Tube type heat exchanger forming assembly method

A technology of tube-and-tube heat exchanger and assembly method, which is applied in the field of heat exchanger manufacturing, and can solve the problem of misalignment of heat exchange tube holes, reduced assembly efficiency of tube sheets, heat exchange tubes and baffles, and time-consuming and laborious problems And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

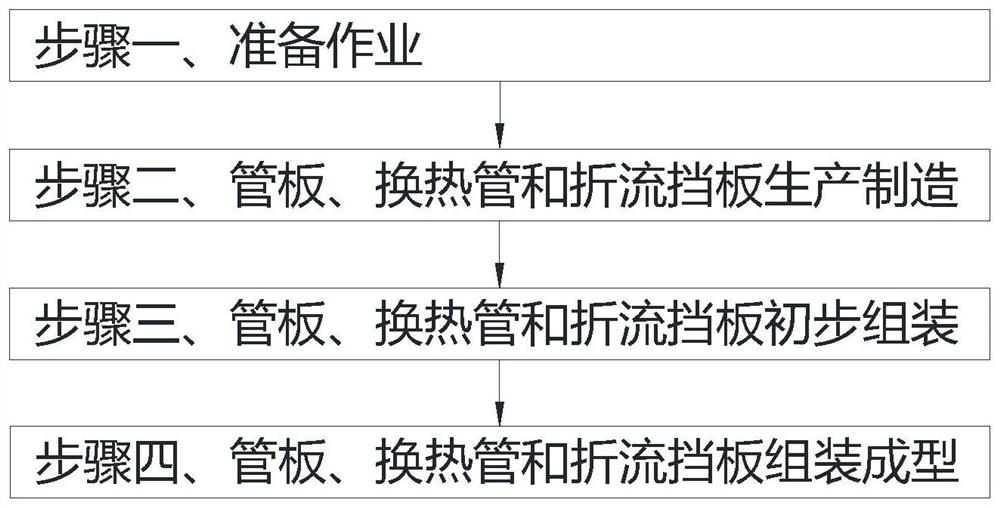

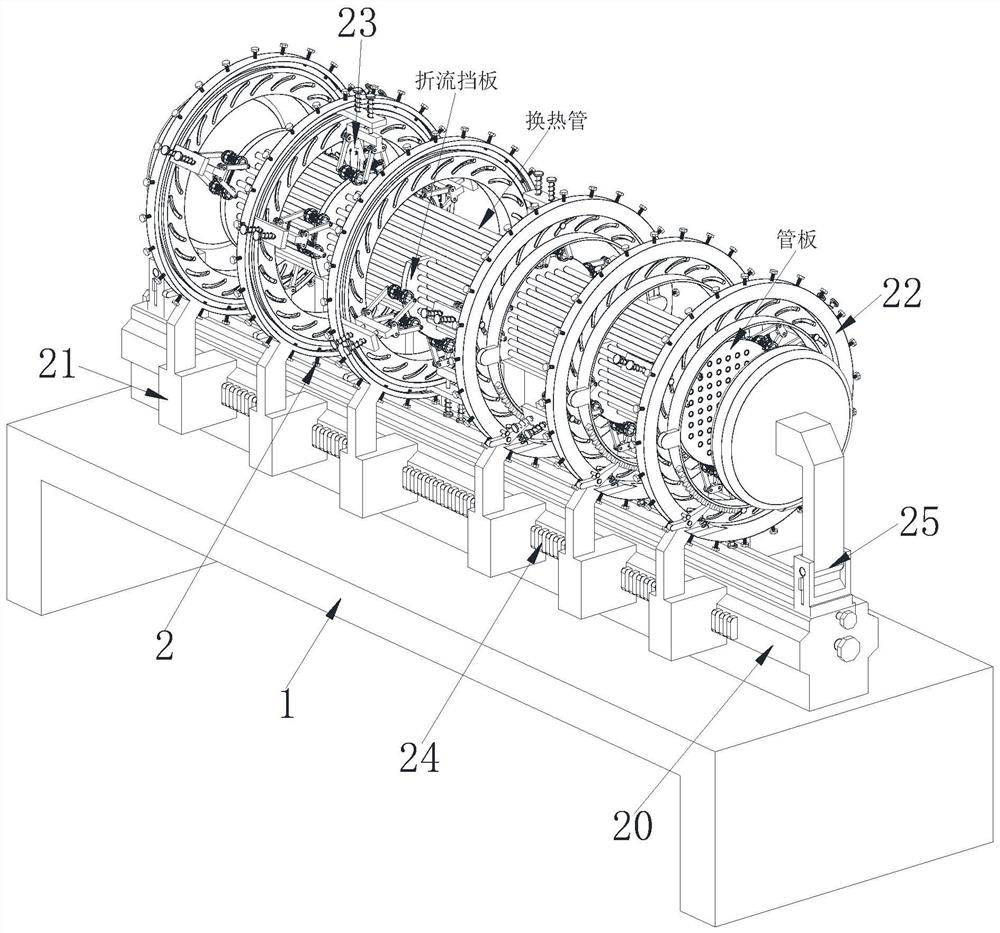

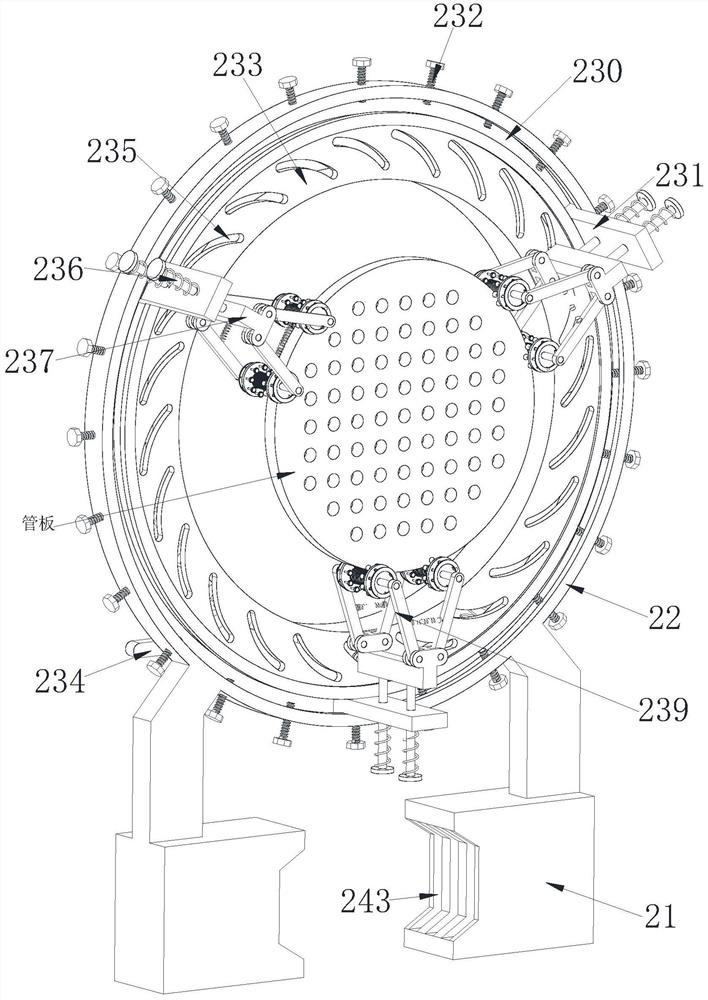

[0035] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0036]A method for forming and assembling a tube-and-tube heat exchanger, which uses a forming and assembling equipment for a tube-and-tube heat exchanger. The forming and assembling equipment for a tube-and-tube heat exchanger includes a base 1 and an auxiliary device 2. The heat exchanger forming and assembly equipment assembles the formed tube sheet, heat exchange tube and baffle plate of the tube-and-tube heat exchanger as follows:

[0037] Step 1. Preparatory work: debug the forming and assembling equipment of the tube-and-tube heat exchanger;

[0038] Step 2. Manufacture of tube sheets, heat exchange tubes and baffles: use existing production equipment to produce the tube sheets, heat exchange tubes and baffles of the tube-and-tube heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com