Steel structure cross beam splicing equipment and steel structure cross beam splicing process

A technology for steel structures and beams, which is applied to building construction, construction, and building material processing. It can solve the problems of manual calibration and alignment, labor-intensive manufacturing, and many rods and nodes, so as to improve efficiency and accuracy. The effect of sex, reducing labor intensity and simplifying the work process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

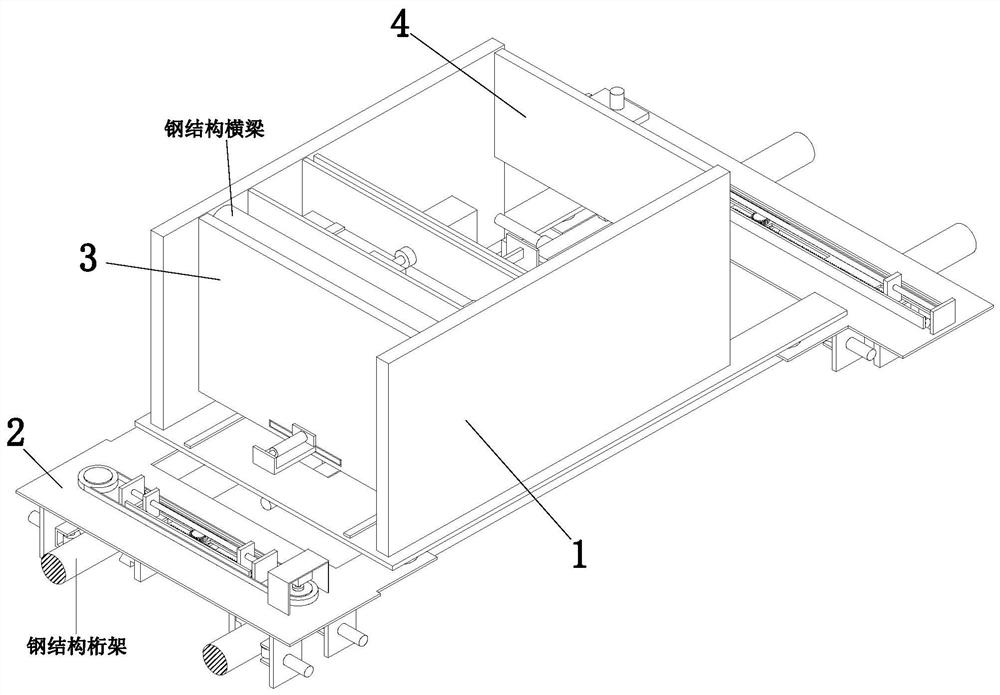

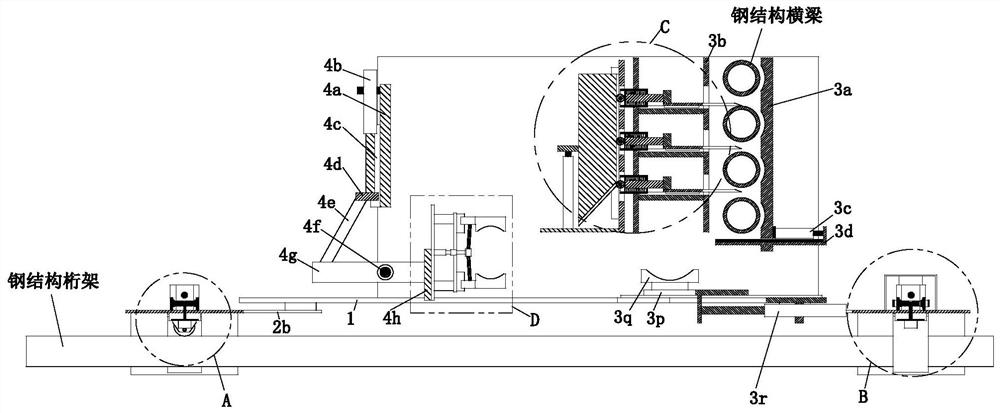

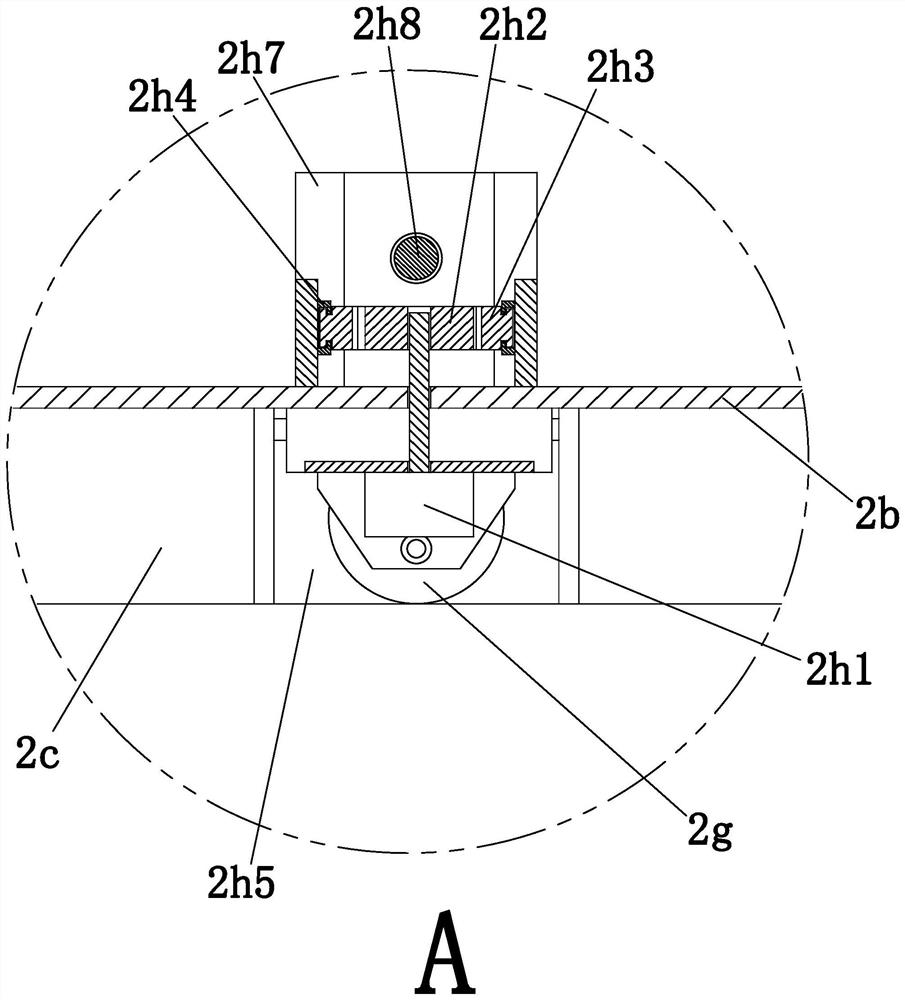

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 11 , to further elaborate the present invention.

[0032] An assembly equipment for steel structure beams, comprising a mobile 匚-shaped bottom plate 1, a traveling mechanism 2, a blanking mechanism 3 and a clamping mechanism 4, the mobile 匚-shaped bottom plate 1 is placed with the opening upward, and the mobile 匚-shaped bottom plate 1 The traveling mechanism 2 is mounted on the lower side through rotation, the blanking mechanism 3 is installed between the inner walls of the two sides of the mobile bottom plate 1, and the clamping mechanism 4 is installed between the inner walls of the two sides of the mobile bottom plate 1, and the clamping mechanism 4 is located at Blanking mechanism 3 rear.

[0033] The traveling mechanism 2 includes a traveling bottom plate 2a, a traveling bottom plate 2b, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com