Modified lithium-ion battery cathode material and preparation method thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficult practicality, high price, capacity loss, etc., to improve air storage performance, improve electrochemical performance, and save energy. The effect of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

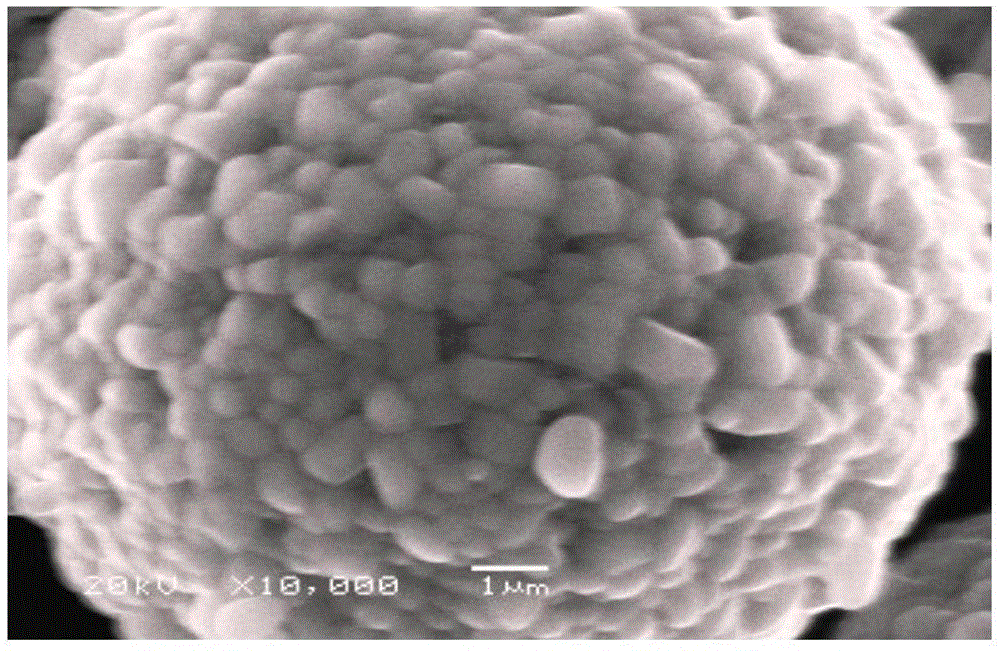

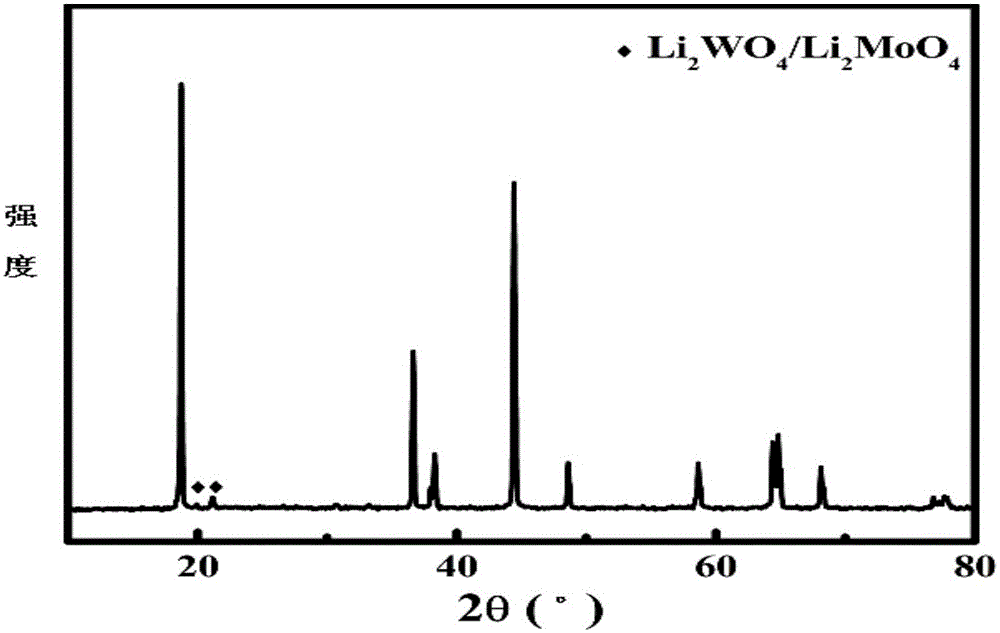

[0033] A modified lithium ion battery positive electrode material of the present invention includes LiNi as the positive electrode material body 0.5 Co 0.2 Mn 0.3 O 2 And coated in LiNi 0.5 Co 0.2 Mn 0.3 O 2 Lithium tungstate molybdate layer on the surface, in which the lithium tungstate molybdate layer and LiNi 0.5 Co 0.2 Mn 0.3 O 2 The mass ratio is 3:100.

[0034] The preparation method of the modified lithium ion battery cathode material of this embodiment includes the following steps:

[0035] 1) APT, an intermediate product of lithium acetate and tungsten metallurgical process that has not been removed from molybdenum, is added to water to form a solution.

[0036] 2) Put LiNi 0.5 Co 0.2 Mn 0.3 O 2 (The added amount is based on lithium tungstate molybdate and LiNi 0.5 Co 0.2 Mn 0.3 O 2 The mass ratio is calculated by the amount of 3:100) added to the solution after step 1), after stirring uniformly at a constant temperature of 50°C, it is placed in a blast drying oven at 150°C f...

Embodiment 2

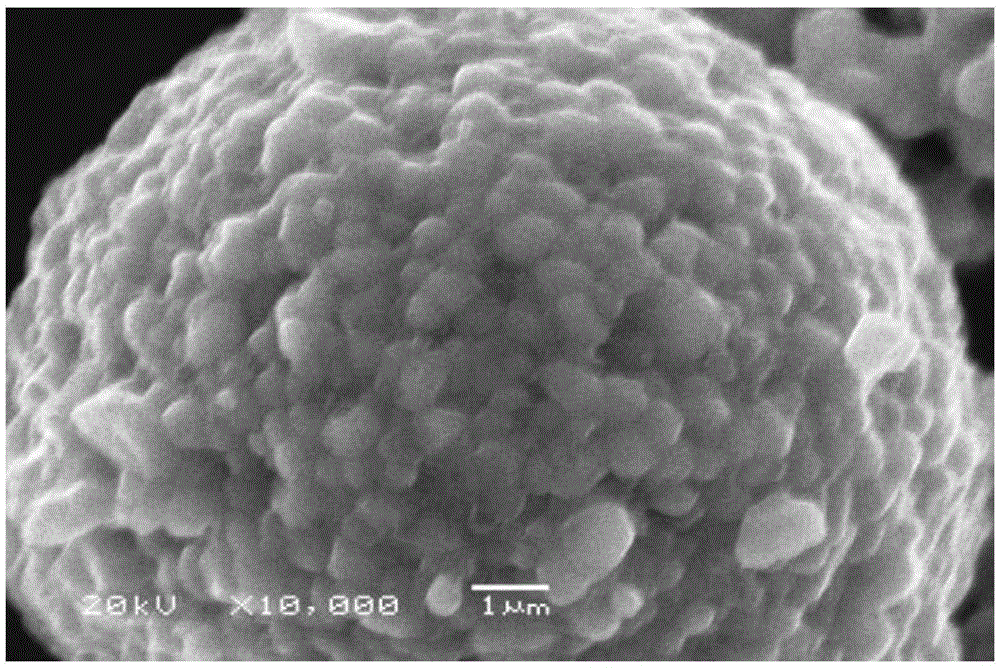

[0040] A modified lithium ion battery cathode material of the present invention, comprising LiNi as the cathode material body 0.8 Co 0.1 Mn 0.1 O 2 And coated in LiNi 0.8 Co 0.1 Mn 0.1 O 2 Lithium tungstate molybdate layer on the surface, in which the lithium tungstate molybdate layer and LiNi 0.8 Co 0.1 Mn 0.1 O 2 The mass ratio is 0.5:100.

[0041] The preparation method of the modified lithium ion battery cathode material of this embodiment includes the following steps:

[0042] 1) Put LiOH, H 2 WO 4 And H 2 MoO 4 Add the mixture of water and alcohol to dissolve to form a solution.

[0043] 2) Put LiNi 0.8 Co 0.1 Mn 0.1 O 2 (The added amount is based on lithium tungstate molybdate and LiNi 0.8 Co 0.1 Mn 0.1 O 2 The mass ratio is 0.5:100) added to the solution after step 1), stirred at a constant temperature of 50°C, and then placed in a blast drying oven at 120°C for drying to obtain a precursor.

[0044] 3) The precursor is heated to 350°C at a heating rate of 5°C / min for firing fo...

Embodiment 3

[0050] A modified lithium ion battery positive electrode material of the present invention, comprising a positive electrode material body Li 1.2 Mn 0.54 Co 0.13 Ni 0.13 O 2 And coated in Li 1.2 Mn 0.54 Co 0.13 Ni 0.13 O 2 The lithium tungstomolybdate layer on the surface, in which the lithium tungstomolybdate layer and Li 1.2 Mn 0.54 Co 0.13 Ni 0.13 O 2 The mass ratio is 2:100.

[0051] The preparation method of the modified lithium ion battery cathode material of this embodiment includes the following steps:

[0052] 1) Put lithium acetate, (NH 4 ) 10 W 12 O 41 ·NH 2 O and (NH 4 ) 2 MoO 4 Add ammonia to dissolve to form a solution.

[0053] 2) Put Li 1.2 Mn 0.54 Co 0.13 Ni 0.13 O 2 (The addition amount is based on lithium tungstate molybdate and Li 1.2 Mn 0.54 Co 0.13 Ni 0.13 O 2 The mass ratio is 2:100) added to the solution after step 1), stirred at a constant temperature of 80°C, and then placed in a blast drying oven at 120°C for drying to obtain a precursor.

[0054] 3) The precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com