Sliding abrasion-resistant device with internal circulation rolling bodies

A rolling element and internal circulation technology, applied in transportation and packaging, non-mechanical conveyors, conveyors, etc., can solve the problems of large surface-to-surface friction, contact surface wear, time-consuming and labor-intensive, etc., to reduce friction and apply Strong, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

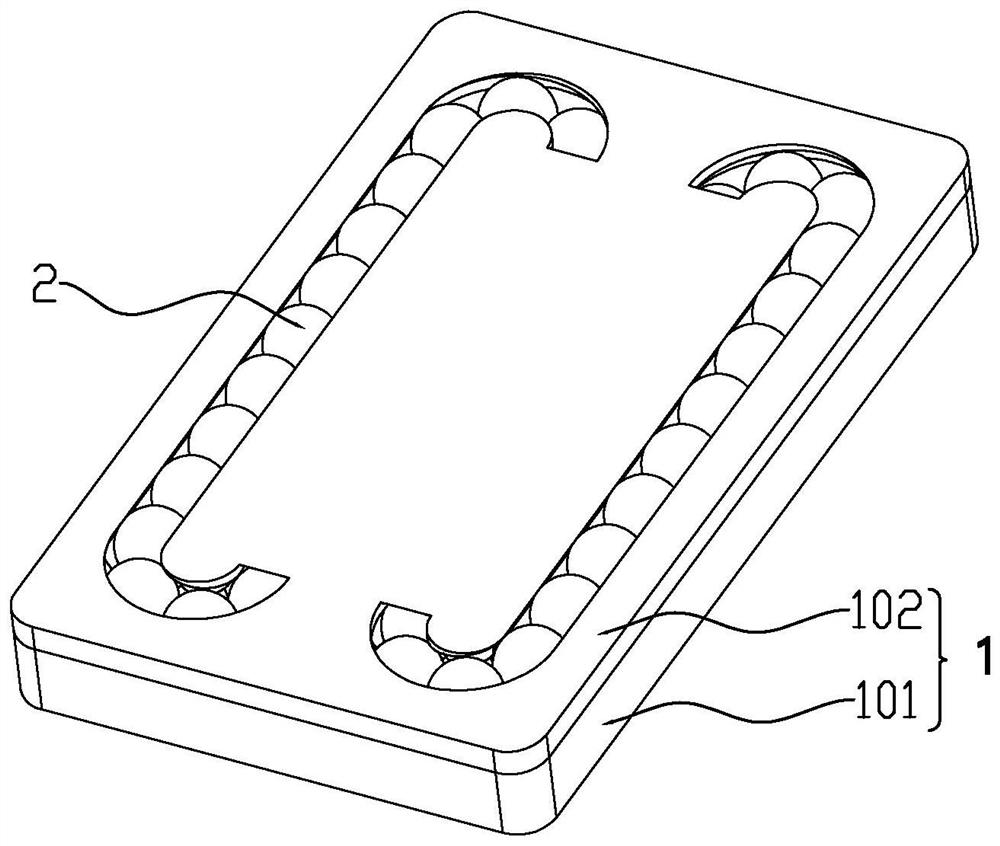

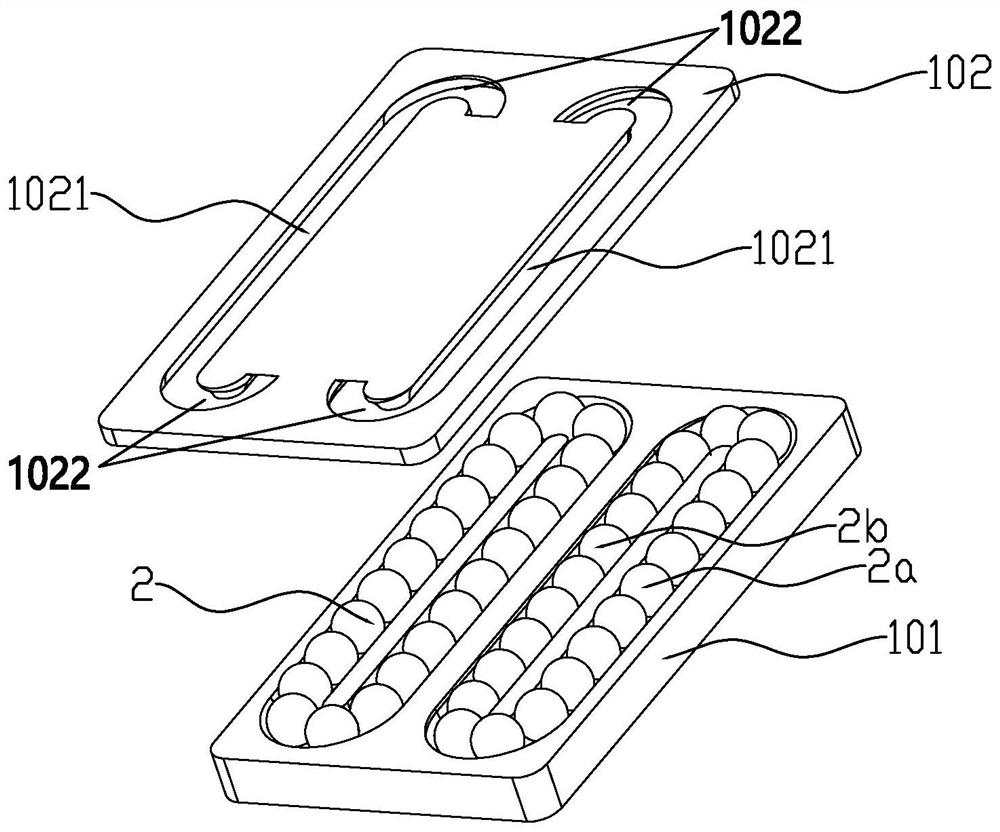

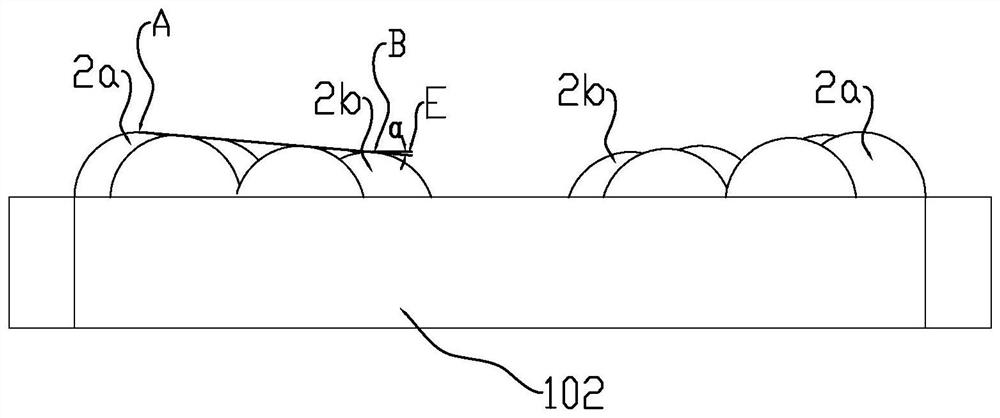

[0034] The sliding anti-wear device with inner circulation rolling body includes an outer frame 1 with a circulation track 1011 and several rolling bodies 2 circulating in the circulation track 1011. The circulation track 1011 includes a load section 1011a, a return section 1011b and The turning section 1011c endlessly connecting the load section 1011a and the return section 1011b, the depth of the return section 1011b is greater than the depth of the load section 1011a, and the slide is carried on the rolling body 2a in the load section, The sliding object has zero contact with the rolling elements 2b in the return section. When the sliding object slides, the rolling elements 2a in the load section roll under the action of friction and drive all the rolling elements 2 to circulate in the circulating track 1011 .

[0035] In this embodiment, the rolling elements 2 roll circularly in the circulating track 1011, and the depth of the return section 1011b is greater than the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com