Dual capacity compressor

A compressor and double-capacity technology, which is applied in the field of compressors, can solve problems such as the difficulty in realizing the precise movement of the eccentric cam and the inability to guarantee the operation reliability, so as to achieve the effect of improving the operation efficiency and ensuring the operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

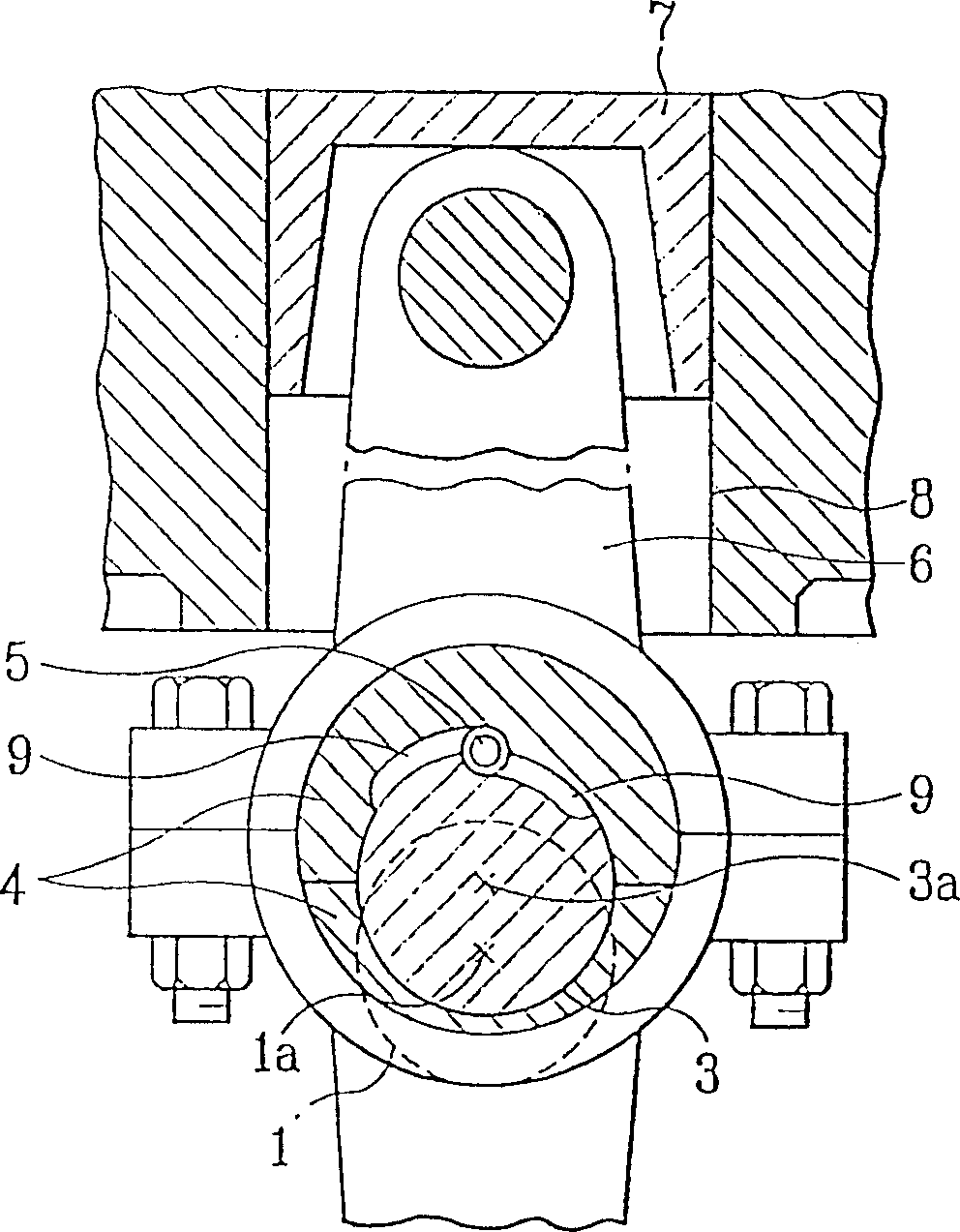

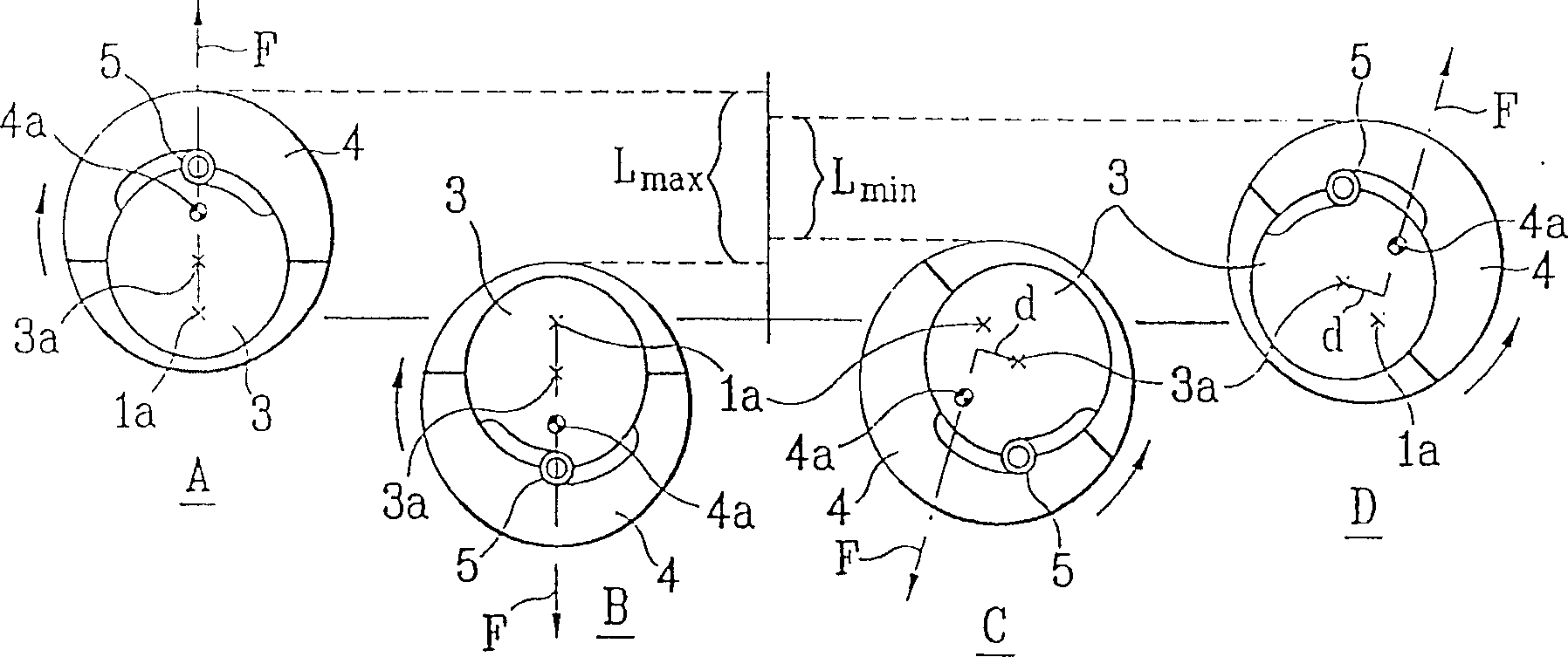

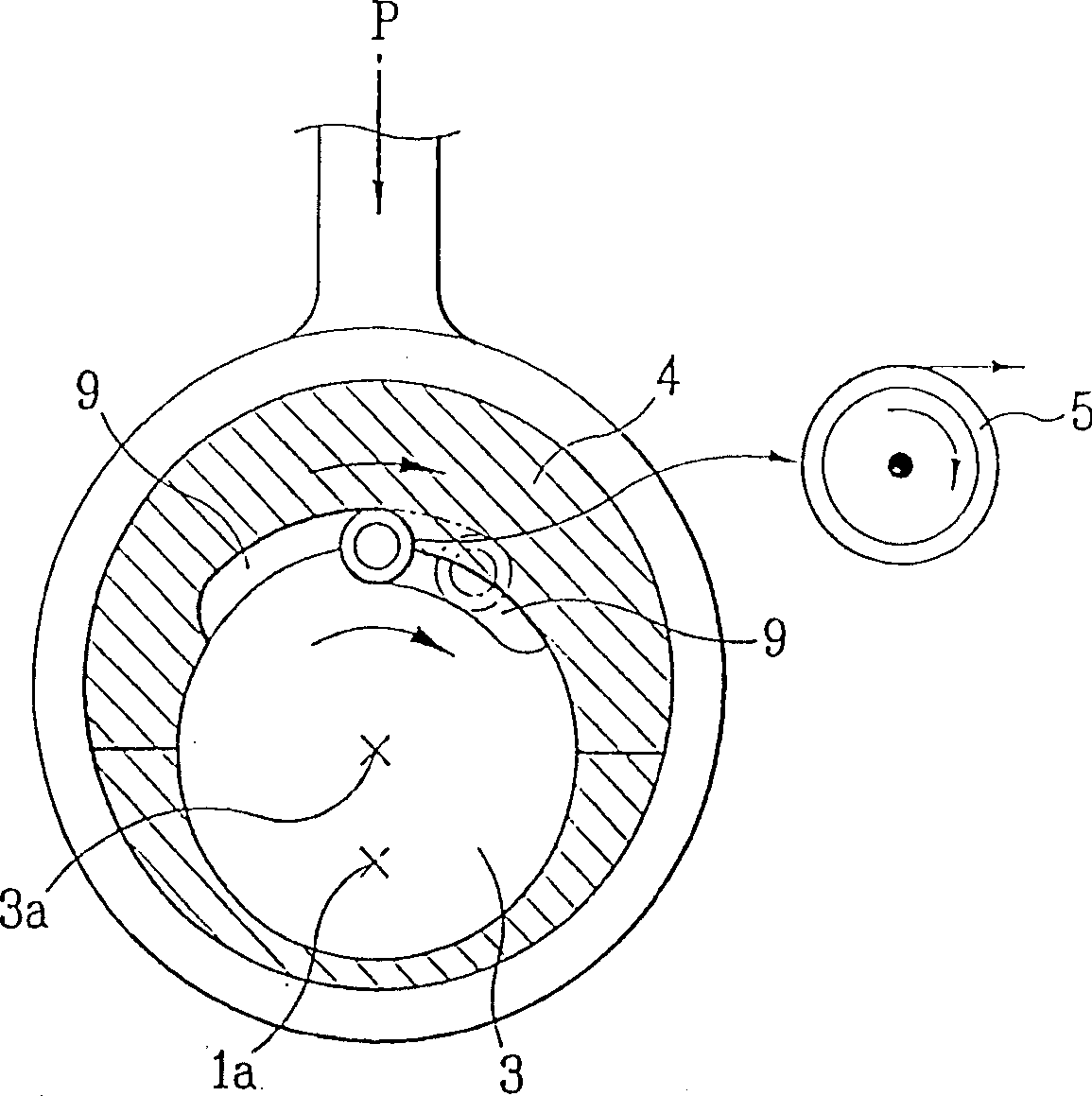

[0046] Reference will now be made in detail to the preferred embodiments of the present invention, several examples of which are illustrated in the accompanying drawings. In describing the embodiments of the present invention, the same components will be denoted by the same names and reference numerals, and their repeated descriptions will be omitted. The overall structure of the dual-capacity compressor described in the present invention will refer to Figure 4 to describe.

[0047] refer to Figure 4 , the dual-capacity compressor of the present invention includes: a power generation part 20, which is located at the lower part of the compressor, for generating and transmitting required power; a compression part 30, which is located above the power generation part 20, to use power to compress the working fluid . Also, in addition to these common parts, the dual capacity compressor includes a stroke changing part 40 connected between the power part 20 and the compressing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com