Patents

Literature

31results about How to "Solve the stuck drill problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

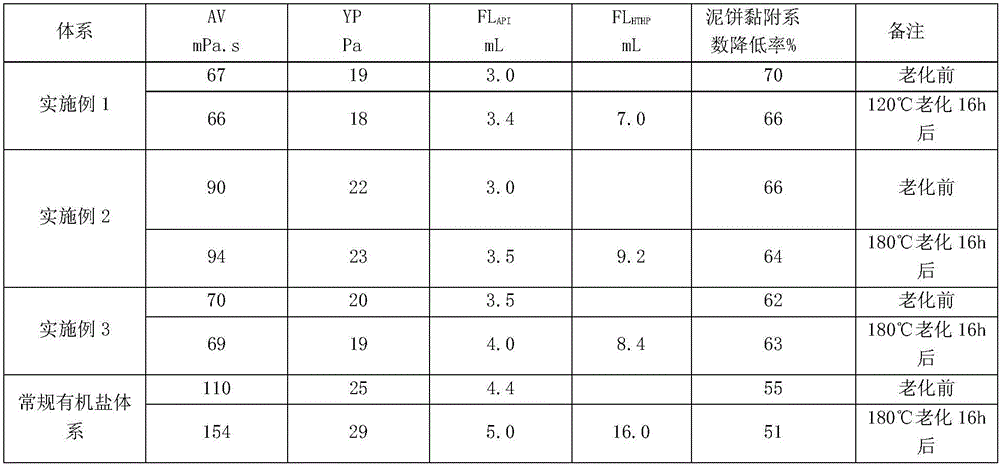

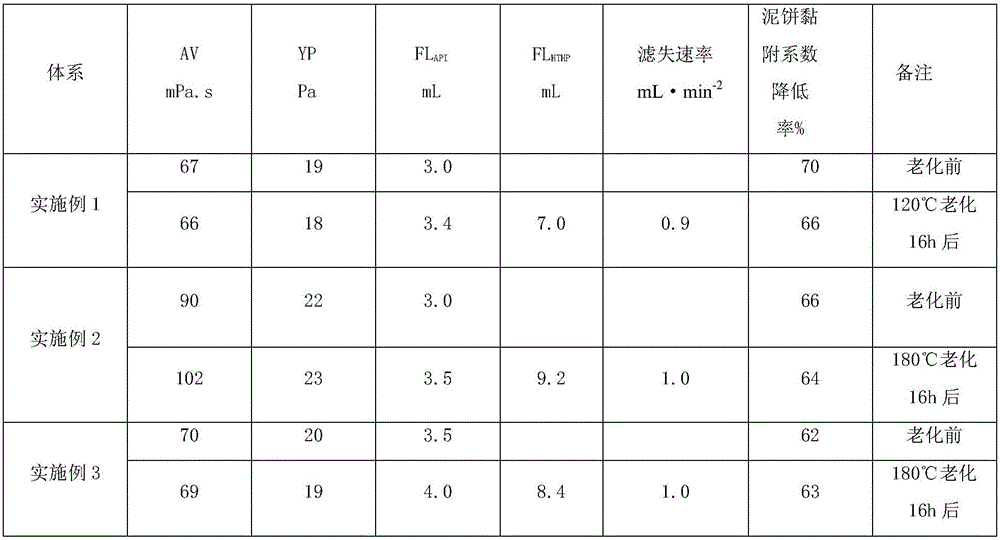

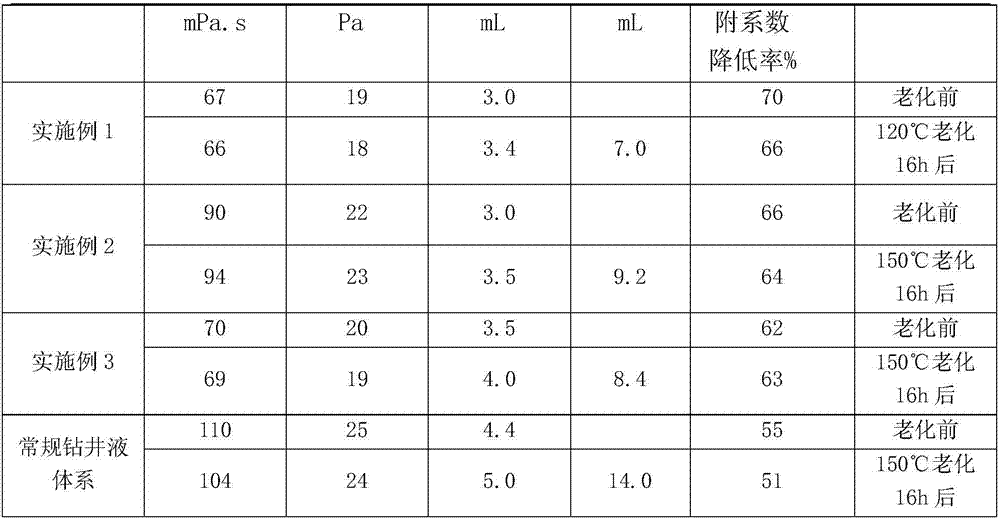

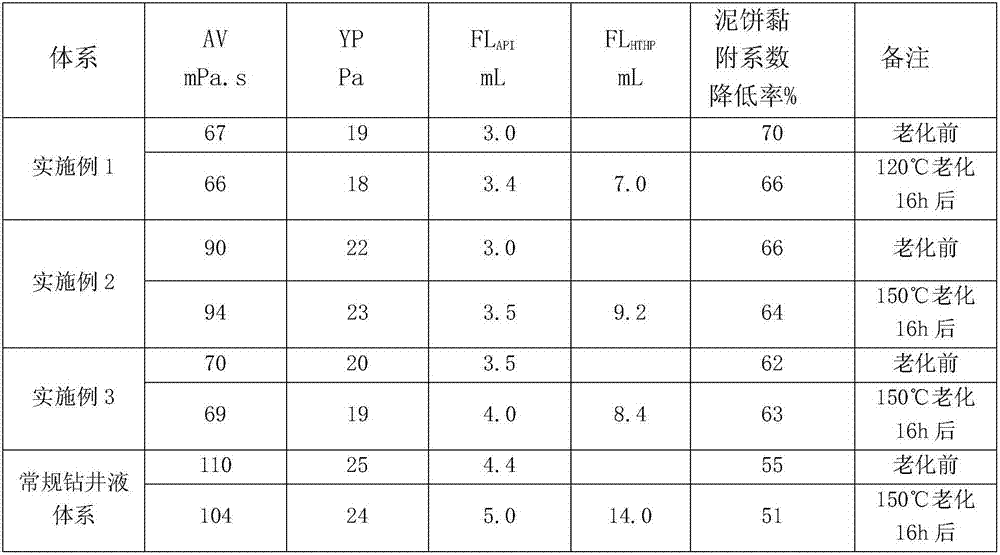

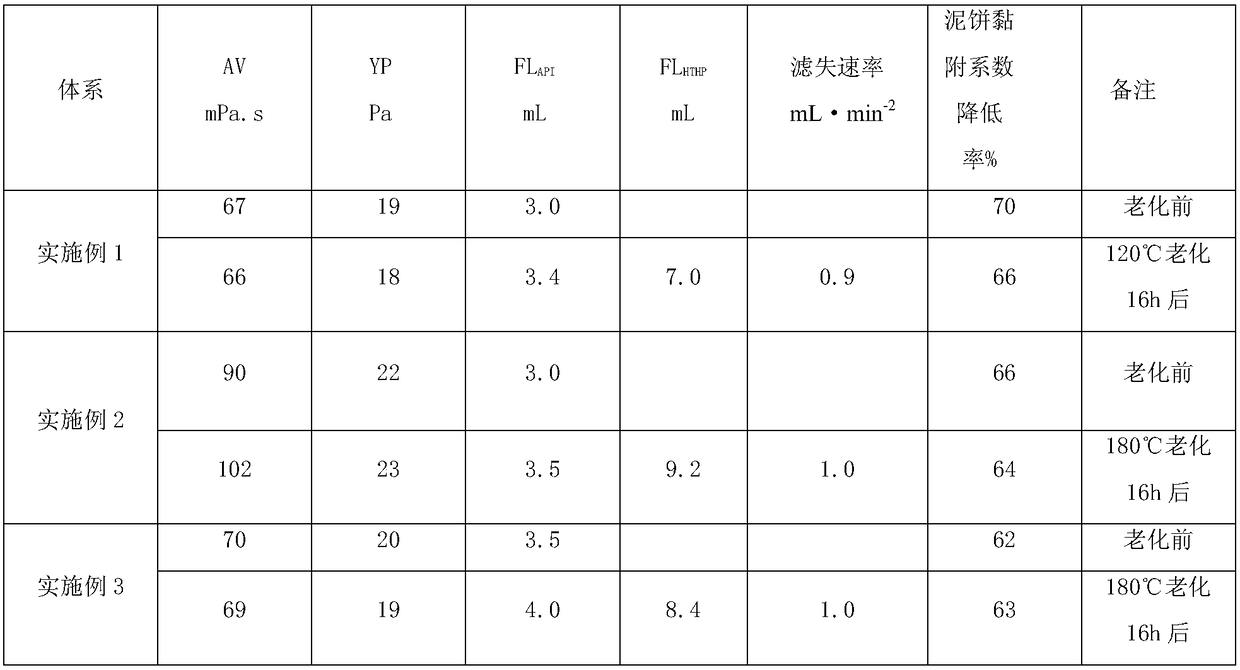

Organic salt drilling fluid applicable to extended-reach wells

ActiveCN105754563AGood thermal stabilityReduce fluid lossDrilling compositionDrilling fluidCastor oil

The invention discloses an organic salt drilling fluid applicable to extended-reach wells.The organic salt drilling fluid comprises 1-4% of bentonite, 0.3-0.5% of sodium carbonate, 0.5-1% of sodium hydroxide, 0.3-1% of xanthan gum, 2-8% of filtrate reducer, 2-5% of nanometer plugging agent, 1-4% of plugging agent, 0.5-4% of lubricant, 40-60% of organic salt and 25-250% of inert weighting agent, wherein the nanometer plugging agent is formed by copolymerization of MAPOSS, N-isopropylacrylamide and acrylamide, the plugging agent is formed by copolymerization of N-isopropylacrylamide, acrylamide and N,N'-methylene diacrylamide, and the lubricant is formed by compounding of castor oil polyoxyethylene ether, polyethylene glycol and polyvinyl pyrrolidone.The organic salt drilling fluid applicable to the extended-reach wells has the advantages of excellent plugging performance, good lubricating property and rheological property and powerful rock debris carrying capability, thereby being particularly applicable to exploitation of the extended-reach wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Organic salt drilling fluid

ActiveCN105694830AImprove thermal stabilityReduce fluid lossDrilling compositionFiltrationPolyethylene glycol

The invention discloses organic salt drilling fluid. The organic salt drilling fluid is prepared from 1%-4% of bentonite, 0.3%-0.5% of sodium carbonate, 0.5%-1% of sodium hydroxide, 0.3%-1% of xanthan gum, 2%-8% of a filtrate loss reducer, 2%-5% of a nanometer blocking agent, 1%-4% of a blocking agent, 0.5%-4% of a lubricating agent, 40%-60% of organic salt and 25%-250% of an inert weighting agent, wherein the nanometer blocking agent is prepared by copolymerizing methacrylic acid carbomethoxy cage-like oligomeric silsesquioxane, N-isopropylacrylamide and acrylamide, and the lubricating agent is prepared by compounding castor oil polyoxyethylene ether, polyethylene glycol and polyvinyl pyrrolidone. The organic salt drilling fluid has the very good heat stability, the low filtration loss and the high blocking performance and lubricating performance and is especially suitable for shale gas well development.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Environmentally-friendly drilling fluid with high plugging performance

InactiveCN107502320AImprove thermal stabilityImprove the lubrication effectDrilling compositionSodium BentoniteHexamethylenetetramine

The invention discloses an environmentally-friendly drilling fluid with high plugging performance. The drilling fluid comprises 2-6% of bentonite, 0.3-0.5% of sodium carbonate, 0.3-0.5% of an inhibitor, 0.2-0.5% of a coating agent, 0.1-0.3% of xanthan gum, 2-8% of a filtrate reducer, 2-5% of a plugging agent, 1-4% of calcium carbonate, 0.5-4% of a lubricant, and 25-250% of an inert weighting agent; and the nano plugging agent is formed by compounding of a product prepared from carbon spheres coated with AlOOH, acrylamide, N-isopropylacrylamide and hexamethylenetetramine and a vinyl acetate-ethylene copolymerization emulsion. The environmentally-friendly drilling fluid has the characteristics of high plugging performance, high lubricating performance, a good rheological property, strong ability of carrying rock debris, and friendliness to environments, and the environmentally-friendly drilling fluid is specially applied to environmental sensitive areas regions.

Owner:CNPC BOHAI DRILLING ENG

Environment-friendly drilling fluid strong in plugging property

InactiveCN107502315AImprove thermal stabilityImprove the lubrication effectDrilling compositionHexamethylenetetramineEnvironmental chemistry

The invention discloses environment-friendly drilling fluid strong in the plugging property. The environment-friendly drilling fluid strong in the plugging property is prepared from 2-6% of bentonite, 0.3-0.5% of sodium carbonate, 0.3-0.5% of inhibitor, 0.2-0.5% of viscosity-shearing agent, 0.1-0.3% of xanthan gum, 2-8% of fluid loss agent, 2-5% of plugging agent, 1-4% of calcium carbonate, 0.5-4% of lubricant and 25-250% of inert weighting agent, wherein the nano plugging agent is obtained by mixing a product, which is obtained from a reaction of carbon balls coated with AlOOH, acrylamide, N-isopropylacrylamide and hexamethylenetetramine, with vinyl acetate-ethylene copolymer emulsion. The environment-friendly drilling fluid has the advantages of strong plugging property, strong lubricating performance, good rheological property, strong debris carrying ability and environmental protection, and is especially suitable for environmentally sensitivity areas.

Owner:CNPC BOHAI DRILLING ENG

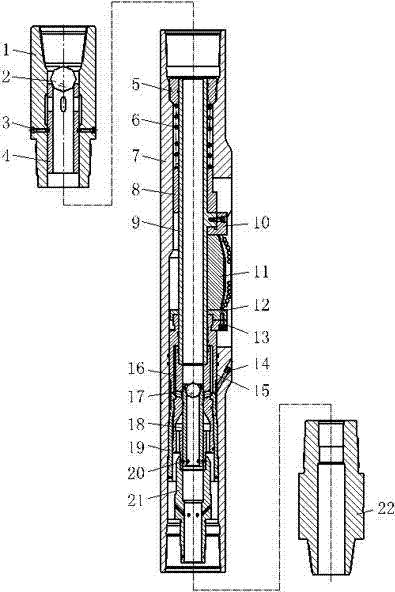

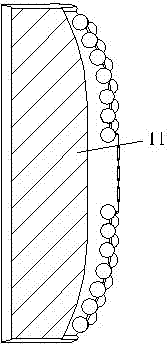

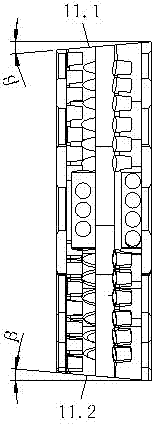

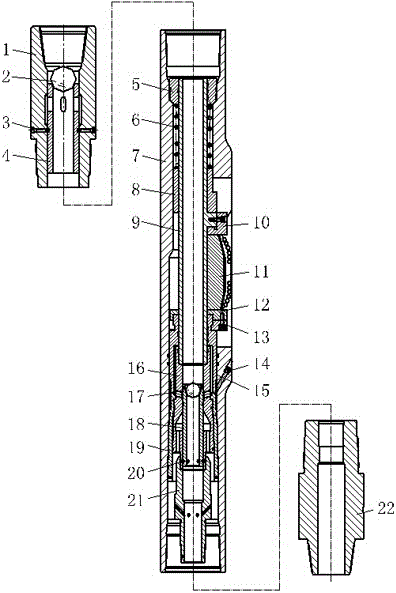

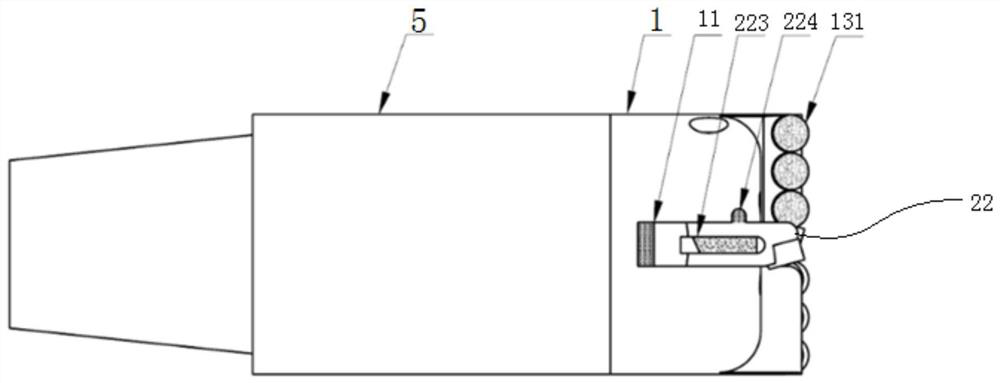

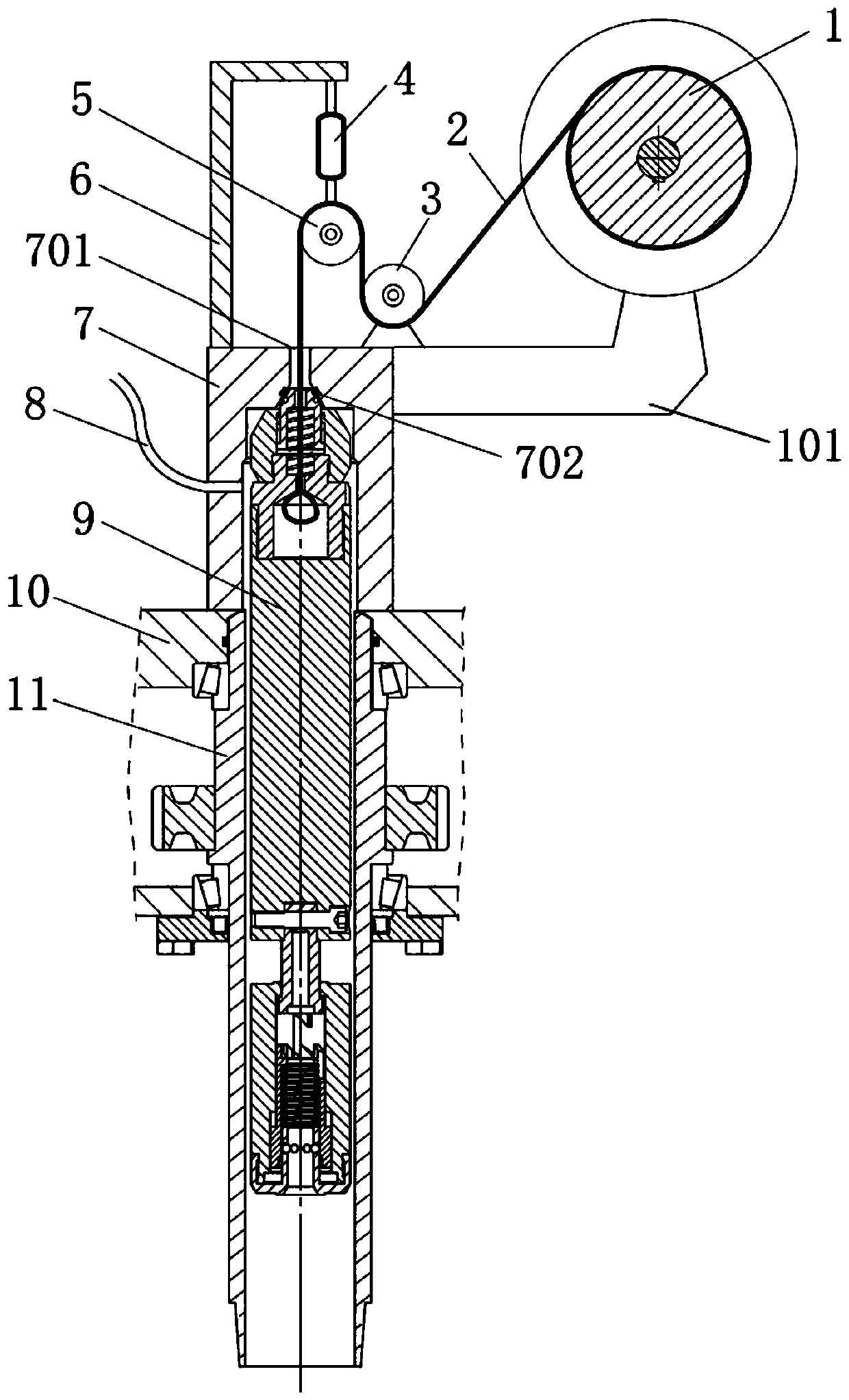

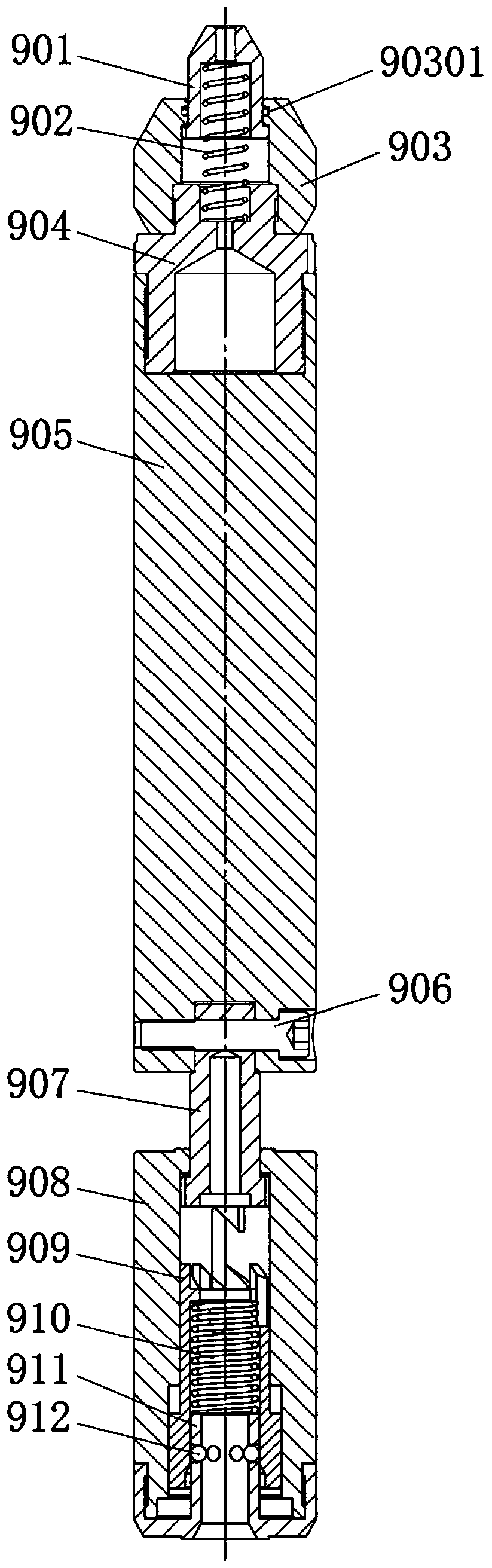

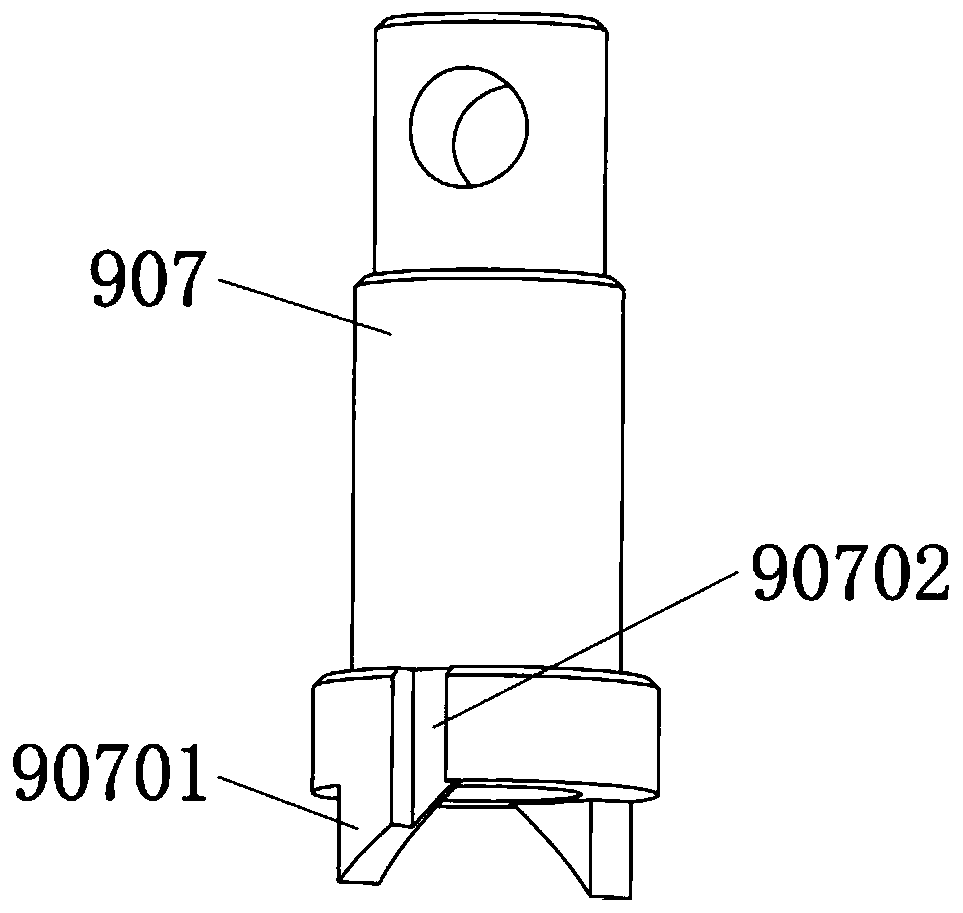

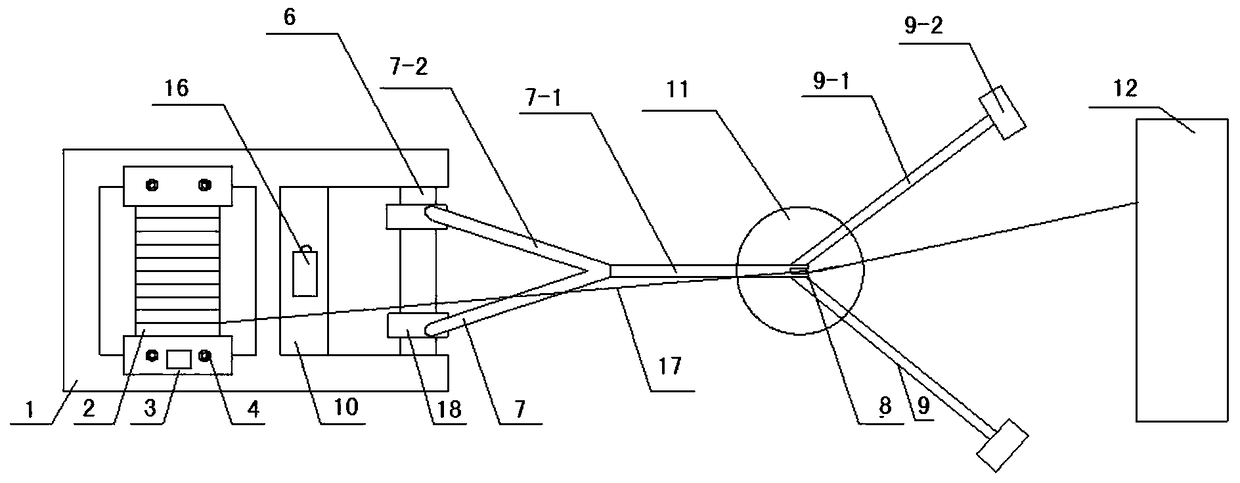

Hydraulic hole opener and hole opening method

The invention discloses a hydraulic hole opener and a hole opening method. The hydraulic hole opener comprises an upper connector 1, the upper connector is connected with the upper end of a body 7 through threads, the lower end of the body is connected with a lower connector 22, an upper ball seat 4 is arranged in the upper connector and is connected with the upper connector through a dowel pin 3, three cutter wing grooves distributed in 120 degrees are formed in the body, a cutter wing 11 is arranged in each cutter wing groove, a mandrel 9 is arranged in the body, a piston 15 sleeves the bottom of the mandrel, a retainer ring 12 is arranged at the top of the piston, and hole opening operation is finished by pushing the cutter wings to expand outwards through the retainer ring. The hole opener is simple in structure, convenient to disassemble and capable of folding the unfolded cutter wings forcedly. Reliability of the cutter wings can be improved by changing a mud channel, cutter wing blocking possibility is reduced, cutter wing deformation is small, and the service life of the cutter wings and the body are prolonged. The safety of the hole opener is greatly improved, and the drill blocking problem caused by the fact that the cutter wings cannot be folded due to fault is solved.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

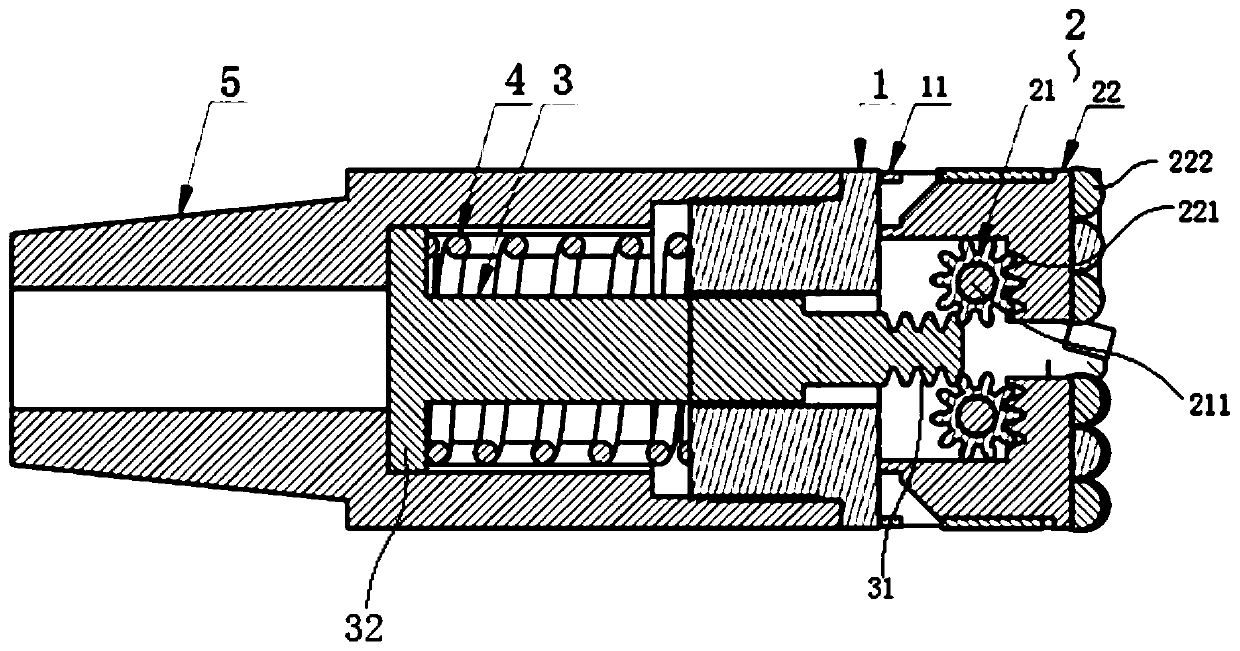

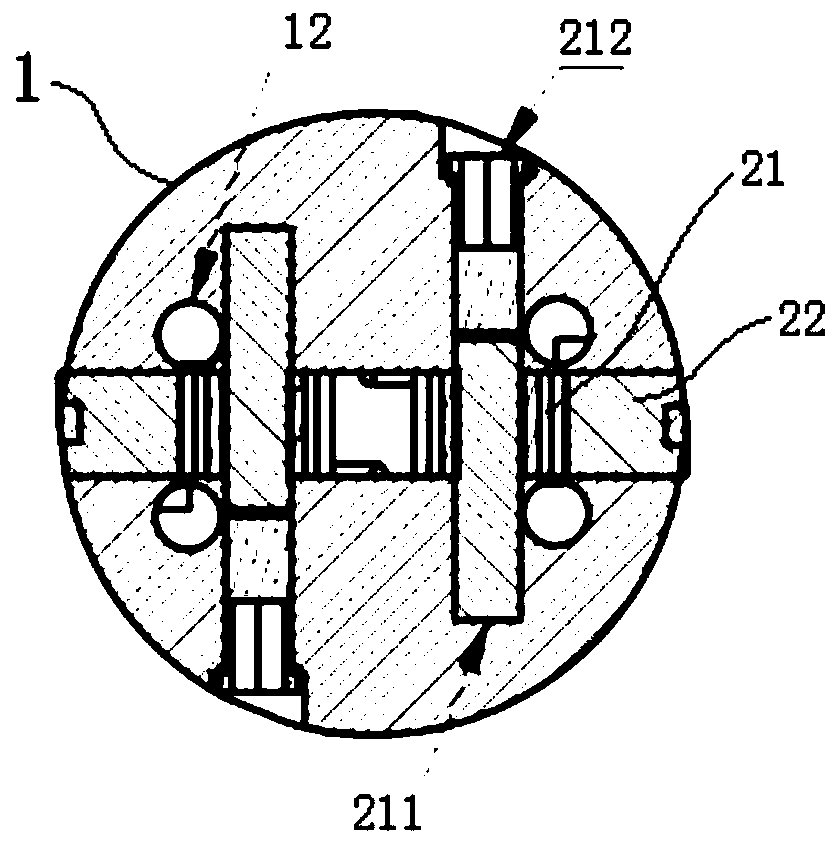

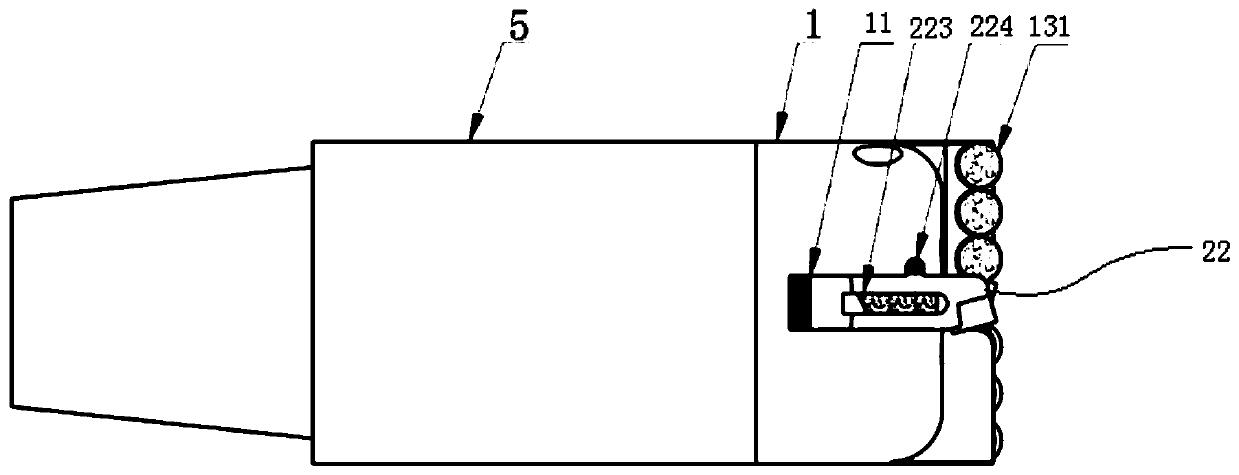

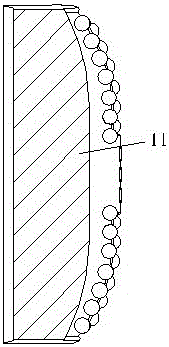

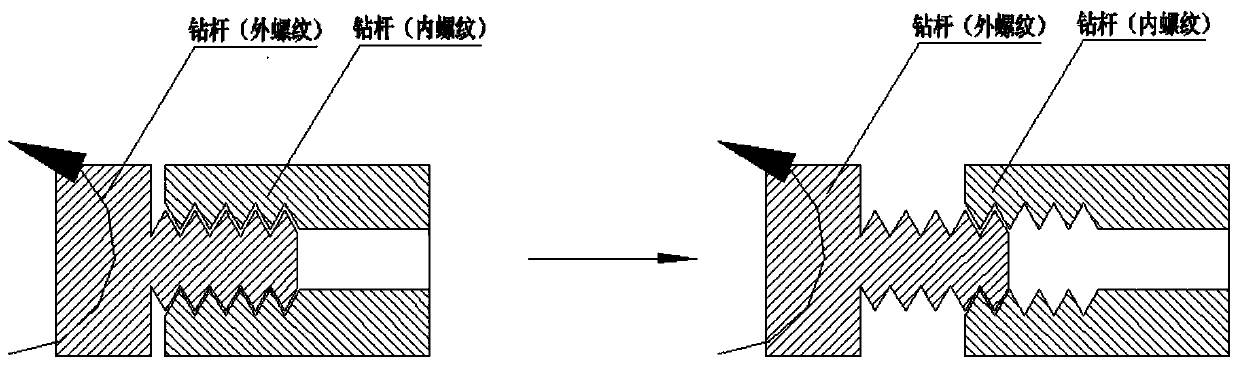

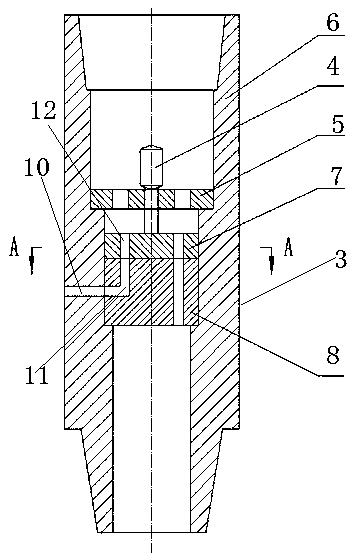

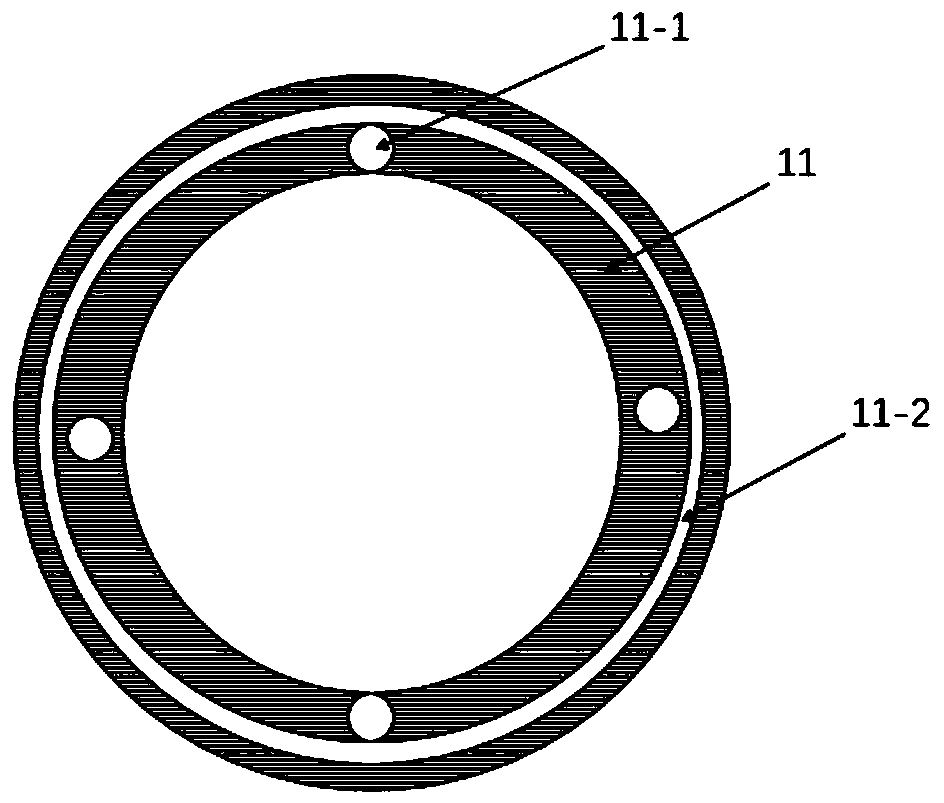

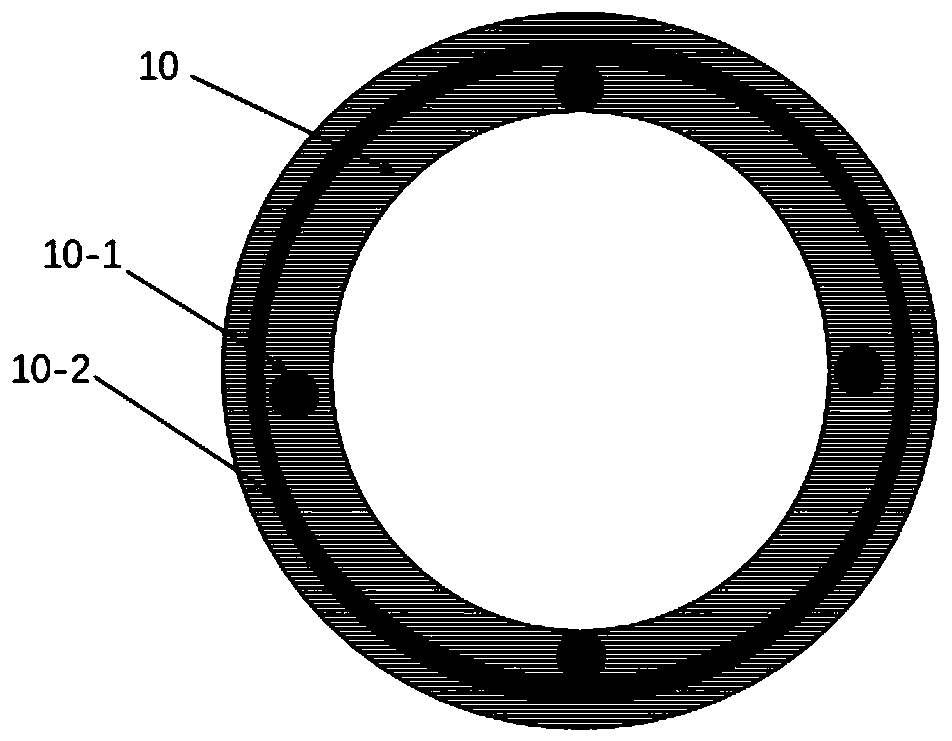

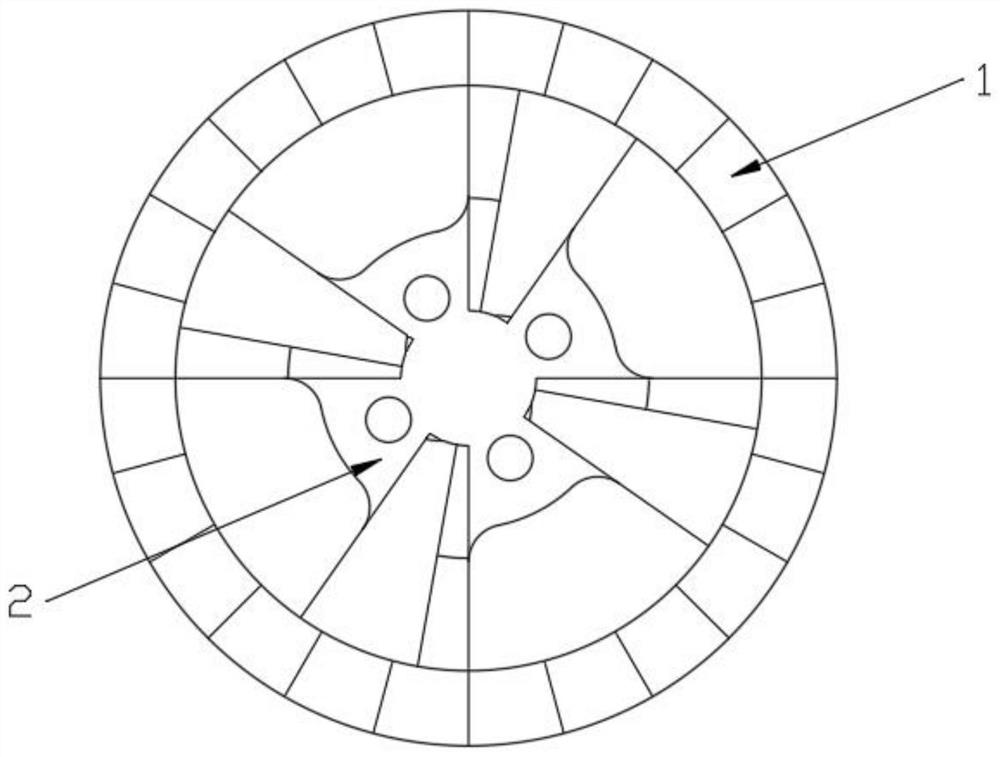

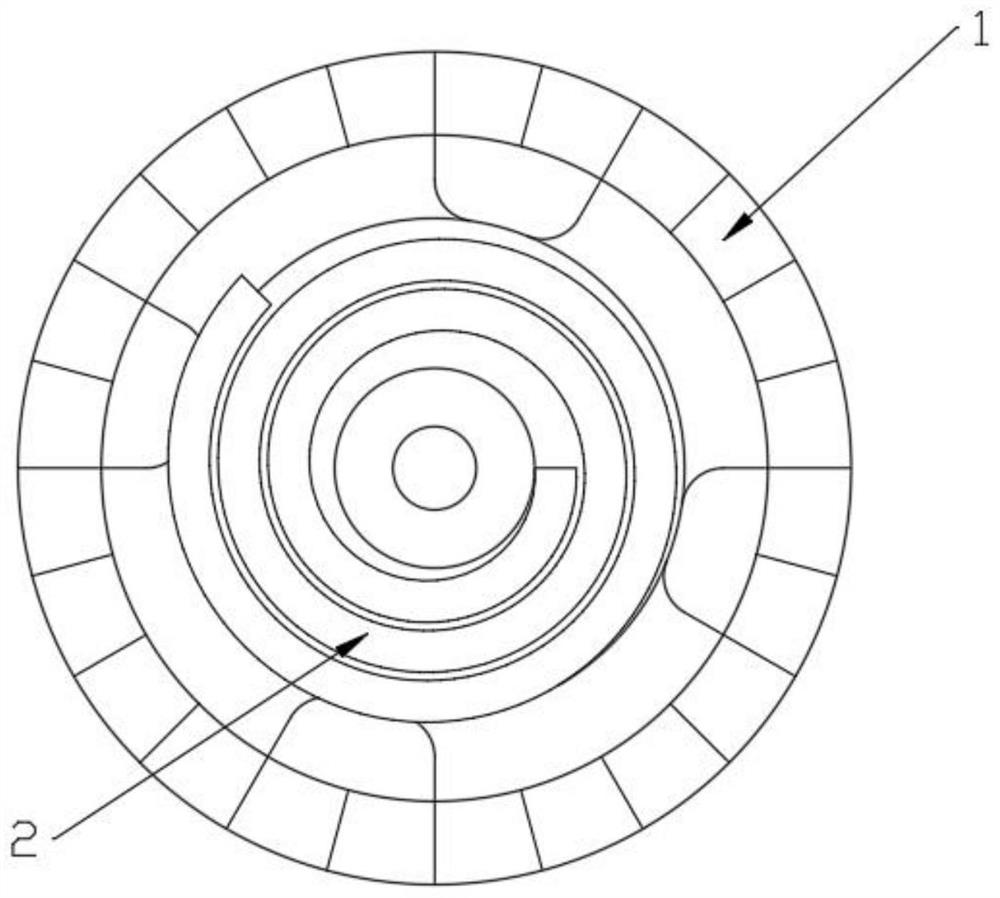

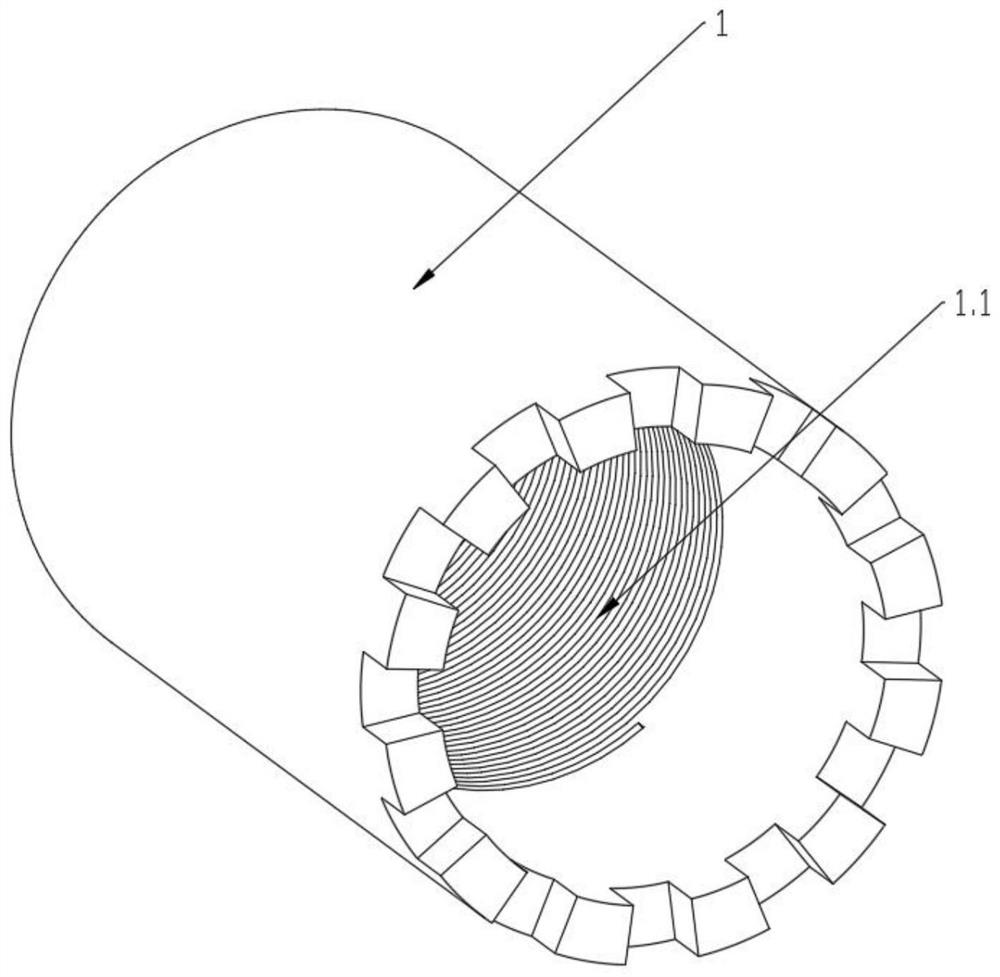

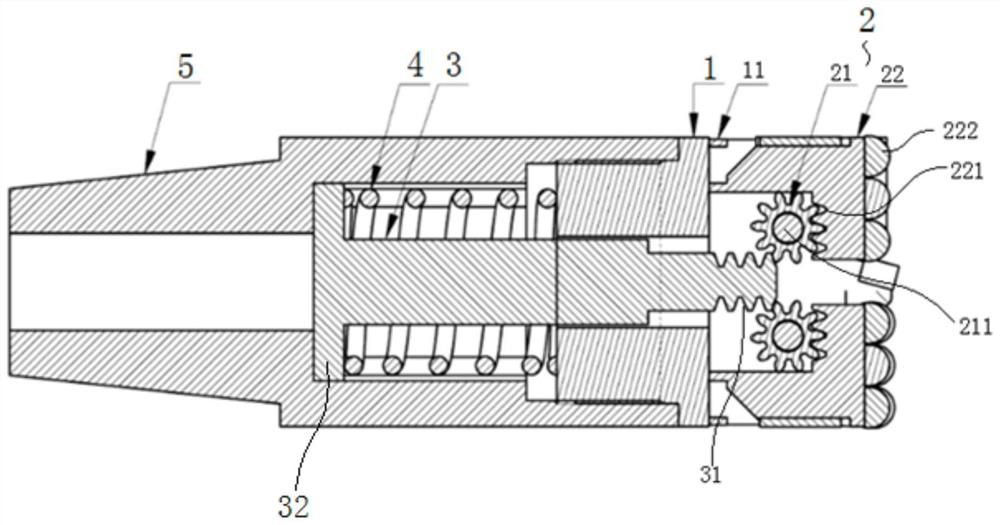

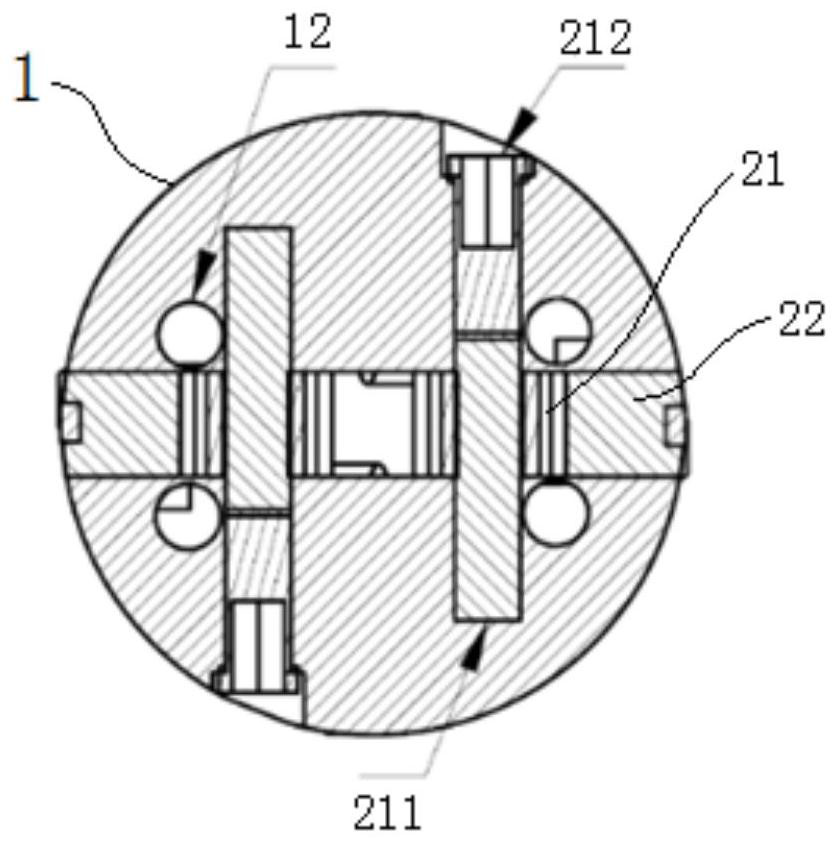

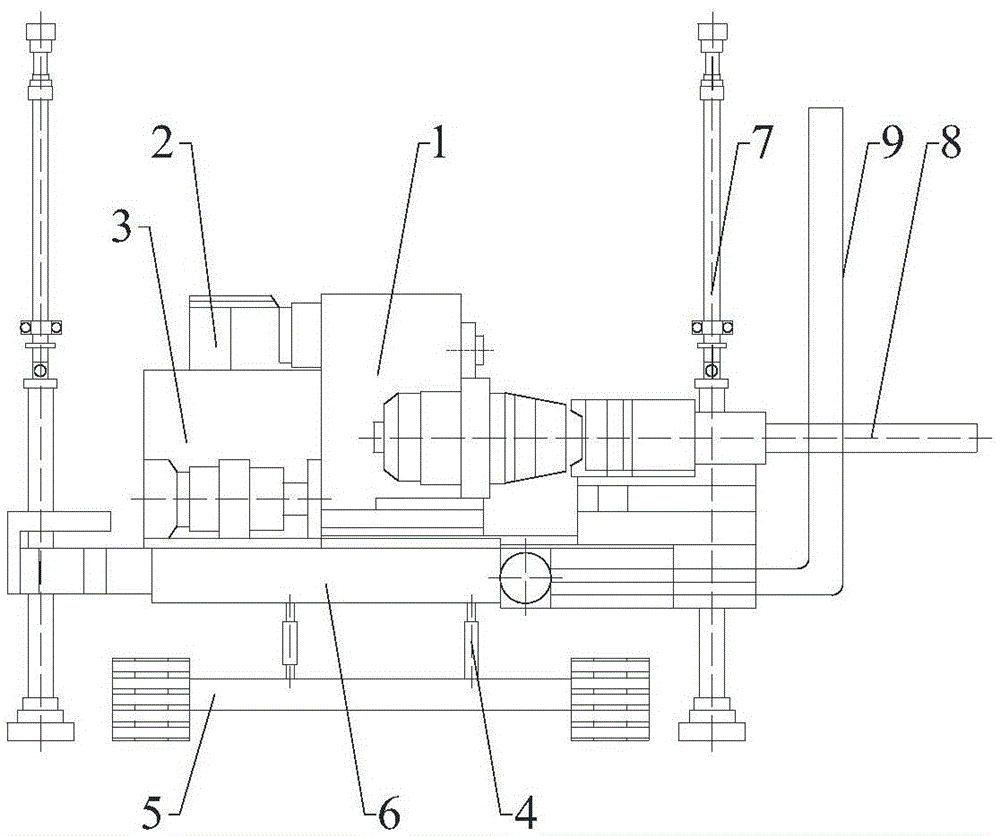

Diameter variable PDC directional drill bit

ActiveCN111119741ASolve the stuck drill problemEnsure safetyDrill bitsConstructionsElastomerRadial motion

The invention discloses a diameter variable PDC directional drill bit. The diameter variable PDC directional drill bit is provided with a drill bit body; a diameter variable cutting component is at least arranged in the radial direction of the drill bit body; the cutting diameter of the drill bit body is changed through linear displacement of the diameter variable cutting component; a gear-rack transmission mechanism is in linkage with the diameter variable cutting component and is embedded into the drill bit body; an elastomer is arranged on the gear-rack transmission mechanism in a sleevingmanner; and a fixed cutting component is also arranged in the radial direction of the drill bit body. After drilling is completed, the size of the outside diameter of the diameter variable PDC directional drill bit disclosed by the invention is reduced, so that the sizes of the outside diameters of a wire measuring drill pipe, a non-magnetic rod, a screw motor and the drill bit connected from a hole orifice are consistent; the problem of jamming of the drill bit caused by drilling hole shrinkage is effectively solved; and the safety of drilling is ensured. The transfer from axial movement to radial movement is realized by adopting the gear-rack transmission mechanism; the structure is stable and reliable; the bearing capacity is high; the transmission precision is high; and the size of thedrill bit can be controlled precisely.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Hydraulic eye reamer and eye reaming method thereof

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

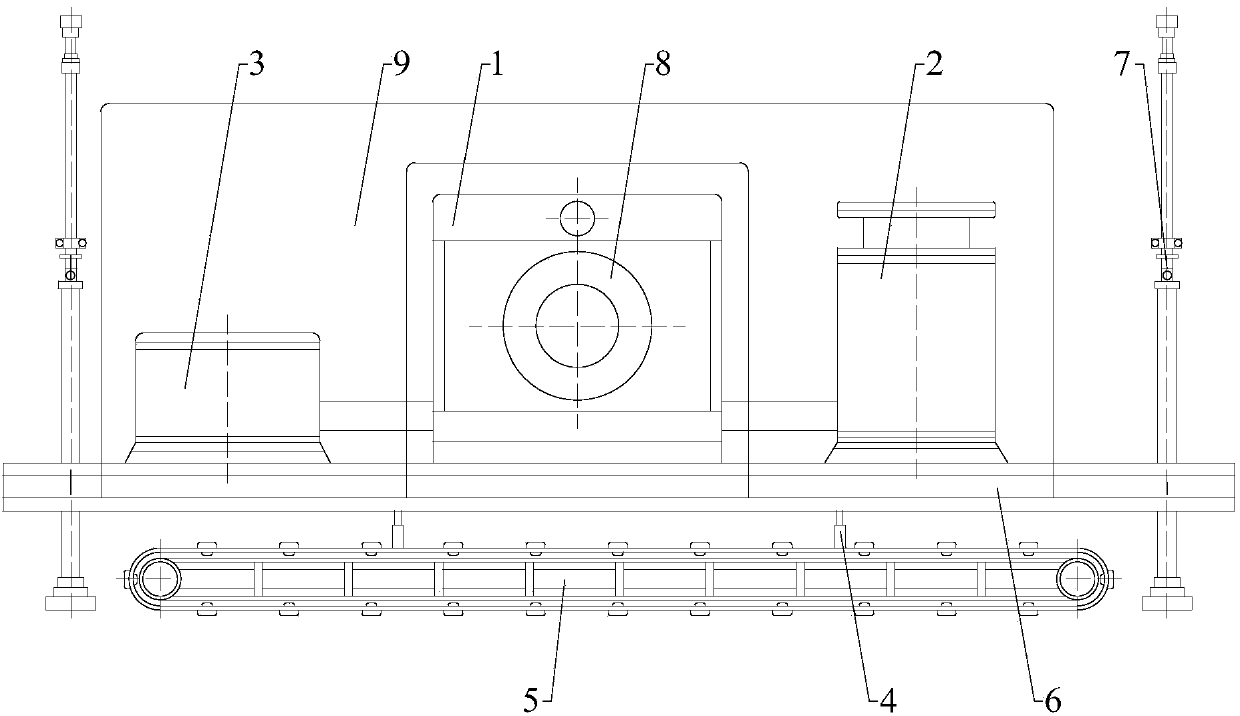

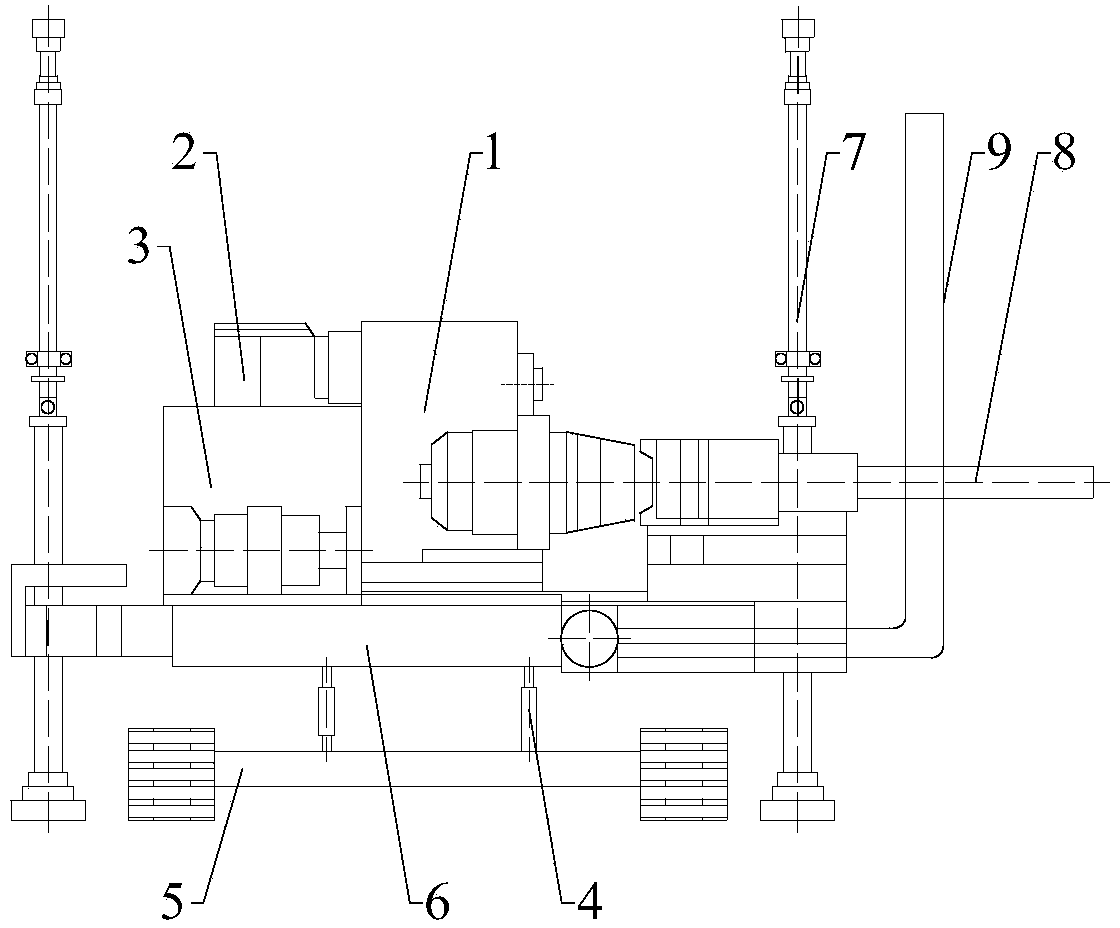

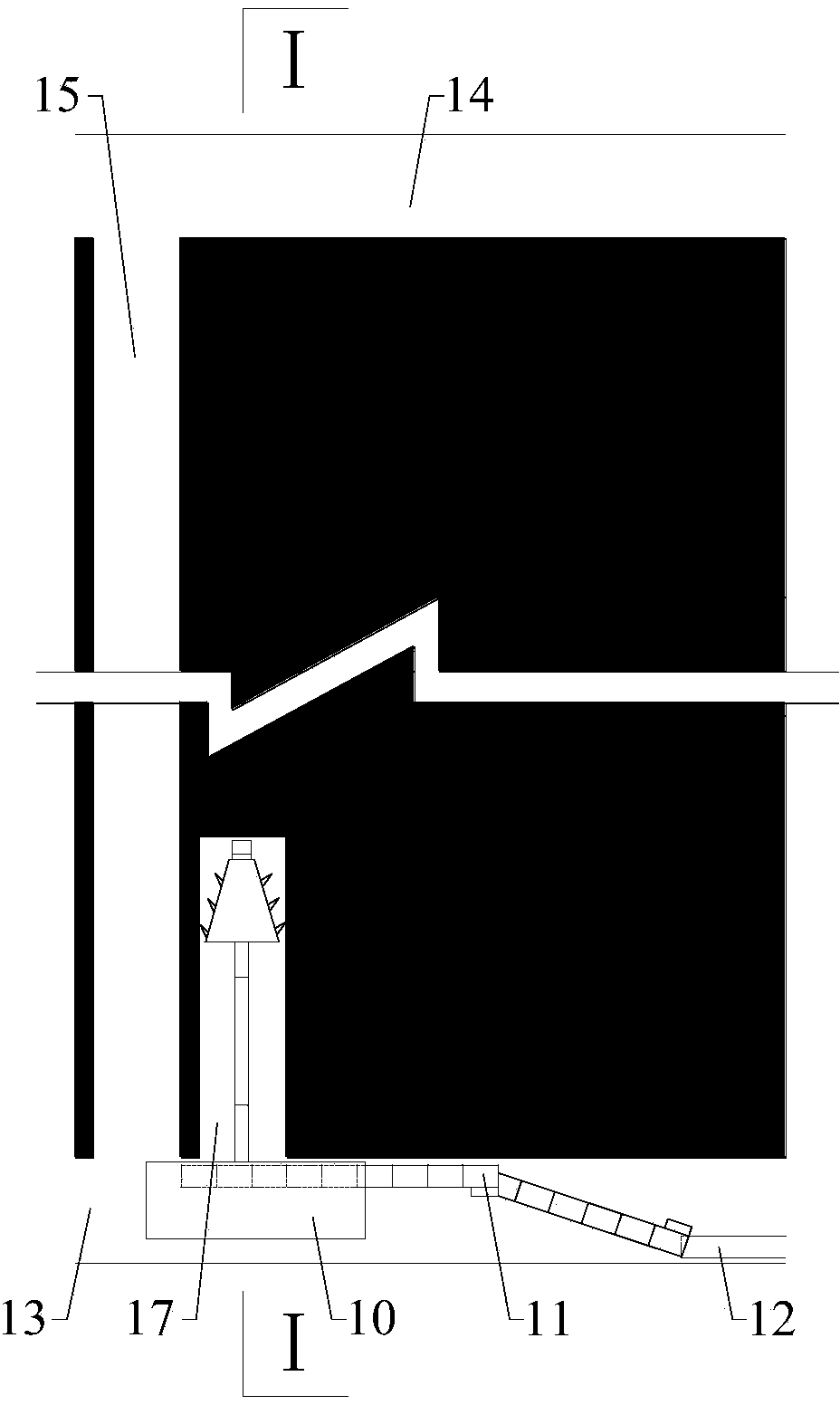

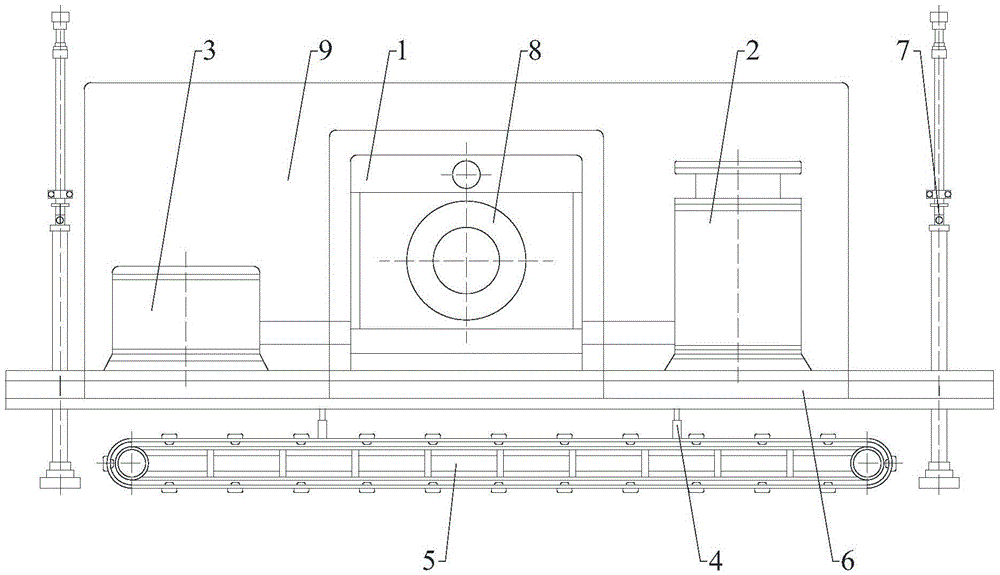

High-dipping low seam self-walking simple drill coal mining machine and mining method thereof

ActiveCN104405385AReduce volumeReduce weightSlitting machinesDrilling machines and methodsEconomic benefitsEngineering

The invention relates to a high-dipping low seam self-walking simple drill coal mining machine and a mining method thereof, which belongs to the drill coal mining machine and mining method. The simple drill coal mining machine comprises a host, a control board, a pumping station, a caterpillar base plate, a support hydraulic column, a pedestal, a stable hydraulic support, a drilling tool assembly and a coal baffle plate. A drilling rod and a drilling rod in the drilling tool assembly are connected through a planetary gear decelerator, the coal baffle plate employs a full transparent design; the invention provides a high-dipping low seam mining method, the height of the support hydraulic column is adjusted to determine the drilling direction, coal mined under gravity effect falls to a scraper plate conveyer along a drill pit, a goaf employs a nature caving method for treatment, and the ventilation mode of a drilling surface is a U type ventilation mode. According to the invention, jamming of a drilling tool can be effectively solved, drilling power and coal breaking effect of the drill coal mining machine can be ensured, and the drill coal mining machine has the advantages of simple production process, low equipment cost of working surface and high technical economic benefit, and the drill coal mining machine has important meaning for increasing coal mining rate and prolong the service time limit.

Owner:CHINA UNIV OF MINING & TECH

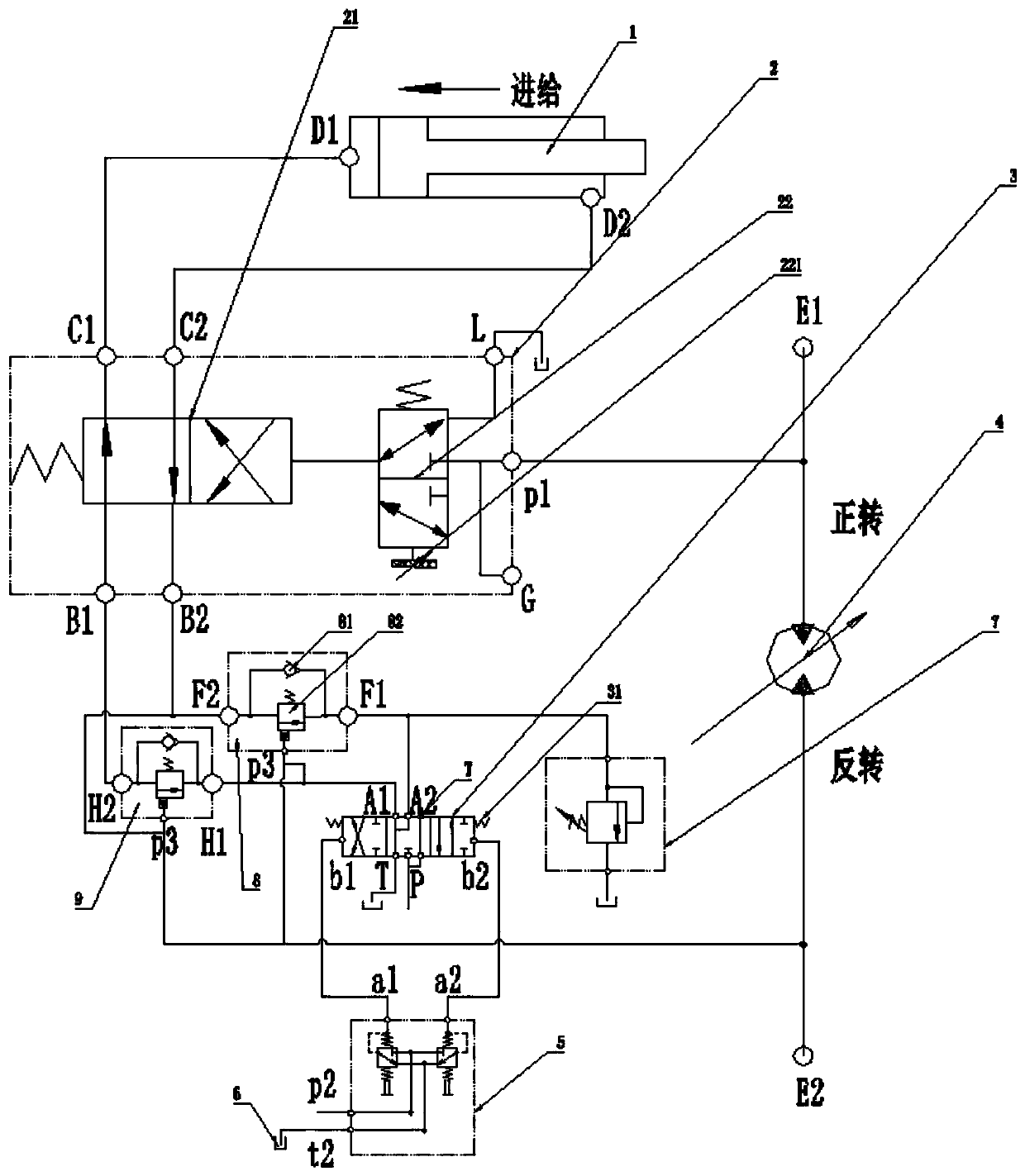

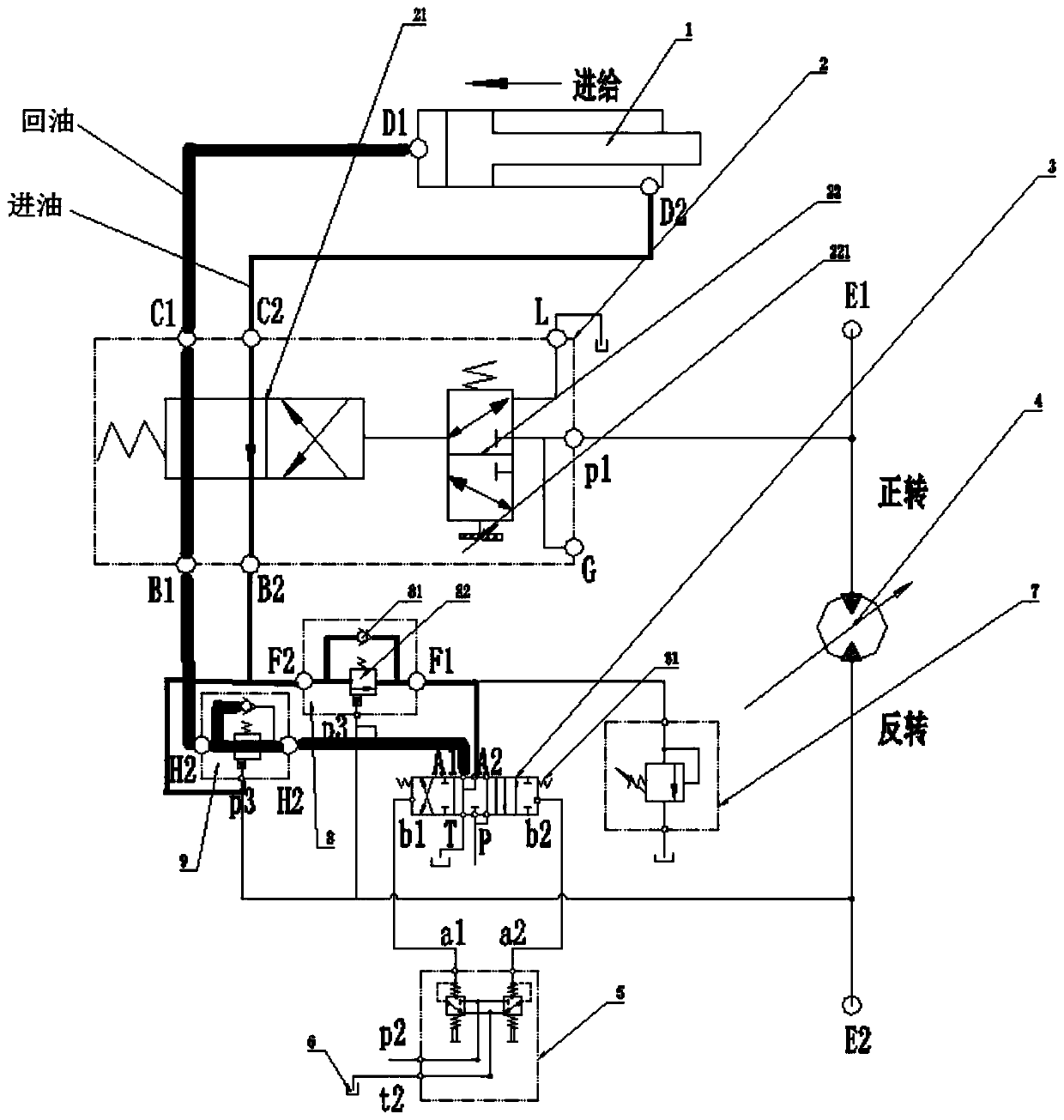

Drilling machine and hydraulic system thereof

PendingCN109944835ASolve the stuck drill problemAvoiding damage to drill pipe threadsDrilling rodsConstructionsHydraulic cylinderElevation angle

The invention provides a drilling machine and a hydraulic system thereof. When the forward rotation pressure of a rotary motor reaches a pressure value to be set of an anti-sticking drilling valve, forward rotation control oil of the rotary motor opens a sequence valve of the anti-sticking drilling valve, and a hydraulic reversing valve of the anti-sticking drilling valve reverses at the same time, so that a hydraulic cylinder is changed from a propulsive state to a retrogressive state; when the rotary motor continues to rotate forward, drilling cuttings are discharged by a drilling tool to avoid sticking; when a drilling rod is disassembled from the drilling machine, a reversing valve is controlled to be in the center, and reverse control oil of the rotary motor opens sequence valves of afirst balance valve and a second balance valve, so that oil circuits of the feeding end and the receding end of the hydraulic cylinder communicate with each other, the hydraulic cylinder is in a floating state, and a damage to drilling rod threads is effectively avoided during disassembling the drilling rod; and when the reversing valve is in the center and the rotary motor does not reverse, hydraulic oil in the oil circuits is sealed in hydraulic cylinder by one-way valves of the first balance valve and the second balance valve to prevent a power head of the drilling machine from falling during drilling holes at an elevation angle or a pitch angle of the drilling tool.

Owner:CHONGQING PINGSHAN MINING ELECTROMECHANICAL EQUIP

Simulation experiment method for drilling-blocking prevention of rock drill in cave

InactiveCN102926683AEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesEngineeringDrill

The invention discloses a simulation experiment method for drilling-blocking prevention of a rock drill in a cave. The method comprises the following steps of: firstly, controlling a rod-disassembling mechanism to pressurize a drilling rod to cause a pressure value of rotary pressure to be stabilized to 12MPa; in the process of the simulation of drilling rocks by a down-the-hole drill, controlling a propulsion handle in an operator cab to pressurize a propulsion mechanism to cause a pressure value of propulsion pressure to be stabilized to 8MPa, and simulating a normal propulsion state of the down-the-hole drill in the process of drilling the rocks; controlling the propulsion handle to depressurize the propulsion mechanism to reduce the propulsion pressure to 5MPa suddenly, and simulating a drilling-blocking phenomenon in the cave and wherein a setting value of a pressure relay of a propulsion circuit is 3MPa, which is less than a critical propulsion pressure value of the drilling-blocking prevention in the cave; and drawing a change curve of the propulsion pressure with changes with time in the process. The method provided by the invention has the beneficial effects that the drilling-blocking problem is solved, the normal drilling operation of the rock drill is ensured, the service life of the rock drill is prolonged, and the body of the rock drill can be assisted to be stressed.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

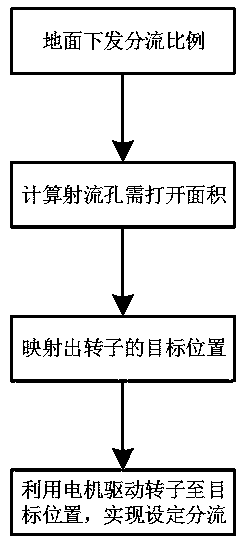

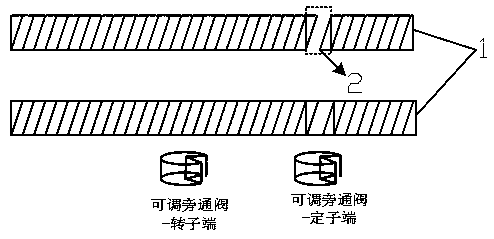

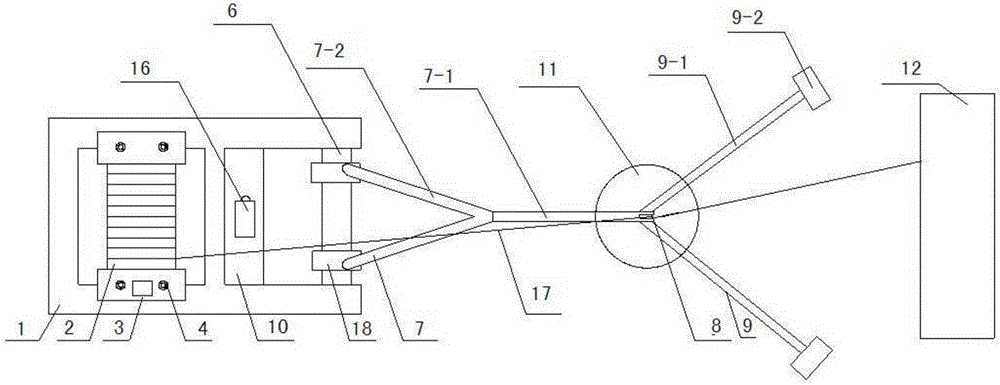

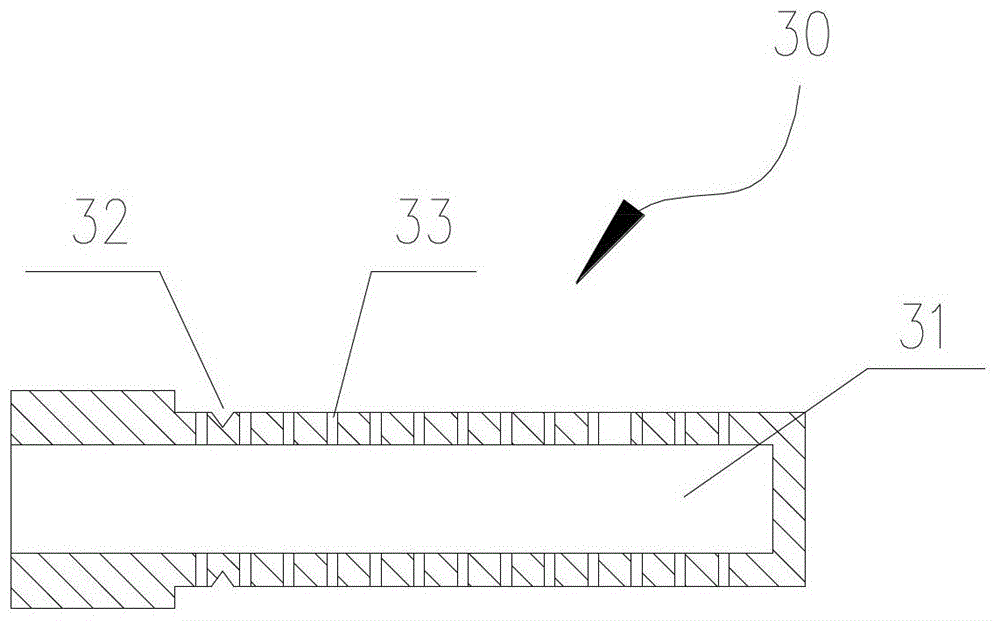

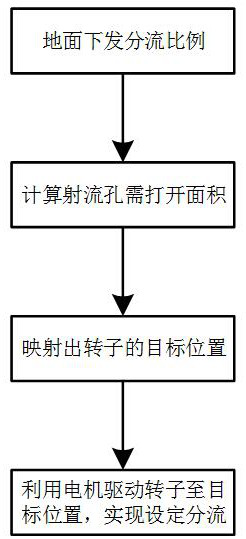

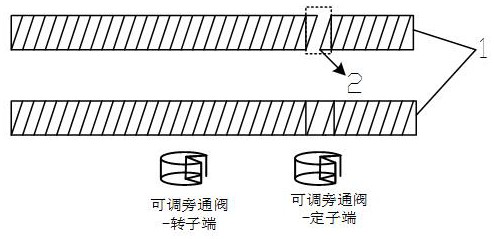

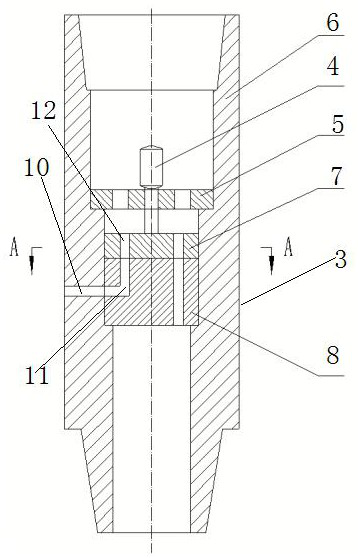

Jet flow adjusting method for rotary steering downhole jam releasing

ActiveCN111502547ARealize the solution cardSolve the stuck drill problemLiquid/gas jet drillingDirectional drillingJet flowWell drilling

The invention discloses a jet flow adjusting method for rotary steering downhole jam releasing, and relates to the technical field of oil well downhole drilling equipment. The jet hole with the adjustable area is designed in a drill column of the rotary steering downhole equipment, and when engineering technicians consider that an downhole rock debris bed is seriously accumulated, an instruction is issued, the flow dividing proportion of the jet hole is determined, the equivalent runner area of a drilling tool is set, the opening area of the jet hole is calculated, part of drilling fluid passes through the jet hole and is combined with rotation of the drill column, and rotating jet flow is formed to destroy a peripheral rock debris bed, so that the rotary steering tool is jam released. Themethod is easy to control and high in jamming releasing capacity, and the drill jamming problem of the downhole rotary steering tool can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Anti-blocking method for hydraulic propulsion circuit of rock drilling machine and rotary circuit in series connection

InactiveCN102926657AEnsure normal drilling workHigh movement precisionDrilling drivesRotary valveFuselage

The invention discloses an anti-blocking method for a hydraulic propulsion circuit of a rock drilling machine and a rotary circuit in series connection. The method comprises the following steps: firstly, arranging an anti-blocking circuit comprising an impactor, a propulsion motor and a rotary motor, wherein an oil way of the impactor is connected with an impacting propulsion pump, a pressure reducing value is arranged outside the propulsion motor, and the rotary motor is connected with a rotary valve; and arranging an anti-blocking valve between the propulsion motor and the rotary motor, wherein the propulsion circuit is that pressure oil of a pump are depressurized to go into a forwarding oil-taking cavity of the propulsion motor, and return oil of the propulsion circuit and the pressure oil of the pump are combined to go into the rotary motor, thus rotary pressure become backpressure, propulsion and rotation of the propulsion motor, thereby forming a series circuit. The method provided by the invention has the beneficial effects of solving drilling-blocking problem advantageously, ensuring normal drilling operation of the rock drilling machine, improving production efficiency, strengthening movement accuracy of the rock drilling machine and reducing wear degree favorably, prolonging the service life and assisting the stress of the body of the rock drilling machine.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Creation method for simulation model of anti-jamming hydraulic control system of rocker driller

InactiveCN102996109AEnsure normal drilling workHigh movement precisionAutomatic control for drillingAnti jammingEngineering

The invention discloses a creation method for a simulation model of an anti-jamming hydraulic control system of a rocker driller, comprising the following steps of: firstly, setting an analogue load input value of a feed mechanism and an analogue input value of a slewing mechanism to cause the feed mechanism and the slewing mechanism to work in a normal state, and to cause feed pressure to stabilize at 8MPA and slewing pressure to stabilize at 12MPA; inputting a process that the feed pressure is reduced from a normal value into the analogue load of the feed mechanism to carry out cave jammed drilling simulation, wherein when the feed pressure is reduced to a setting value of a pressure relay signal of a feeding loop, an electromagnetic reversing valve acts, a multi-way valve changes direction to push a motor to slew, and the feed mechanism retreats; observing whether the anti-jamming hydraulic control system is capable of preventing cave jammed drilling; and inputting a process that the slewing pressure is increased slowly from a normal value into the analogue load of the slewing mechanism to carry out simulated slow varying jammed drilling. The method disclosed by the invention has the beneficial effects that the method is conductive to solving the problem of jammed drilling, ensures normal drilling work of the rock driller, and is conductive to prolonging service life and assisting driller stressing.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Slowly-varying drilling sticking preventing simulation experimental method of rock chiseling machine

InactiveCN102953692AEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesExperimental methodsFuselage

The invention discloses a slowly-varying drilling sticking preventing simulation experimental method of a rock chiseling machine, and the method comprises the following steps that a down-the-hole drill device is started to work at a normal rock chiseling state and is normally rotated after being normally propelled; then a breakout mechanism is controlled to slowly pressurize a drill rod, so that the rotation pressure is slowly increased to 6MPa so as to simulate the slowly-varying drilling sticking, and the applied pressure is smaller than 20 percent of an adjustment value of a pressure relay of a rotation circuit and greater than 30 percent of an adjustment value of a jamming prevention valve; and through the test, a variation curve of the propelling pressure along the time is drawn in the process. The method has the beneficial effects that the drilling sticking problem is solved, the normal drilling work of the rock chiseling machine is guaranteed, the service life is prolonged, and the stress of a machine body can be assisted.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Hydraulic anti-sticking method of rock drill propulsion loop

InactiveCN102943644AEnsure normal drilling workHigh movement precisionBorehole/well accessoriesHydraulic motorSpool valve

The invention discloses a hydraulic anti-sticking method of a rock drill propulsion loop. Firstly, a hydraulic control reversing valve is arranged between a working propulsion oil cylinder and a hydraulic motor, and meanwhile, a hydraulic control anti-sticking valve is additionally arranged between the outer end of an oil passage of the hydraulic control reversing valve and the propulsion oil cylinder. The end of the anti-sticking valve is connected with a hydraulic control loop, and is connected with the hydraulic control valve, one of two loops of the hydraulic control valve is connected with a propulsion loop, and the other of the two loops of the hydraulic control valve is connected with a rotary loop by the hydraulic control loop. The hydraulic system is provided with an anti-sticking loop which is connected with a rock impact system, and then a rock drill is automatically in the light impact state. Meanwhile, a valve core of an upper slide valve of the hydraulic control valve is provided with a sealing structure. The hydraulic anti-sticking method has the beneficial effects that the drill sticking problem is favorably solved, the normal drilling operation of the rock drill is ensured, the production efficiency is improved, the operation precision of the machine is favorably improved, the abrasion condition is favorably reduced, the service life is prolonged, the force on a machine body is assisted to bear, and the like.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Device and working method for drilling hydrate tiny wellbore and rapidly completing well

ActiveCN110029968BSolve the stuck drill problemSimple mechanical structureConstructionsLiquid/gas jet drillingThermodynamicsWell drilling

The invention discloses a device and working method for drilling a hydrate micro-hole and rapidly completing the well, and belongs to the technical field of hydrate mining devices and mining methods. It includes a continuous operation machine, a power control mechanism, a high-pressure water jet pump, a guide, a main pipe and a sub-pipe, the main pipe is connected to the continuous operation machine, and a water jet nozzle is connected to the end of the sub-pipe; the working method is generally as follows: first, Use a large-size drill bit to drill to the target layer at one time to form the main wellbore; secondly, use the high-pressure water jet device composed of the sub-tube to drill the horizontal micro-wellbore in the natural gas hydrate reservoir, and then heat the sub-tube to make the skin fall off and leave The screen is lowered; finally, the mother and child pipes are disconnected to complete the well. The invention is applicable to various natural gas hydrate exploitation methods, realizes the integration of drilling and completion, can effectively suppress sand production, increase the output of hydrate reservoirs, has little influence on hydrate reservoirs, and accelerates the progress of drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Control method for automatic anti-jamming hydraulic system of rock driller

InactiveCN102996091AEnsure normal drilling workHigh movement precisionBorehole/well accessoriesRotary pumpAnti jamming

The invention discloses a control method for an automatic anti-jamming hydraulic system of a rock driller, comprising the following steps that: firstly, an anti-jamming loop which is composed of a propel motor and a rotary motor is arranged, an oil path area which is composed of the propel motor and a propel pump is connected with a sub-system which is composed of an electromagnetic reversing valve, a one-way valve, a control oil supply pump and a handle, the part between the outer side of the rotary motor and a rotary pump is orderly connected with a pressure relay and a hydraulic control multi-way valve; and pressure oil is introduced into the multi-way valve between a rotary loop and the rotary pump, the pressure oil entering the rotary motor positively turns into an oil chamber to cause the rotary motor to rotate forwardly, the pressure relay does not move, and the oil introduced by the control pump orderly passes through the reversing valve, the control handle, and then the control multi-way valve. The control method disclosed by the invention has the beneficial effects that the method is conductive to solving the problem of jammed drilling, ensures normal drilling work of the rock driller, is capable of improving production efficiency, is conductive to improving driller movement precision and reducing wear condition, and is capable of prolonging service life and assisting driller stressing.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

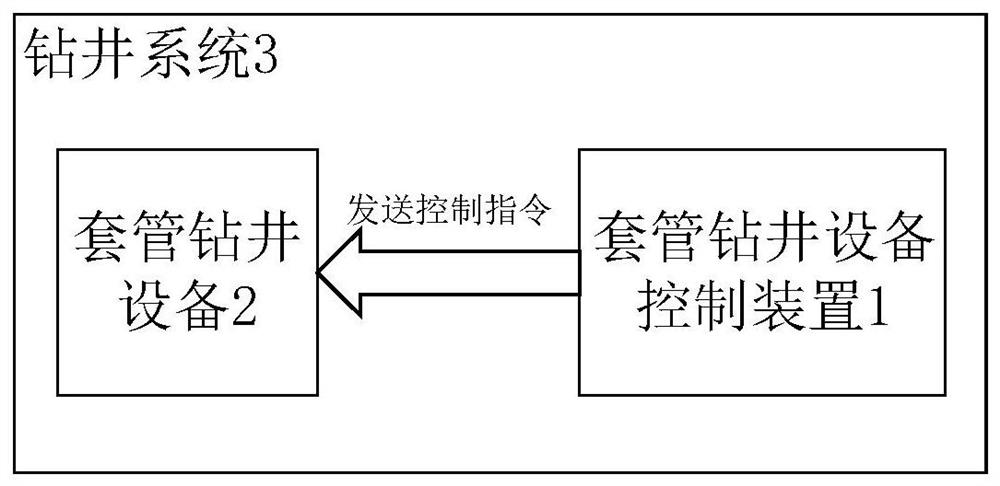

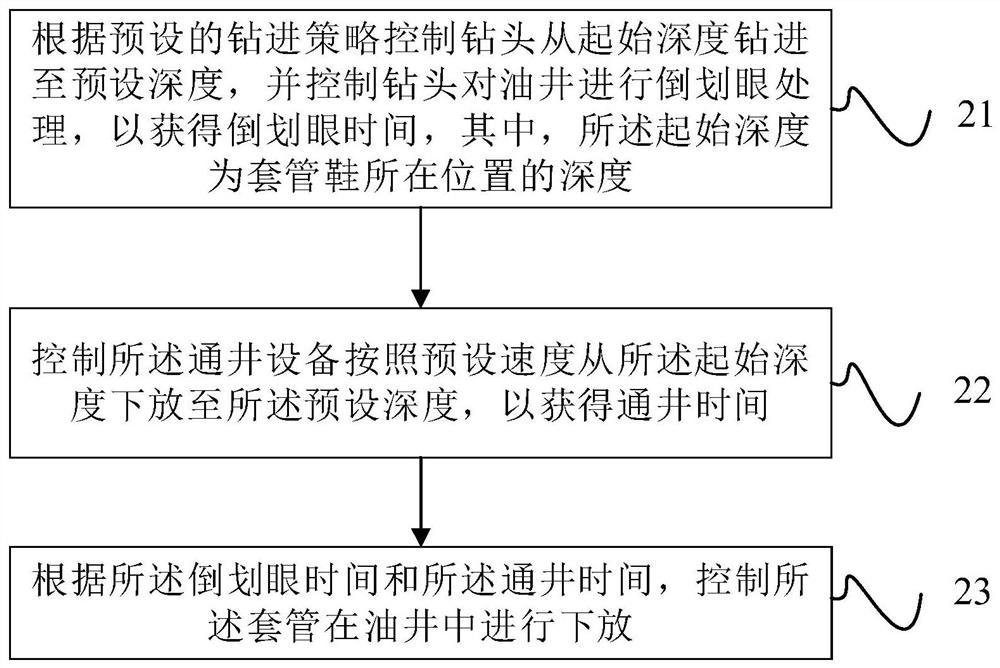

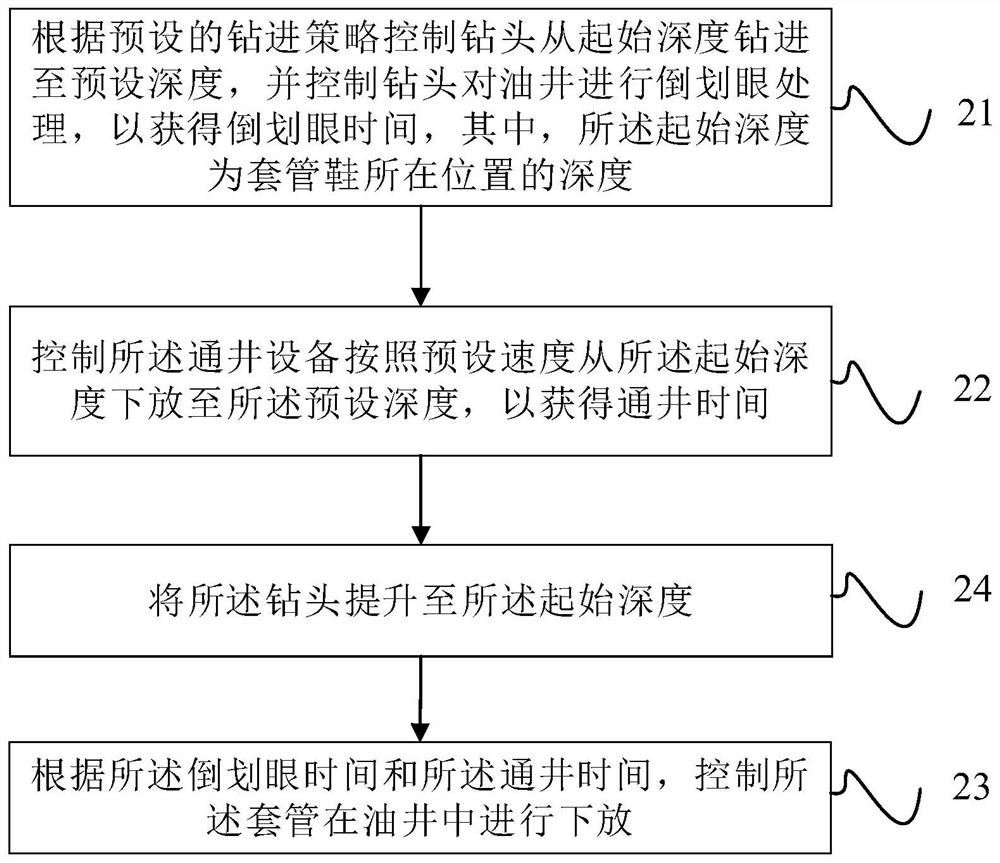

Casing drilling equipment control method and device, electronic equipment and drilling system

PendingCN114876441ASolve the stuck drill problemImprove drilling efficiencyAutomatic control for drillingWell drillingTime control

The invention provides a casing drilling equipment control method and device, electronic equipment and a drilling system, a drill bit is controlled to drill from an initial depth to a preset depth according to a preset drilling strategy, the drill bit is controlled to perform back reaming treatment on an oil well to obtain back reaming time, and the initial depth is the depth of the position where a casing shoe is located; the drifting equipment is controlled to be lowered from the initial depth to the preset depth according to the preset speed, so that drifting time is obtained; and according to the back reaming time and the drifting time, the casing pipe is controlled to be lowered in the oil well. According to the scheme, the problem of low efficiency caused by static observation of hole diameter reduction can be solved, the casing drilling time is shortened, and the casing drilling efficiency is improved.

Owner:PETROCHINA CO LTD

Simulation experiment method for drilling-blocking prevention of rock drill in cave

InactiveCN102926683BEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesEngineeringDrill

The invention discloses a simulation experiment method for drilling-blocking prevention of a rock drill in a cave. The method comprises the following steps of: firstly, controlling a rod-disassembling mechanism to pressurize a drilling rod to cause a pressure value of rotary pressure to be stabilized to 12MPa; in the process of the simulation of drilling rocks by a down-the-hole drill, controlling a propulsion handle in an operator cab to pressurize a propulsion mechanism to cause a pressure value of propulsion pressure to be stabilized to 8MPa, and simulating a normal propulsion state of the down-the-hole drill in the process of drilling the rocks; controlling the propulsion handle to depressurize the propulsion mechanism to reduce the propulsion pressure to 5MPa suddenly, and simulating a drilling-blocking phenomenon in the cave and wherein a setting value of a pressure relay of a propulsion circuit is 3MPa, which is less than a critical propulsion pressure value of the drilling-blocking prevention in the cave; and drawing a change curve of the propulsion pressure with changes with time in the process. The method provided by the invention has the beneficial effects that the drilling-blocking problem is solved, the normal drilling operation of the rock drill is ensured, the service life of the rock drill is prolonged, and the body of the rock drill can be assisted to be stressed.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

A method for preventing jamming in series with hydraulic propulsion circuit and slewing circuit of rock drilling machine

InactiveCN102926657BEnsure normal drilling workHigh movement precisionDrilling drivesRotary valveFuselage

The invention discloses an anti-blocking method for a hydraulic propulsion circuit of a rock drilling machine and a rotary circuit in series connection. The method comprises the following steps: firstly, arranging an anti-blocking circuit comprising an impactor, a propulsion motor and a rotary motor, wherein an oil way of the impactor is connected with an impacting propulsion pump, a pressure reducing value is arranged outside the propulsion motor, and the rotary motor is connected with a rotary valve; and arranging an anti-blocking valve between the propulsion motor and the rotary motor, wherein the propulsion circuit is that pressure oil of a pump are depressurized to go into a forwarding oil-taking cavity of the propulsion motor, and return oil of the propulsion circuit and the pressure oil of the pump are combined to go into the rotary motor, thus rotary pressure become backpressure, propulsion and rotation of the propulsion motor, thereby forming a series circuit. The method provided by the invention has the beneficial effects of solving drilling-blocking problem advantageously, ensuring normal drilling operation of the rock drilling machine, improving production efficiency, strengthening movement accuracy of the rock drilling machine and reducing wear degree favorably, prolonging the service life and assisting the stress of the body of the rock drilling machine.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Combined drill

InactiveCN112012660AEnsure smoothEnsure integrityDrill bitsConstructionsMining engineeringWater flow

The invention discloses a combined drill. The combined drill comprises a first drill bit and a second drill bit, wherein the first drill bit is cylindrical; the second drill bit connected with the first drill bit is coaxially arranged in the first drill bit; a plurality of drainage grooves used for outputting slag flow from the interiors of the drill bits are formed between the first drill bit andthe second drill bit; the drainage grooves are evenly formed in the outer ring of the second drill bit in the axial direction of the second drill bit; a through hole used for inputting water flow isformed in the middle of the second drill bit; the head of the second drill bit is arranged at the position, close to one end of the head of the first drill bit by a certain distance in the axial direction; the tail of the first drill bit is flush with the tail of the second drill bit; and the second drill bit is connected with a drill rod. Through cooperative work of two different drill bit functional combinations and change of drill bit cutting and de-slagging ways, smoothness and completeness of the inner wall face of a drill hole are guaranteed, the hole forming rate of the drill hole is increased, the length of the drill hole is increased, and the problems of hole collapse and drill jamming in the stratum drilling process are effectively solved.

Owner:郑乃国

A variable diameter pdc directional drill bit

ActiveCN111119741BSolve the stuck drill problemEnsure safetyDrill bitsConstructionsRadial motionGear wheel

The invention discloses a variable-diameter PDC directional drill, which is provided with a drill body, and a variable-diameter cutting member is arranged on the drill body at least radially, and the linear displacement of the variable-diameter cutting member realizes the cutting diameter of the drill body. Change; in conjunction with the variable-diameter cutting member, a rack-and-pinion transmission mechanism is embedded in the drill bit body, and an elastic body is sleeved on the rack-and-pinion transmission structure; radially on the drill bit body A stationary cutting member is also provided. After the drilling is completed, the outer diameter of the variable-diameter PDC directional drill bit of the present invention becomes smaller, thereby forming a wired measurement drill pipe connected from the hole, a non-magnetic drill pipe, a screw motor and a drill bit with the same outer diameter, effectively solving the problem of It solves the problem of drill bit sticking caused by the shrinkage of the drill hole, and ensures the safety of the drill hole. The rack and pinion transmission structure is adopted to realize the transfer from axial movement to radial movement. The structure is stable and reliable, the bearing capacity is large, the transmission precision is high, and the size of the drill bit can be precisely controlled.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

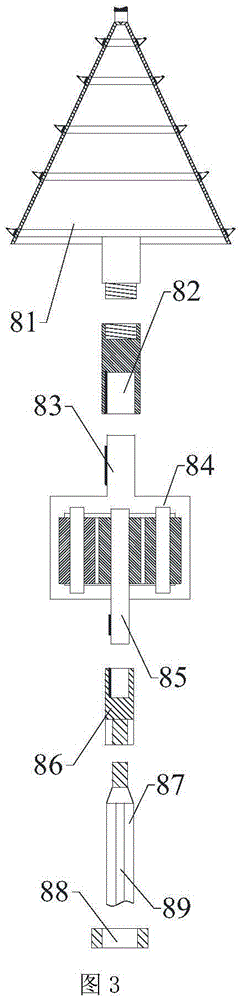

Rope coring fishing system for deep sea subsea drilling rig and method of use thereof

The invention discloses a deep-sea submarine drilling rig rope coring salvage system and its use method. The deep-sea submarine drilling rig rope coring salvage system includes a salvage winch, a salvage rope, an underwater pull force sensor, a top cover, a main shaft and a salvage device; a salvage rope One end is wound on the salvage winch, and the other end of the salvage rope goes around the pulley at the lower end of the underwater pull force sensor, passes through the tapered hole on the top cover and is connected with the upper end of the overshot placed in the central hole of the main shaft. The present invention utilizes the self-weight of the heavy hammer rod of the dredge to provide the driving force, and through the cooperative work among the helical teeth of the pressing rod, the helical teeth of the rotating core, the helical teeth of the rotating core II and the compression spring, not only can the spearhead be fished out of the inner tube of the rock core It can also be locked by driving the rotary core ferrule to rotate an angle of the rotary core helical tooth Ⅰ or rotary core helical tooth Ⅱ to release the clamping of the spear head of the inner tube of the core, so that the inner tube of the core can be realized very conveniently. fishing and release; and the present invention can also easily solve the problem of pipe sticking in the inner pipe of the core.

Owner:HUNAN UNIV OF SCI & TECH

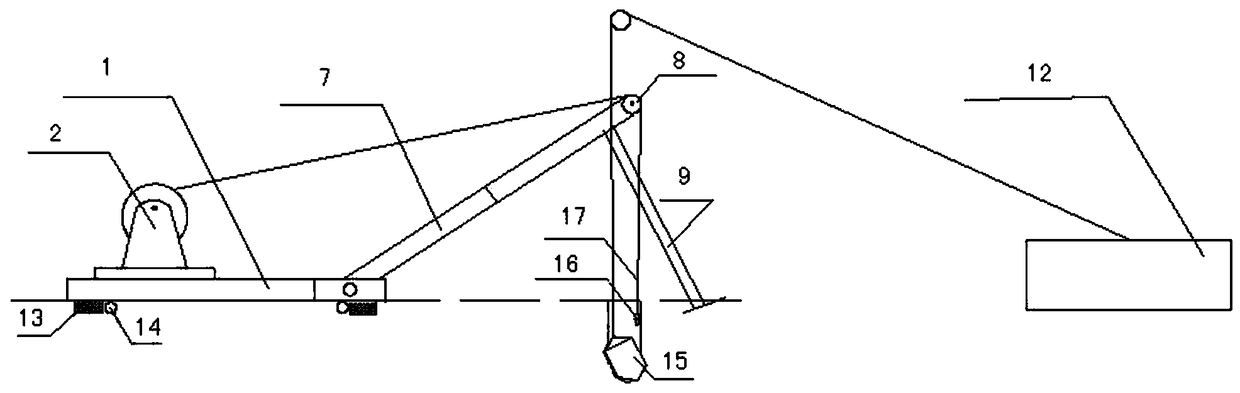

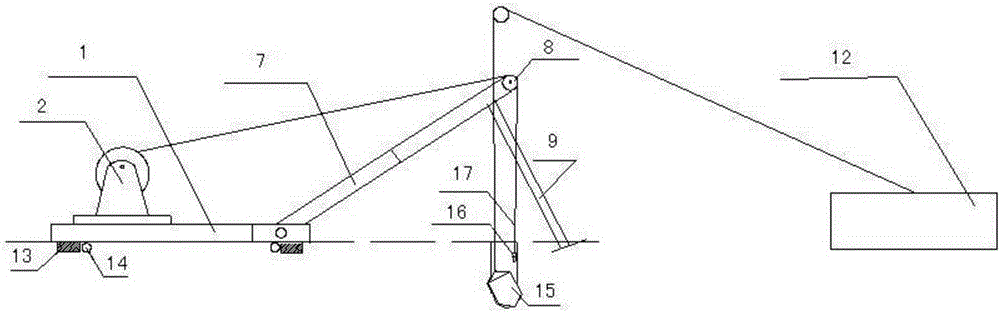

Device and method for treating stuck drill of perforated pile

The invention discloses a punched-pile drill blocking processing device. The drill blocking processing device comprises a chassis and a suspension arm. A winch support, a tray for containing a hammer and a suspension arm sliding rail are arranged on the chassis. A winch is arranged on the winch support. The suspension arm comprises two suspension-arm back sections and a suspension-arm front section, and a pulley is arranged at the front end of the suspension-arm front section. Two sliding blocks are arranged on the suspension arm sliding rail and are hinged to the two suspension-arm back sections respectively. The suspension-arm front section is hinged to two supporting frames, and the two supporting frames and the suspension arm form a tripod structure. A steel wire rope with scales on the winch penetrates through the pulley on the suspension arm and then is connected with the hammer. The projection of the hammer is located in a punched pile by adjusting the relative positions of the two sliding blocks and / or moving the two supporting frames. The invention further provides a punched-pile drill blocking processing method. By means of the drill blocking processing device and method, the problems that in the pile-foundation construction process, drill blocking occurs, and construction can not be normally carried out are solved, and smooth construction is guaranteed.

Owner:WUHAN ENGINEERING CO LTD OF CHINA RAILWAY SEVENTH GROUP

Punched-pile drill blocking processing device and method

The invention discloses a punched-pile drill blocking processing device. The drill blocking processing device comprises a chassis and a suspension arm. A winch support, a tray for containing a hammer and a suspension arm sliding rail are arranged on the chassis. A winch is arranged on the winch support. The suspension arm comprises two suspension-arm back sections and a suspension-arm front section, and a pulley is arranged at the front end of the suspension-arm front section. Two sliding blocks are arranged on the suspension arm sliding rail and are hinged to the two suspension-arm back sections respectively. The suspension-arm front section is hinged to two supporting frames, and the two supporting frames and the suspension arm form a tripod structure. A steel wire rope with scales on the winch penetrates through the pulley on the suspension arm and then is connected with the hammer. The projection of the hammer is located in a punched pile by adjusting the relative positions of the two sliding blocks and / or moving the two supporting frames. The invention further provides a punched-pile drill blocking processing method. By means of the drill blocking processing device and method, the problems that in the pile-foundation construction process, drill blocking occurs, and construction can not be normally carried out are solved, and smooth construction is guaranteed.

Owner:WUHAN ENGINEERING CO LTD OF CHINA RAILWAY SEVENTH GROUP

An organic salt drilling fluid

ActiveCN105694830BImprove thermal stabilityReduce fluid lossDrilling compositionFiltrationPolyethylene glycol

The invention discloses organic salt drilling fluid. The organic salt drilling fluid is prepared from 1%-4% of bentonite, 0.3%-0.5% of sodium carbonate, 0.5%-1% of sodium hydroxide, 0.3%-1% of xanthan gum, 2%-8% of a filtrate loss reducer, 2%-5% of a nanometer blocking agent, 1%-4% of a blocking agent, 0.5%-4% of a lubricating agent, 40%-60% of organic salt and 25%-250% of an inert weighting agent, wherein the nanometer blocking agent is prepared by copolymerizing methacrylic acid carbomethoxy cage-like oligomeric silsesquioxane, N-isopropylacrylamide and acrylamide, and the lubricating agent is prepared by compounding castor oil polyoxyethylene ether, polyethylene glycol and polyvinyl pyrrolidone. The organic salt drilling fluid has the very good heat stability, the low filtration loss and the high blocking performance and lubricating performance and is especially suitable for shale gas well development.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of self-propelled simple drilling and shearing machine and mining method for steeply inclined thin coal seam

ActiveCN104405385BReduce volumeReduce weightSlitting machinesDrilling machines and methodsEconomic benefitsEngineering

The invention relates to a high-dipping low seam self-walking simple drill coal mining machine and a mining method thereof, which belongs to the drill coal mining machine and mining method. The simple drill coal mining machine comprises a host, a control board, a pumping station, a caterpillar base plate, a support hydraulic column, a pedestal, a stable hydraulic support, a drilling tool assembly and a coal baffle plate. A drilling rod and a drilling rod in the drilling tool assembly are connected through a planetary gear decelerator, the coal baffle plate employs a full transparent design; the invention provides a high-dipping low seam mining method, the height of the support hydraulic column is adjusted to determine the drilling direction, coal mined under gravity effect falls to a scraper plate conveyer along a drill pit, a goaf employs a nature caving method for treatment, and the ventilation mode of a drilling surface is a U type ventilation mode. According to the invention, jamming of a drilling tool can be effectively solved, drilling power and coal breaking effect of the drill coal mining machine can be ensured, and the drill coal mining machine has the advantages of simple production process, low equipment cost of working surface and high technical economic benefit, and the drill coal mining machine has important meaning for increasing coal mining rate and prolong the service time limit.

Owner:CHINA UNIV OF MINING & TECH

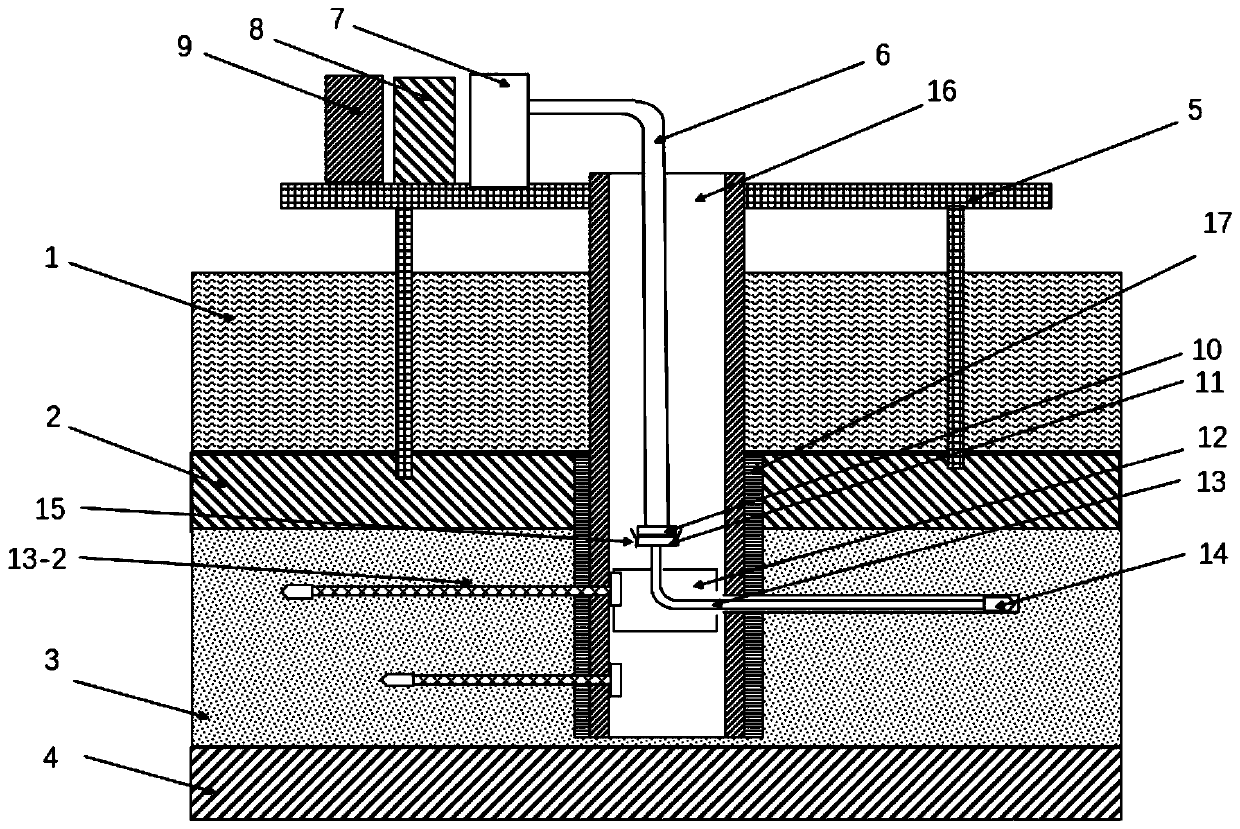

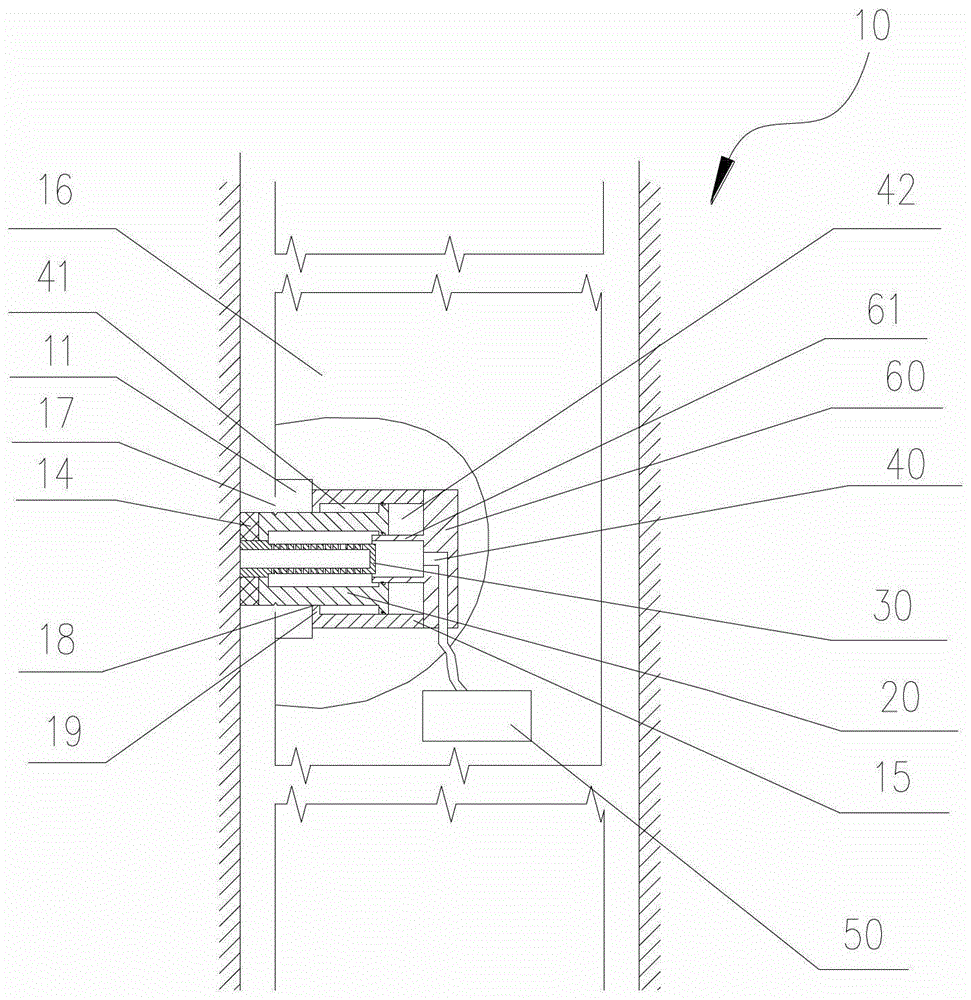

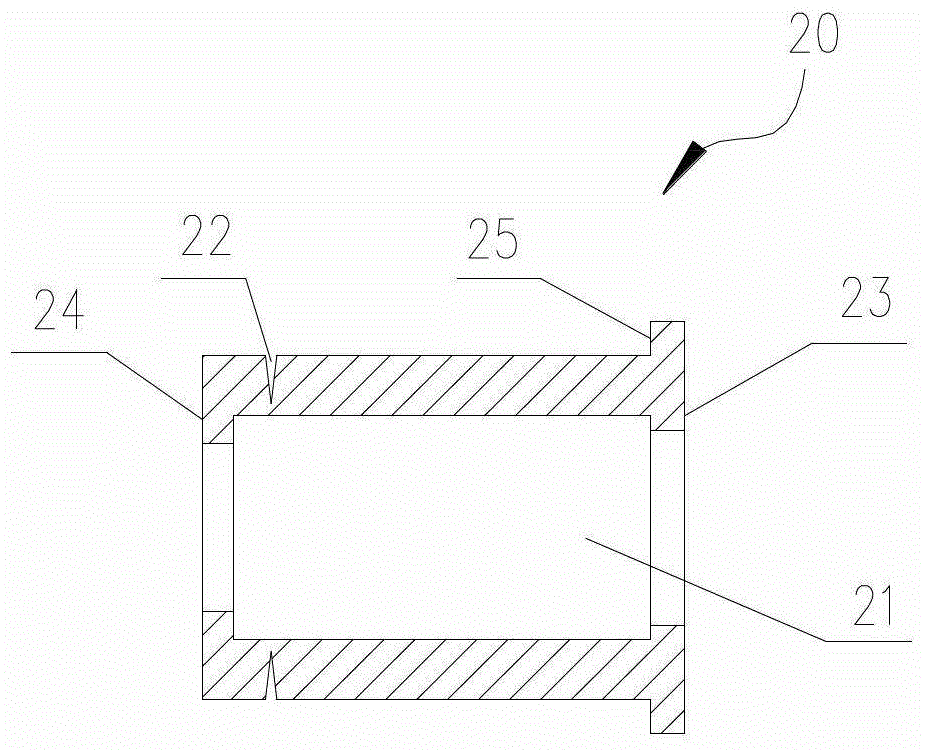

Probes for measuring formation pressure

The invention relates to a probe for measuring formation pressure. The probe comprises a shell, a measuring component mounted inside the shell, and a piston, a first extending hole is arranged on the peripheral wall of the shell, the measuring component comprises an axially-mounted piston cylinder, a second extending hole aligning at the first extending hole is arranged on a first end portion, facing the outer side, of the piston cylinder, a second end portion, positioned on the opposite side of the first end portion, of the piston cylinder is closed by an end cap and provided with a fluid passage axially penetrating the end cap, the piston is arranged in the piston cylinder and can penetrate the first extending hole and the second extending hole to reciprocate, a through hole penetrating the piston is arranged along the axial direction of the piston, and a first notch capable of aligning at the peripheral wall of the shell is arranged on the outer surface of the peripheral wall of the piston. By the probe, the problem of pipe sticking caused by the fact that a probe cannot be normally withdrawn can be solved, and well drilling safety is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A jet adjustment method for downhole sticking of rotary steerable

ActiveCN111502547BRealize the solution cardSolve the stuck drill problemLiquid/gas jet drillingDirectional drillingThermodynamicsJet flow

The invention discloses a jet regulating method for downhole jamming of rotary steering, and relates to the technical field of downhole drilling equipment for oil wells. In the present invention, a jet hole with adjustable area is designed on the drill string of the rotary steerable downhole equipment. When engineers and technicians think that the downhole cuttings bed is seriously accumulated, an instruction is issued to clarify the split ratio of the jet hole and set the equivalent of the drilling tool. The area of the flow channel is calculated by calculating the opening area of the jet hole, allowing a part of the drilling fluid to pass through the jet hole, combined with the rotation of the drill string, to form a rotating jet, destroying the surrounding cuttings bed, and realizing the release of the rotary steerable tool. The invention has simple control and strong jamming ability, and can effectively solve the drill jamming problem of the downhole rotary steering tool.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

An online control hydraulic drilling anti-jamming method

ActiveCN102926738BEnsure normal drilling workHigh movement precisionAutomatic control for drillingOnline testRemote computer

The invention discloses a method for controlling anti-blocking of hydraulic drilling on line. The method comprises the following steps of: firstly, arranging an anti-blocking circuit comprising an impactor, a propulsion motor and a rotary motor; connecting a propulsion pump with an oil-way of the impactor, and connecting an online monitoring device at the outer parts of the propulsion motor and the rotary motor; connecting the online monitoring device with a remote computer to perform online test and monitor propulsion pressure or speed, and mounting a sensor capable of detecting sudden reduction of the propulsion pressure or sudden increment of the propulsion speed onto the online monitoring device to determine that a drill bit drills into a cave; and performing online test and monitoring on rotary pressure through the sensor by the remote computer, and adjusting a gradually-increasing signal of the rotary pressure to control stepless reduction of the pressure when the rotary pressure exceeds a normal value. The method provided by the invention has the beneficial effects that the blocking problem in the drilling is solved, normal drilling operation of a rock drill is ensured, the production efficiency is improved, movement accuracy of the rock drill is improved, the wear degree of the rock drill is reduced, the service life of the rock drill is prolonged, the stress of the body of the rock drill can be assisted, and the like.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com