A cutting device for building sound insulation panels

A sound insulation board and cutting technology, which is applied in the direction of sound insulation, building components, building structures, etc., can solve the problems of reducing the efficiency of sound insulation board installation, low cutting efficiency, and high labor intensity, so as to ensure the quality of cutting and improve Cutting quality and efficiency, labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

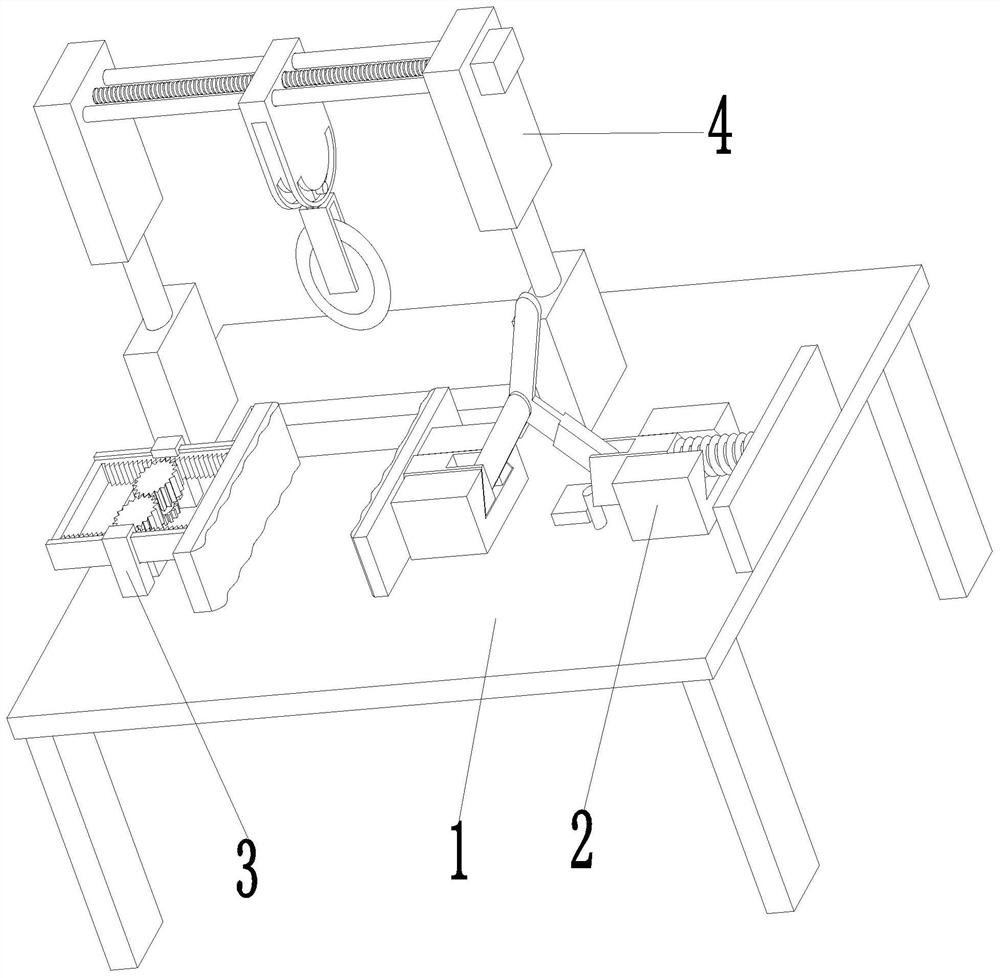

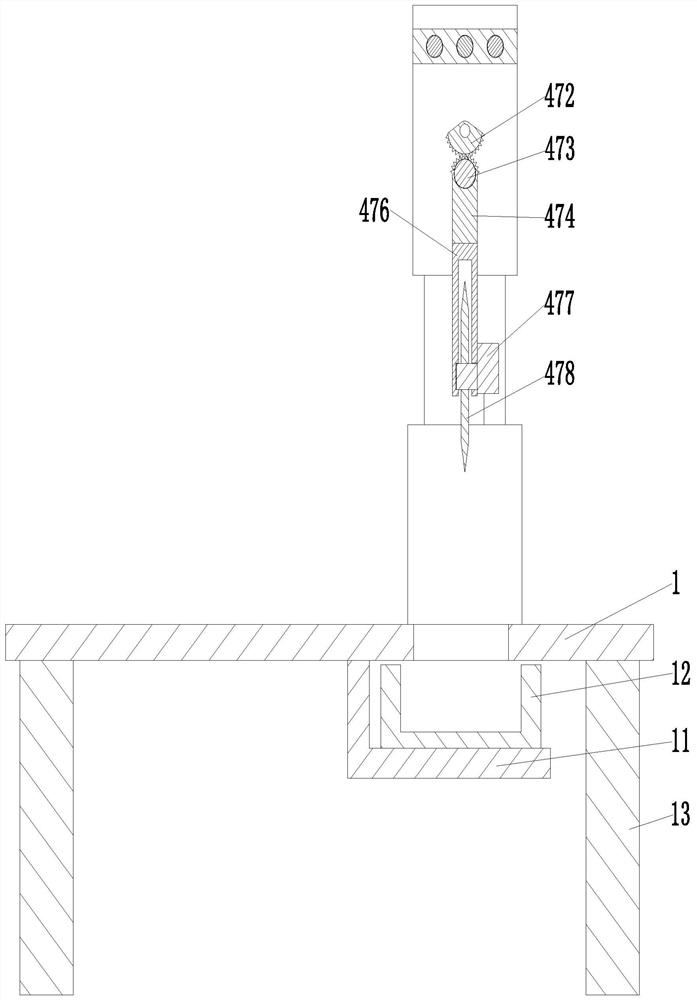

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

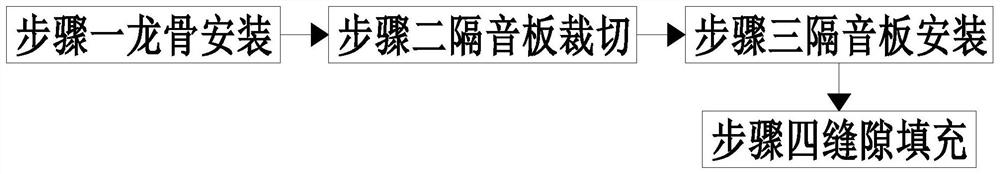

[0034] like Figure 1 to Figure 8 As shown, the method for installing the sound insulation panel using the cutting equipment for building sound insulation panels mainly includes the following steps:

[0035] Step 1, keel installation, manually use tools to install the keel, and get the keel after installation;

[0036] Step 2, cutting the sound insulation board, placing the sound insulation board on the sound insulation board cutting equipment to cut the sound insulation board into the required size, and obtaining the cut sound insulation board;

[0037] Step 3, installing the sound insulation board, installing the cut and completed sound insulation board obtained in step 2 on the installed keel obtained in step 1, to obtain the installed sound insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com