Modification method of ternary anode material of lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as hindering lithium-ion transmission, lack of lithium-ion channels, and affecting material rate performance, etc., to achieve material processing performance and Excellent electrochemical performance, simple preparation method, and the effect of improving air storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

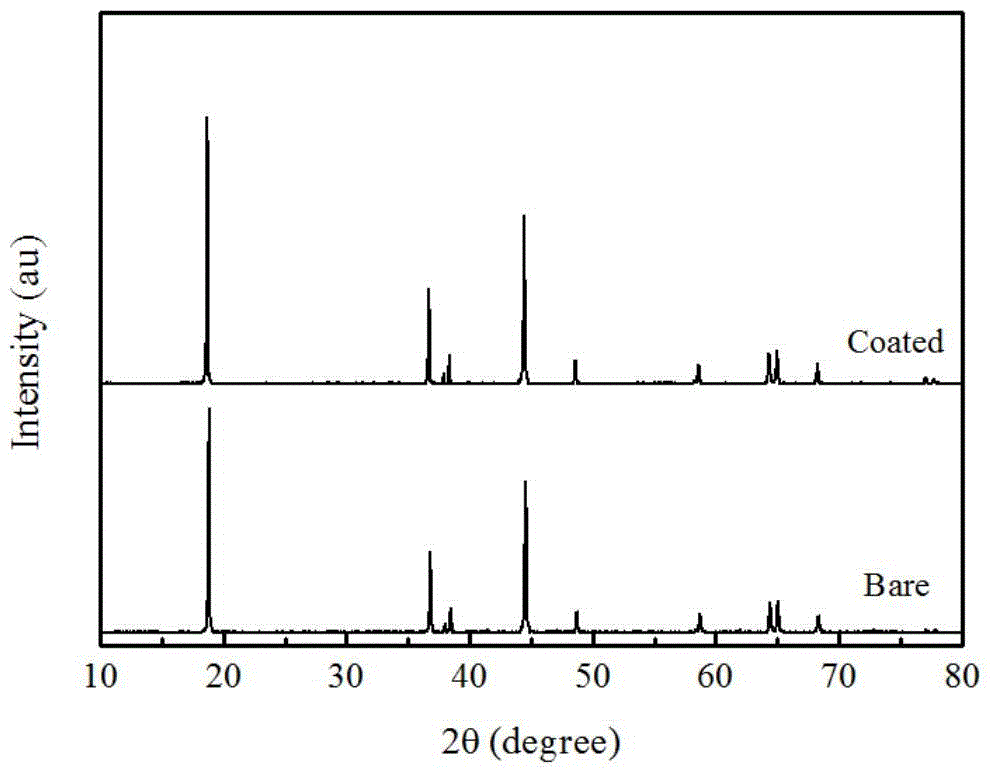

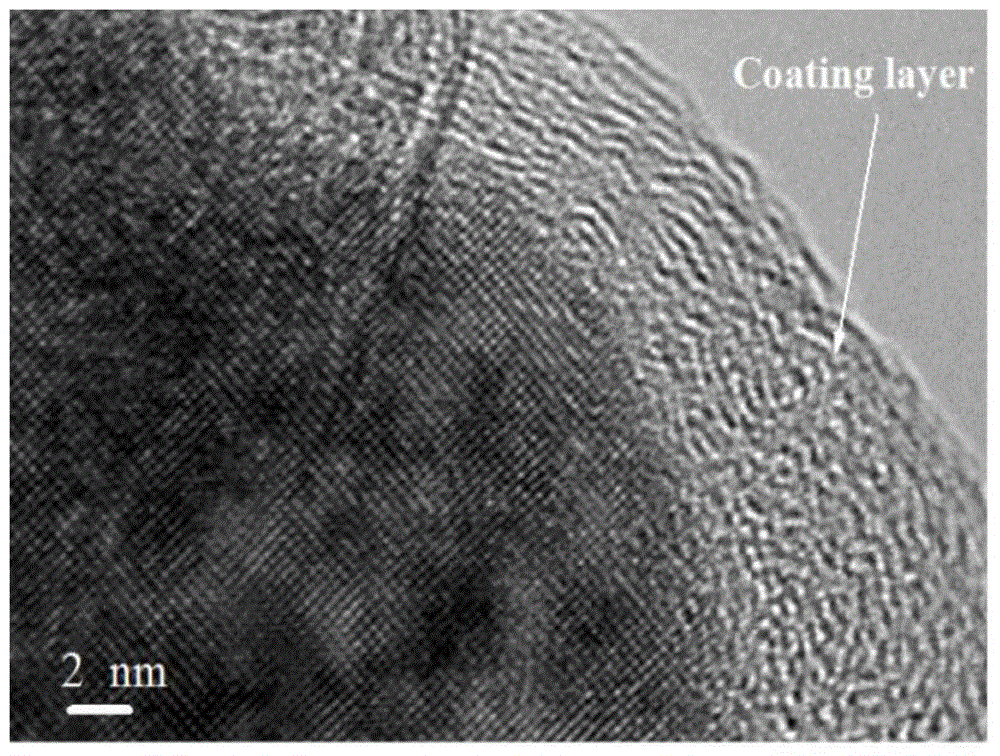

[0023] Example 1: NH with a molar ratio of 2:1:2 4 H 2 PO 4 , V 2 O 5 And C 6 H 8 O 7 ·H 2 O is placed in deionized water to control the concentration of vanadium ions to 0.1 mol L -1 , Add ammonia water to adjust pH=6, stir at 80℃ to form a solution; VOPO 4 The amount of coating is 1% to calculate the required LiNi 0.5 Co 0.2 Mn 0.3 O 2 The quality of the deionized water is placed in the solution and diluted with deionized water; the quality of deionized water is the same as that of LiNi 0.5 Co 0.2 Mn 0.3 O 2 The mass ratio is 1:1; after mixing uniformly, spray drying, control the inlet air temperature to 150°C, and the outlet temperature to 100°C. The obtained powder is calcined in oxygen at 850°C for 180 minutes, cooled in the furnace and sieved to obtain VOPO 4 LiNi battery with 1% coating 0.5 Co 0.2 Mn 0.3 O 2 Cathode material. From figure 1 It can be seen that there is no impurity peak in the XRD spectrum of the coated sample. From figure 2 It can be seen that there is a u...

Embodiment 2

[0024] Example 2: NH with a molar ratio of 2:1:2 4 H 2 PO 4 , V 2 O 5 And C 6 H 8 O 7 ·H 2 O is placed in deionized water to control the concentration of vanadium ions to 0.3 mol L -1 , Add ammonia water to adjust pH=5, stir at 70℃ to form a solution; take VOPO 4 The amount of cladding is 3% to calculate the required LiNi 0.8 Co 0.1 Mn 0.1 O 2 The quality of the deionized water is placed in the solution and diluted with deionized water. 0.5 Co 0.2 Mn 0.3 O 2 The mass ratio is 2:1; after mixing uniformly, spray drying, control the inlet air temperature to 120°C, and the outlet temperature to 100°C. The obtained powder is calcined in oxygen at 700°C for 300 minutes, cooled in the furnace and sieved to obtain VOPO 4 LiNi battery with 3% coating 0.8 Co 0.1 Mn 0.1 O 2 Cathode material. The sample was made into a button battery and charged to 4.3V with 0.1C, then placed in a 90°C constant temperature box for 5 hours, and then subjected to a 2C cycle test. From Figure 4 It can be seen ...

Embodiment 3

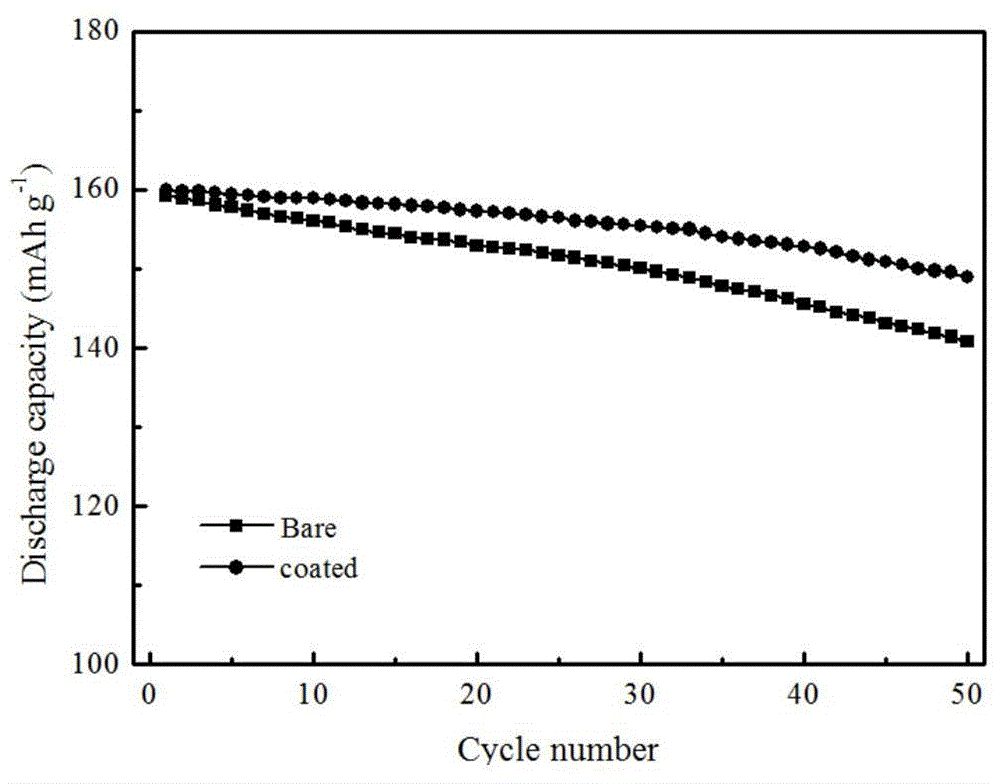

[0027] Example 3: NH with a molar ratio of 2:1:2 4 H 2 PO 4 , V 2 O 5 And C 6 H 8 O 7 ·H 2 O is placed in deionized water to control the concentration of vanadium ions to 0.05 mol L -1 , Add ammonia water to adjust pH=7, stir at 60℃ to form a solution; take VOPO 4 The coating amount is 0.5% to calculate the required LiNi 0.6 Co 0.2 Mn 0.2 O 2 The quality of the deionized water is placed in the solution and diluted with deionized water. 0.5 Co 0.2 Mn 0.3 O 2 The mass ratio is 0.5:1; after mixing uniformly, spray drying, control the inlet air temperature to 150°C and the outlet temperature to 110°C. The obtained powder is calcined in oxygen at 800°C for 240 minutes, cooled in the furnace and sieved to obtain VOPO 4 LiNi battery with 0.5% coating 0.6 Co 0.2 Mn 0.2 O 2 Cathode material. The samples were made into button batteries to test the electrochemical performance, from Figure 5 It can be seen that the cycle performance of the coated sample is better than that of the uncoated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com