An improved motor rotor

An improved technology for motor rotors, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of difficult disassembly and reinstallation, affecting the normal operation of the motor, permanent magnet disassembly cannot be disassembled at the same time, and achieves the convenience of later maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

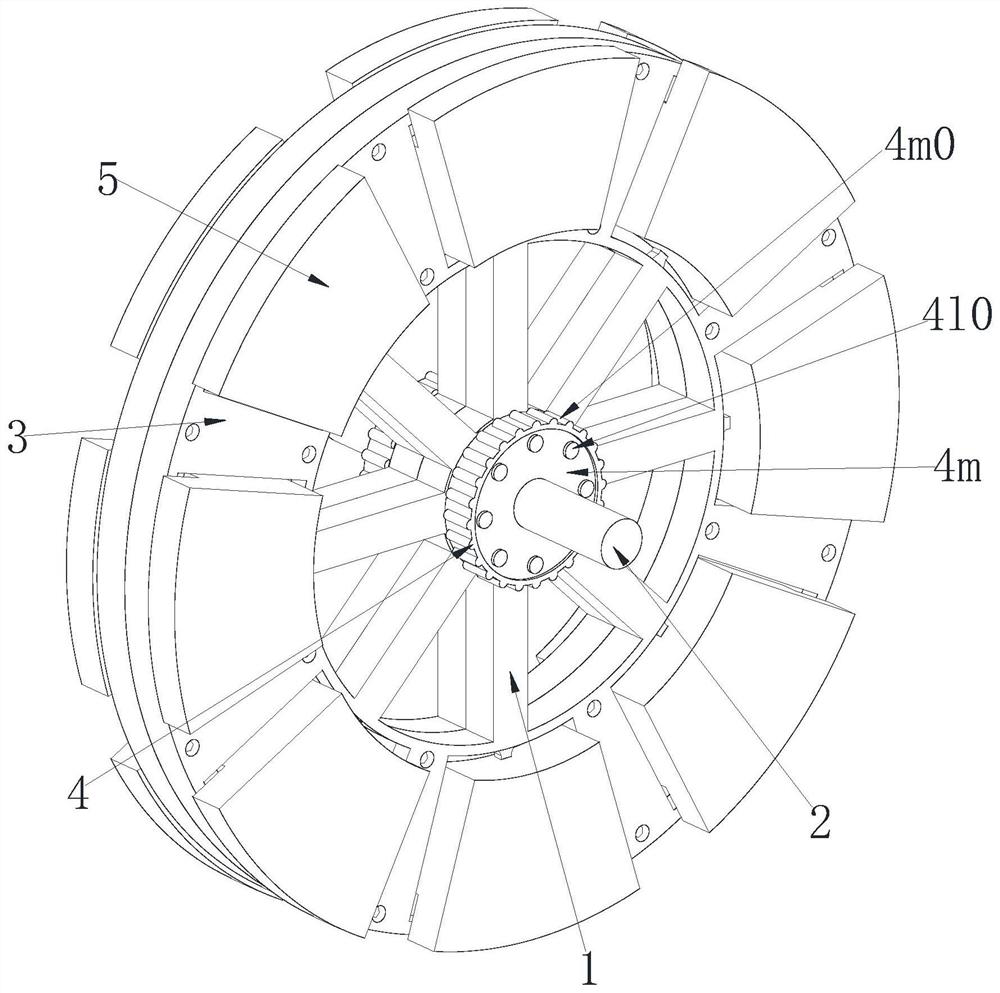

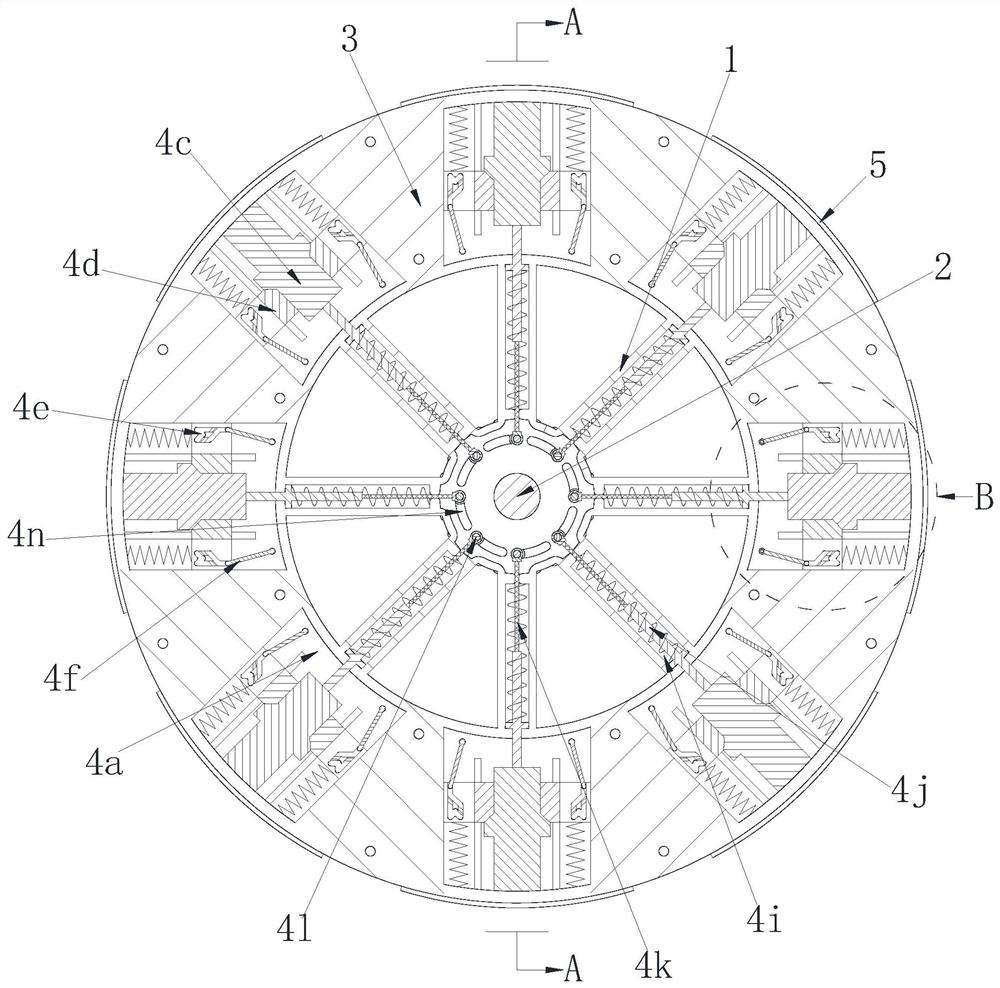

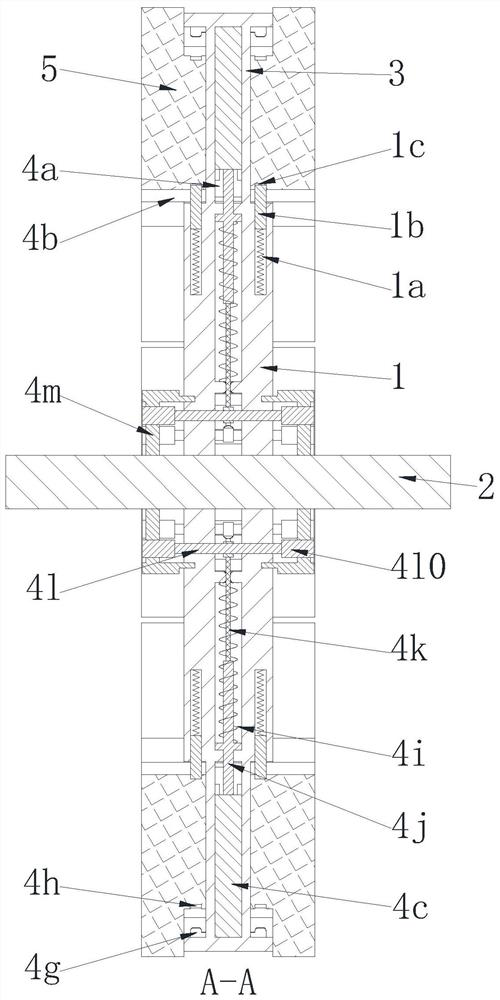

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0030] An improved motor rotor, including a rotor bracket 1, a rotating shaft 2, a rotor yoke 3, an installation unit 4 and a permanent magnet 5, two rotor brackets 1 are symmetrically arranged and connected by bolts, and the two A rotating shaft 2 is fixedly installed in the middle of the rotor bracket 1, and a rotor yoke 3 is fixedly installed on the outer edge of the rotor bracket 1. Several installation units 4 are jointly arranged on the rotor bracket 1 and the rotor yoke 3 along the circumferential direction thereof, and each installation unit 4 is symmetrically installed with a permanent magnet 5; wherein:

[0031] The installation unit 4 includes an installation cavity 4a, an installation groove 4b, an installation top block 4c, an installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com