Piston air compressor pump head assembling machinery and assembling method

A technology of air compressors and pump heads, which is applied in the direction of workpiece clamping devices, metal processing, metal processing equipment, etc., can solve problems such as low efficiency, difficult pump head shells, and continuous operations that are difficult to mass-produce, so as to reduce shaking The possibility of deflection, the improvement of work efficiency, and the effect of stable clamping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

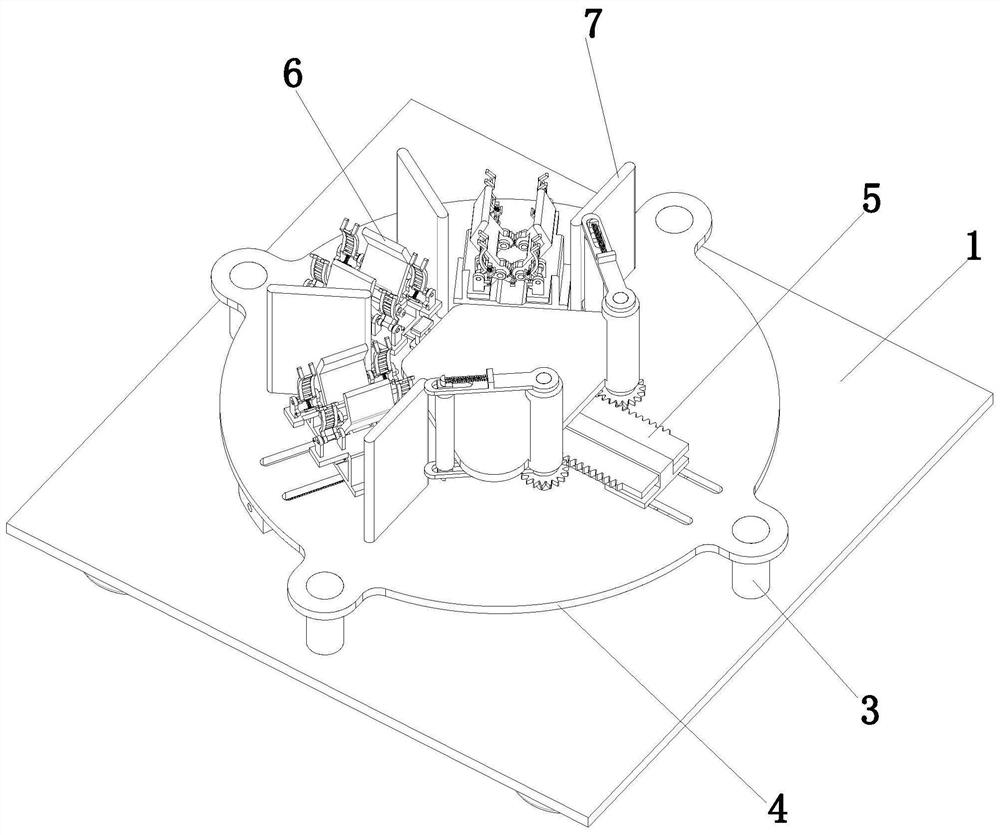

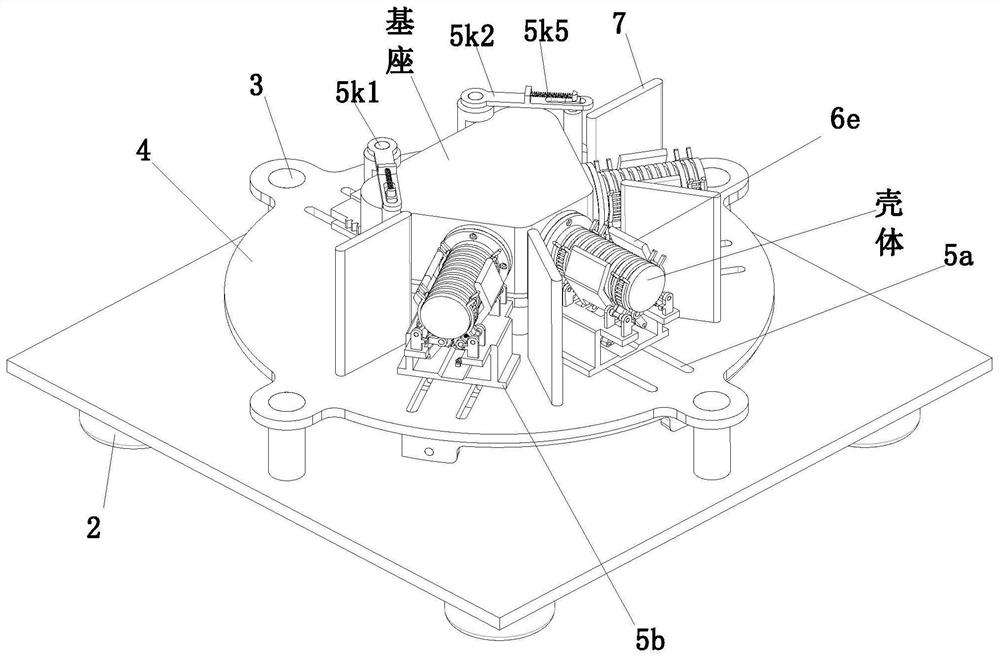

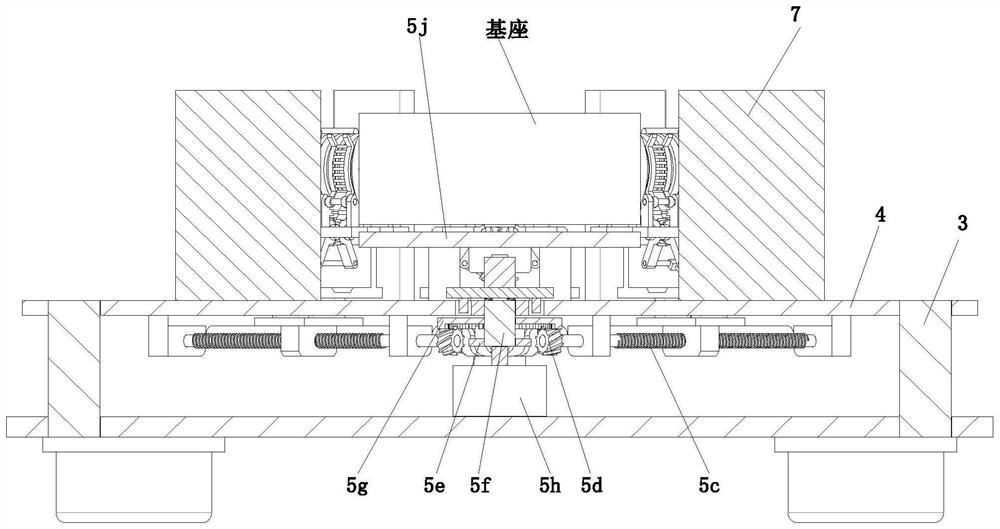

[0035] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0036] A pump head assembly machine for a piston air compressor, comprising a mounting base plate 1, a supporting foot 2, a supporting rod 3, a supporting plate 4, a positioning mechanism 5 and a clamping mechanism 6, and the corners around the lower end surface of the mounting base plate 1 are evenly installed There are support feet 2, support rods 3 are evenly installed at the corners around the upper end surface of the installation base plate 1, support discs 4 are installed on the upper ends of the support rods 3, positioning mechanisms 5 are installed on the support disc 4, and multiple A clamping mechanism 6 is assembled, and the clamping mechanism 6 is connected with the positioning mechanism 5 .

[0037] The positioning mechanism 5 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com