Hydraulic hole opener and hole opening method

A reamer and hydraulic technology, which is used in earth-moving drilling, drilling equipment, drill bits, etc., can solve the problems of the blade cannot be retracted and the blade groove of the blade can be damaged, so as to ensure the smooth flow of mud, radial force and shearing. Reduce the force and ensure the effect of thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

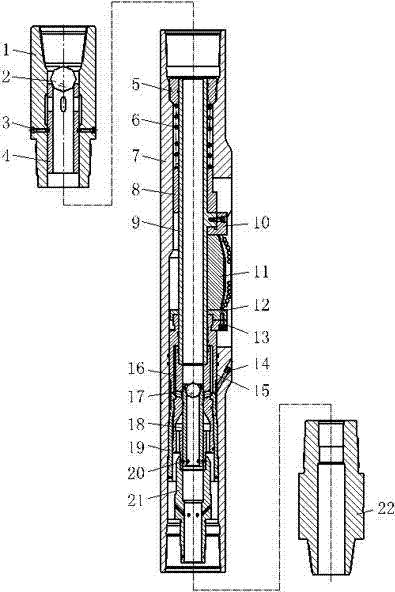

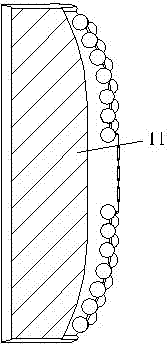

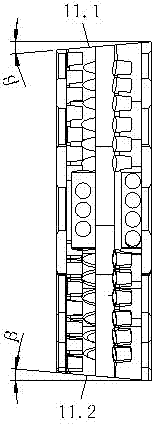

[0024] The structure schematic diagram of a kind of hydraulic reamer of the present invention is as figure 1 As shown, it includes an upper joint 1, the upper joint 1 is threadedly connected to the upper end of the body 7, and the lower end of the body 7 is connected to the lower joint 22; the upper joint 1 is provided with an upper ball seat 4, and the upper ball seat 4 is connected to the upper joint 1 through a pin 3; The body 7 is provided with three blade grooves distributed at 120°, and the blade groove is provided with a blade 11; the body 7 is provided with a mandrel 9, the bottom of the mandrel 9 is covered with a piston 15, and the top of the piston 15 is provided with a retaining ring 12. Push the knife wing 11 to expand outward through the retaining ring 12 to complete the reaming operation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com