Lithium-silicon alloy negative electrode preparation method and sulfide all-solid-state battery

An all-solid-state battery, lithium-silicon alloy technology, applied in battery electrodes, secondary batteries, electrode manufacturing, etc., can solve the problems of poor negative electrode conductivity and reduce battery capacity, to improve energy density, improve cycle life, inhibit formation and effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

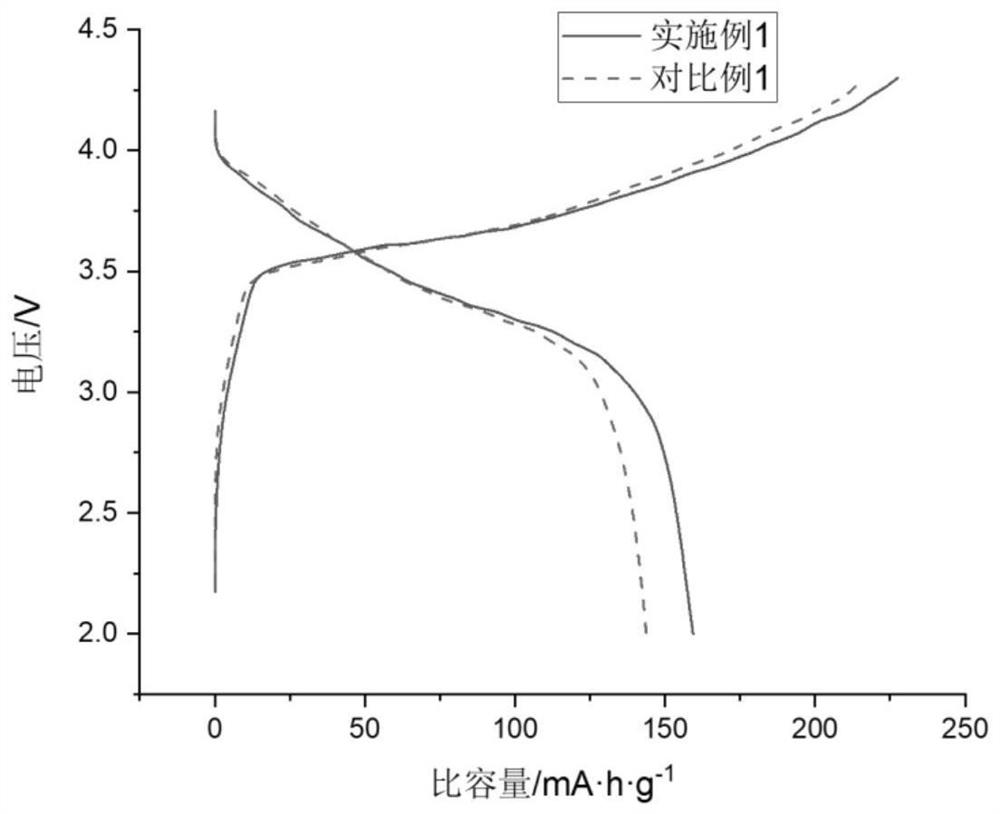

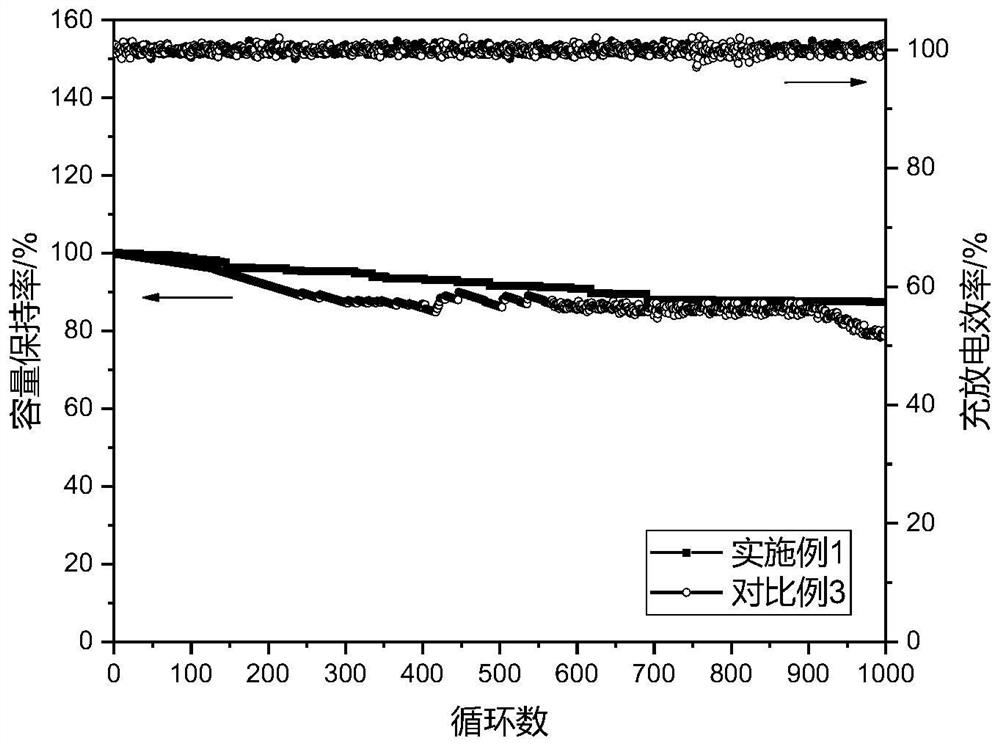

Embodiment 1

[0053] In an argon-filled glove box, place about 0.3 g of lithium powder and 0.18 g of micron-sized silicon powder in an agate ball mill jar, add about 9.6 g of ball milling beads, add 3 mL of hexane as a lubricant, and use a tape to grind the ball. The jar was well sealed, and the glove box was removed for ball milling. The ball milling time was 100 min and the rotation speed was 500 rpm. Put the ball-milled Li-Si mixed powder in a glove box to volatilize the solvent for more than 12 hours, and finally obtain Li 4.4 Si alloy powder. Xiang Li 4.4 The Si alloy powder was added with 10% (mass ratio) polytetrafluoroethylene (PTFE) as a binder, and 5% (mass ratio) conductive carbon fiber (VCGF) was manually ground in a mortar for 10 min to mix it uniformly. Weigh 10 mg of the above powder and place it in a tableting die with a diameter of 10 mm, press it into a tablet on the surface of the Cu foil current collector, and obtain Li after demolding. 4.4 Si alloy negative pole piec...

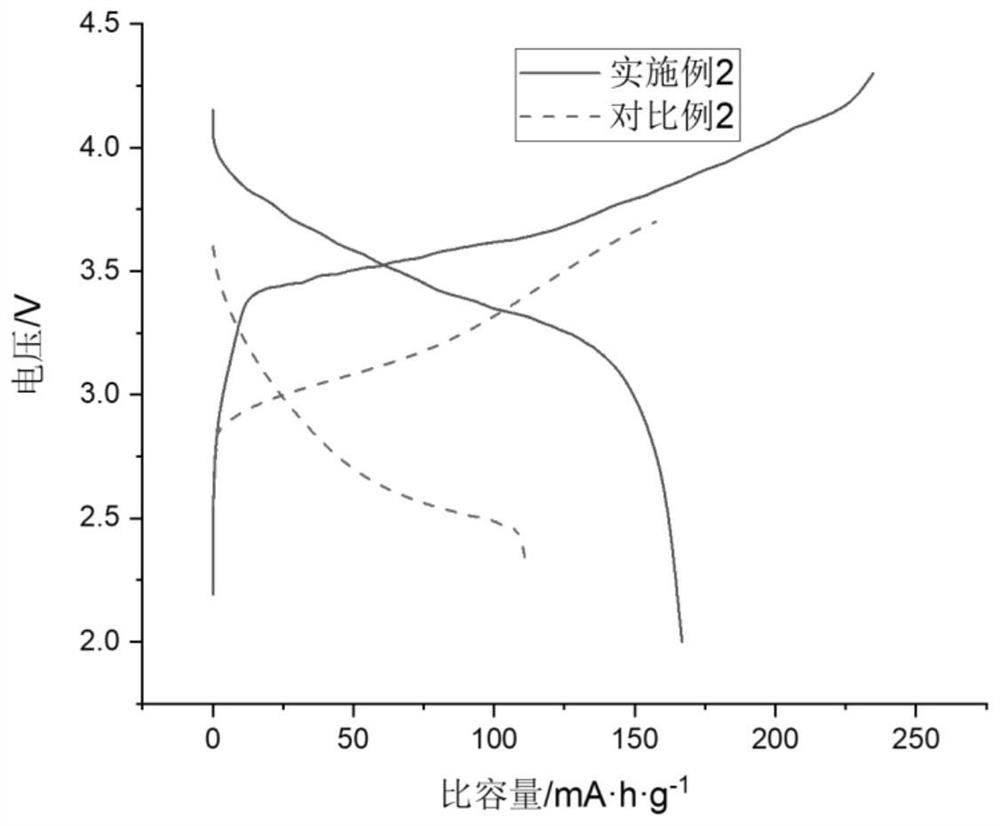

Embodiment 2

[0055] In an argon-filled glove box, place about 0.263g of lithium powder and 0.28g of micron silicon powder in an agate ball mill jar, add about 27g of ball milling beads, add 5mL of hexane as a lubricant, and use a tape to seal the ball mill jar. Seal well, remove the glove box, and perform ball milling. The ball milling time is 100 min, and the rotation speed is 550 rpm. Put the ball-milled Li-Si mixed powder in a glove box to evaporate the solvent for 15 hours, and finally obtain Li 3.75 Si alloy powder. Xiang Li 3.75 The Si alloy powder was added with 12% (mass ratio) hydroxypropyl methylcellulose (HPMC) as a binder, and 8% (mass ratio) conductive carbon black (HGCB) was manually ground in a mortar for 10 min to make it Mix well and get. Weigh 10 mg of the above powder and place it in a tableting die with a diameter of 10 mm, press it into a tablet on the surface of the Cu foil current collector, and obtain Li after demolding. 3.75 Si alloy negative pole piece, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com