Dual capacity compressor

A compressor and dual-capacity technology, applied in the field of compressors, can solve problems such as inability to guarantee work stability, difficulty in accurate movement, etc., and achieve the effects of improving work stability and efficiency and preventing relative rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

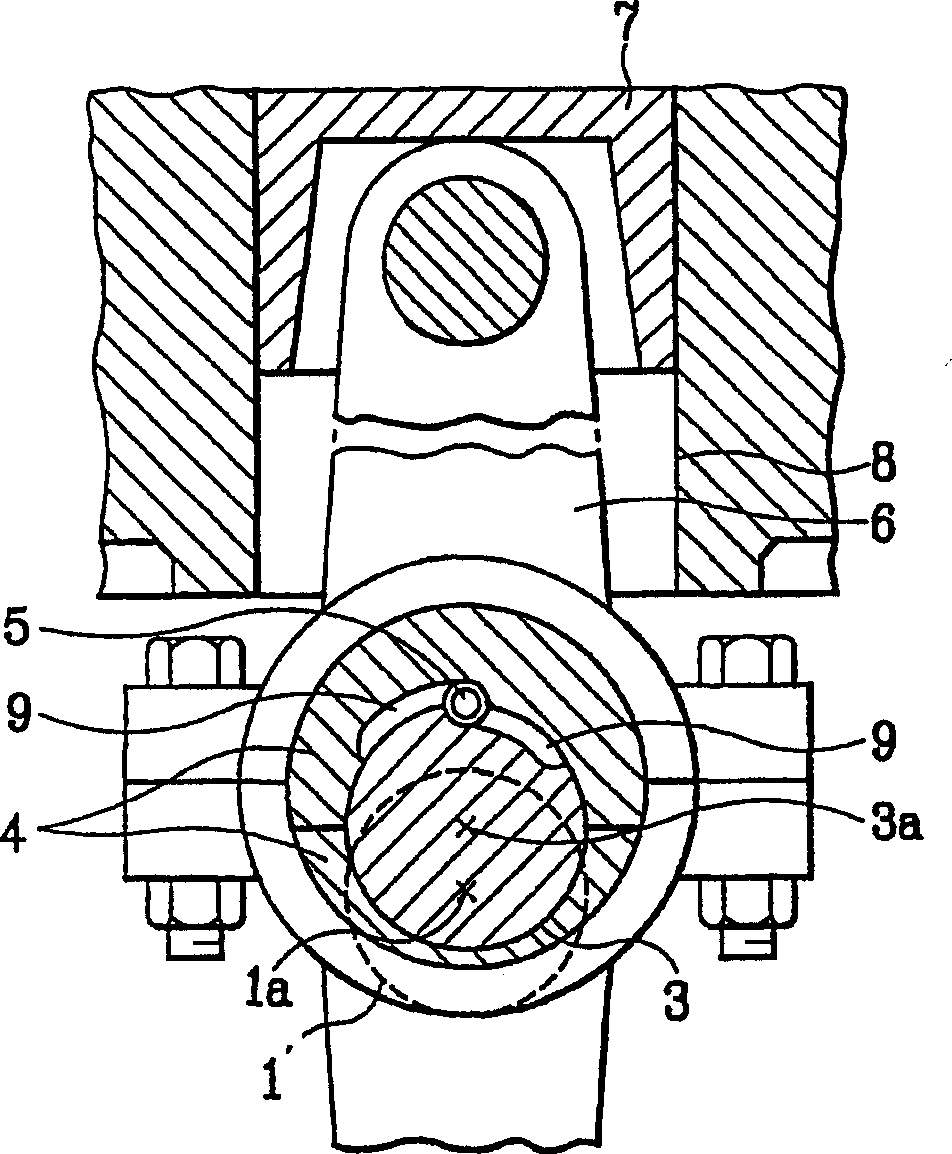

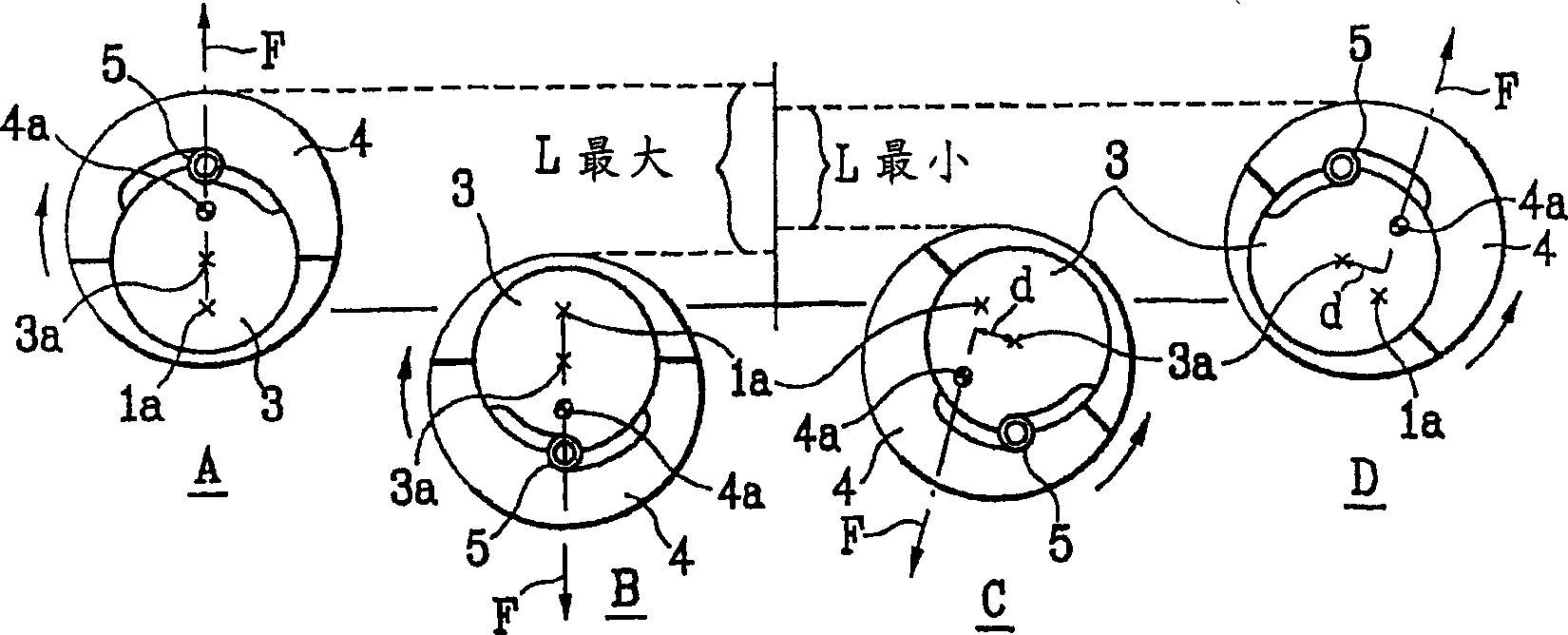

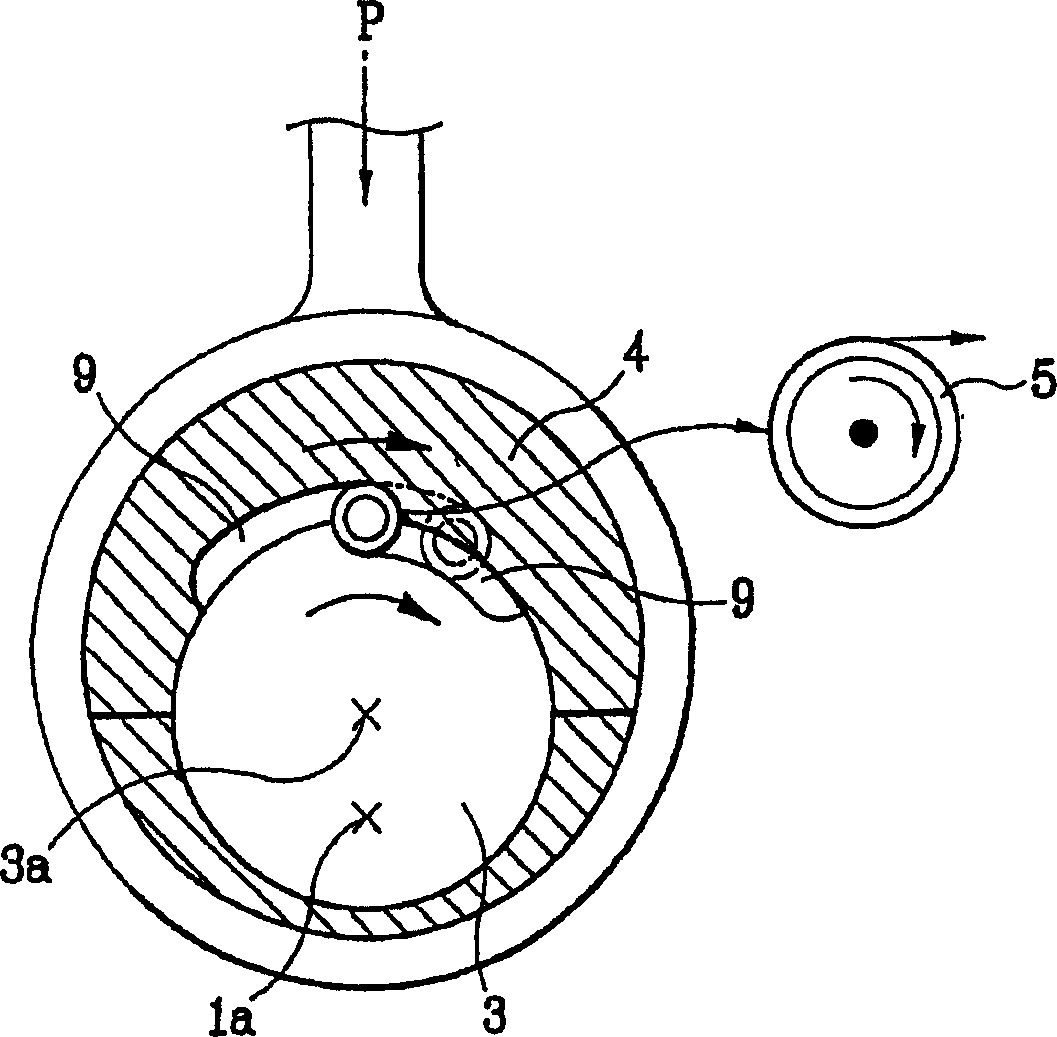

[0061] Figure 5A and 5B A side view and a plan view of a dual capacity compressor according to a first embodiment of the present invention are shown, wherein components of the dual capacity compressor are shown in an assembled state through partial cutaway for easy understanding and clarity. Figures 6A-11C With the individual components shown, a first preferred embodiment of the present invention will be described below with reference to these drawings.

[0062] The dual capacity compressor of the first preferred embodiment comprises: a crank pin 110 having a pair of opposing key member mounting portions 111 in an oblique position; an eccentric sleeve 120 for locally restricting the rotation of the protruding portion of the key member and a key member 130 for being installed through the key member mounting portion 111 so that at least a part of it protrudes from the crank pin 110. The other components included in the dual capacity compressor are the same as Figure 4 The ...

no. 2 example

[0075] The dual-capacity compressor of the second embodiment of the present invention has a completely different key member mounting portion from the compressor of the first embodiment.

[0076] Figure 12A and 12B Respectively represent a side view and a plan view of a dual-capacity compressor according to a second embodiment of the present invention; Figure 13-15C Indicates its main components. As with the first embodiment, the components are shown in an assembled state and include partial cross-sections for ease and clarity of illustration. Next, a second preferred embodiment of the present invention will be described with reference to the above-mentioned drawings.

[0077] The dual-capacity compressor 200 of the second preferred embodiment includes: a crank pin 210 having a pair of opposing and parallel key member mounting portions 211; an eccentric sleeve 220 for partially restricting the rotation of the protruding portion of the key; And a key member 230 for mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com