Coaxial probe short-circuit mechanism and operation method thereof

A technology of coaxial probe and shorting piece, applied in the direction of circuit, circuit/collector parts, contact parts, etc., can solve the damage of coaxial probe and shorting piece, difficult to ensure the consistency of preload force, measurement and calculation error, etc. problem, to achieve the effect of good consistency, moderate preload, and reduced local wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

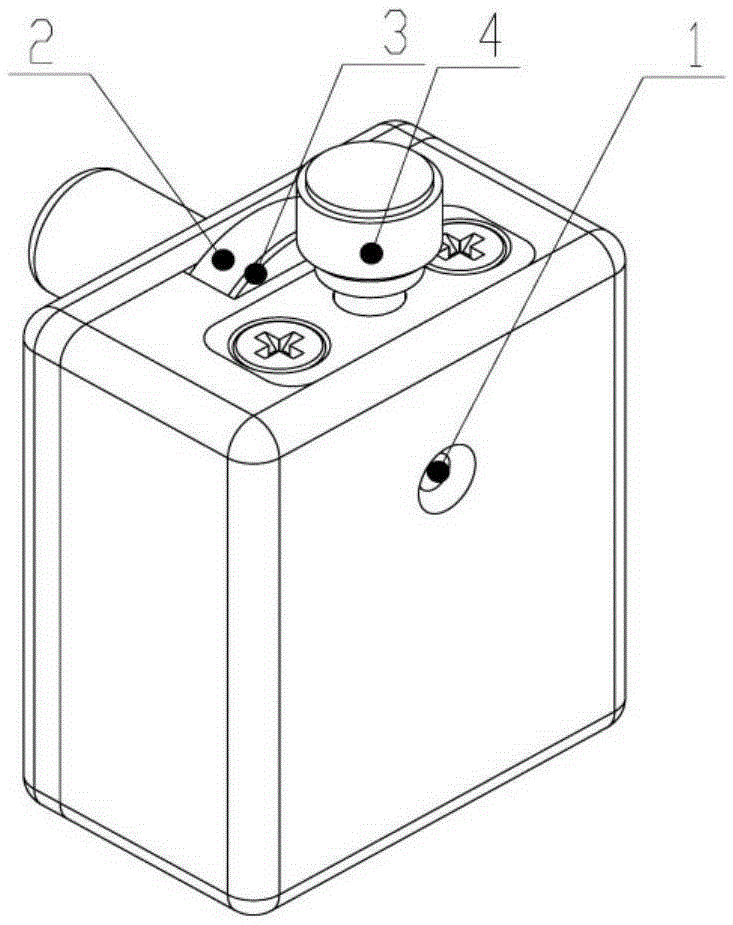

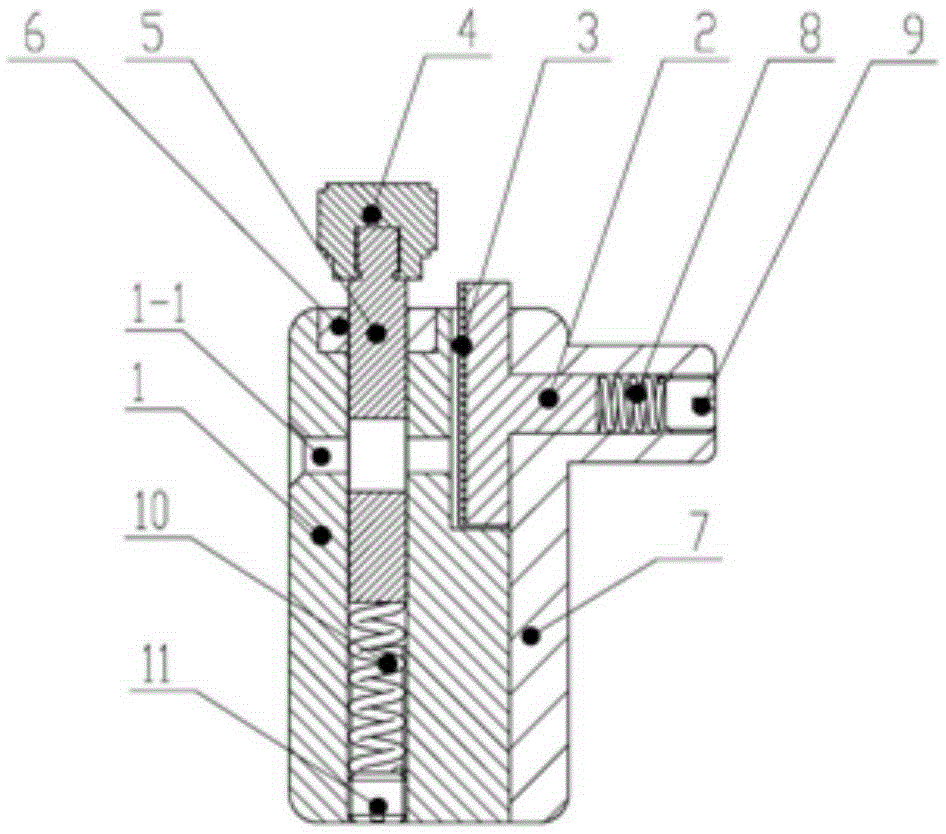

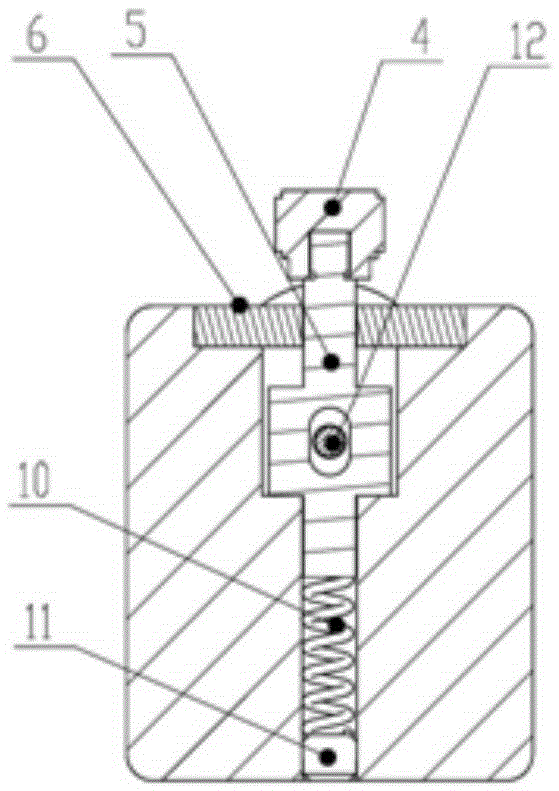

[0034] like figure 1 , figure 2 shown. A coaxial probe short circuit mechanism, including a coaxial probe 12 and a short circuit 3, also includes a base 1, a cover 7 and a spacer 2, the cover 7 is installed on one side of the base 1, and the spacer 2 is installed on the base Between the seat 1 and the cover plate 7; the short circuit 3 is made of a conductive rubber plate, and the short circuit 3 is fixedly installed on the pad 2 and is located on the side of the pad 2 adjacent to the base 1; on the base 2 There is a probe limit hole 1-1 for the coaxial probe 12 to pass through, and the open end of the coaxial probe 12 passes through the probe limit hole 1-1 and is in contact with the short circuit piece 3; the spacer 2 and the cover plate 7 A spacer spring 8 is provided on the adjacent side to press the short circuit piece 3 agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com