Manufacturing process of oil-immersed transformer

An oil-immersed transformer and manufacturing process technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of transformer dislocation, high labor intensity, transformer falling, etc., to improve stability and assembly. Quality and efficiency, the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

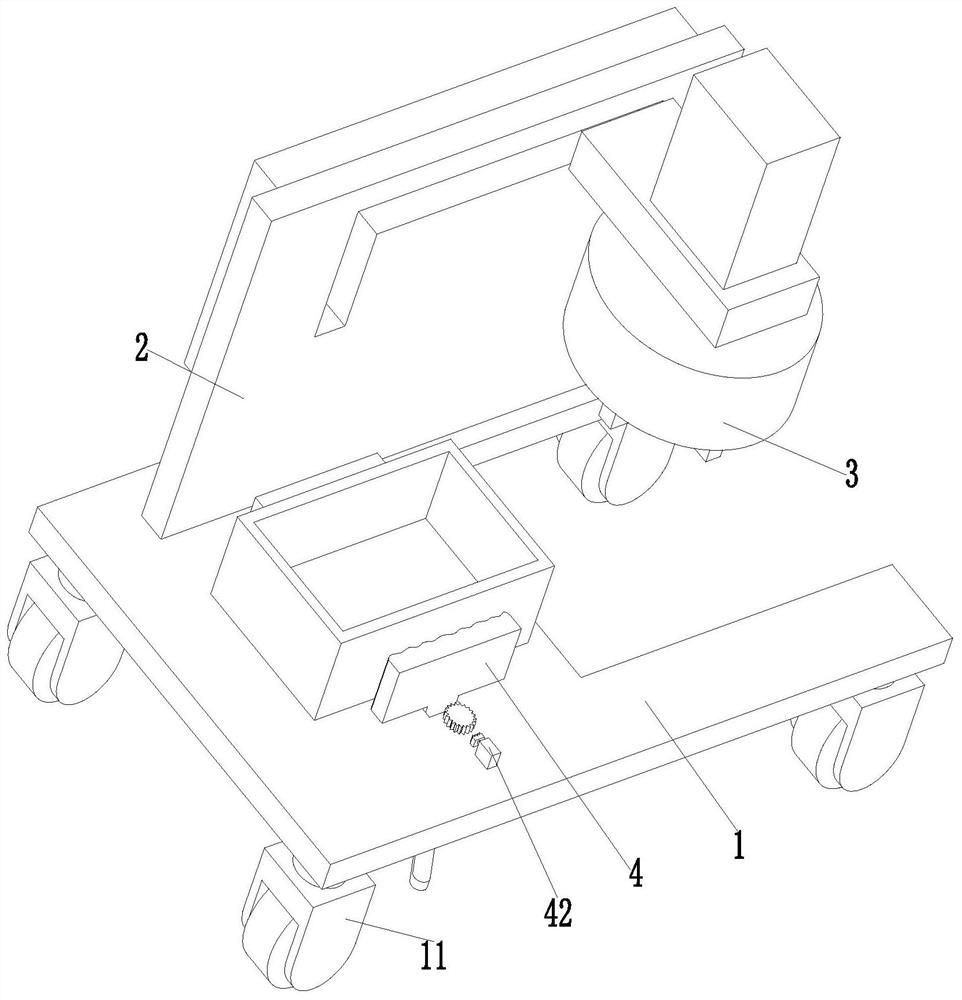

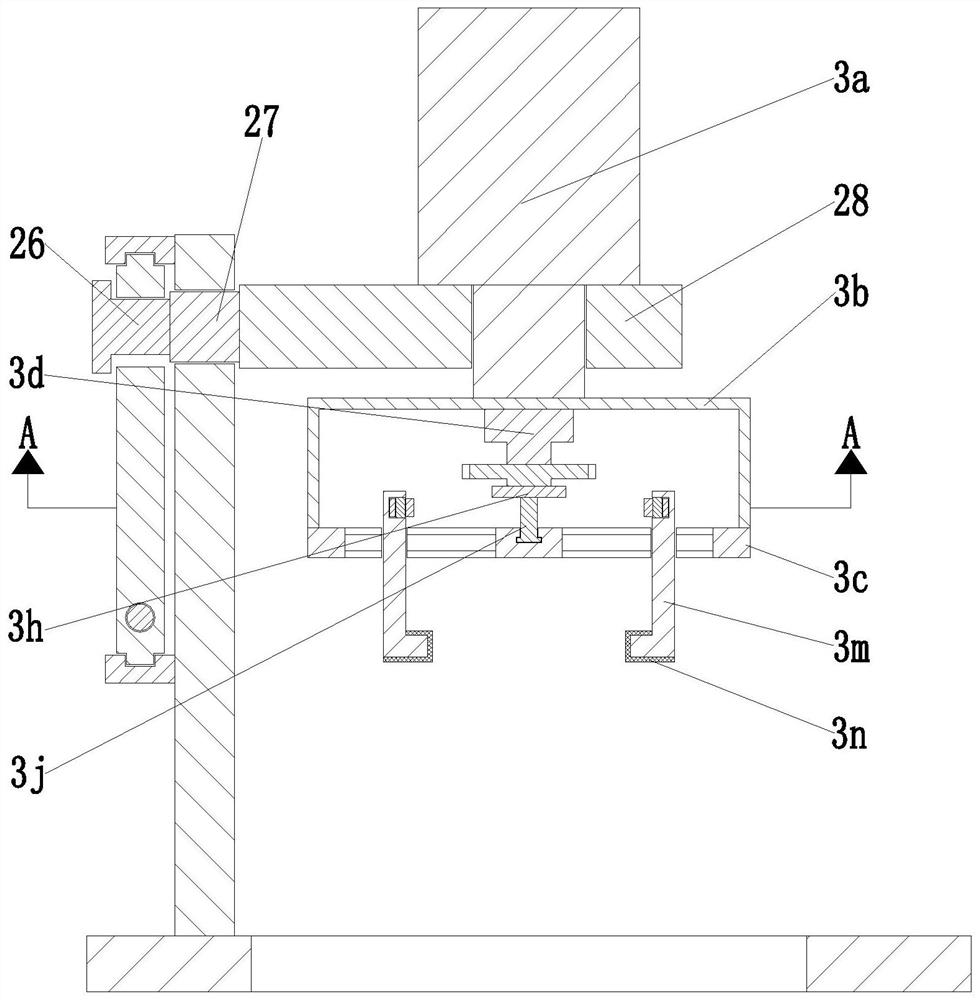

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

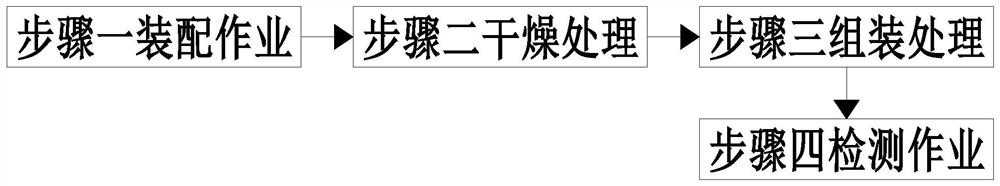

[0033] like Figure 1 to Figure 8 As shown, an oil-immersed transformer manufacturing process mainly includes the following steps:

[0034] Step 1, assembly operation, manually assembling the components of the transformer to obtain the assembled transformer;

[0035] Step 2, drying treatment, drying the assembled transformer obtained in step 1 to obtain a dried transformer;

[0036] Step 3, assembly process, install the dried transformer obtained in step 2 into the oil tank through the transformer assembly equipment, and fasten the oil tank and the transformer to obtain the assembled oil-immersed transformer;

[0037] Step 4, inspection operation, the inspection operation is performed on the assembled oil-immersed transformer obtained in step 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com