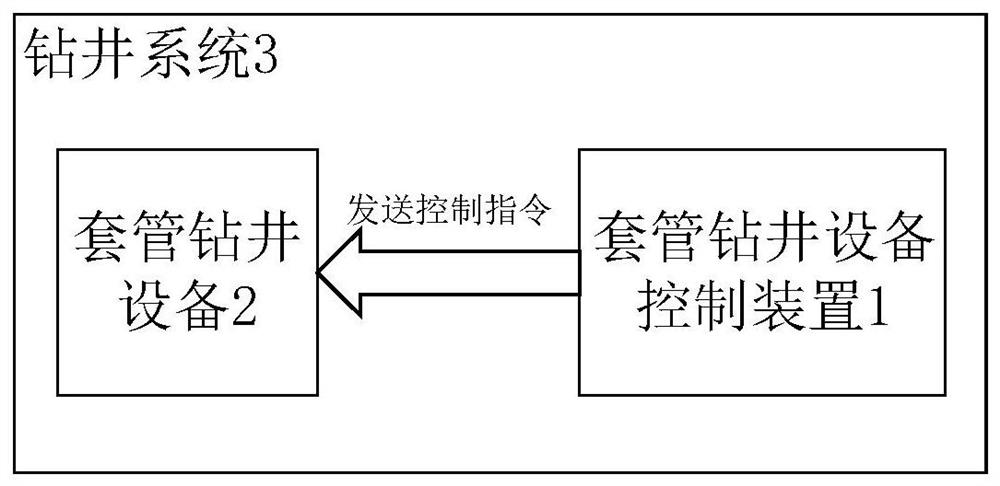

Casing drilling equipment control method and device, electronic equipment and drilling system

A technology of equipment control and casing drilling, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of low efficiency, avoid stuck pipe, improve casing drilling efficiency, and shorten casing drilling the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

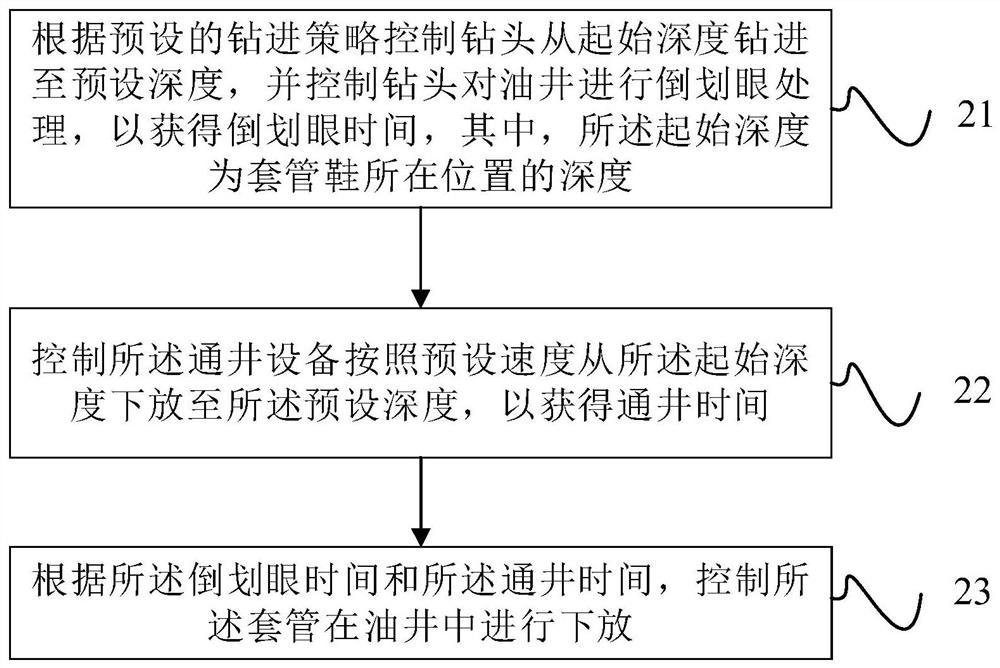

[0067] figure 2 A flowchart of a method for controlling casing drilling equipment provided in an embodiment of the present disclosure, the method is applied to a casing drilling equipment control device, and the casing drilling equipment includes a drill bit, a well-passing equipment, a casing shoe and a casing , and the stiffness of the well-passing equipment is greater than the stiffness of the casing, such as figure 2 As shown, the executive body of this embodiment is a casing drilling equipment control device, and a casing drilling equipment control method provided by an embodiment of the present disclosure includes:

[0068] S21. Control the drill bit to drill from the initial depth to the preset depth according to the preset drilling strategy, and control the drill bit to perform back-reaming processing on the oil well, so as to obtain the back-reaming time, wherein the initial depth is the casing The depth of where the shoe is located.

[0069] Wherein, the preset d...

Embodiment 2

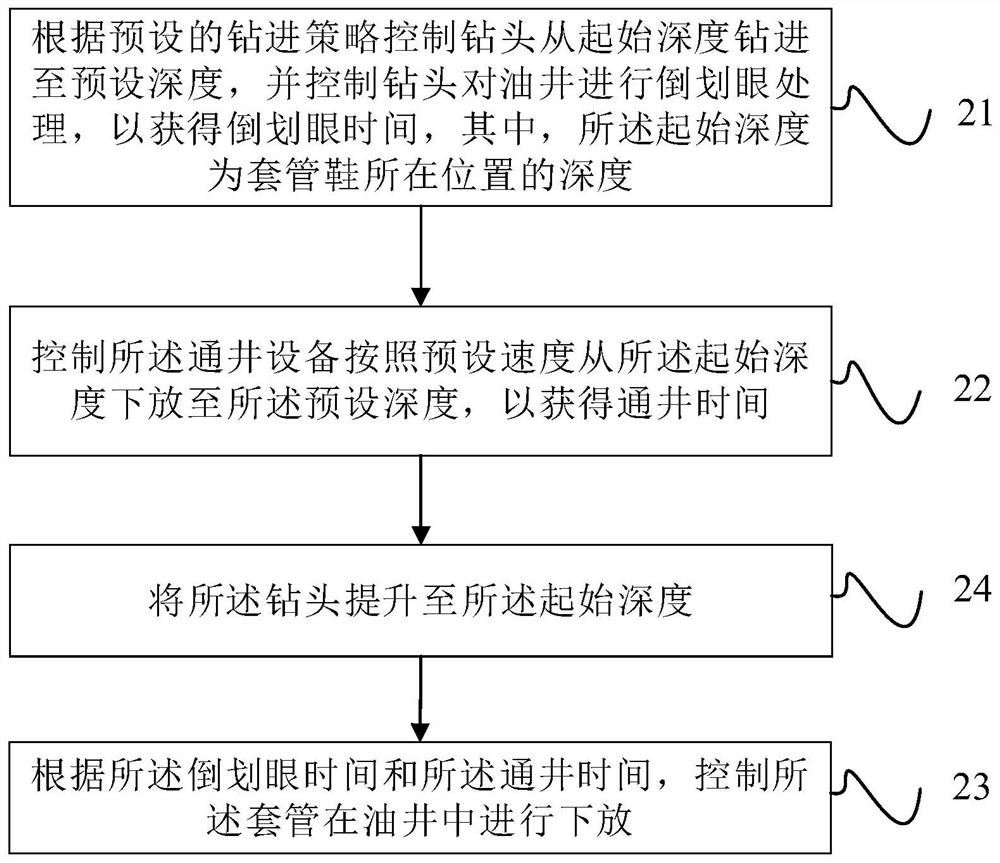

[0080] image 3 The flow chart of another casing drilling equipment control method provided by the embodiment of the present disclosure, such as image 3 As shown, the executive body of this embodiment is a casing drilling equipment control device. In order to better control the running of the well-passing equipment in the oil well, the casing drilling equipment control method provided by the embodiment of the present disclosure further includes before S22:

[0081] S24. Raise the drill bit to the starting depth.

[0082] Wherein, the starting depth is the depth where the casing shoe is located.

[0083] In this embodiment, after the drill bit is raised to the initial depth, the drill bit can be replaced, and the generated oil well is processed by using the well-passing equipment, so as to reduce the interference of the drill bit with the well-passing equipment.

Embodiment 3

[0085] The execution body of this embodiment is the casing drilling equipment control device. The casing drilling equipment control method provided by the embodiment of the present disclosure is a further description of step S21 in the first embodiment. In this embodiment, the preset drilling strategy is: The segmented drilling strategy, correspondingly, S21 includes:

[0086] S211. Set a plurality of target depths within a preset depth range, where the preset depth range is a range between the starting depth and the preset depth.

[0087] In this embodiment, the purpose of setting multiple target depths is to perform segmented drilling, and segmented drilling can perform drilling and back-reaming in segments, so as to ensure the smoothness of newly generated well sections and avoid early generation of wells. Severe diameter reduction problem occurred in the segment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com