Bidirectional flat-nose pliers for machine

A technology of flat-nose pliers and pliers body, which is applied in the field of flat-nose pliers to achieve the effect of increasing the cutting stroke, reducing local wear and reducing the number of downtimes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

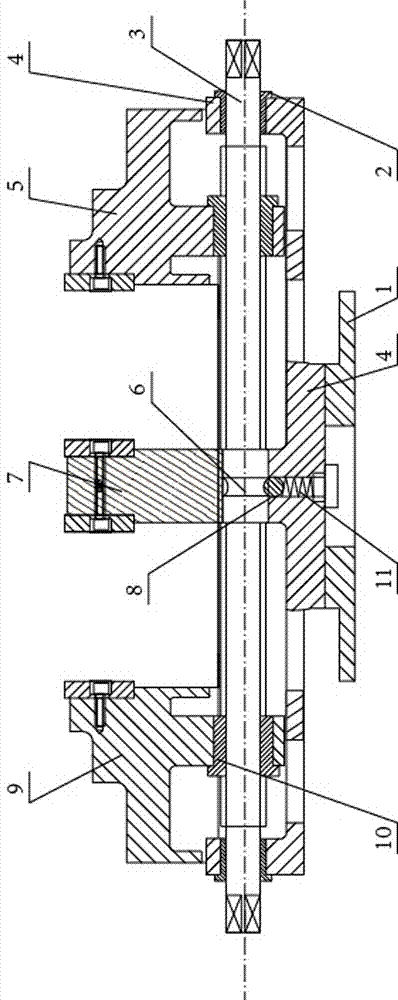

[0018] Embodiment one: the present invention is used as the embodiment of double-jaw flat-nose pliers.

[0019] Such as figure 1 As shown, this embodiment includes a base 1, a clamp body 4 fixed on the base 1 by bolts, and a detachable fixed jaw seat 7 is installed on the clamp body 4. The detachable fixed jaw seat 7 is installed and positioned on the body of the pliers 4 through bolts and two tapered pins.

[0020] An X-axis circular through hole is opened on the clamp body 4, and a lead screw 3 is installed in the circular through hole. Two left and right movable jaw seats are arranged on the left and right sides of the clamp body 4, that is, the left movable jaw seat 9 and the right movable jaw seat 5, and the two movable jaw seats are respectively connected with the left and right nuts that are sleeved on the lead screw 3. 10 are closely fitted and connected, and the two sections of screw threads that the leading screw 3 matches with the left and right nuts 10 move in t...

Embodiment 2

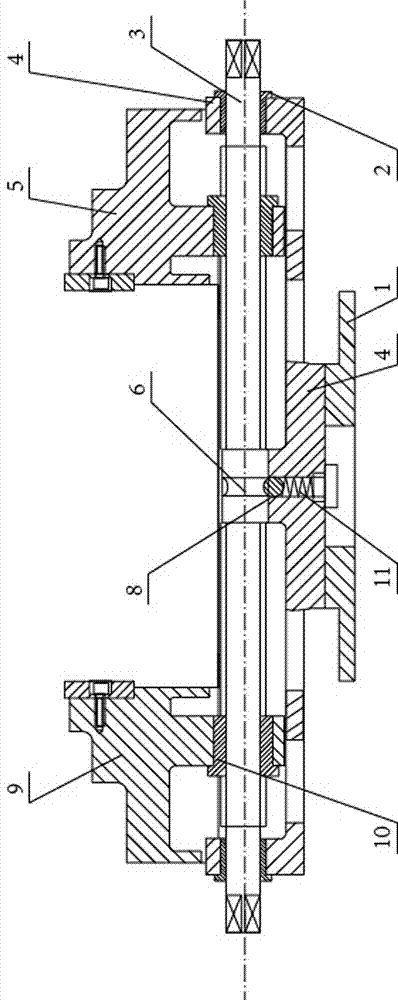

[0025] Embodiment 2: The present invention is used as the embodiment of the flat-nose pliers for the centering machine.

[0026] Such as figure 2 As shown, in this embodiment, the detachable fixed jaw seat 7 is removed on the basis of the first embodiment, and the following screw axial positioning mechanism is added.

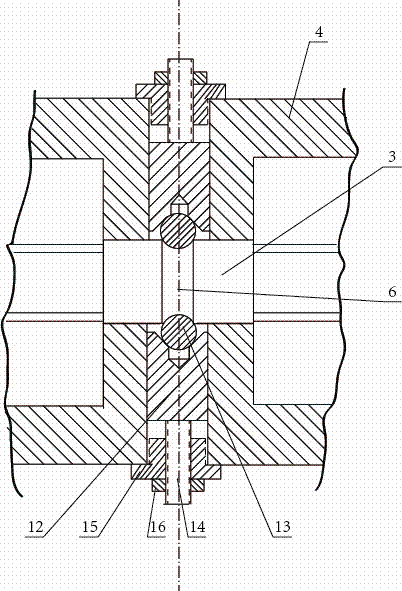

[0027] Such as image 3 , the described screw axial positioning mechanism is as follows:

[0028] A circular through hole is opened on the clamp body 4 at the front and rear, and the axes of the two circular through holes coincide and perpendicularly intersect with the axis of the lead screw 3 . A centering plunger 12 is respectively arranged in each through hole. The inner end of the centering plunger 12 is provided with a conical hole, and a centering steel ball 13 is installed in the conical hole. Groove 6 matches. An adjusting screw rod 14 is fixedly installed on the outer end of the centering plunger 12 .

[0029] A fixed nut 15 is installed at the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com