Reusable thrust chamber

A thrust chamber and inner ring technology, applied in the field of thrust chambers, can solve the problems of shortening the processing cycle and cost, complex processing technology, and large number of parts, and achieve the effect of simple structure, simplified processing technology, and small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

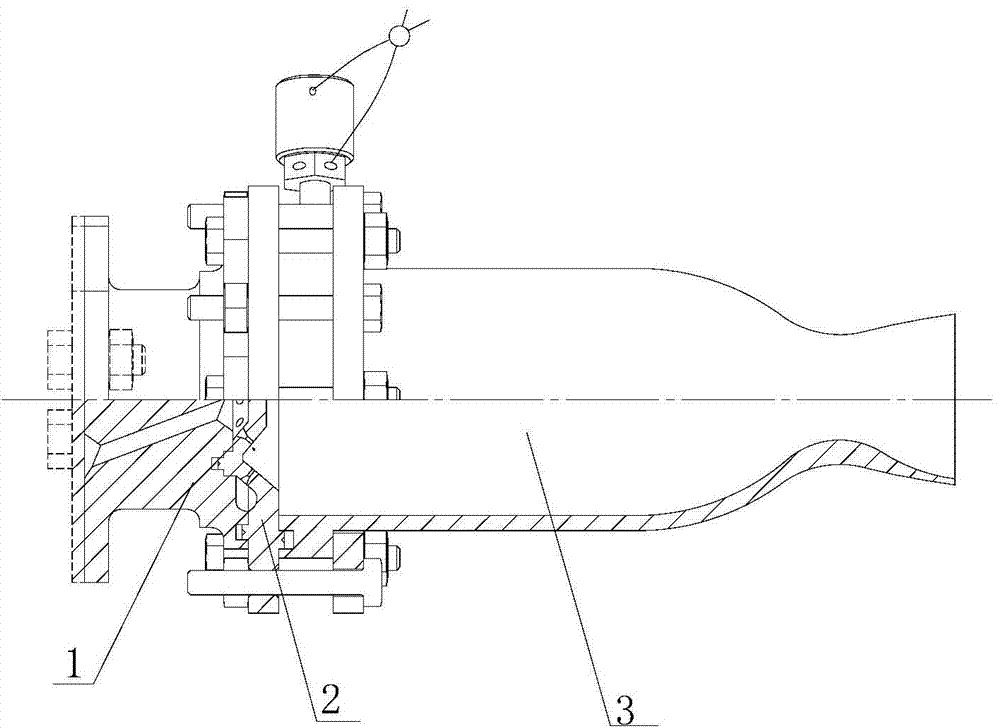

[0025] Such as figure 1 As shown, a reusable thrust chamber includes a cover plate 1, an injection plate 2 and a body 3 connected in sequence.

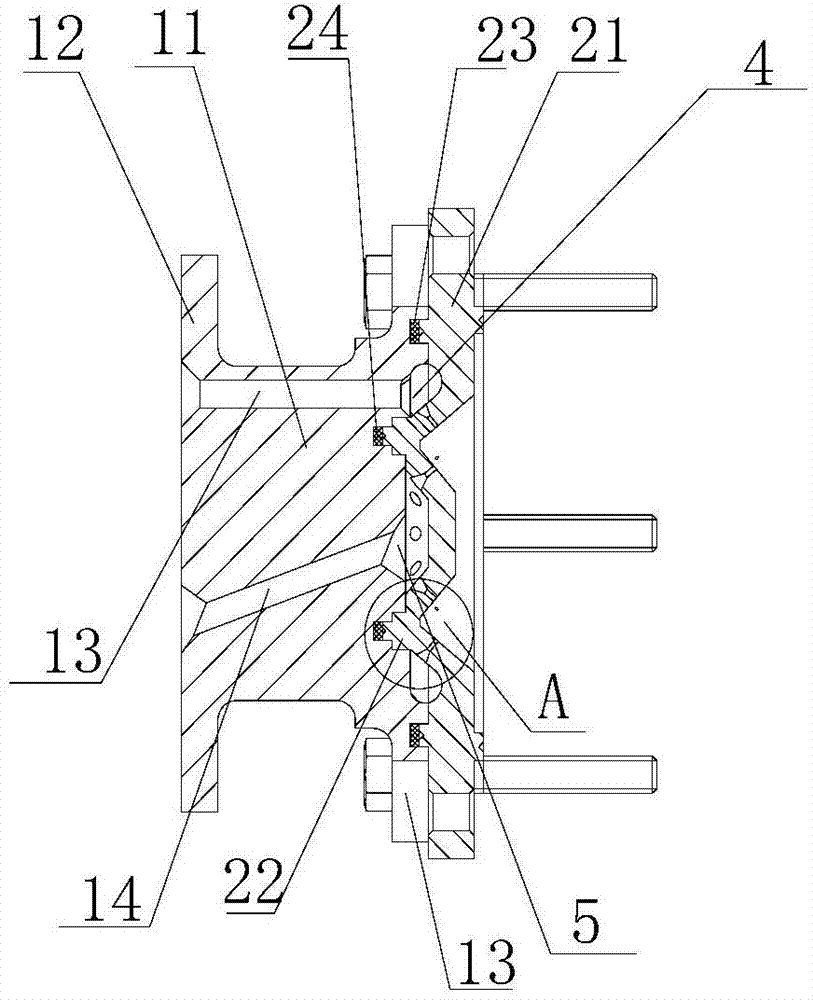

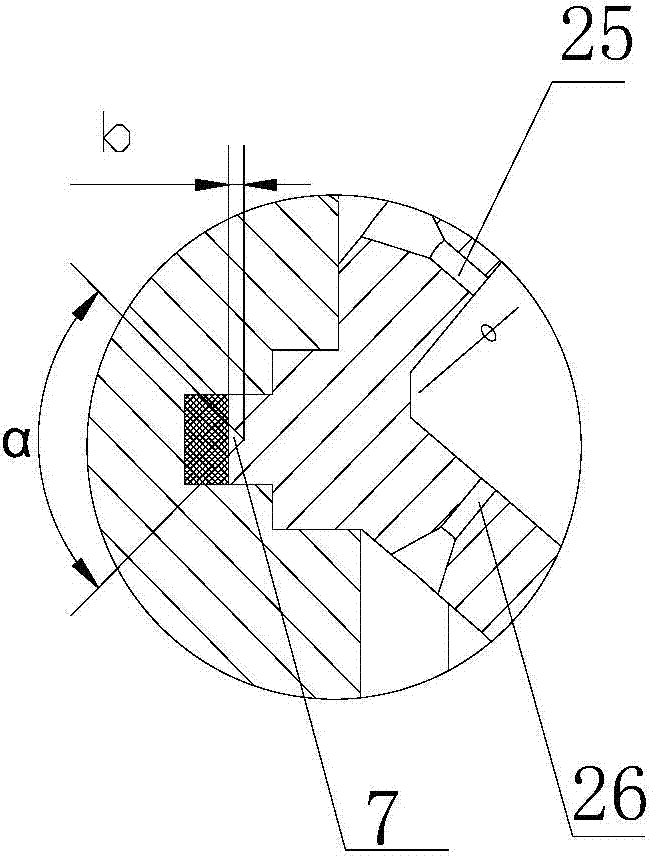

[0026] Such as figure 2 As shown, the injection tray 2 includes a base 21 and an annular boss 22, an outer ring sealing tenon 23 and an inner ring sealing tenon 24 arranged on the base 21, and a plurality of first injection holes 25 and a plurality of first injection holes 25 are uniformly distributed on the circumference of the base. A second injection hole 26, the first injection hole is located in the annular boss, the second injection hole is located between the outer ring seal tenon and the annular boss, the first injection hole 25 and the second injection hole The number is equal and corresponds one to one, the first injection hole and the second injection hole are both facing the body,

[0027] The cover plate 1 includes a heat-insulating frame 11, and flanges 12 and a butting plate 13 arranged at both ends of the heat-insulating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com