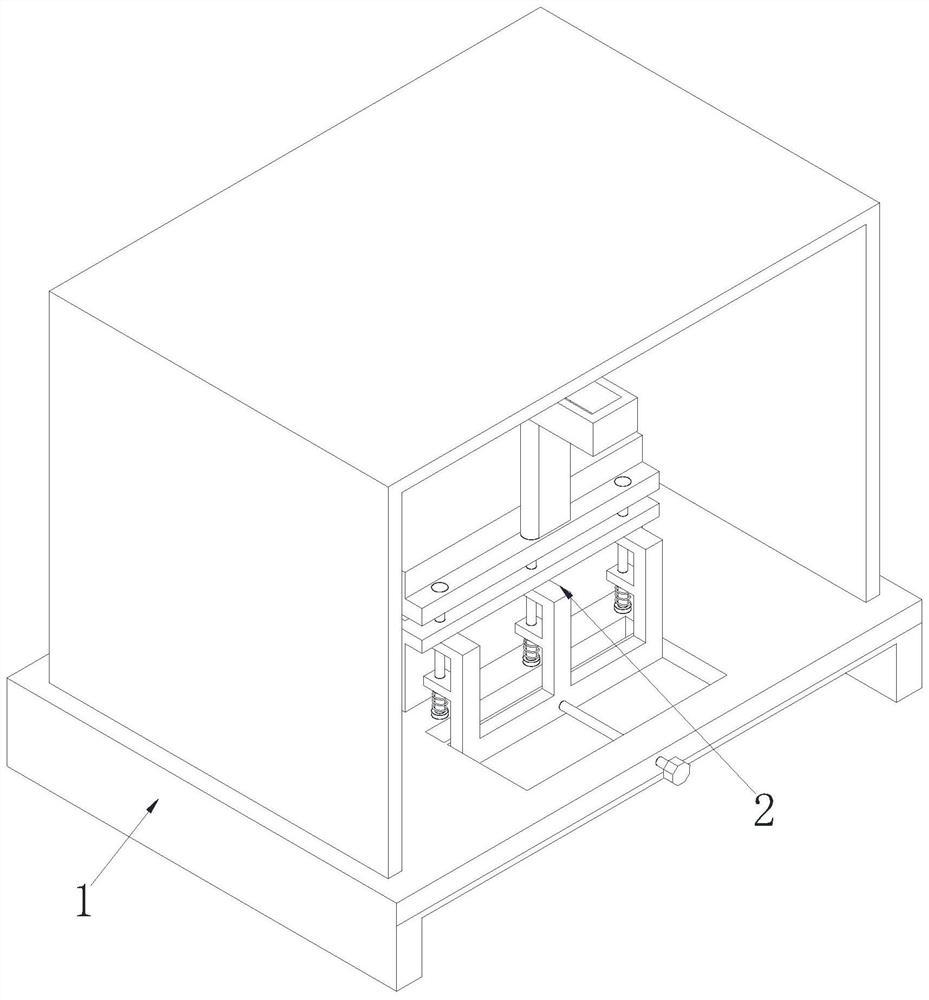

Lithium battery production and assembly method

ActiveCN112421096ALow assembly efficiencyImprove assembly efficiencyAssembling battery machinesFinal product manufactureElectric carsElectric vehicle

The invention relates to a lithium battery production and assembly method, which uses lithium battery production and assembly equipment, the lithium battery production and assembly equipment comprisesa base and an assembly device, and the upper surface of the base is provided with the assembly device. The problems that when an outer shell and a shell cover of a produced lithium battery for an electric vehicle are assembled at present, the existing shell of the lithium battery for the electric vehicle is assembled manually, so that the assembling efficiency is low, chemicals are contained in the lithium battery some leakage problems may occur, a worker may get ill after long-term contact, the effect of manually mounting the outer shell and the shell cover is poor, the problem of sealing dislocation of the shell cover and the outer shell is easily caused, the protection effect of the lithium battery during use is poor, the lithium battery is easily damaged, and the service life of the lithium battery is influenced are solved.

Owner:江苏天辉锂电池有限公司

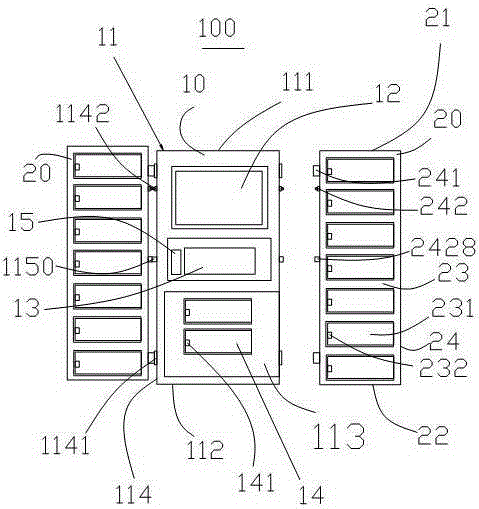

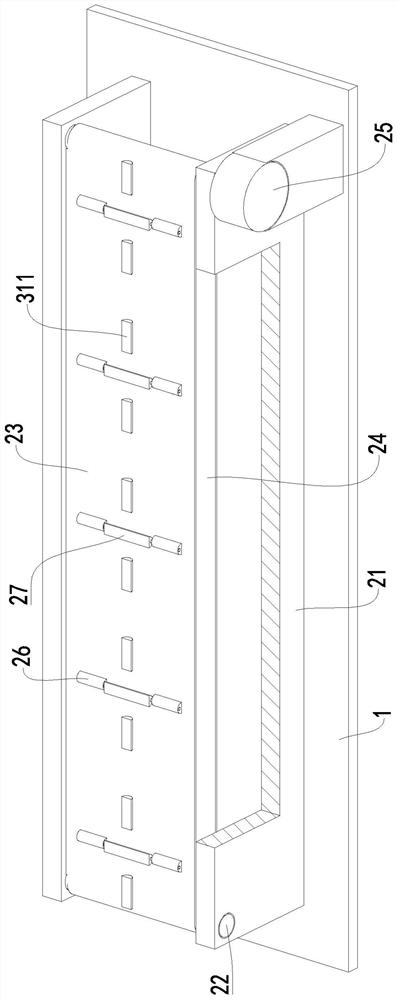

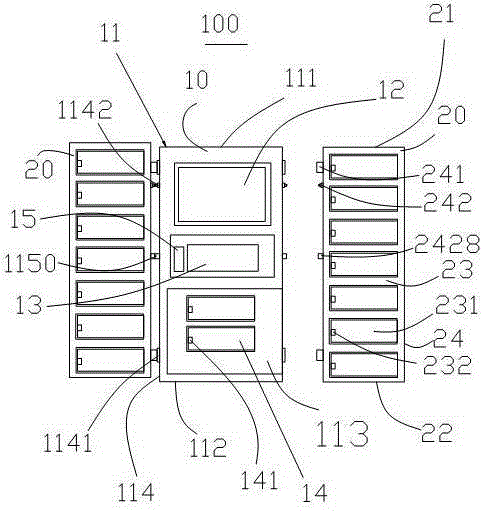

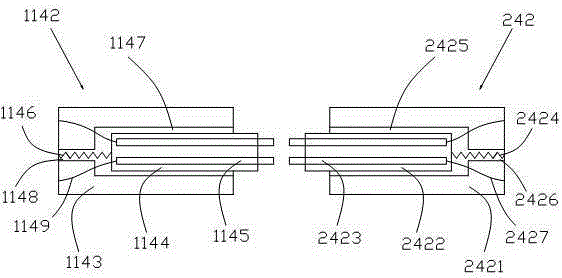

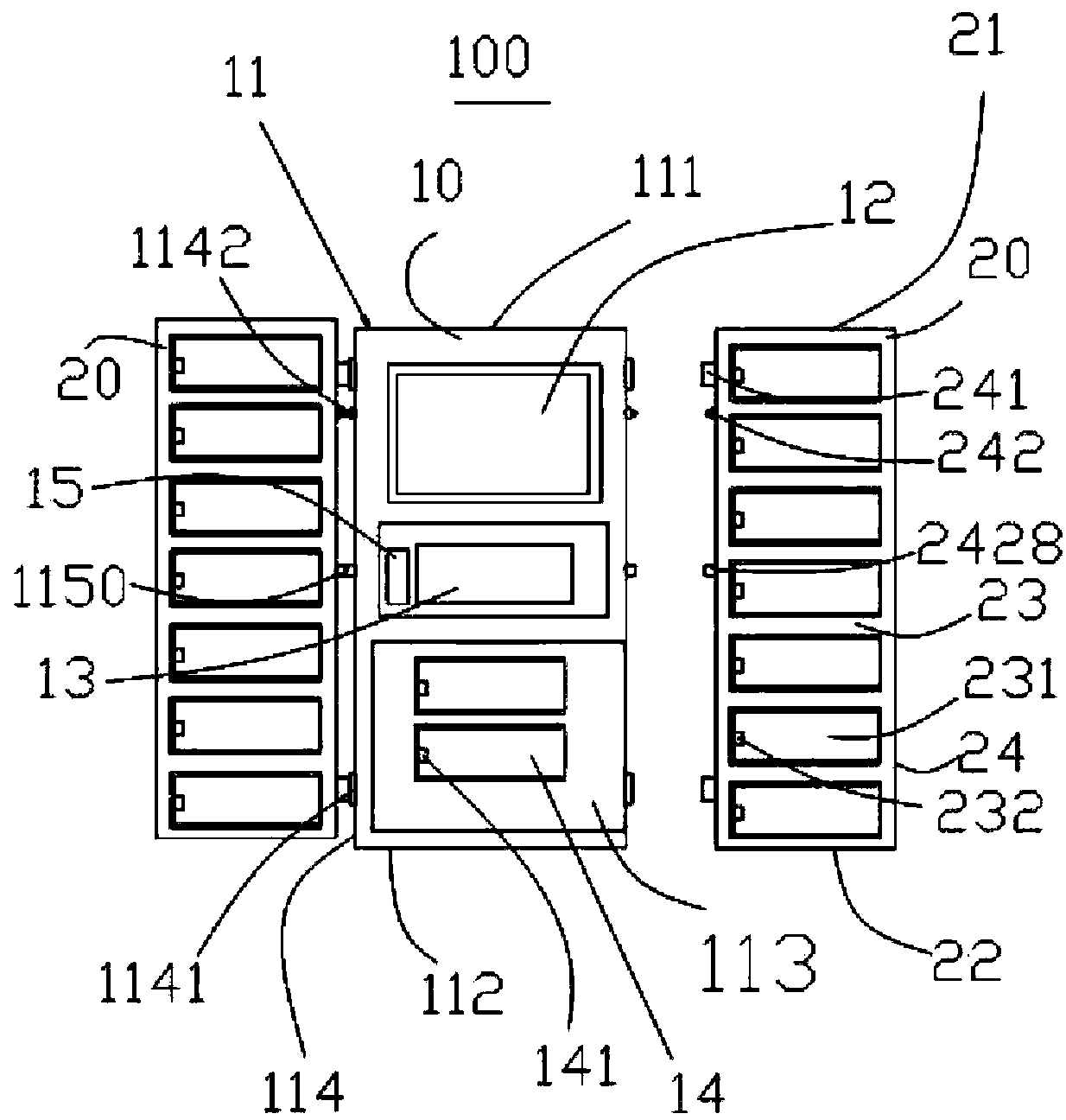

Freely disassembled express cabinet

ActiveCN105231683ALow assembly efficiencyGuaranteed stabilityCabinetsApparatus for meter-controlled dispensingEngineeringElectrical and Electronics engineering

The invention provides a freely disassembled express cabinet, which comprises a main cabinet and a subordinate cabinet, wherein the main cabinet comprises a main cabinet body; the main cabinet body comprises main cabinet side plates; a first magnetic adsorption piece and a first telescopic electrode are arranged on the outer surface of each main cabinet side plate; the subordinate cabinet comprises subordinate cabinet side plates which face the main cabinet; a second magnetic adsorption piece and a second telescopic electrode are arranged on the outer surface of each subordinate cabinet side plate; the first magnetic adsorption pieces and the second magnetic adsorption pieces are mutually attracted through magnetic force; and the first telescopic electrodes and the second telescopic electrodes are propped against from each other, so that a circuit of the subordinate cabinet is electrically connected to a circuit of the main cabinet. Since the main cabinet and the subordinate cabinet are adsorbed together through the magnetic force between the first magnetic bodies and the second magnetic bodies, the express cabinet disclosed by the invention, compared with conventional assembling by virtue of screws and the like, not only reduces an assembling efficiency but also avoids influence on appearance through surface machining; and in addition, by electrically connecting the main cabinet and the subordinate cabinet through the first telescopic electrodes and the second telescopic electrodes, the express cabinet is high in contact stability, convenient to connect and high in efficiency, and the express cabinet avoids complexity and time consumption of conventional cable connection.

Owner:李燕玲

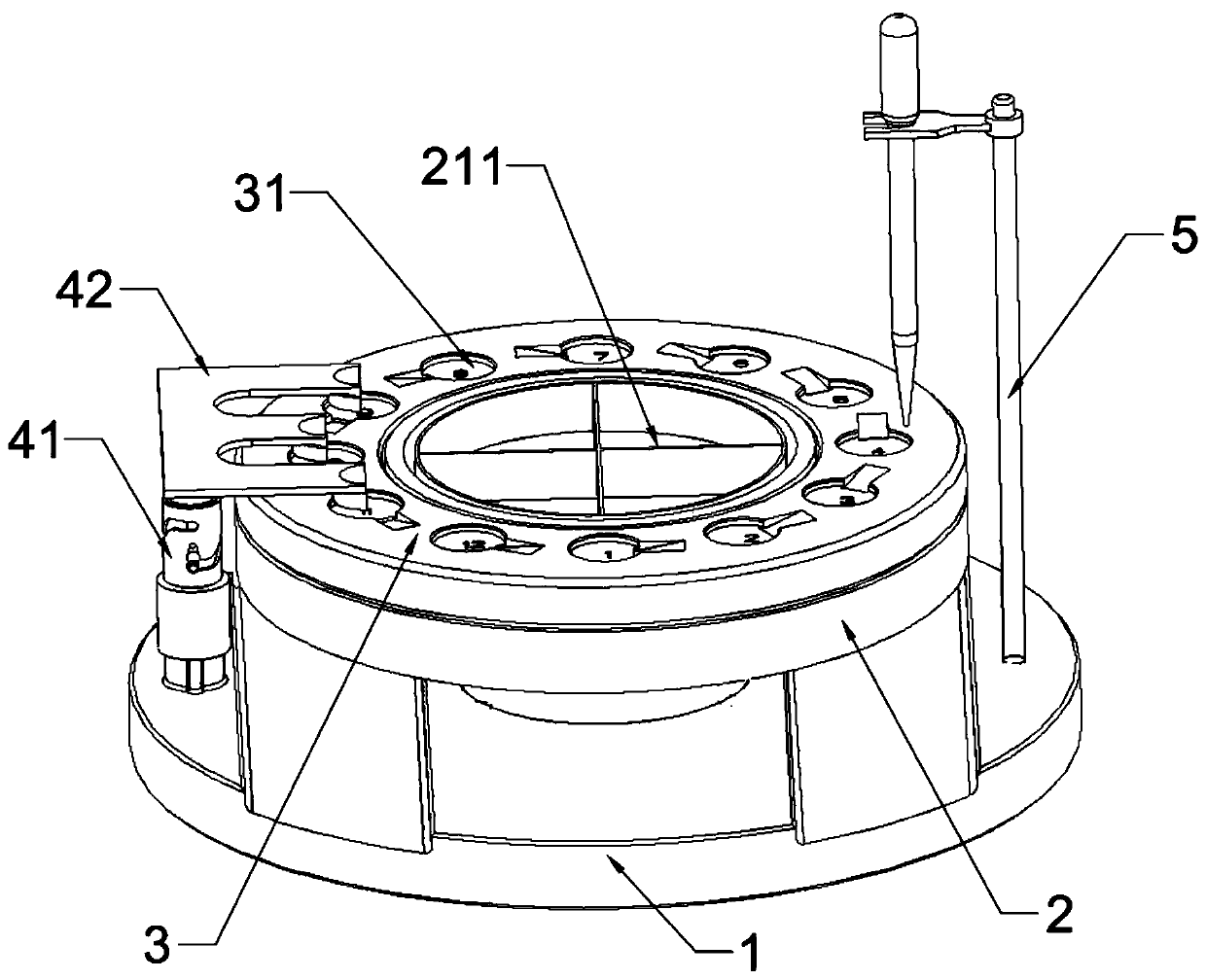

High-low voltage switch cabinet metal plate manufacturing and assembling machine and assembling method

InactiveCN113182722ALower assembly qualityLow assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesLow voltageStructural engineering

The invention relates to a high-low voltage switch cabinet metal plate manufacturing and assembling machine and an assembling method. The high-low voltage switch cabinet metal plate manufacturing and assembling machine comprises a bottom plate, a positioning device, propelling devices, an abutting device and a pressing device, wherein the positioning device is installed on the bottom plate, the propelling devices are symmetrically installed on the bottom plate front and back, the abutting device is installed at the left end of the bottom plate, and the pressing device is installed at the rear end of the bottom plate. The high-low voltage switch cabinet metal plate manufacturing and assembling machine can solve the following problems existing in welding and assembling of a frame and a metal plate shell of an existing high-low voltage switch cabinet: 1, when the frame and the metal plate shell of the traditional high-low voltage switch cabinet are welded and assembled, the frame needs to be manually placed on the ground, the metal plate shell is manually abutted against the outer wall of the frame, and the problem of assembling dislocation exists; and 2, when the metal plate shell is manually abutted against the outer wall of the frame, the labor intensity of workers is increased due to the fact that the weight of a metal plate part is large, and the assembling efficiency of the high-low voltage switch cabinet is reduced.

Owner:叶欢欢

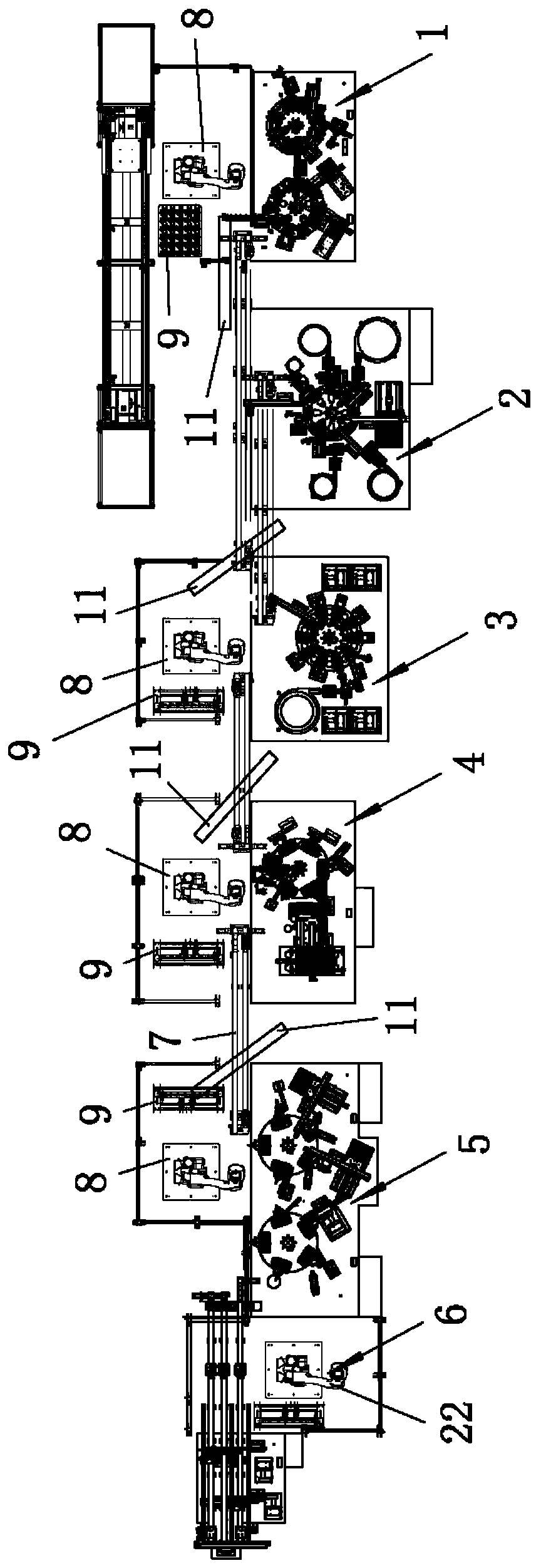

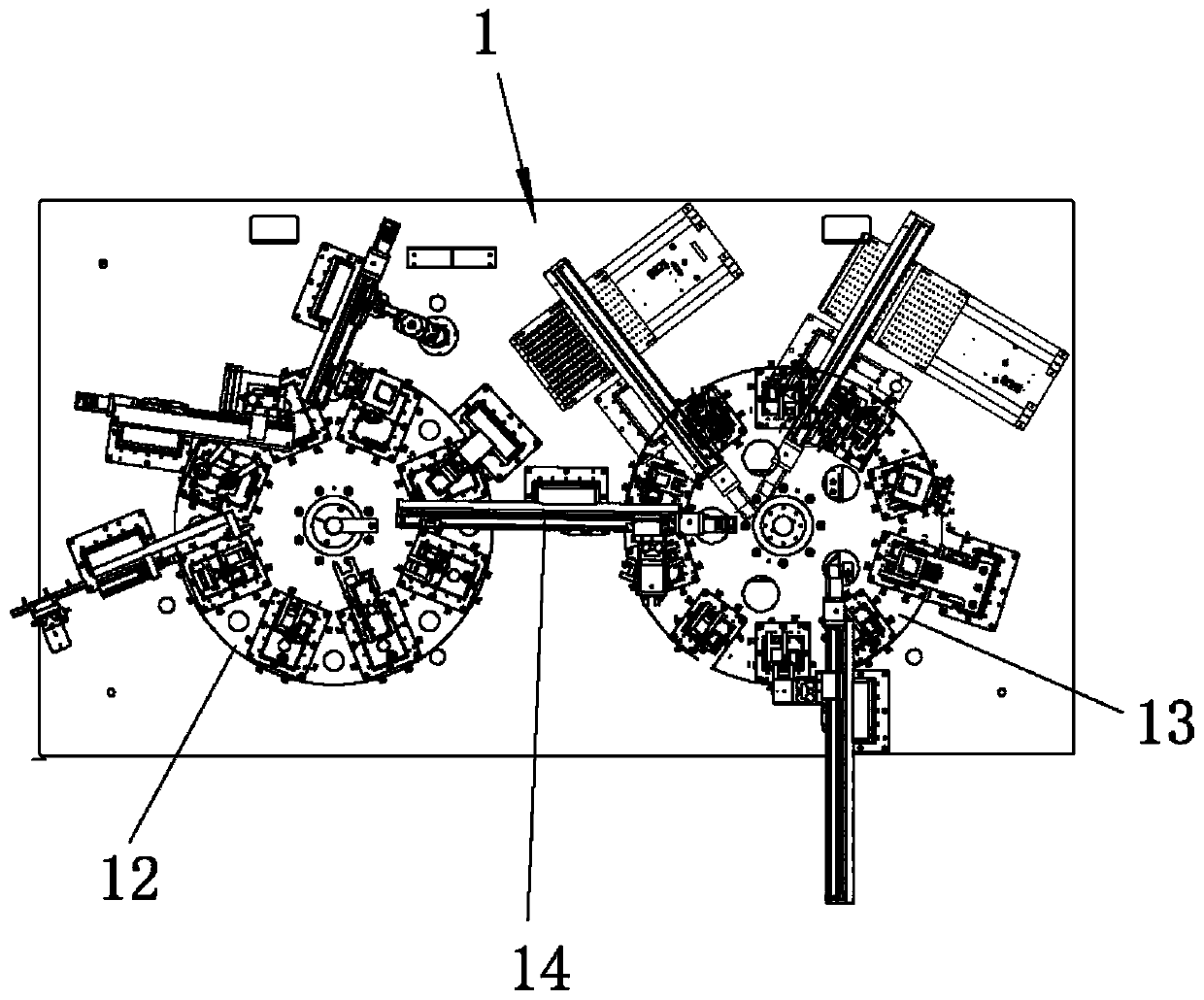

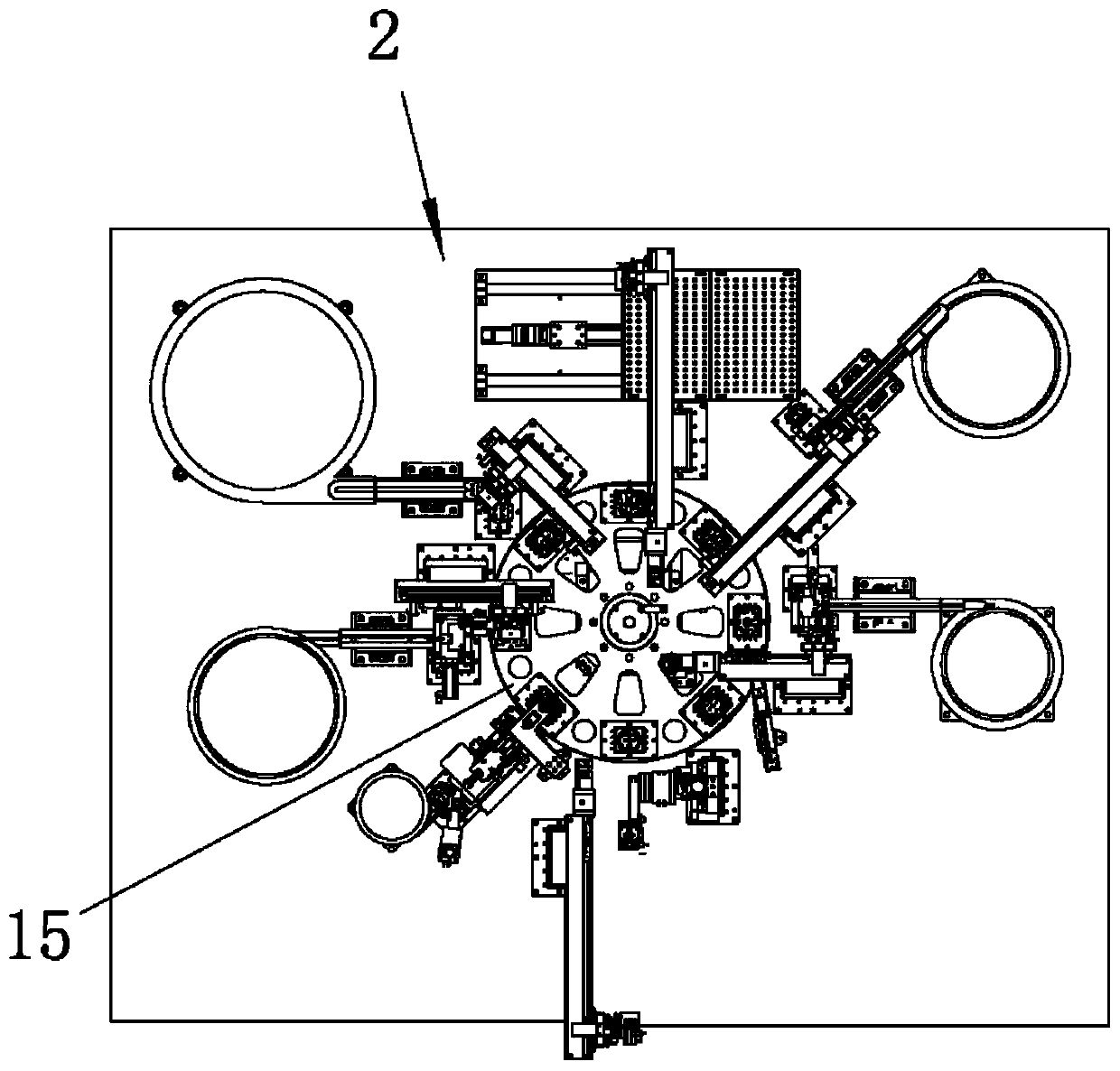

Automatic assembly production line for stove gas valves

ActiveCN111250978AImprove assembly efficiencyLow assembly efficiencyAssembly machinesSortingProduction lineProcess engineering

The invention relates to the technical field of stove gas valve assembly, and particularly discloses an automatic assembly production line for stove gas valves. The automatic assembly production linefor the stove gas valves comprises a valve core assembly machine, a transmission assembly assembling machine, a valve closing assembling machine, an electromagnetic valve assembling machine, a nozzleassembling machine, a rear cover assembling machine and a transferring mechanism; the automatic assembly production line for the stove gas valves further comprises a plurality of first six-axis robots, a plurality of storage bins and a plurality of bad conveying units which are matched with the assembly machines respectively, wherein the first six-axis robots are used for transferring the components transferred by the transferring mechanism into the storage bins, and are used for transferring the components in the storage bins to the transferring mechanism or are for moving the components transferred by the transferring mechanism to the bad conveying units. Each assembly machine cooperates with each other to achieve automatic assembly of the stove gas valves, and the assembly efficiency ofthe stove gas valves is improved; when a certain assembling machine is shut down, the first six-axis robots move the products assembled by the other assembling machines to the corresponding storage bin, and the situation in which the assembly efficiency is reduced due to all the shutdown of all the assembling machines is avoided.

Owner:东莞市科讯机械自动化设备有限公司

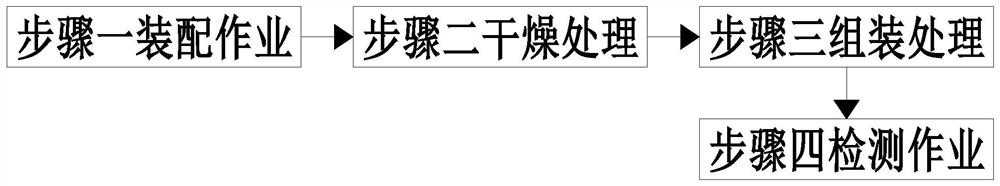

Manufacturing process of oil-immersed transformer

ActiveCN113035548AImprove stabilityImprove assembly quality and efficiencyInductances/transformers/magnets manufactureProcess engineeringTransformer

The invention relates to a manufacturing process of an oil-immersed transformer. The manufacturing process mainly comprises the following steps: assembling operation, drying treatment, assembling treatment, detection operation and the like. Used transformer assembling equipment comprises a bottom plate, a conveying device, a clamping device and a positioning device. The manufacturing process of the invention can solve the following problems existing when a traditional transformer and an oil tank are assembled: a, when the traditional transformer and the oil tank are assembled, the transformer needs to be manually lifted by using a tool and slowly conveyed into the oil tank, and due to the fact that the transformer is heavy, the labor intensity of manual assembling is large, and the phenomenon that the transformer is prone to falling off when being manually lifted and causes damage to the transformer and influence on subsequent use of the oil-immersed transformer occurs; and b, when an existing oil-immersed transformer is assembled, stable clamping and conveying operation cannot be carried out on the transformer, and due to the fact that the oil tank slides, assembly of the transformer is misplaced and the assembly quality and efficiency of the oil-immersed transformer are reduced.

Owner:中电变压器股份有限公司

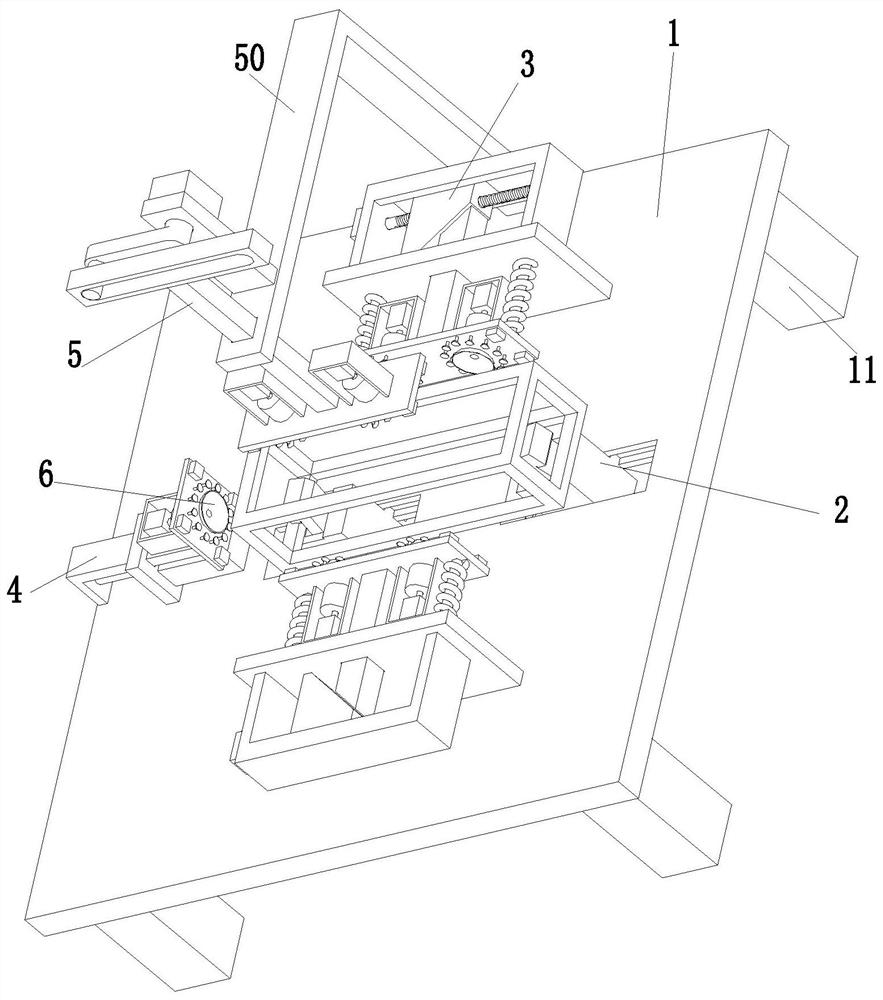

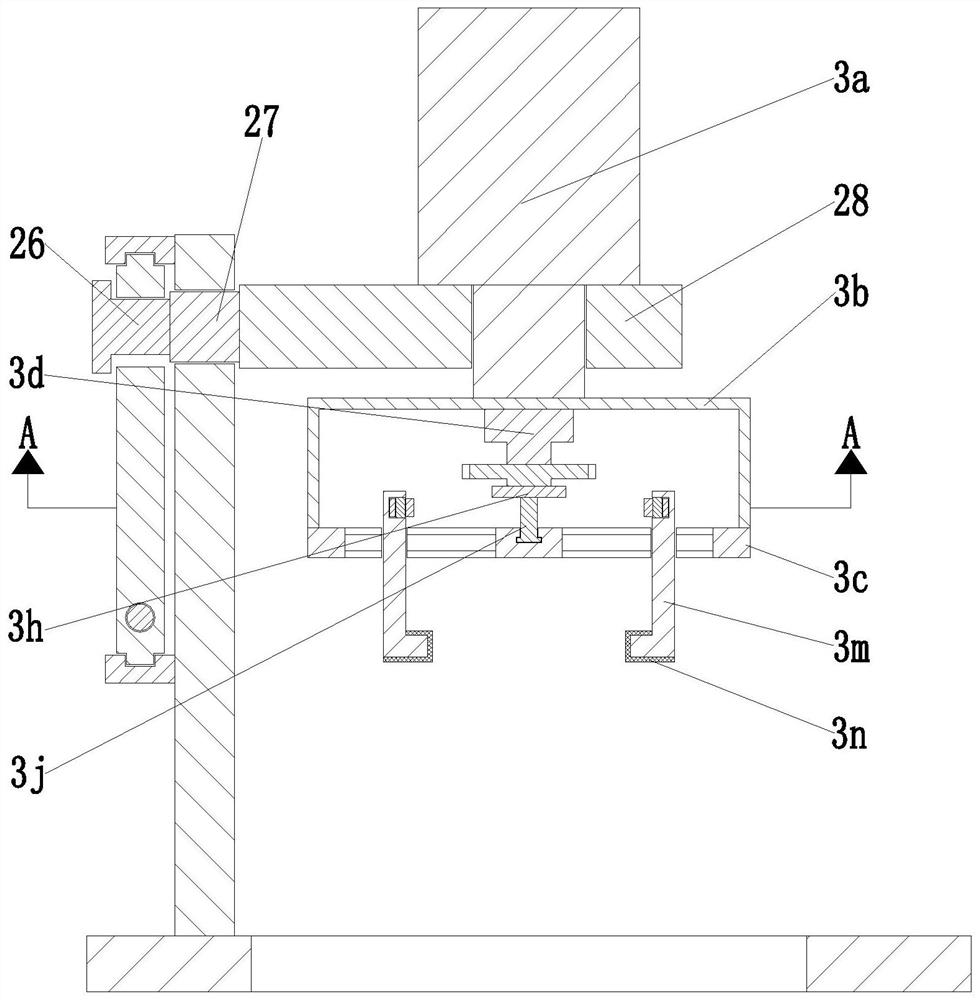

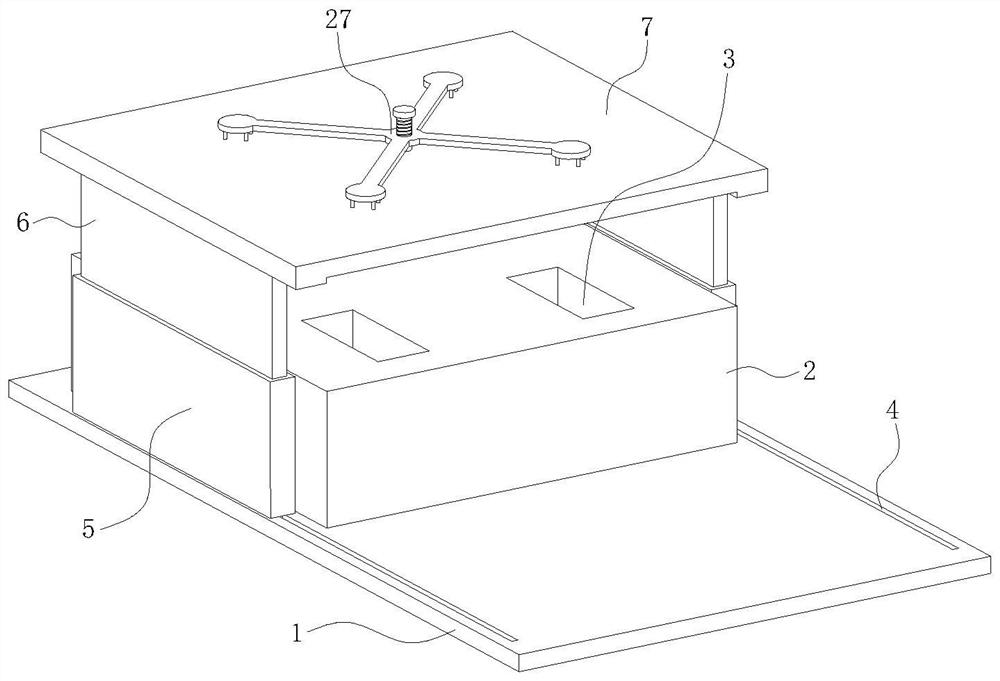

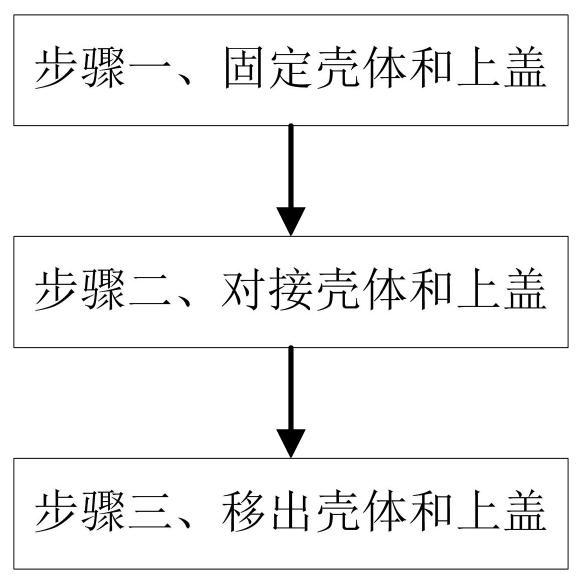

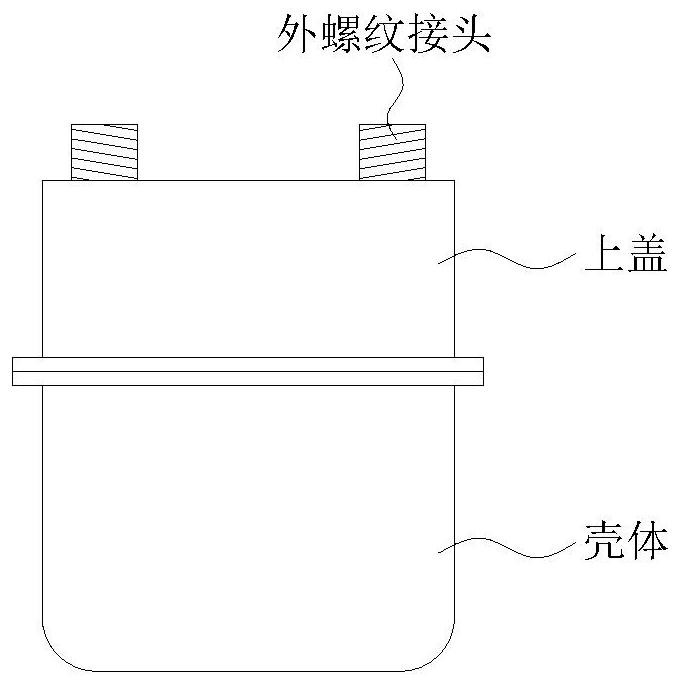

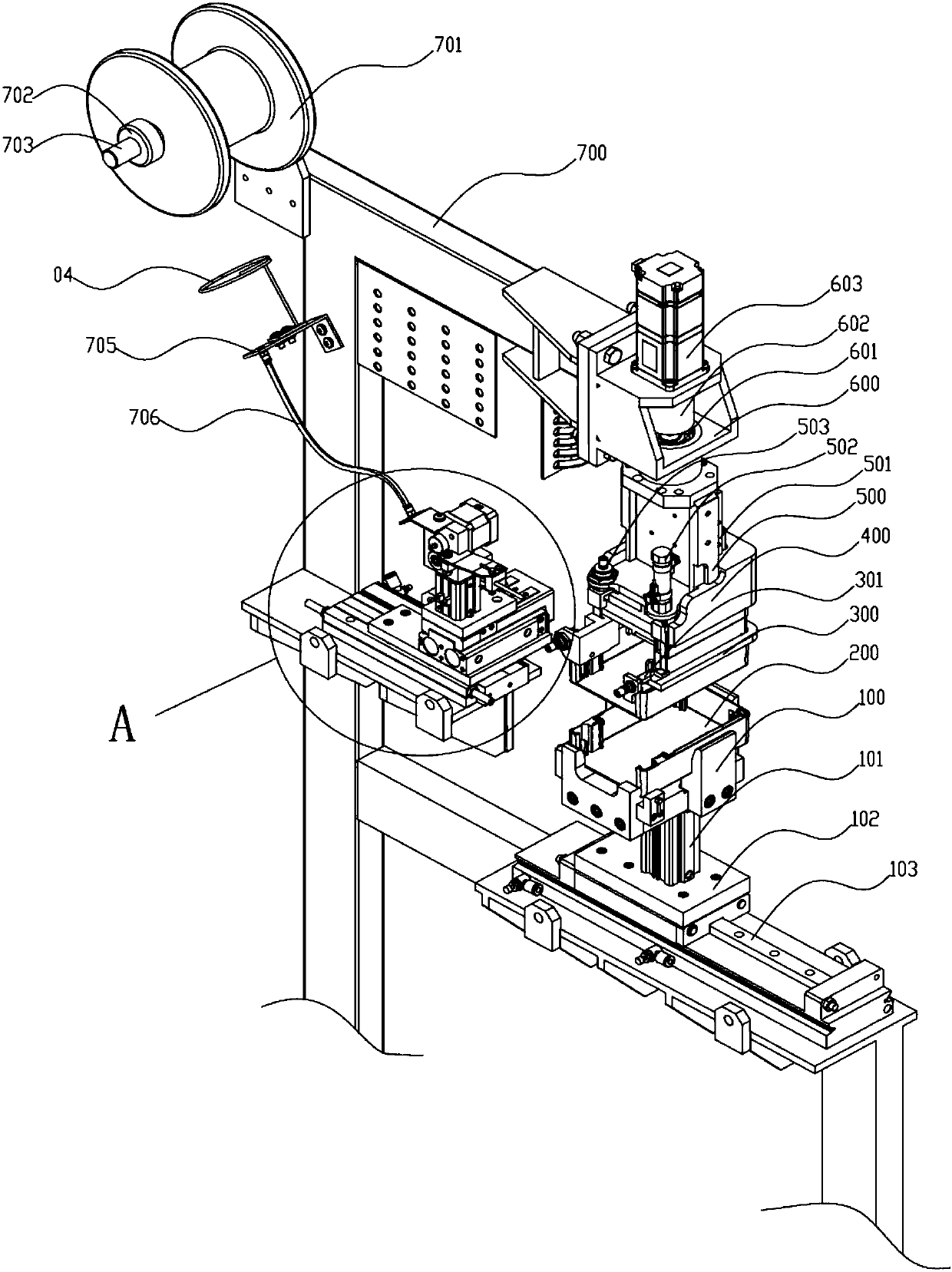

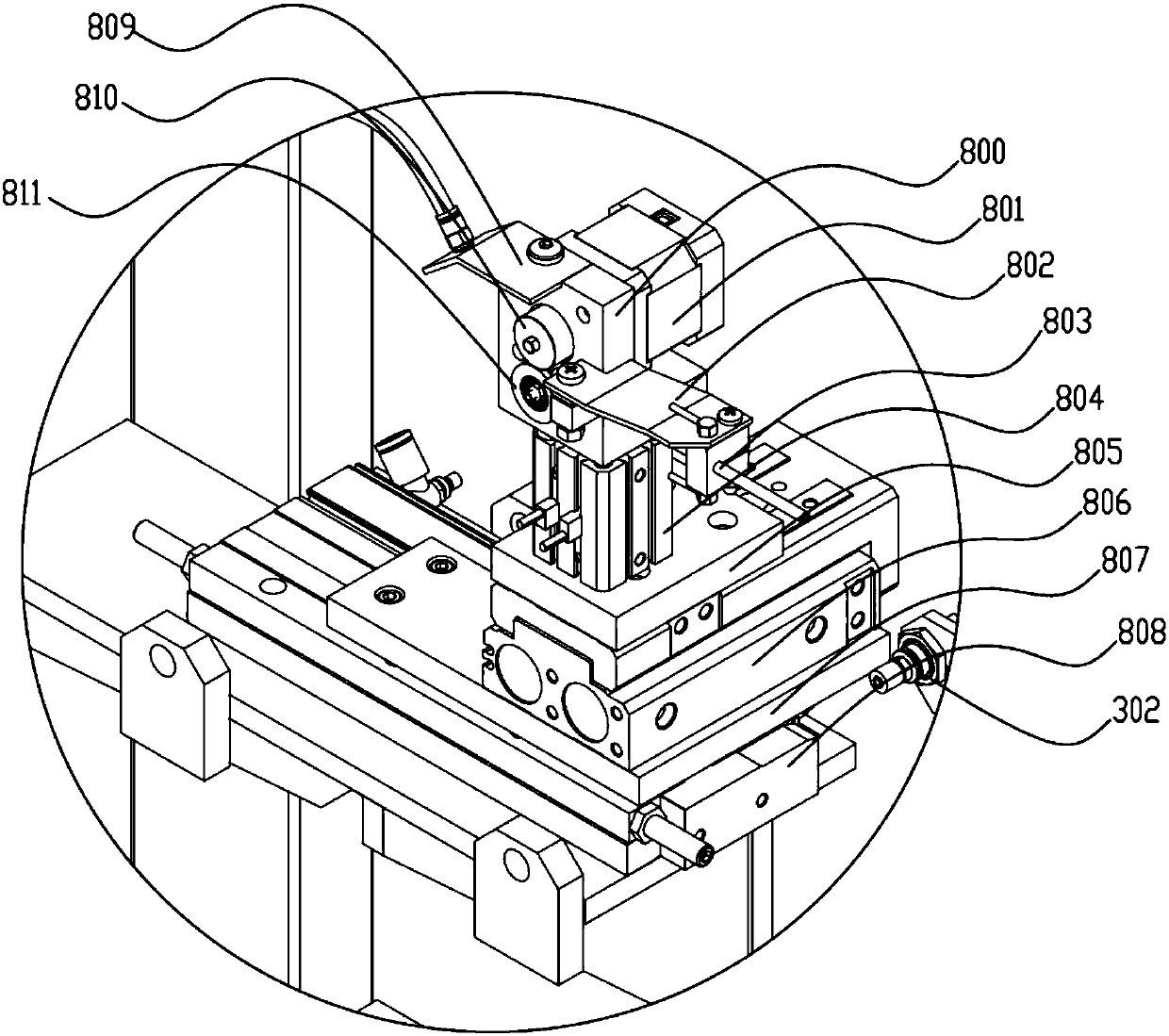

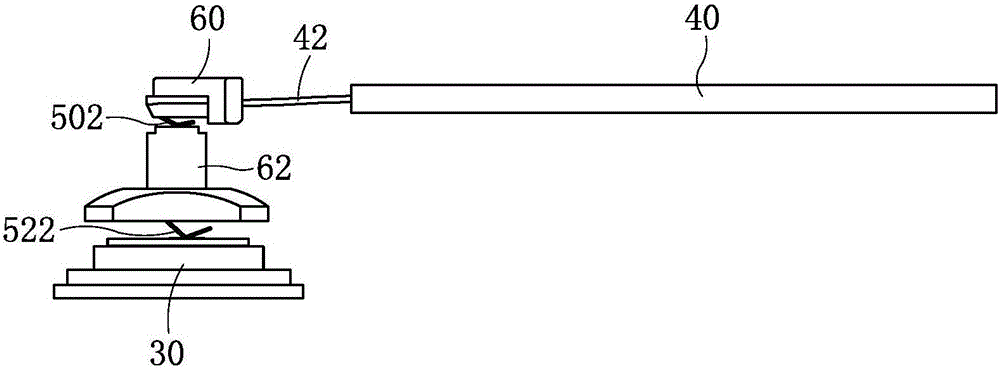

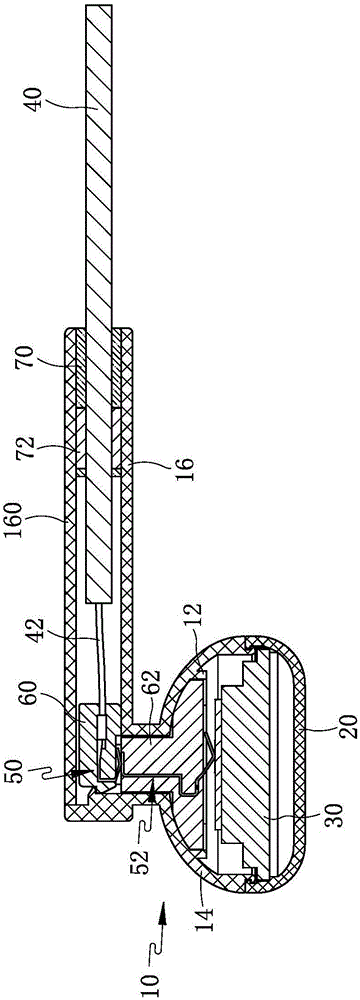

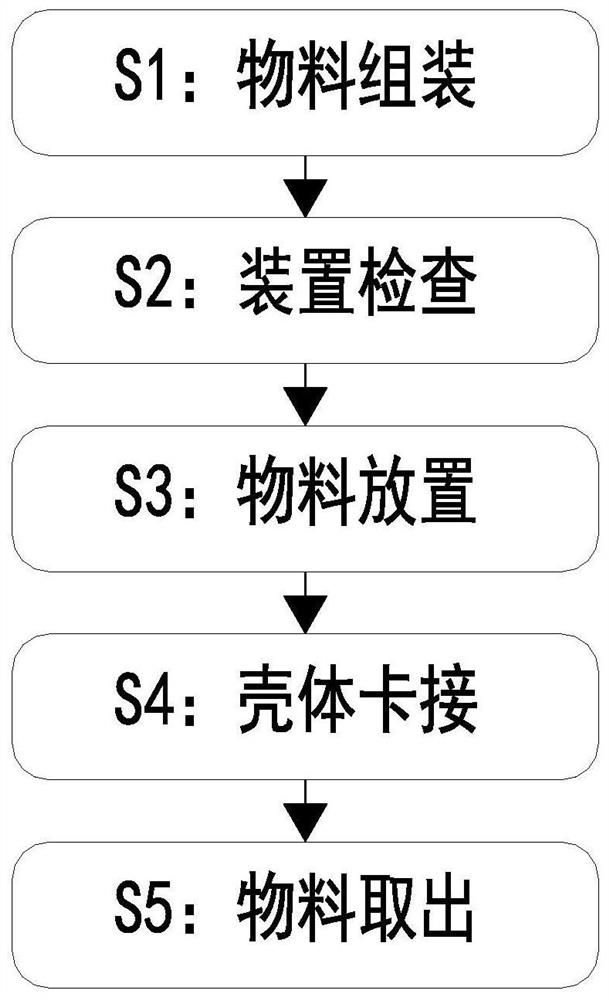

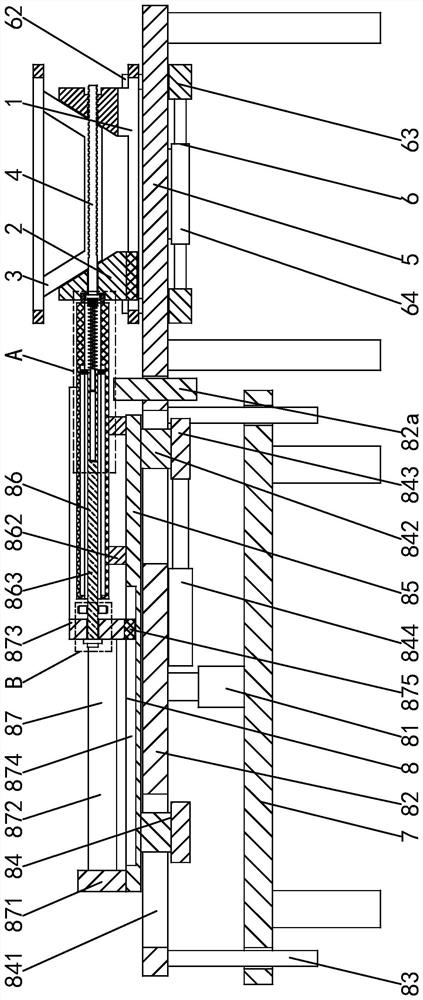

Intelligent diaphragm gas meter automatic assembling machine and assembling method

The invention belongs to the technical field of gas equipment, and particularly relates to an intelligent diaphragm gas meter automatic assembling machine and an assembling method. The assembling method comprises the following steps that 1, a shell and an upper cover are fixed, specifically, the shell is placed in a containing groove, an opening of the upper cover faces downwards, and then an external thread connector is aligned with a limiting column and inserted into the limiting column; 2, the shell and the upper cover are in butt joint, specifically, a guide plate is pushed to drive a top plate to reach a set position above a supporting base, and a lifting plate drives the upper cover to move downwards till buckles of the shell and the upper cover are connected together in a clamped manner; and 3, the shell and the upper cover are moved out, specifically, the shell and the upper cover are driven by the lifting plate to ascend synchronously, the guide plate is pushed to drive the shell and the upper cover to horizontally move to initial positions, and then the shell and the upper cover are taken down. According to the assembling machine and the assembling method, multiple shells and upper covers can be assembled at the same time, and the assembling efficiency is high. By means of the the assembling machine and the assembling method, when an intelligent diaphragm gas meter is assembled, the situation that the buckles are damaged is avoided.

Owner:王大凤

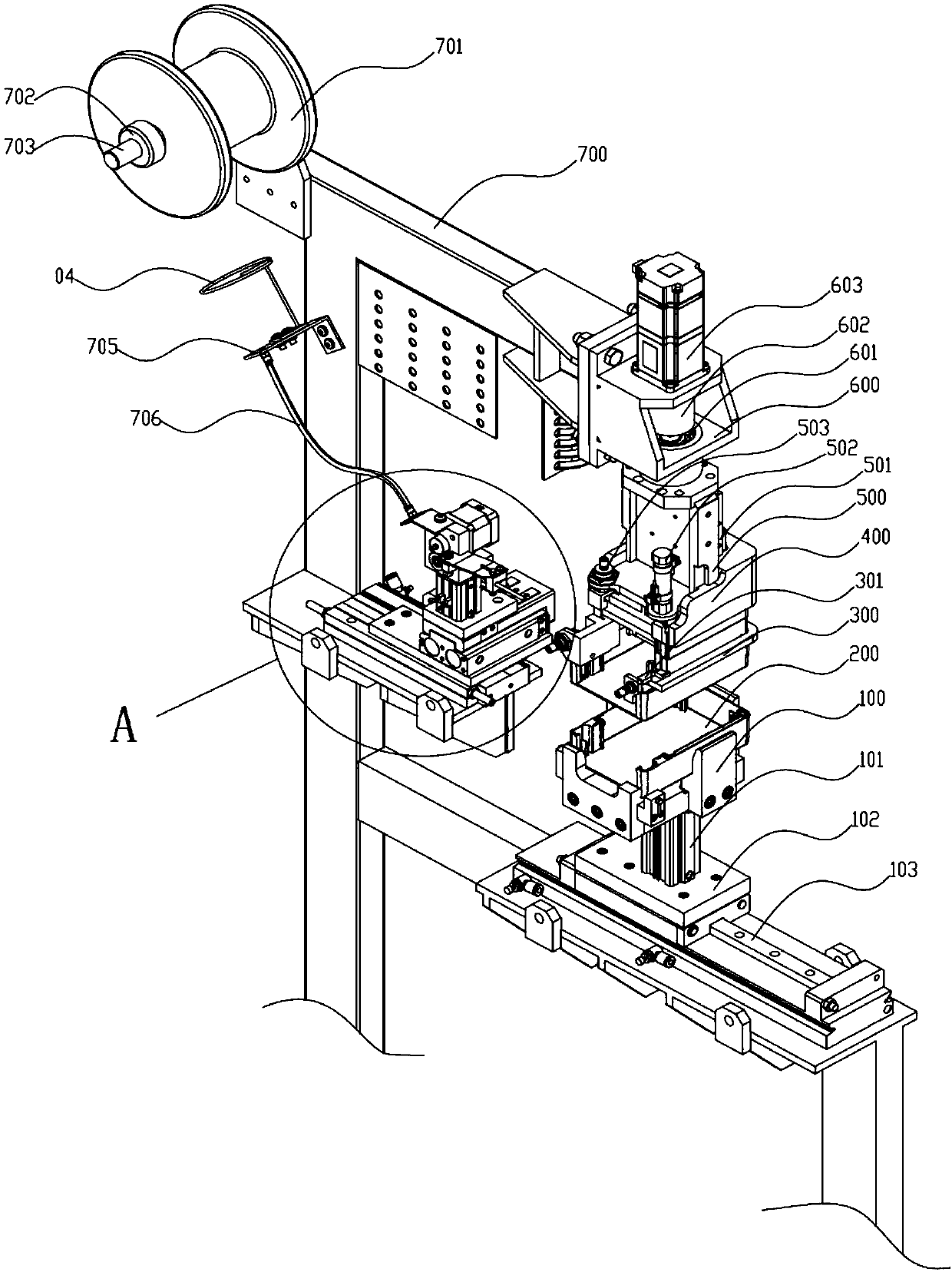

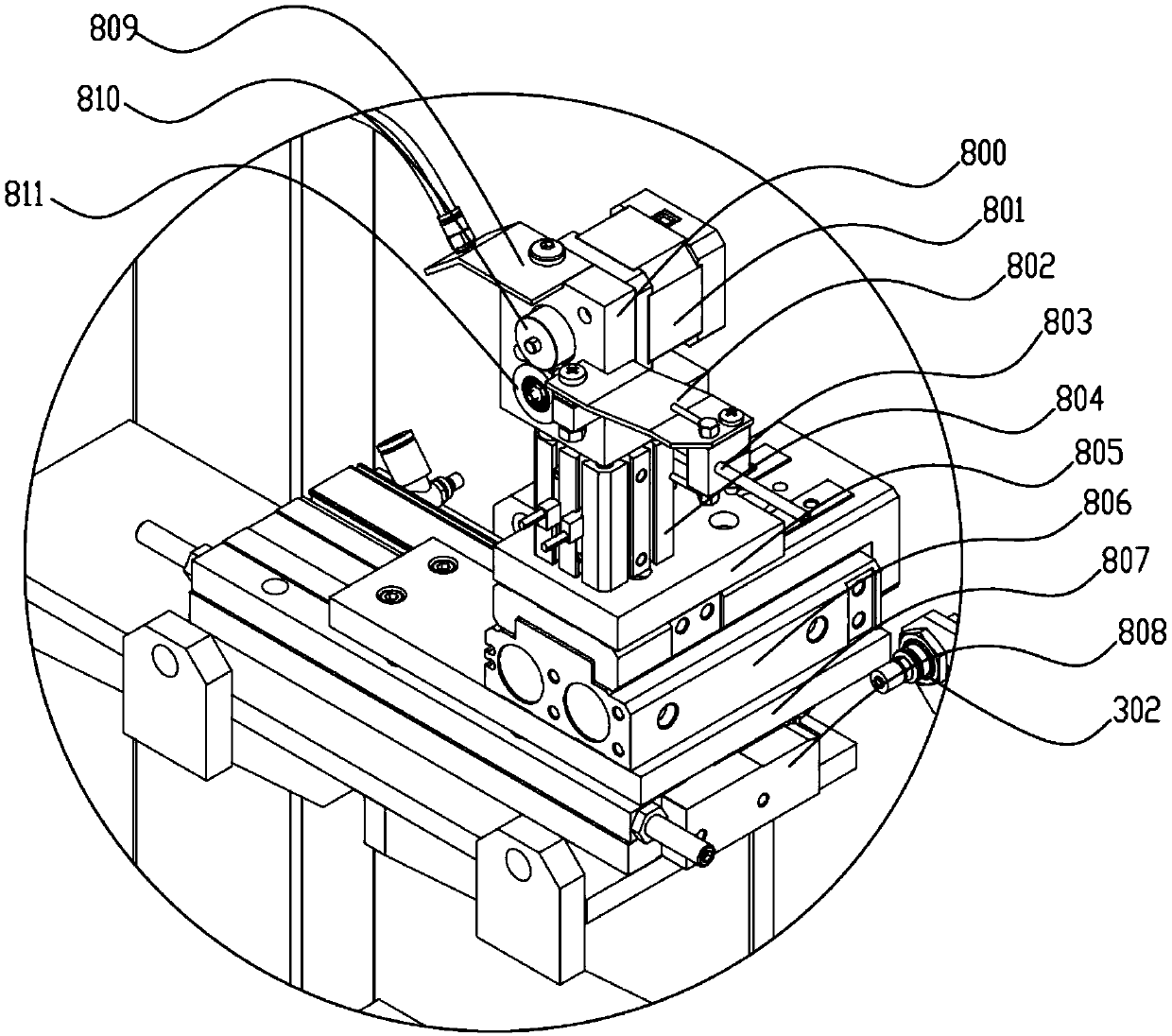

Equipment and device and assembling method for assembling linear sealing strip

ActiveCN107717374AAutomate installationMeet the requirements of automated installationMetal working apparatusFrame basedEngineering

The invention discloses equipment and device and assembling method for assembling a linear sealing strip. The device for assembling the linear sealing strip comprises a swinging rotor, a mold frame base and a groove pressing plate, the mold frame base is arranged below the swinging rotor, and the groove pressing plate is mounted in the swinging rotor and can slide relative to the swinging rotor and the mold frame base; a workpiece clamp table is arranged below the mold frame base, and a workpiece accommodating gap is formed between the mold frame base and the workpiece clamp table, and the mold frame base is used for conducting form imitation and locating on the workpiece on the workpiece clamp table; and a sealing strip feeding device is arranged on one side of the workpiece accommodatinggap. According to the device for assembling the linear sealing strip, through the mode of guiding of the mold frame base, the automatic mounting condition of the linear sealing strip is achieved, andthe assembling efficiency is greatly improved. In particular, the device for assembling the linear sealing strip can cooperate and assist a robot to assemble the sealing strip, and requirements of fully-automated mounting are achieved.

Owner:湖南瑞森可机器人科技有限公司

Earphone

ActiveCN105120408AReliable electrical connectionIncrease contactElectrical transducersEngineeringHeadphones

The invention discloses an earphone, relating to the technical field of electroacoustic products. The earphone comprises an earphone shell and a loudspeaker cover combined together; a loudspeaker unit is contained in a space formed by the earphone shell and the loudspeaker cover in an encircling manner; the earphone further comprises an earphone line for being electrically connected to the loudspeaker unit and audio-frequency equipment; the earphone line and the loudspeaker unit are electrically connected through an elastic sheet component; the elastic sheet component comprises an elastic sheet and a fixing part for fixing the elastic sheet in the earphone shell; the elastic sheet and the fixing part are combined into a whole; one end of the elastic sheet and the earphone line are electrically connected fixedly; and the other end of the elastic sheet and the loudspeaker are electrically connected in a contact manner. According to the invention, the technical problems of low circuit conduction reliability, low assembly efficiency and the like of the earphone in the prior art can be solved; automatic modular assembly of the earphone disclosed by the invention can be realized; and the earphone disclosed by the invention is high in production efficiency, low in production cost, high in working stability and long in service life simultaneously.

Owner:GOERTEK INC

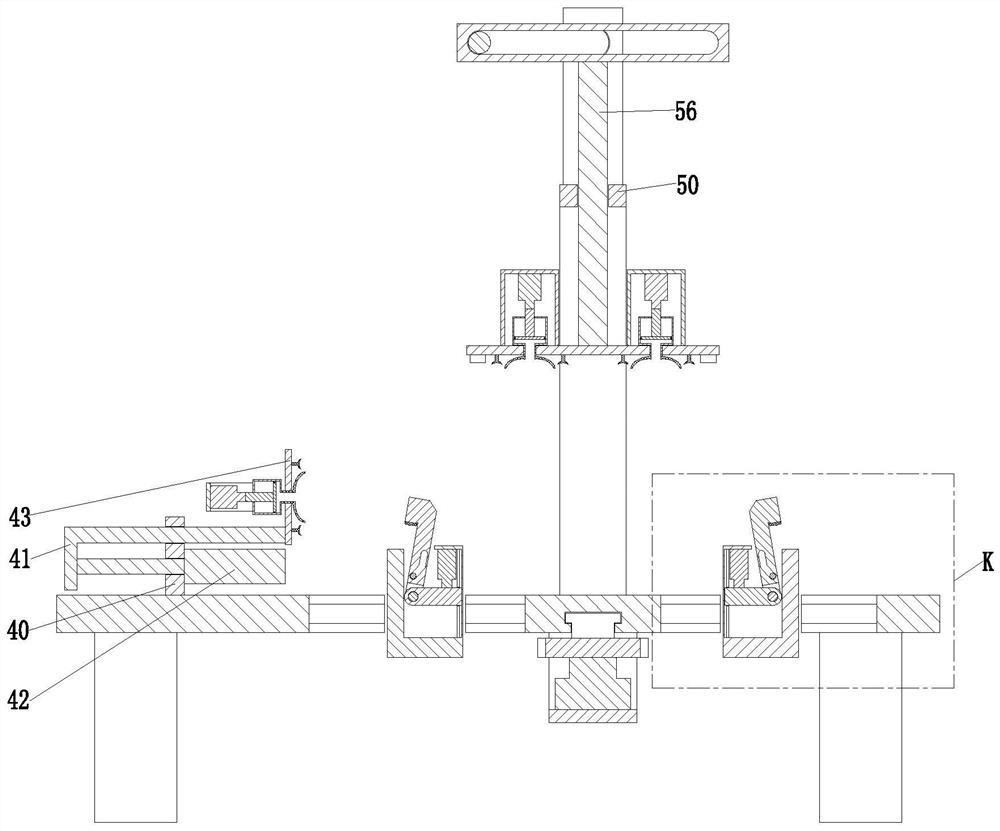

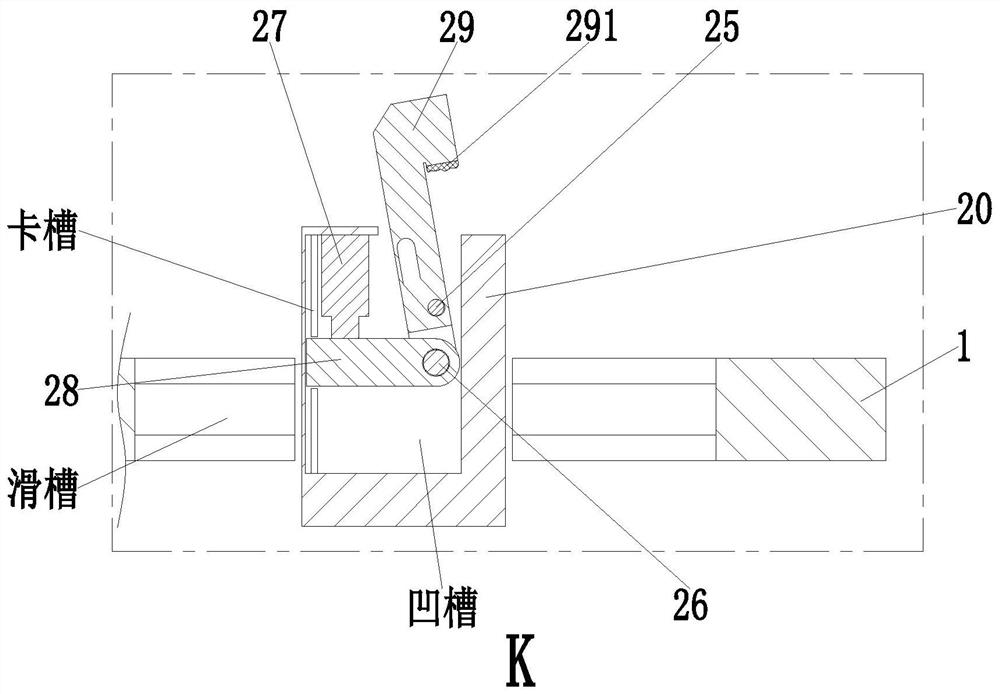

Industrial instrument and meter producing and assembling method

InactiveCN113211053ALow assembly efficiencyReduce the effect of butt assemblyMetal working apparatusButt jointEngineering

The invention relates to an industrial instrument and meter producing and assembling method. The industrial instrument and meter producing and assembling method adopts an industrial instrument and meter producing and assembling device which comprises a base, a conveying mechanism, bearing mechanisms and a press fitting mechanism, wherein the conveying mechanism is arranged on the upper end face of the base, the bearing mechanisms are evenly arranged on the outer side of the conveying mechanism, and the press fitting mechanism is arranged in the middle of the upper end face of the base and located above the conveying mechanism. According to the industrial instrument and meter producing and assembling method, the problems that in the industrial instrument and meter assembling process in the prior art, after a transparent shell and a fixing shell of an industrial instrument and meter are placed, the transparent shell and the fixing shell usually need to be manually adjusted to be aligned, but the assembling efficiency is reduced in the process, the alignment degree between the transparent shell and the fixing shell of the industrial instrument and meter is difficult to accurately adjust in a manual adjustment mode, and the butt joint assembly effect between the transparent shell and the fixing shell of the industrial instrument and meter is lowered can be solved.

Owner:武汉顺为众创科技有限公司

Combined logistics cabinet

ActiveCN105231682AAvoid cumbersome and time-consuming connectionsLow assembly efficiencySheet joiningCabinetsLogistics managementEngineering

The invention provides a combined logistics cabinet, which comprises a main cabinet and a subordinate cabinet, wherein the main cabinet comprises a main cabinet body; the main cabinet body comprises main cabinet side plates; a first magnetic adsorption piece and a first telescopic electrode are arranged on the outer surface of each main cabinet side plate; the subordinate cabinet comprises subordinate cabinet side plates which face the main cabinet; a second magnetic adsorption piece and a second telescopic electrode are arranged on the outer surface of each subordinate cabinet side plate; the first magnetic adsorption pieces and the second magnetic adsorption pieces are mutually attracted through magnetic force; and the first telescopic electrodes and the second telescopic electrodes are propped against from each other, so that a circuit of the subordinate cabinet is electrically connected to a circuit of the main cabinet.

Owner:POOKE TECH

Outdoor unit and underframe assembly thereof

InactiveCN106247486AImprove component versatilityLow assembly efficiencyLighting and heating apparatusAir conditioning systemsMechanical engineeringEngineering

The invention discloses an underframe assembly, comprising an underframe body. The underframe body is provided with a U-shaped terrace set mating with a condenser and is also provided with an assembly top mating with a compressor. In assembly and use, the U-shaped terrace set is adaptable to assembly with an L-shaped condenser and is also reliably adaptable to assembly with a U-shaped condenser, so that component universality of the underframe assembly is significantly improved, condition adaptability of the underframe assembly is improved, and overall assembly efficiency of the air conditioner outdoor unit and its manufacture cost are correspondingly reduced. The invention also discloses an outdoor unit employing the underframe assembly.

Owner:GREE ELECTRIC APPLIANCES INC

A lithium battery production and assembly method

ActiveCN112421096BLow assembly efficiencyImprove assembly efficiencyAssembling battery machinesFinal product manufactureElectric carsElectric vehicle

Owner:江苏天辉锂电池有限公司

Wire protection sleeve sheath assembly with built-in Bluetooth module, BLDC motor controller and motor

PendingCN112688496AReduce volumeAvoid installationAssociation with control/drive circuitsSingle motor speed/torque controlManufacturing cost reductionElectric machine

The invention discloses a wire protection sleeve assembly with a built-in Bluetooth module, a BLDC motor controller and a motor. The wire protection sleeve assembly comprises a wire protection sleeve main body, the wire protection sleeve main body is an injection molding body, the wire protection sleeve main body is provided with an installation groove, a circuit board is embedded in the installation groove, the Bluetooth module is integrated on the circuit board, the circuit board is electrically connected with a plurality of leads, the leads are led out of the wire protecting sleeve main body and are electrically connected with the motor controller; the Bluetooth module is arranged in the wire protection sleeve main body, and then the wire protection sleeve main body is embedded in a control box, so that the space is reasonably utilized, the Bluetooth module is prevented from being directly arranged on the motor, the size of the motor is reduced, the use of parts is reduced, and the manufacturing cost is reduced; the Bluetooth module is directly and electrically connected with the main control circuit board of the motor controller, so that a built-in battery is prevented from being additionally arranged, the motor assembly steps are simplified, and the assembly efficiency is improved; and besides, the wire protection sleeve main body is an injection-molded body, so that the shielding effect on wireless signals can be weakened, and the influence on signal transmission can be avoided.

Owner:ZHONGSHAN BROAD OCEAN

Express logistics cabinet capable of rapid connection

ActiveCN107676349AAvoid cumbersome and time-consuming connectionsLow assembly efficiencySheet joiningCabinetsLogistics managementEngineering

The invention provides an express logistics cabinet capable of rapid connection. The express logistics cabinet capable of rapid connection comprises a main cabinet and auxiliary cabinets; the main cabinet comprises a main cabinet body; the main cabinet body comprises main cabinet side plates; the outer surface of each main cabinet side plate is provided with a first magnetic adsorption piece and afirst telescopic electrode; each auxiliary cabinet comprises auxiliary cabinet side plates which face the main cabinet; the outer surface of each auxiliary cabinet side plate is provided with a second magnetic adsorption piece and a second telescopic electrode; each first magnetic adsorption piece is mutually attracted with the corresponding second magnetic adsorption piece through a magnetic force; and each first telescopic electrode is mutually abutted against the corresponding second telescopic electrode to enable a circuit of each auxiliary cabinet to be mutually electrically connected with a circuit of the main cabinet.

Owner:CHONGQING ZONGSHEN THIRD WHEEL MOTORCYCLE MFG CO LT

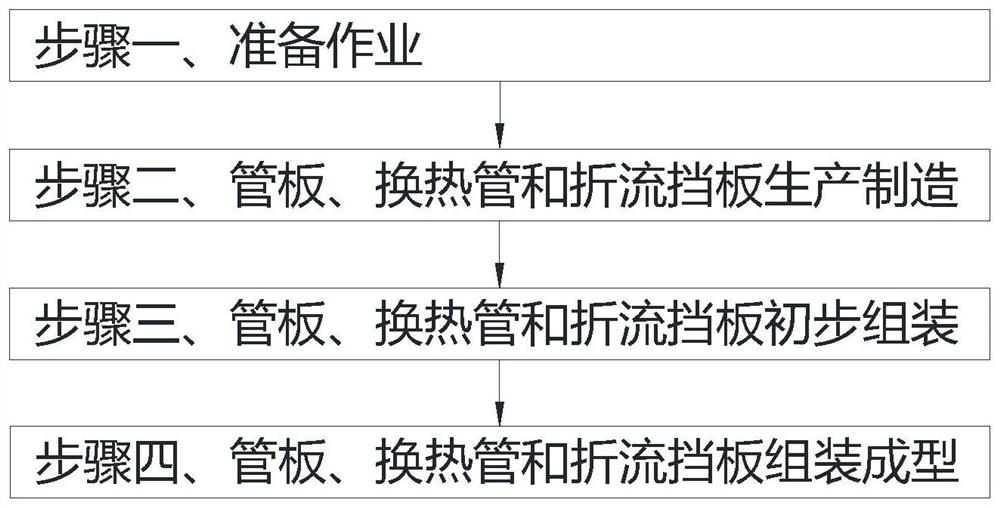

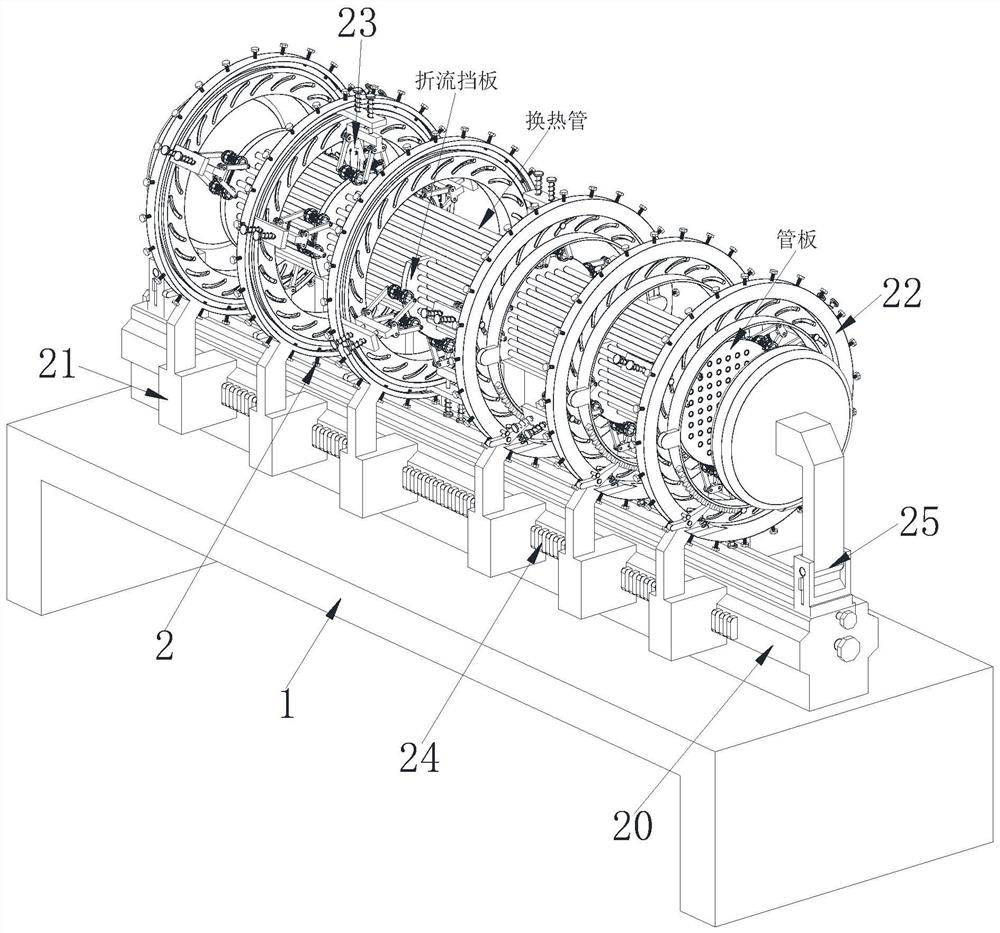

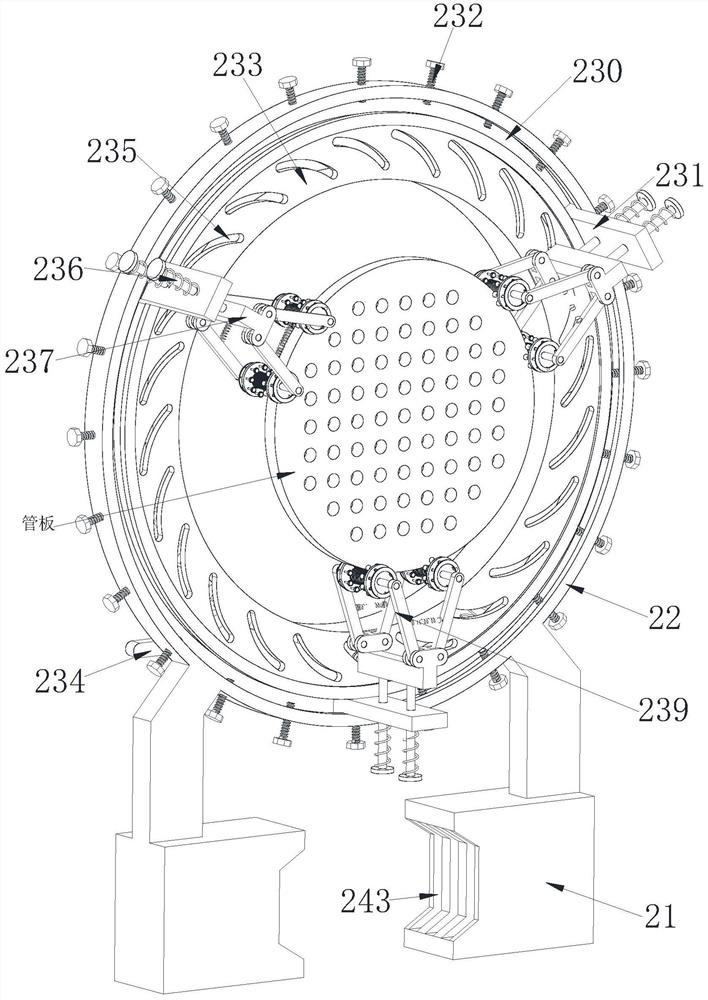

Tube type heat exchanger forming assembly method

ActiveCN113070841ASolve the following problemsLow assembly efficiencyWork holdersMetal-working hand toolsEngineeringMechanical engineering

The invention relates to a tube type heat exchanger forming assembly method which uses tube type heat exchanger forming assembly equipment. The tube type heat exchanger forming assembly equipment comprises a base and an auxiliary device which is arranged on the upper surface of the base. The tube type heat exchanger forming assembly method can solve the current problems that as the shapes of a tube plate and a deflection baffle are different, but existing clamping equipment has the same clamping and fixing mode on the tube plate and the deflection baffle, it is difficult to completely clamp and fix the deflection baffle at the position where the tube plate can be clamped and fixed, the tube plate and the deflection baffle are completely fixed after one-time position calibration is performed for clamping and fixing, it is needed to open the clamping equipment again to adjust the positions of the tube plate and the deflection baffle for the problem of hole misalignment in subsequent assembly of heat exchange tubes, time and labor are wasted, and the heat exchanger production efficiency is seriously affected.

Owner:江苏东南环保科技有限公司

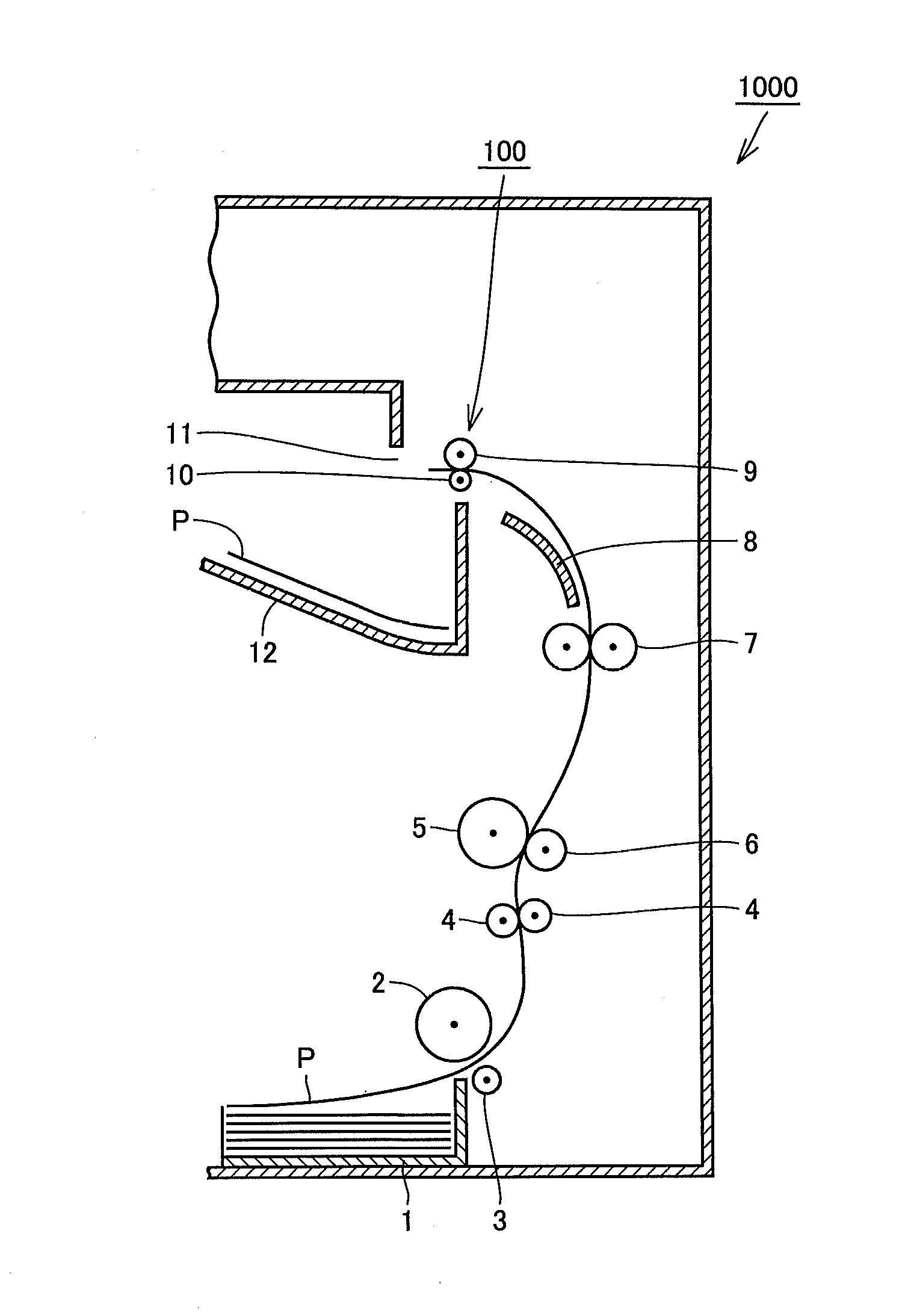

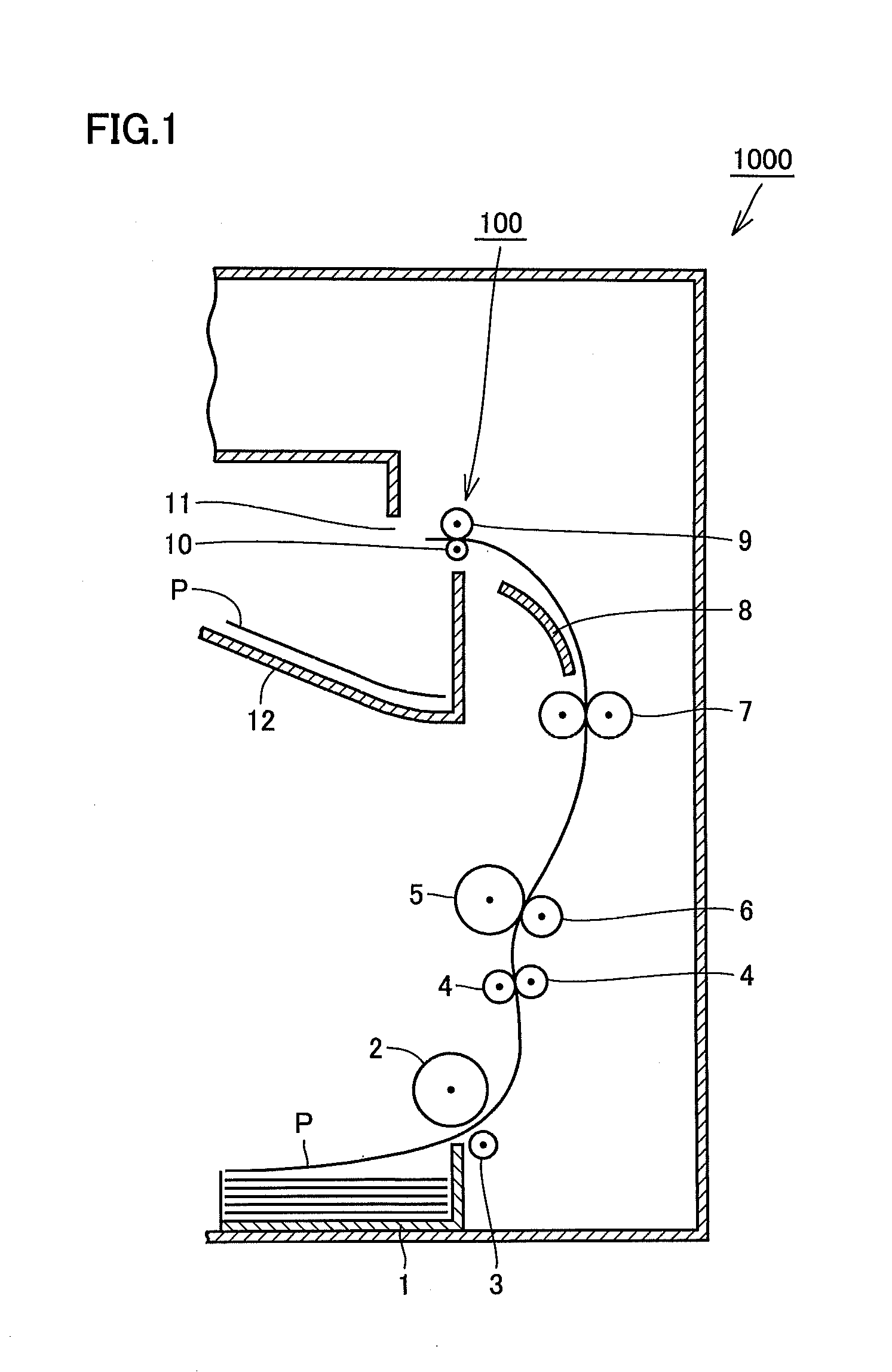

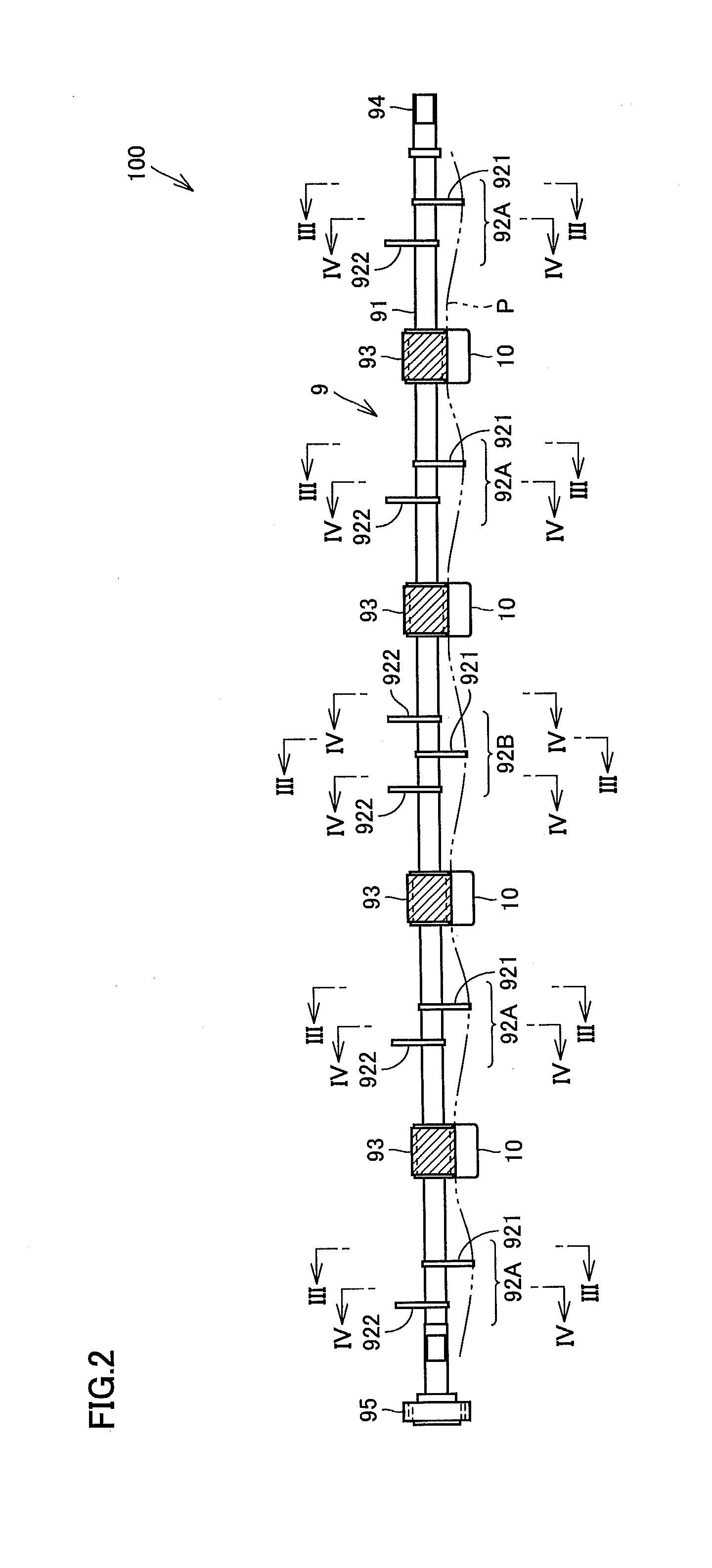

Sheet discharge roller and image forming apparatus

ActiveUS20110309573A1Improve rigidityLow assembly efficiencyArticle deliveryEngineeringSheet material

In a sheet discharge roller, a transportation roller includes a roller portion formed integrally on a rotation shaft, and an annular elastic member attached to a surface of the roller portion, each of rigidity increasing portions includes a plurality of plate members axially spaced from each other by a predetermined distance, and the plurality of plate members have forms each obtained by circumferentially dividing a circular plate, respectively, are arranged in positions circumferentially shifted from each other, respectively, and thereby exhibit an outer periphery of a substantially circular form when viewed in the axial direction.

Owner:KONICA MINOLTA BUSINESS TECH INC

A device for assembling a linear sealing strip, its device, and its assembly method

ActiveCN107717374BAutomate installationMeet the requirements of automated installationMetal working apparatusFrame basedMechanical engineering

The invention discloses equipment and device and assembling method for assembling a linear sealing strip. The device for assembling the linear sealing strip comprises a swinging rotor, a mold frame base and a groove pressing plate, the mold frame base is arranged below the swinging rotor, and the groove pressing plate is mounted in the swinging rotor and can slide relative to the swinging rotor and the mold frame base; a workpiece clamp table is arranged below the mold frame base, and a workpiece accommodating gap is formed between the mold frame base and the workpiece clamp table, and the mold frame base is used for conducting form imitation and locating on the workpiece on the workpiece clamp table; and a sealing strip feeding device is arranged on one side of the workpiece accommodatinggap. According to the device for assembling the linear sealing strip, through the mode of guiding of the mold frame base, the automatic mounting condition of the linear sealing strip is achieved, andthe assembling efficiency is greatly improved. In particular, the device for assembling the linear sealing strip can cooperate and assist a robot to assemble the sealing strip, and requirements of fully-automated mounting are achieved.

Owner:湖南瑞森可机器人科技有限公司

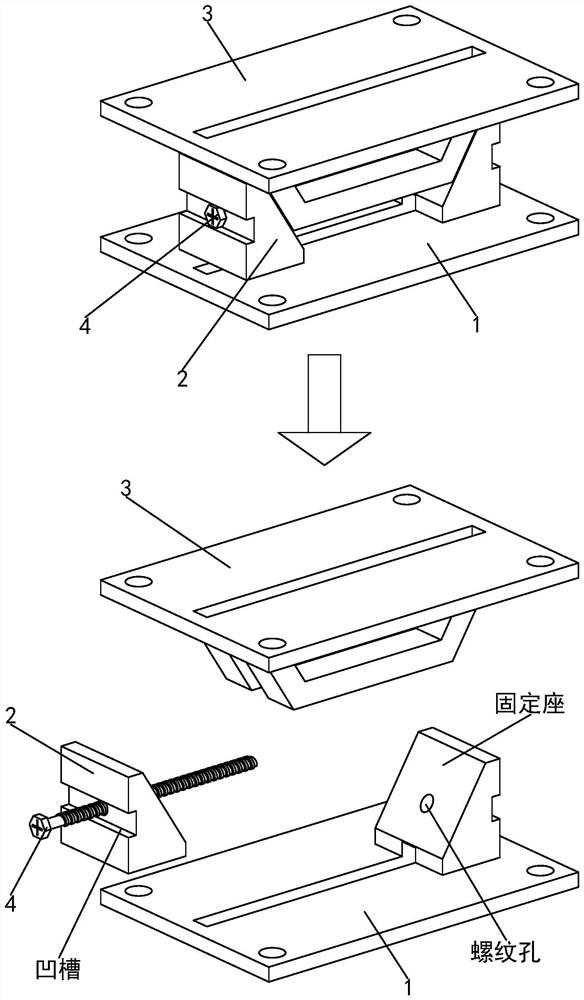

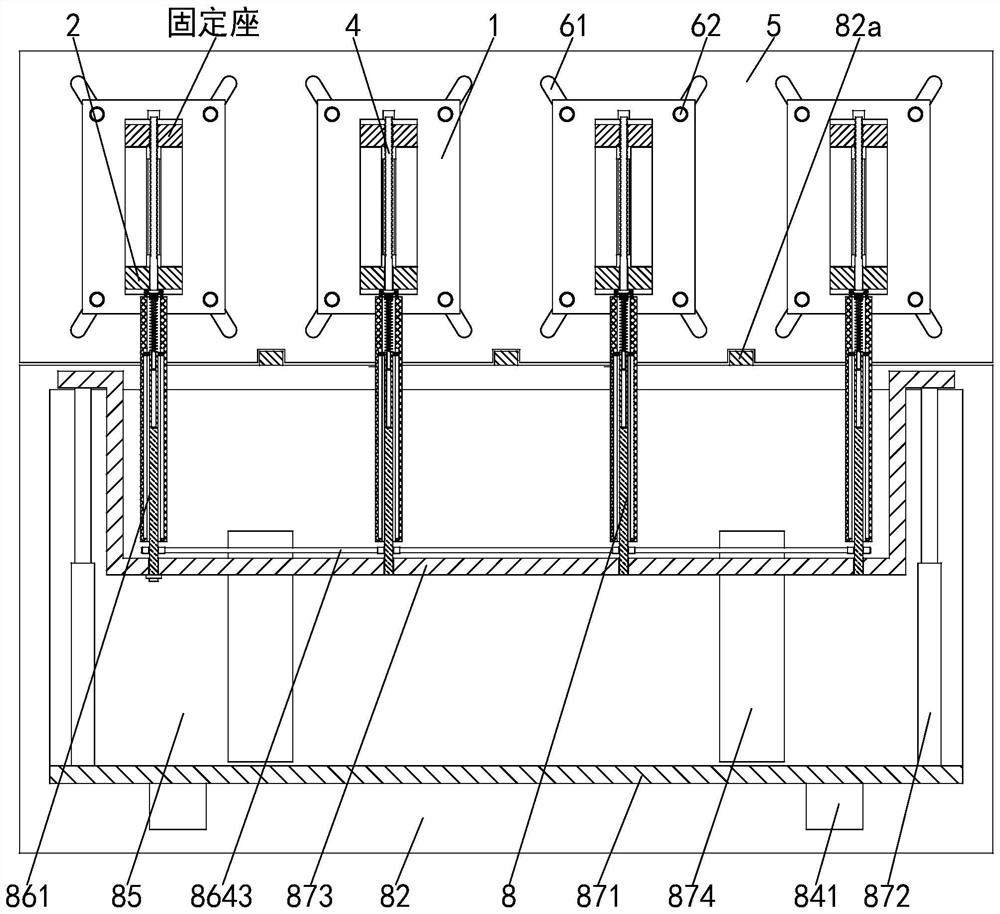

Fabricated building installation leveling assembly and production assembly equipment thereof

ActiveCN114102531ALow assembly efficiencyIncrease production costWork holdersWork benchesConstruction engineeringStructural engineering

The invention provides a fabricated building installation leveling assembly and production and assembly equipment thereof, the fabricated building installation leveling assembly comprises a base, a movable accessory, a leveling base and a locking bolt, and the fabricated building installation leveling assembly relates to the assembly equipment in the specific manufacturing and production process. The assembling equipment comprises a placing platform, a limiting device, an assembling platform and an assembling device. According to the invention, the following problems existing in the production and assembly process of the fabricated building installation leveling assembly can be solved: a, when the current fabricated building installation leveling assembly is assembled, all parts are sequentially placed on a platform to be assembled, and then a locking bolt penetrates through a movable accessory to be in threaded connection with a fixed seat on a base; according to existing assembling equipment, locking bolts are difficult to accurately penetrate through round holes of movable accessories to be in threaded connection with threaded holes of fixed seats, meanwhile, the locking bolts are mostly tightened one by one, and the assembling efficiency is low.

Owner:佛山市有为科技有限公司 +1

An air conditioner assembly intelligent tooling board

ActiveCN105479415BAvoid Composition CostsLow costAssembly machinesWork benchesElectricityAssembly line

The invention relates to an intelligent tooling plate for assembling an air conditioner. The intelligent tooling plate comprises a bottom plate assembly, a rotating plate assembly, a rotary table assembly, guide pulleys, dog catch spacing openings, file folder grooves, one or more first die sets, one or more second die sets, connecting line assemblies, a connector mounting plate, coolant connectors, an electric connection terminal, an upper mounting plate, a fillister head screw, an elastic washer, a rotary table, a rotary table lower mounting plate, upper mounting plate screws, lower mounting plate screws and a rotating plate mat. The rotary table disclosed by the invention has the functions of automatic positioning and being capable of elastically adjusting rising or falling, so that more than two die sets can perform synchronous assembly or synchronous test simultaneously and accurately on air conditioner assemblies with a plurality of different faces placed on the rotary table, the problem that the operation of the next station of a conventional air conditioner mounting assembly line can be started only after the completion of the operation of the previous station so that time is wasted is solved, the disadvantages of being high in cost, large in volume, difficult to maintain and low in assembling efficiency in the conventional air conditioner mounting assembly line are avoided, and the intelligent tooling plate disclosed by the invention is high in intelligent degrees and low in cost.

Owner:GUANGDONG HUI LIXING SEIKO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com