Rope coring fishing system for deep sea subsea drilling rig and method of use thereof

A wireline coring and drilling rig technology, which is applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as core tube stuck, core sample contamination, and coring failure, so as to achieve salvage and The effect of release, easy manipulation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

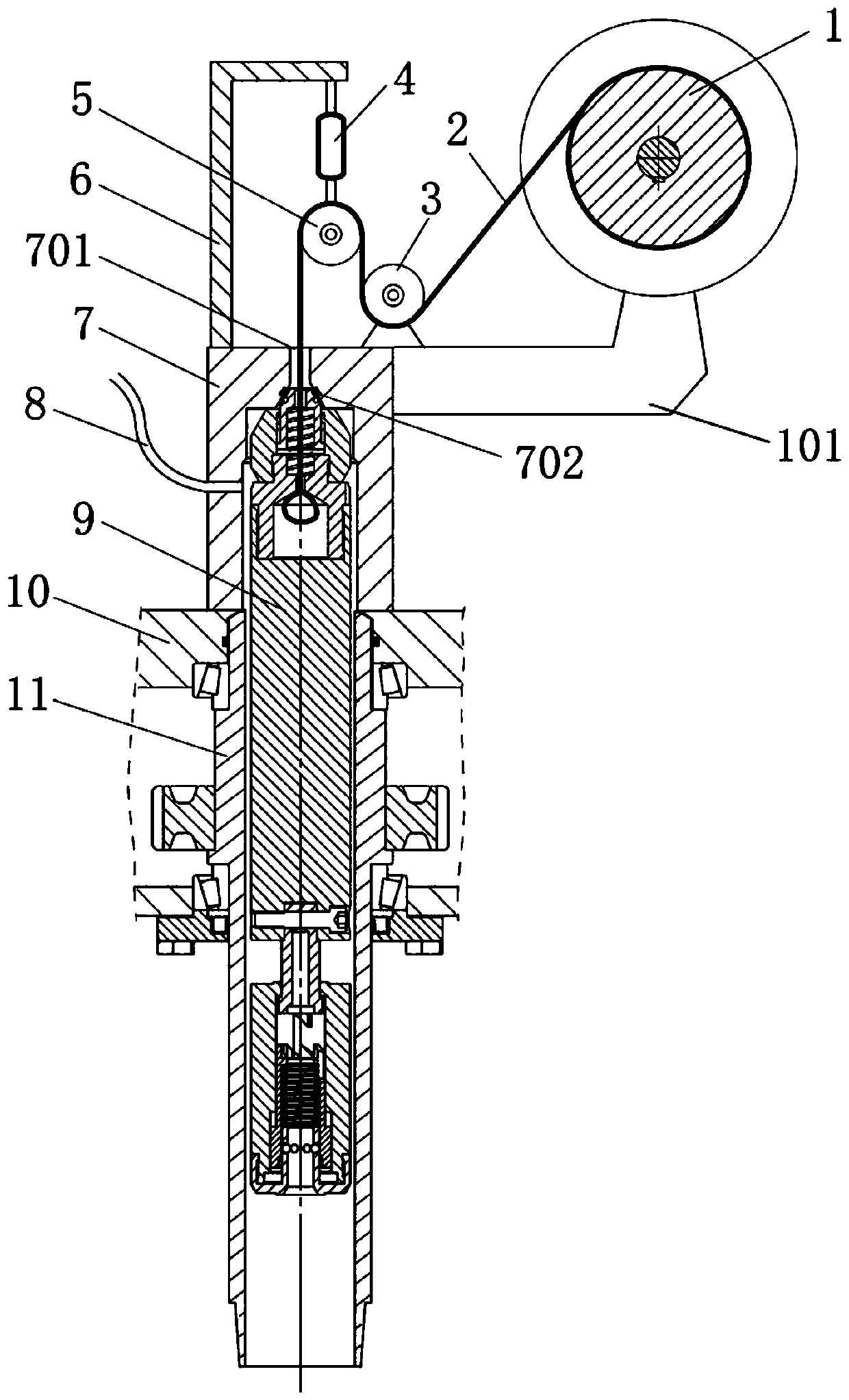

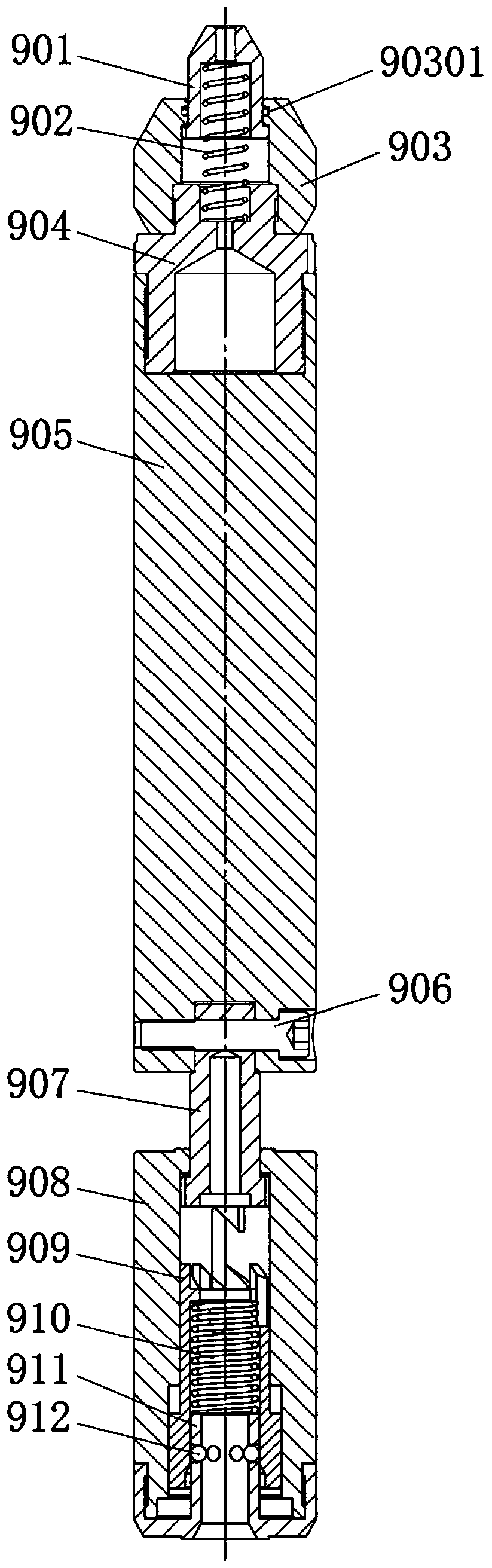

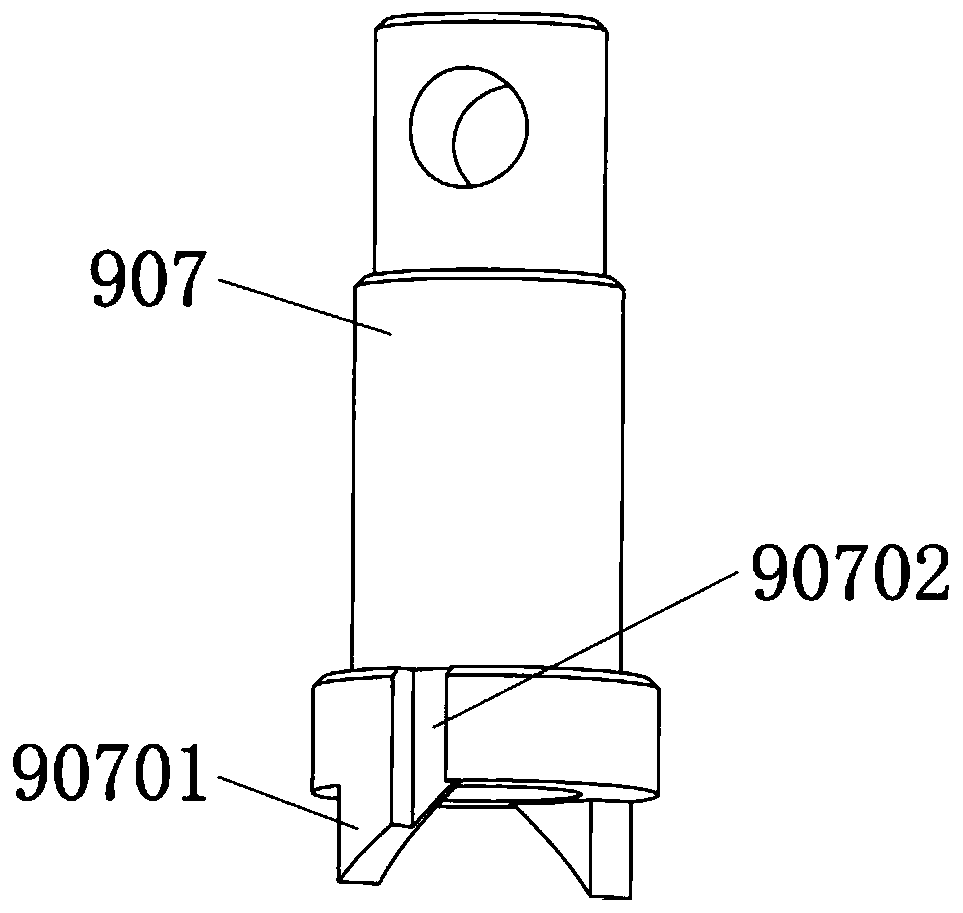

[0038] Such as Figure 1-11 As shown, the deep-sea subsea drilling rig rope coring salvage system of the present invention includes a salvage winch 1, a salvage rope 2, an underwater pull force sensor 4, a top cover 7 and a salvage device 9; the top cover 7 is installed on the drilling power head 10, The central hole of the top cover 7 communicates with the central hole of the main shaft 11 of the drilling head 10 . The side wall of the top cover 7 is provided with a water inlet to communicate with the central hole of the top cover 7, and the water inlet is connected with a flushing water pipe 8. The top cover 7 is provided with a sensor bracket 6 and a support frame 101, the sensor bracket 6 is connected with a pulley 5 through a connecting rod, and the connecting rod is provided with an underwater pull force sensor 4. Salvage winch 1 is installed on support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com