A compressor and method for welding a fluid tubing to a compressor housing and fluid-transporting tubing

A technology for fluid transportation and compressors, which is applied in the field of compressors and can solve practical problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

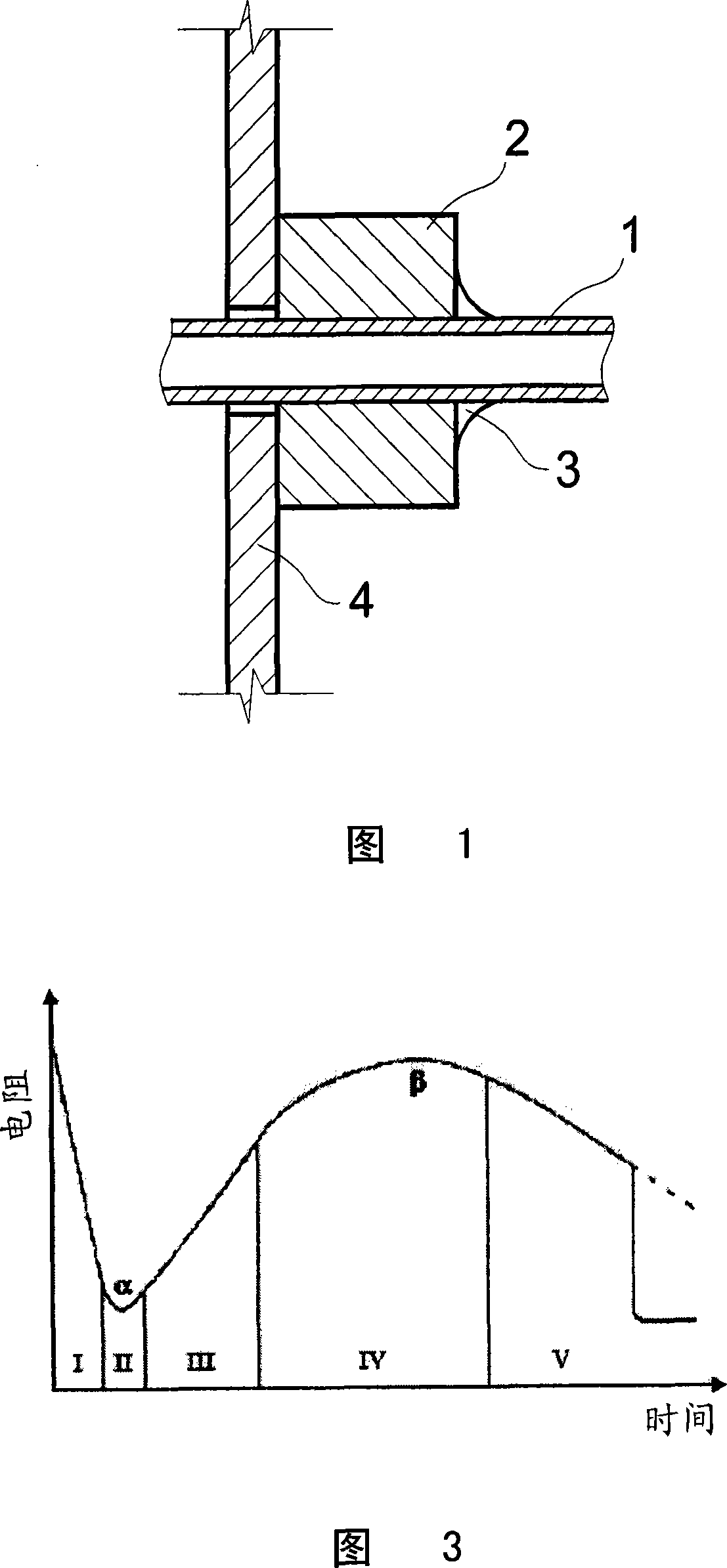

[0022] In Fig. 1 it can be seen that, according to the prior art, a tube union of a fluid-passer (or fluid-passing pipe) made of copper is applied to a closed on the steel casing of the compressor. In this configuration, the pipe 1 is connected to a cylindrical connection 2 made of carbon steel by means of induction welding or flame brazing in a furnace. The assembly formed by the pipe 1 and the cylindrical connection 2 after the brazing operation is then connected on the outside to the steel casing 4 of the compressor (not shown) by means of electric resistance welding.

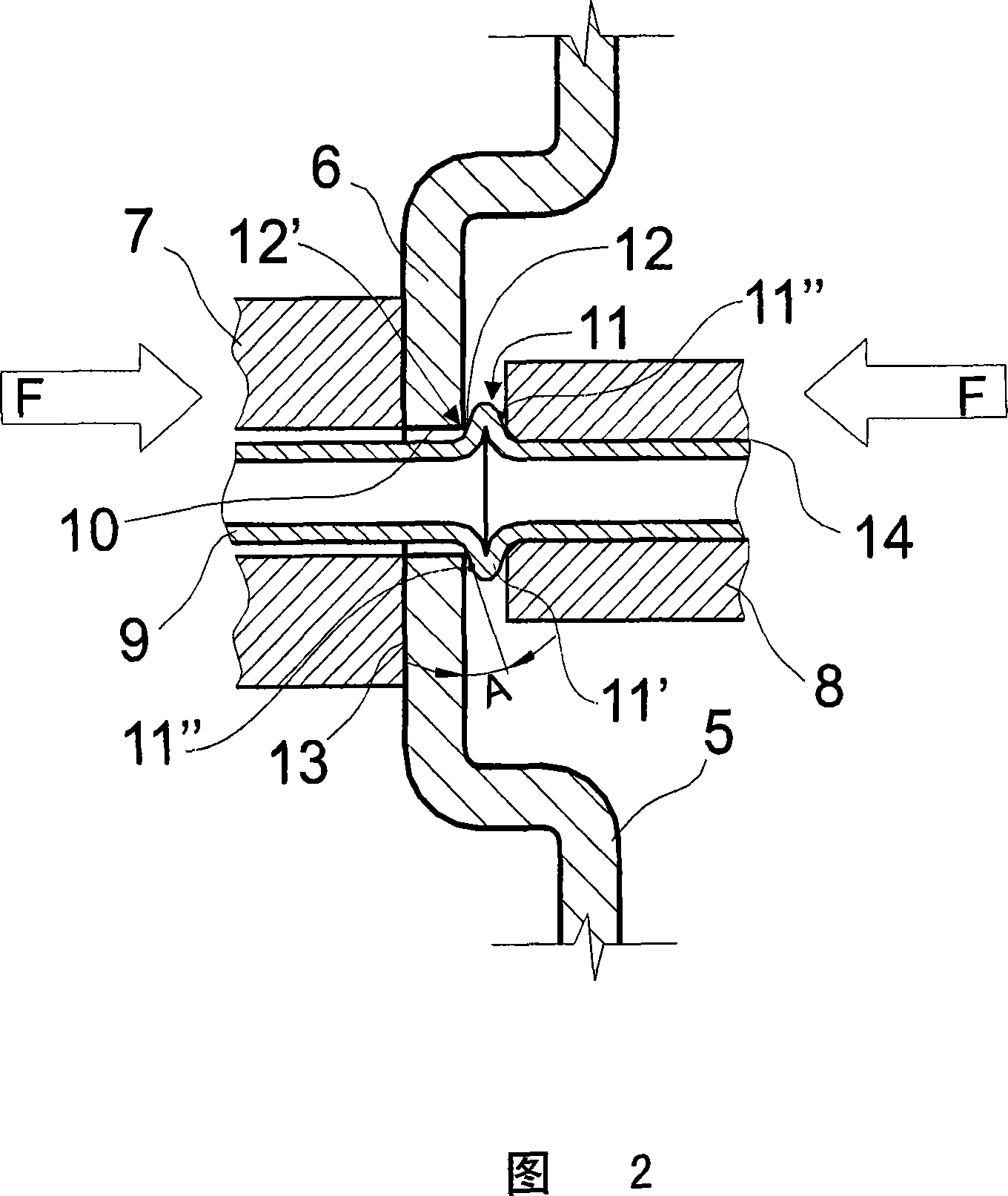

[0023] It can be seen in FIG. 2 that according to the teaching of the present invention, in order to achieve the desired purpose, by only welding the fluid delivery pipe 9 to the compressor shell 5, so as to save the use of brazing and cylindrical connectors 2 .

[0024] Figure 3 shows the steps of the welding method, comprising phases I to V, with the following actions: In phase I, the metal surfaces are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com