Patents

Literature

46 results about "Debris bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Safe and efficient mud drilling jet mill bit for horizontal wells

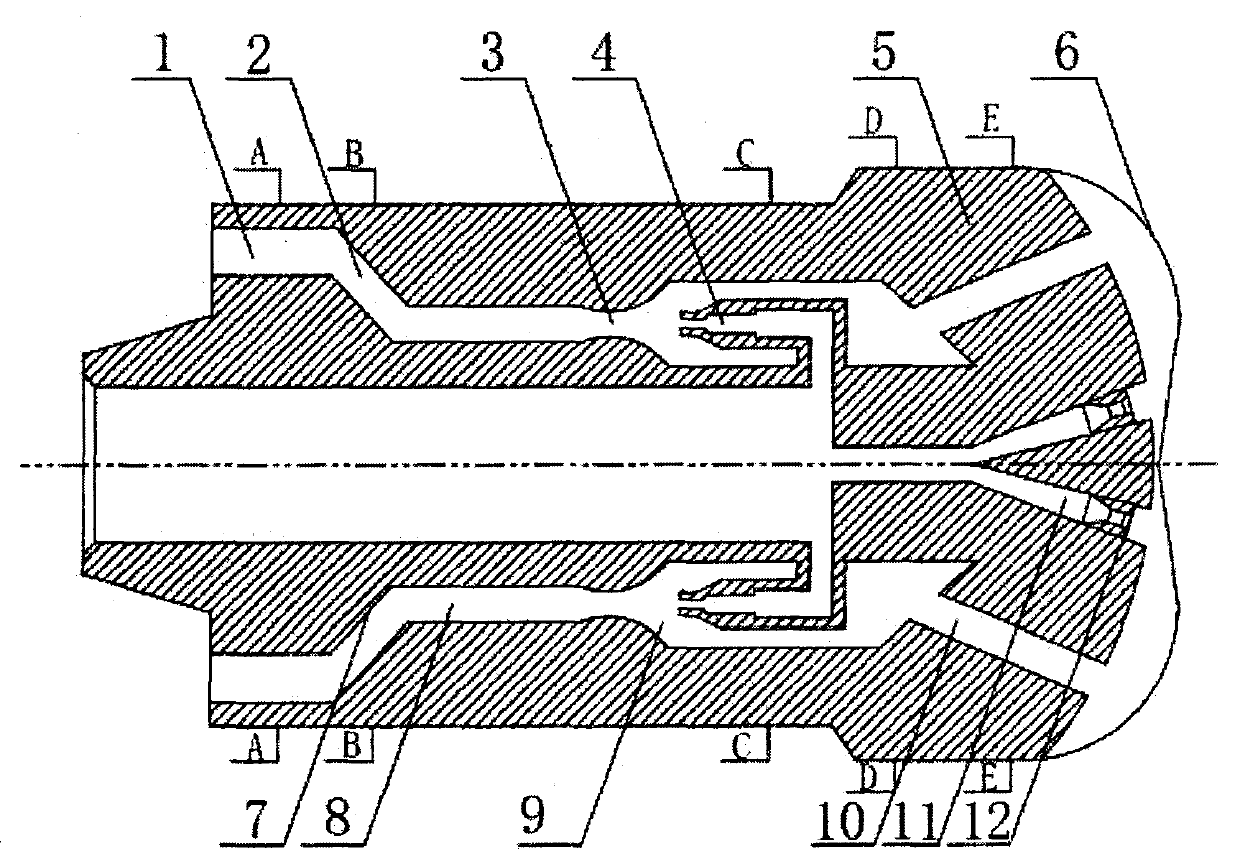

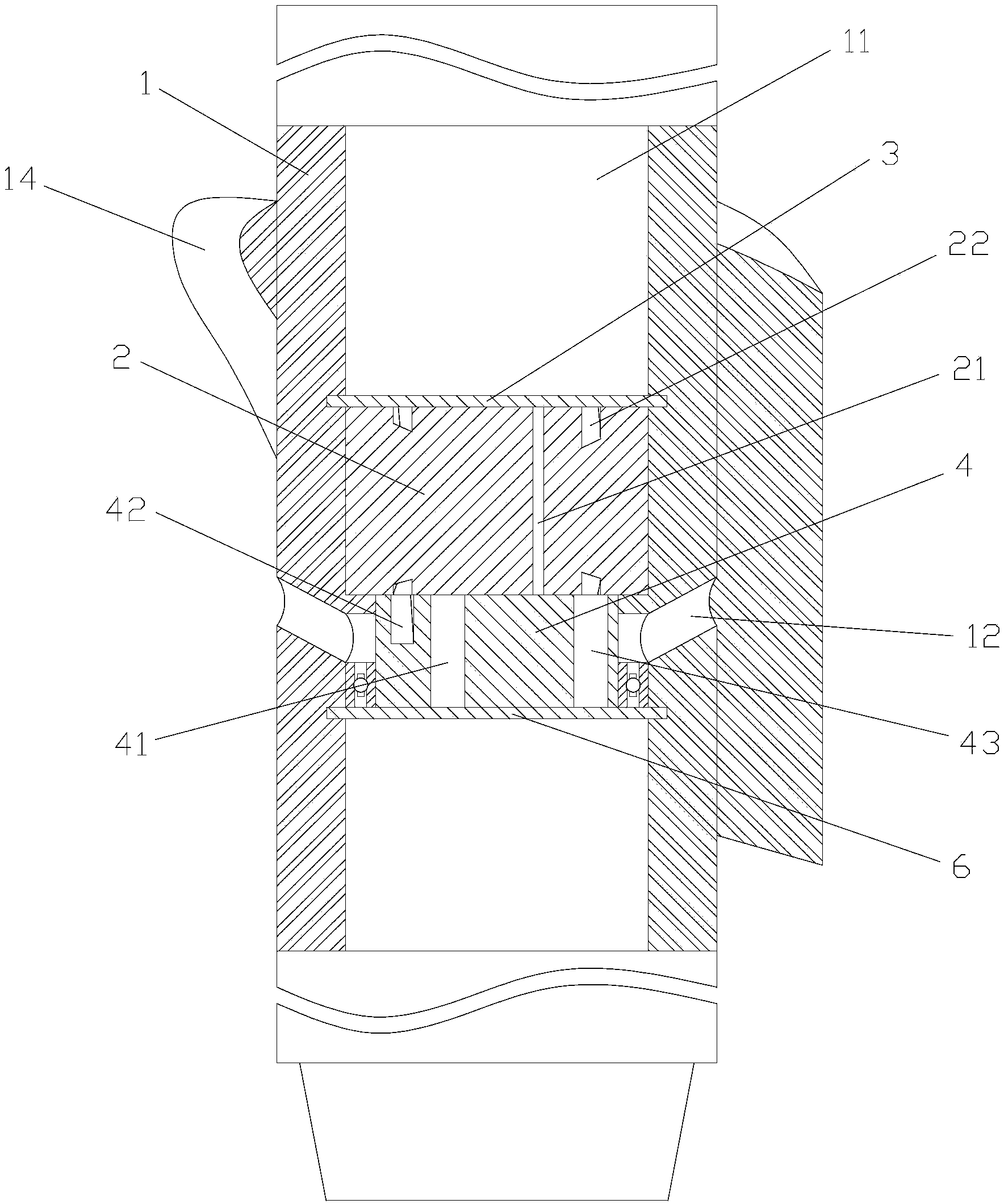

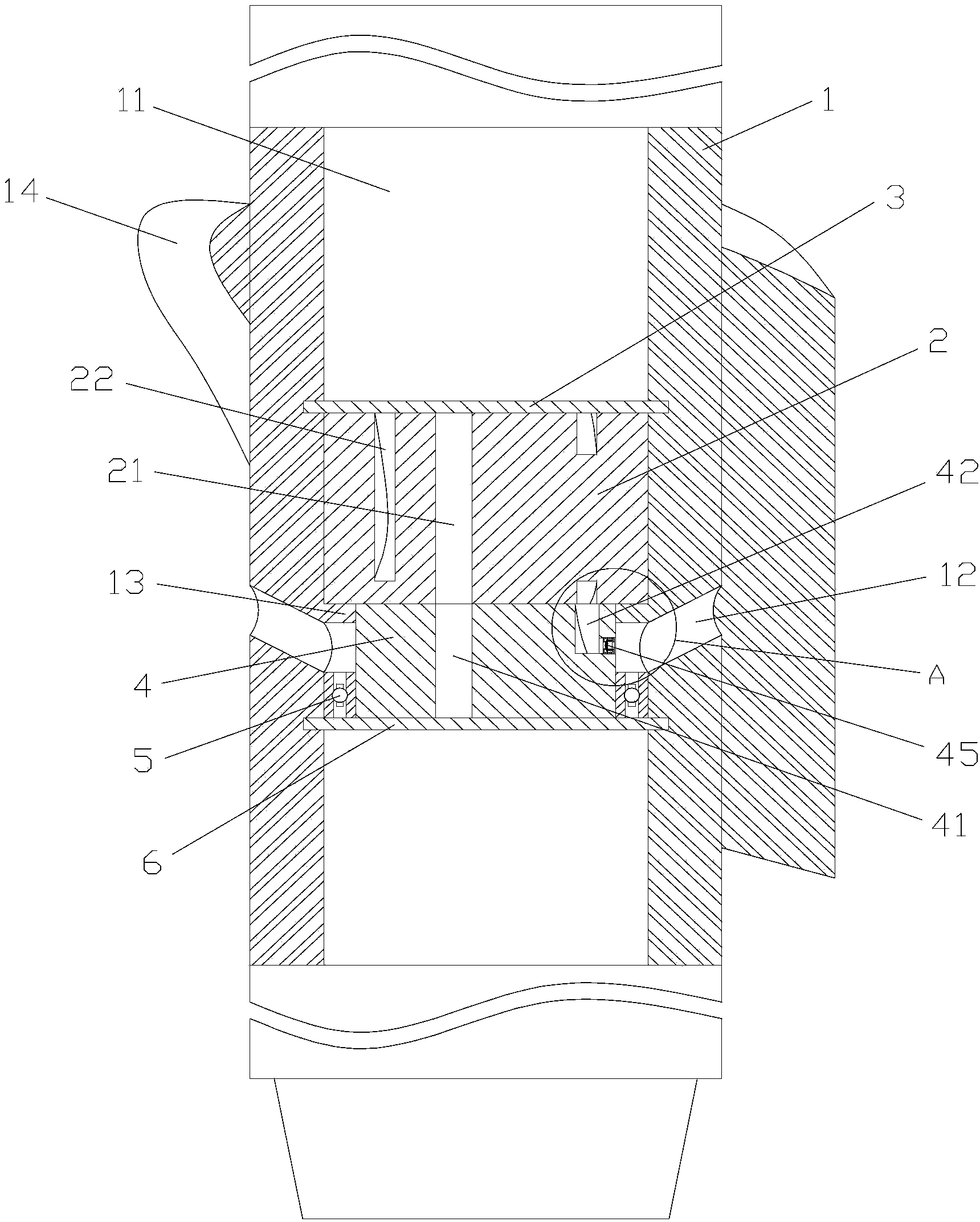

ActiveCN103790521AGood effectDecrease terminal velocityDrill bitsLiquid/gas jet drillingHigh concentrationCavitation

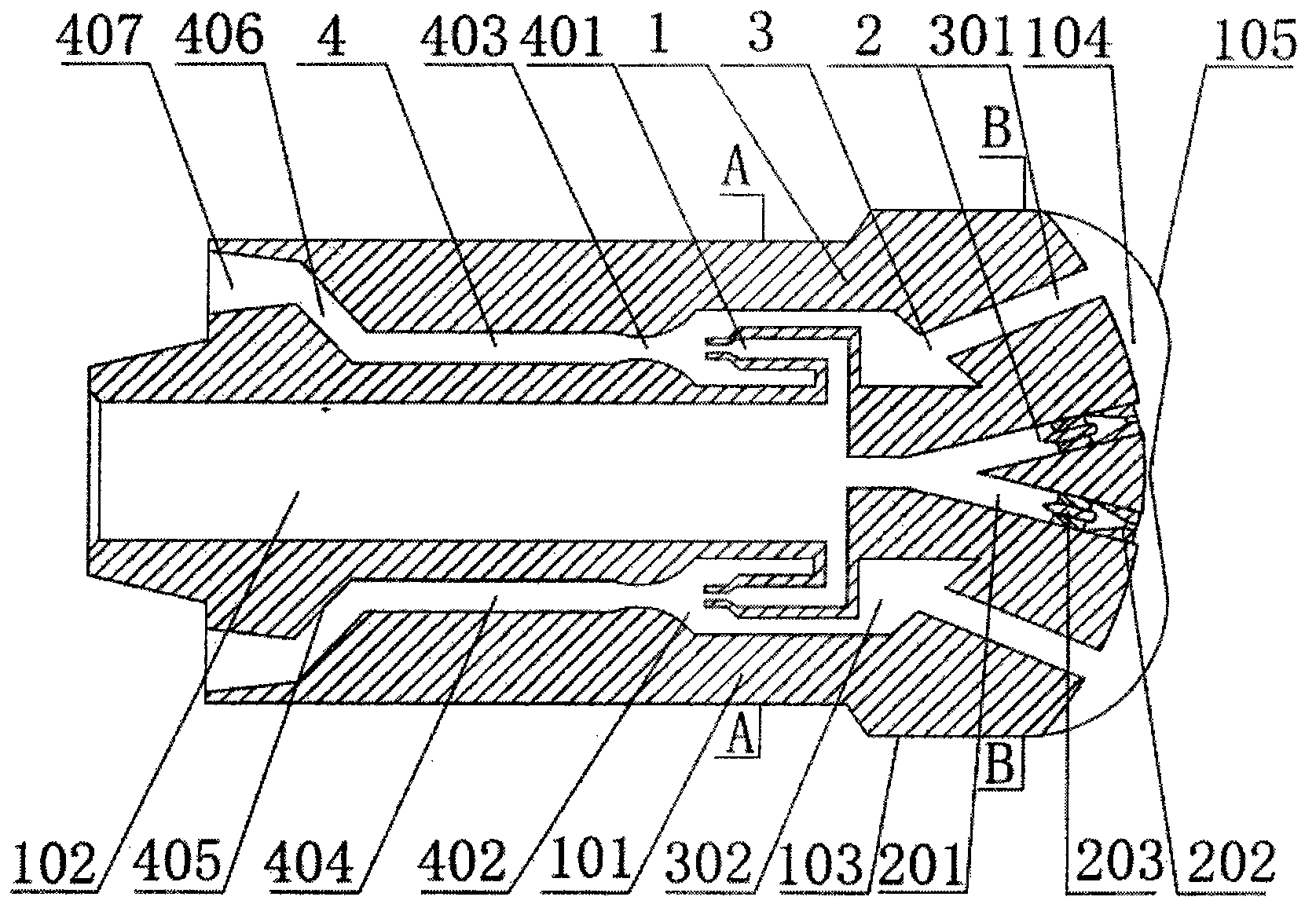

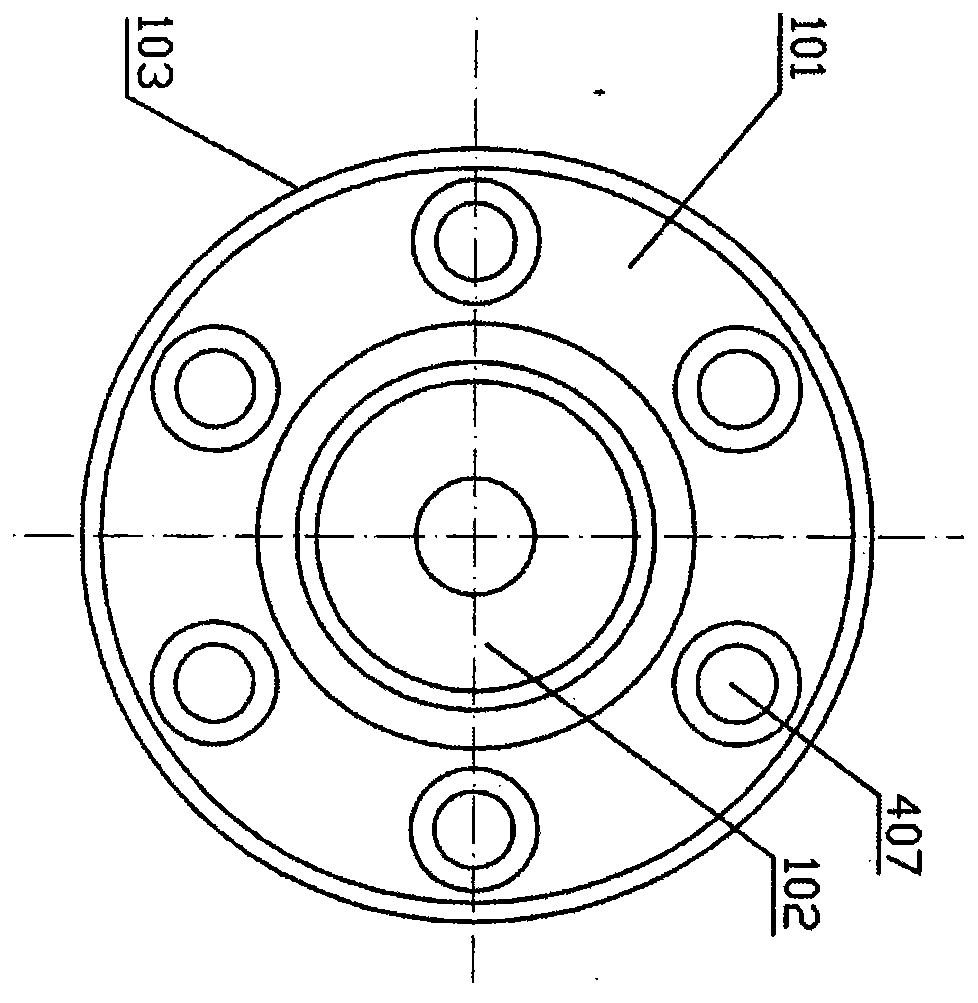

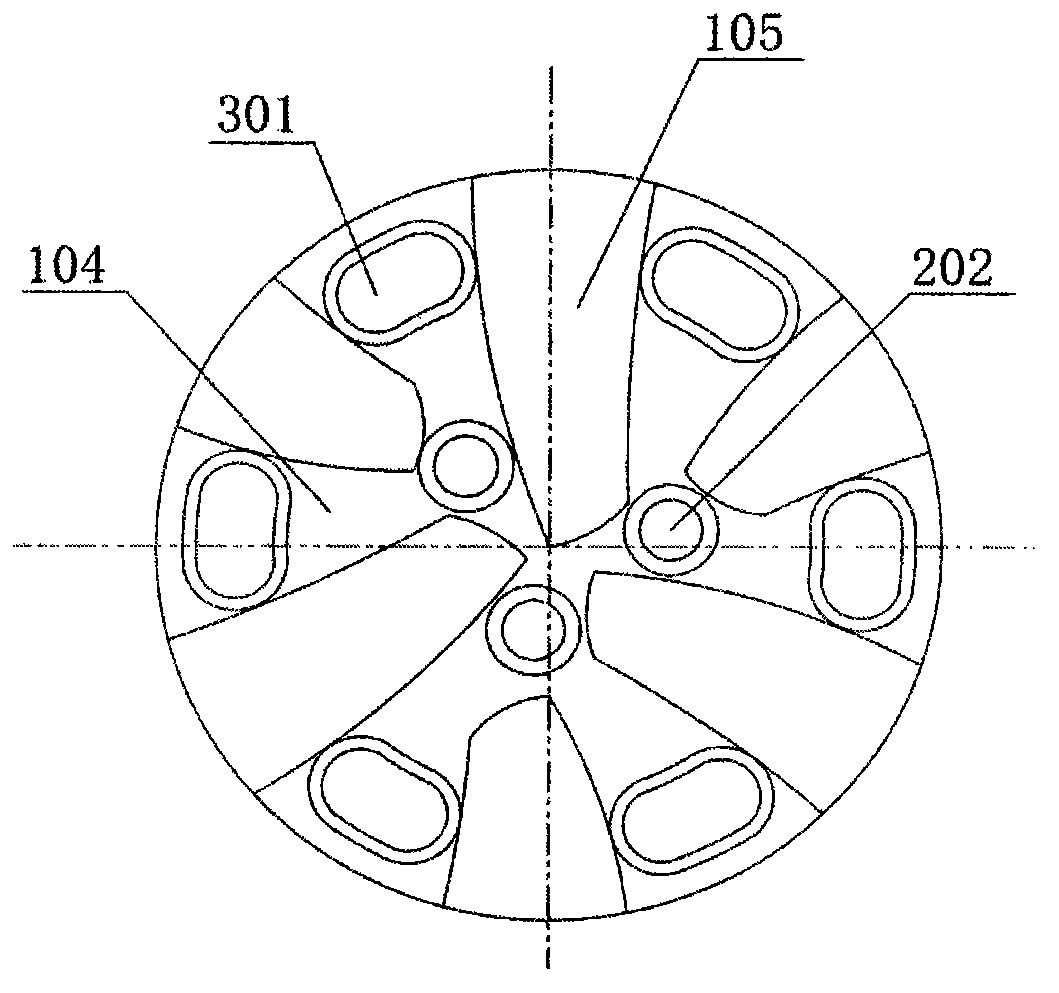

The invention discloses a safe and efficient mud drilling jet mill bit for horizontal wells. The safe and efficient mud drilling jet mill bit is characterized in that a jet crushing device and a high-concentration turbulence sand-pumping device are mounted on a conventional bit. The jet mill bit mainly comprises a jet crushing part and a high-concentration turbulence sand-pumping part. The jet crushing part is characterized by comprising reverse natural-vibration cavitation jet nozzles, mixing chambers, throat tubes, debris separation accelerating tubes, crushing targets, crushing chambers and bypasses; the high-concentration turbulence sand-pumping part is characterized by comprising well-bottom debris stirring and cleaning channels, debris suction tubes and bit nozzles. On the basis of principles of a sand pump, the debris suction tube and the well-bottom debris stirring and cleaning channel function in pumping high-concentration turbulence debris, so that well bottom pressure difference can be reduced effectively and mechanical drilling speed is increased; on the basis of the principles of the jet mill, debris is crushed further under hydraulic pulse cavitation jet effect, so that liquid and solid suspending flowing is achieved and debris beds formed in the horizontal wells is eliminated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

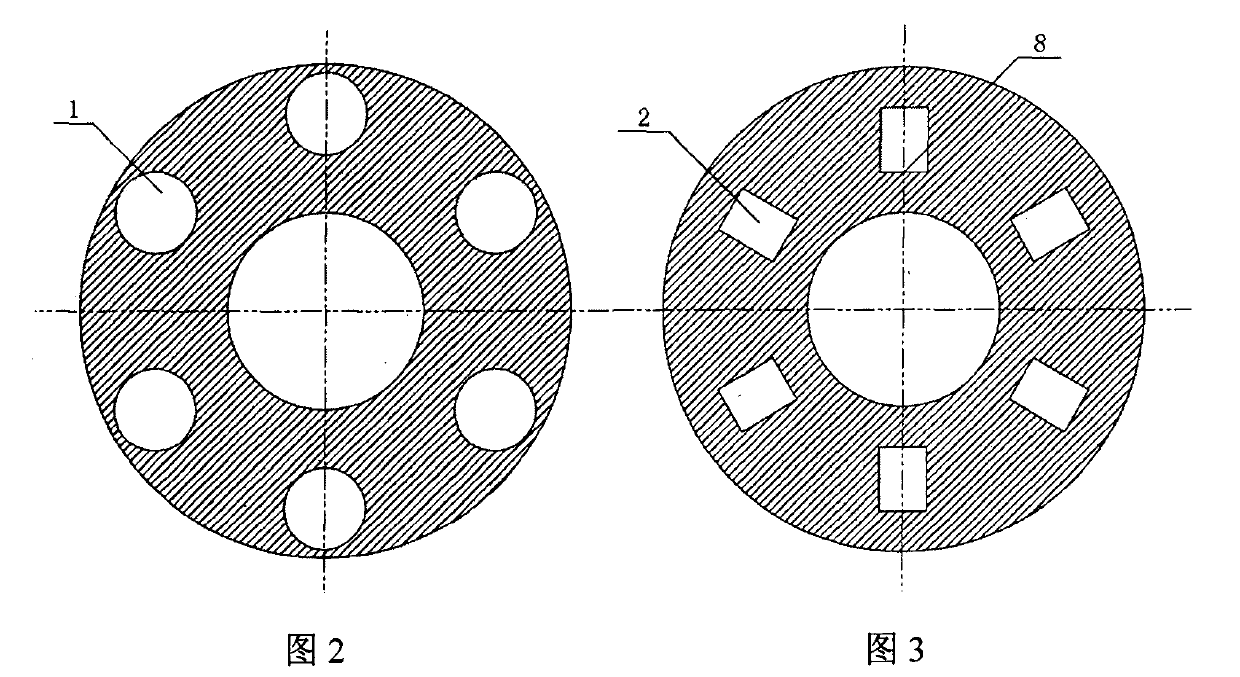

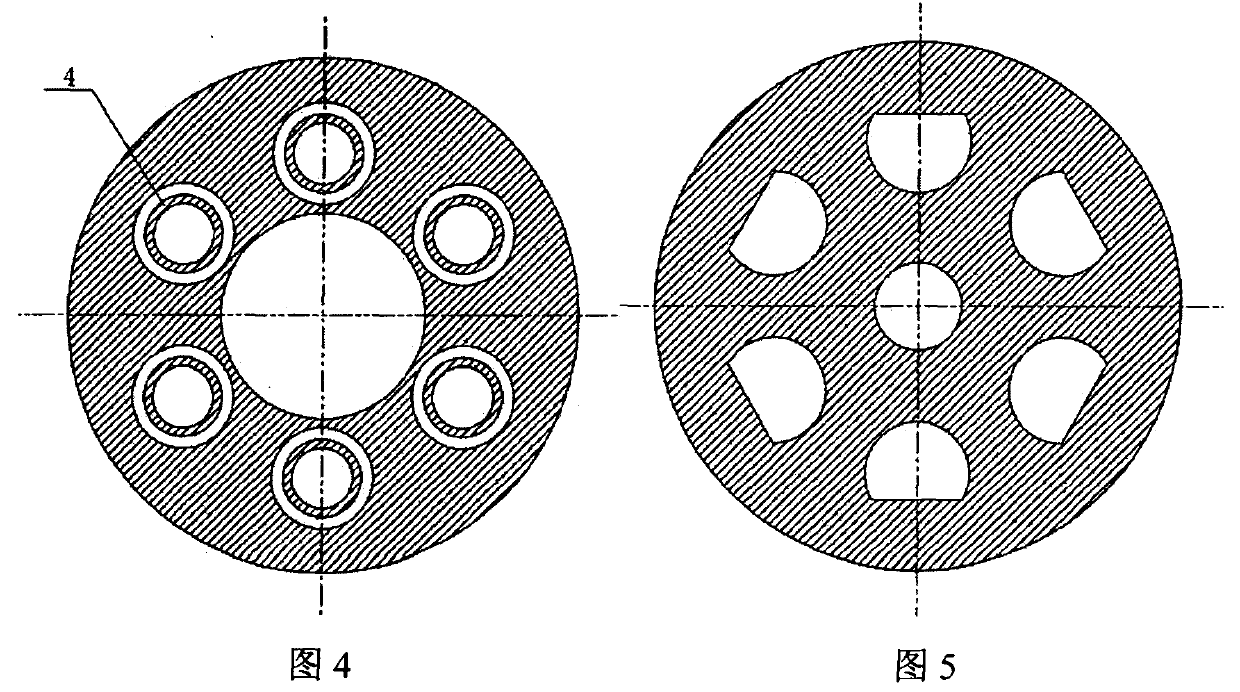

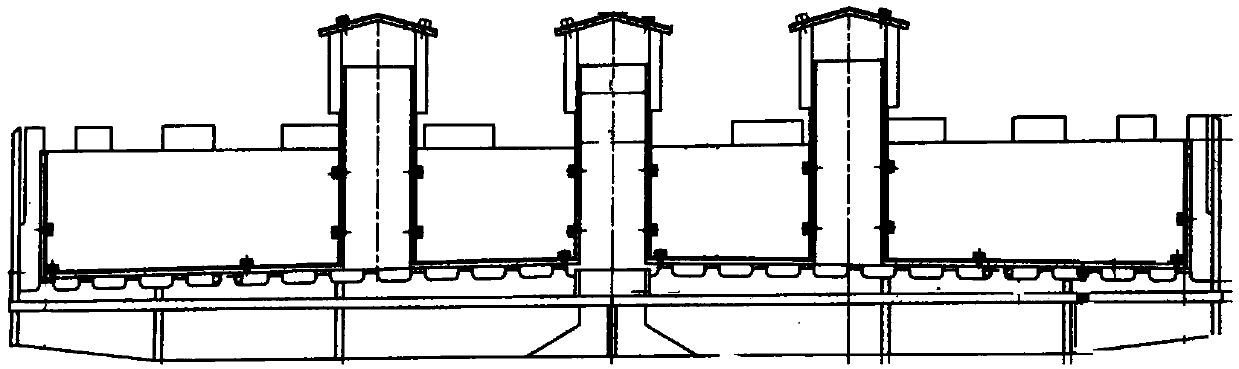

Low Head Loss Modular Suction Strainer with Contoured Surfaces

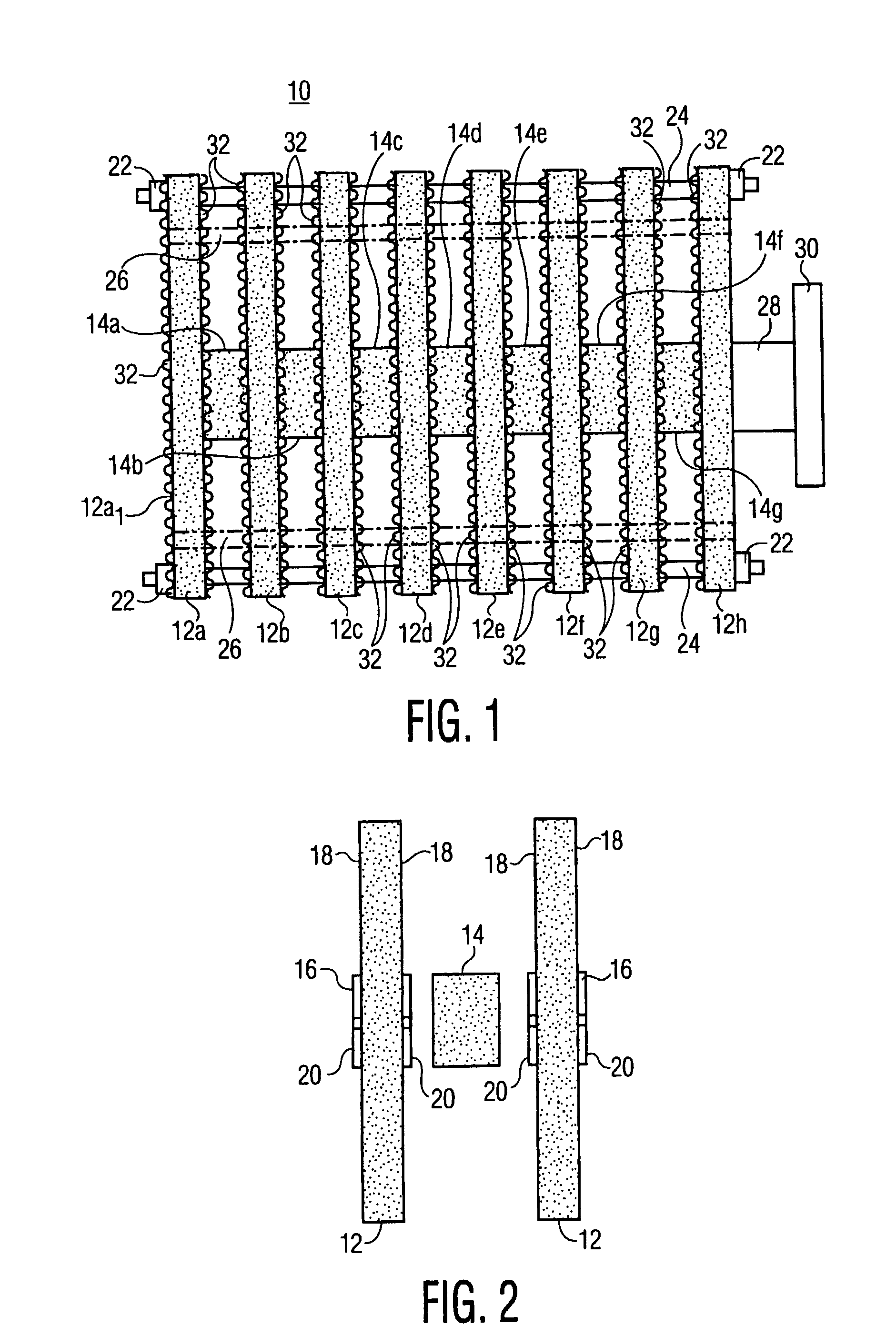

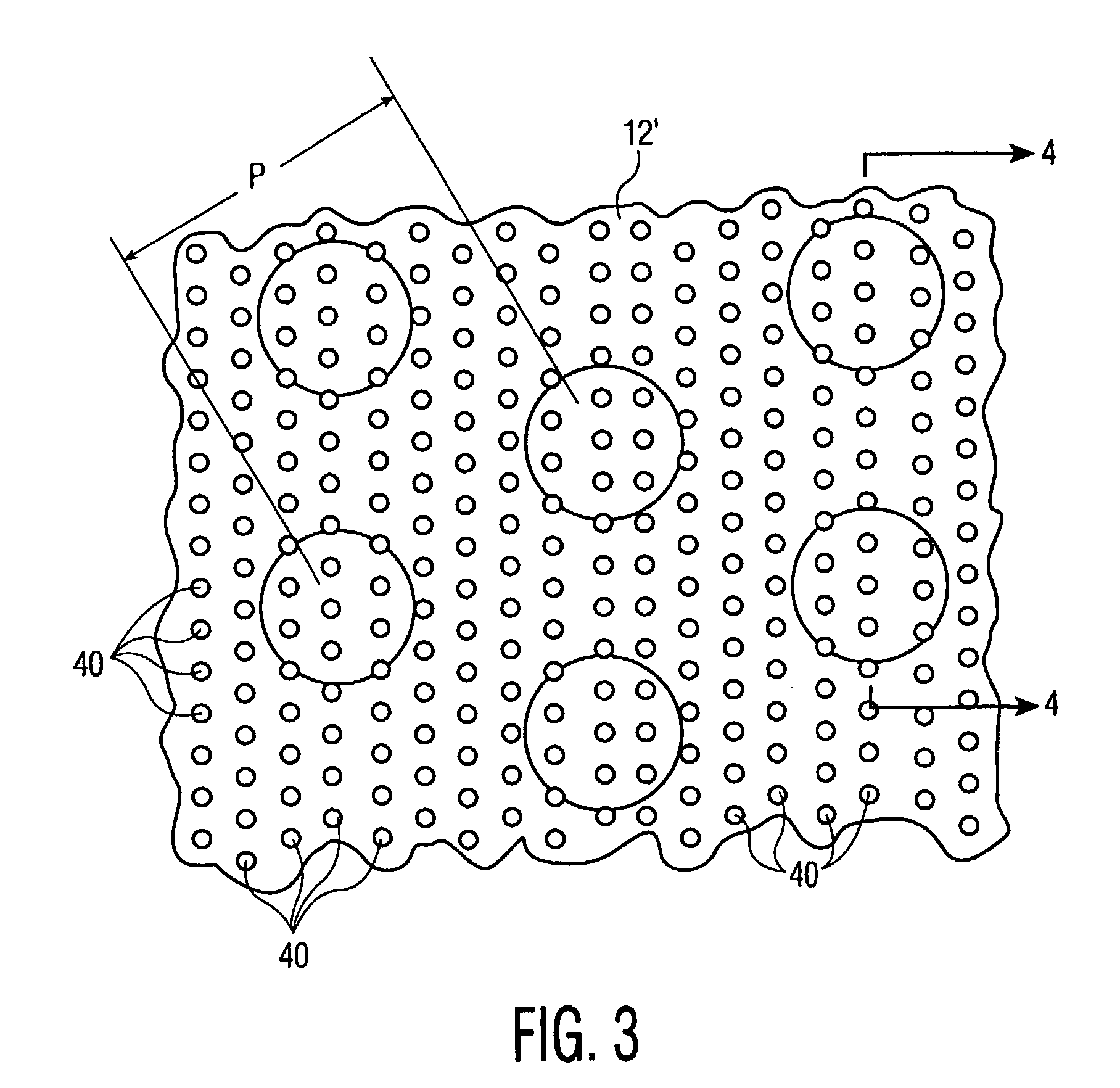

A strainer for an emergency core cooling system (ECCS) in a nuclear power plant comprises a perforated strainer element that is immersed in a reservoir of cooling water, which is drawn through the strainer element into the emergency core cooling system. The side of the strainer element in contact with the cooling water has a contoured configuration for disrupting the formation of a flat bed of fibrous material that can trap small particulate material intended to pass through the strainer element. Incorporating this strainer element into an ECCS strainer enables the strainer to be made more compact, because the debris bed need not be spread over an unduly large area to prevent excessive head loss from the debris load in the event of a reactor loss of coolant accident. The strainer also incorporates a modular construction that uses individual strainer disc modules. Each disc module includes a perforated first disc part having a central opening and a perforated second disc part also having a central opening. The first and second disc parts fit together to form an interior space with facing perforated major surfaces and an axial opening, and connecting tubes between the discs place the axial openings in fluid communication. The entire assembly is secured together by tie rods that hold the discs together with the connecting tubes compressed between them.

Owner:CONTINUUM DYNAMICS

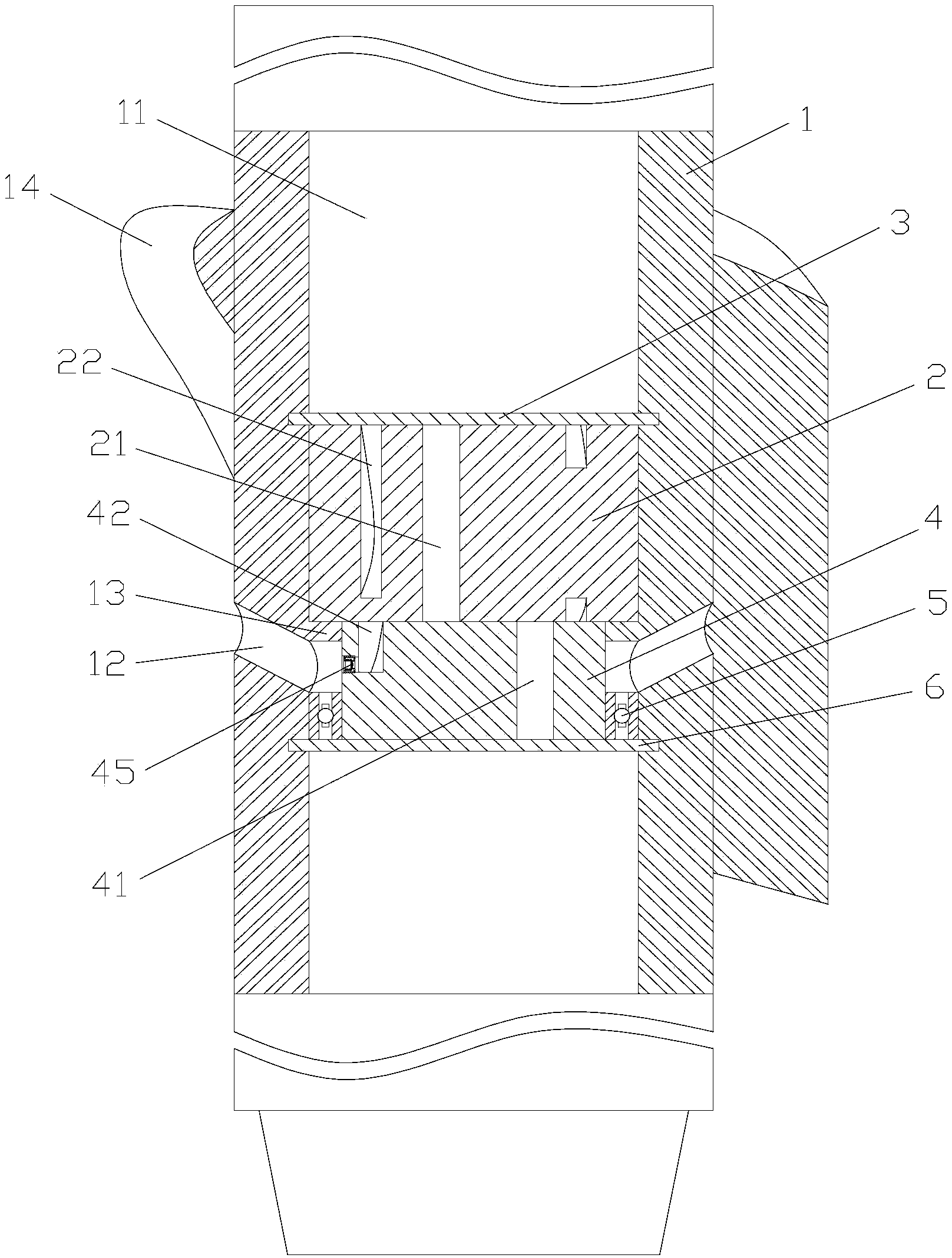

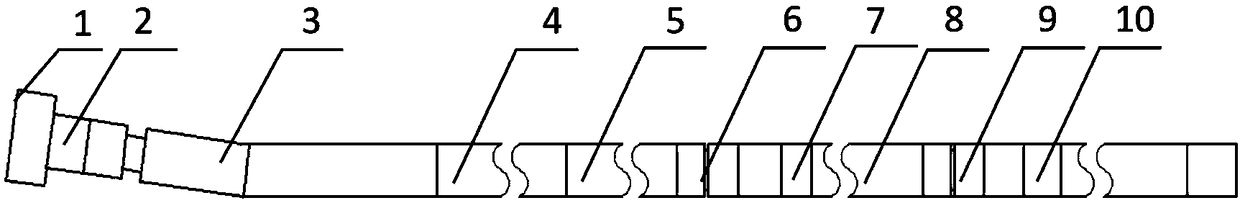

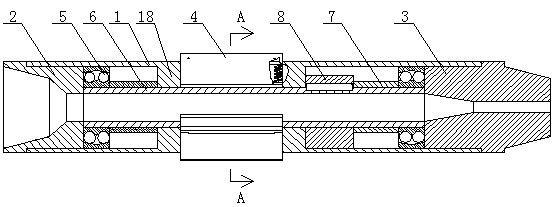

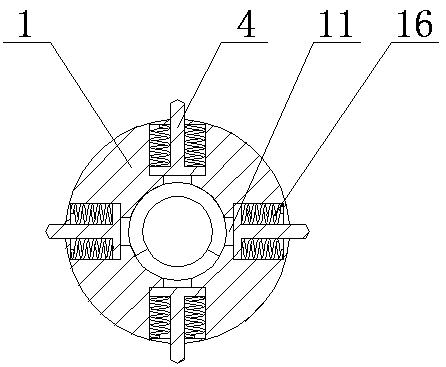

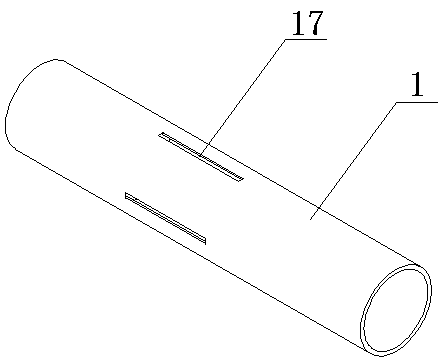

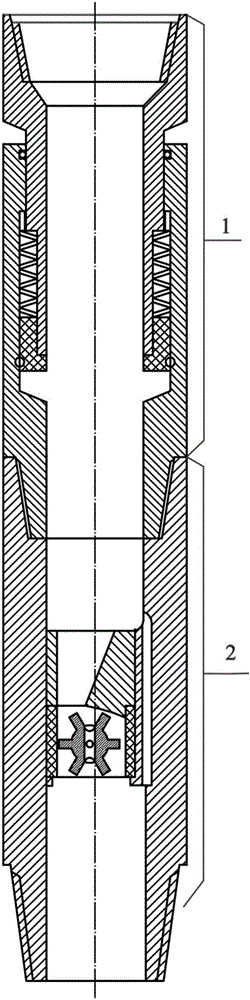

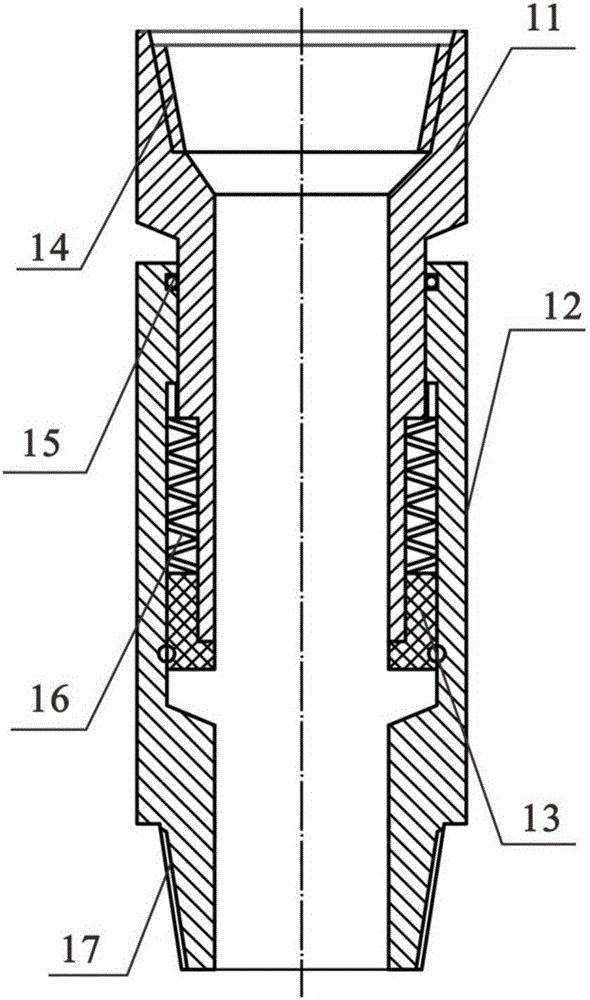

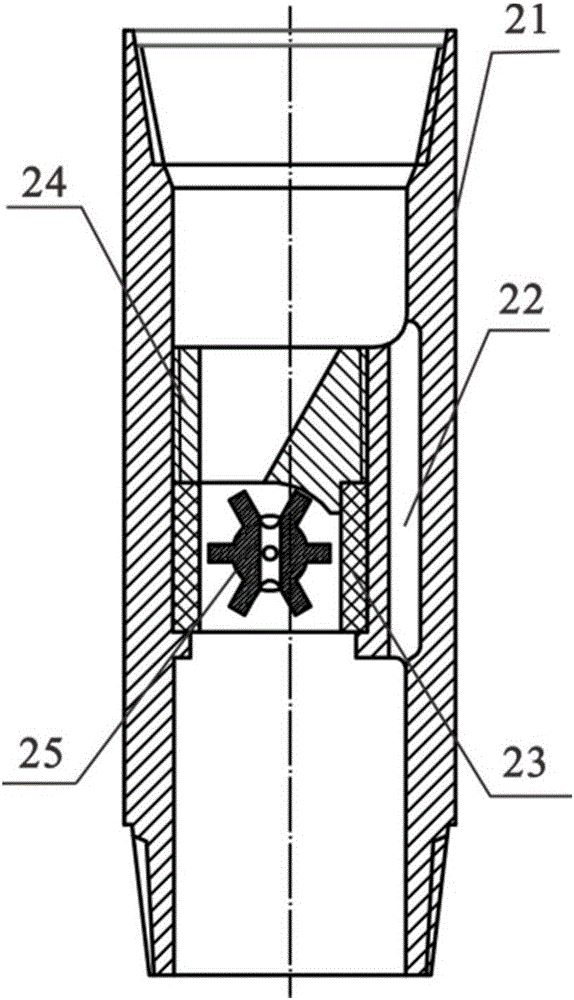

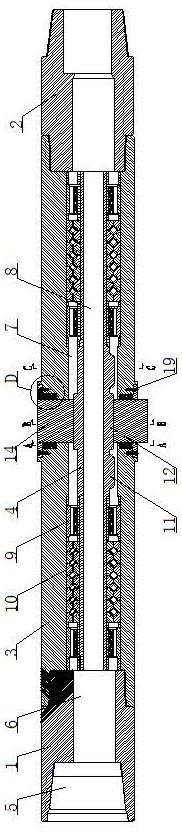

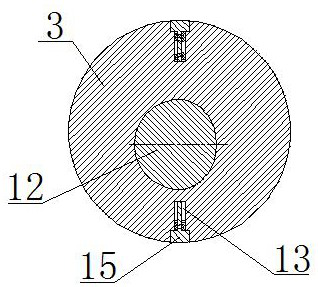

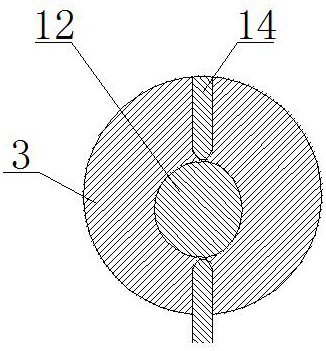

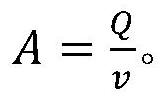

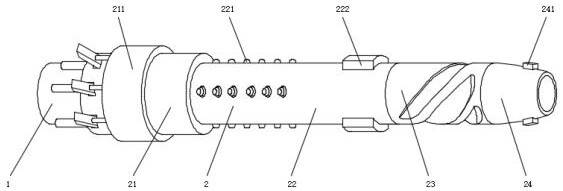

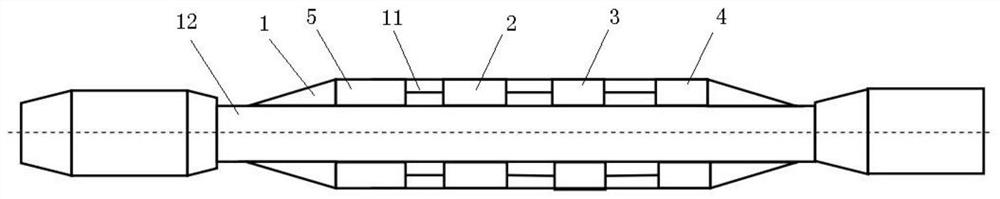

Drilling power rock debris bed eraser

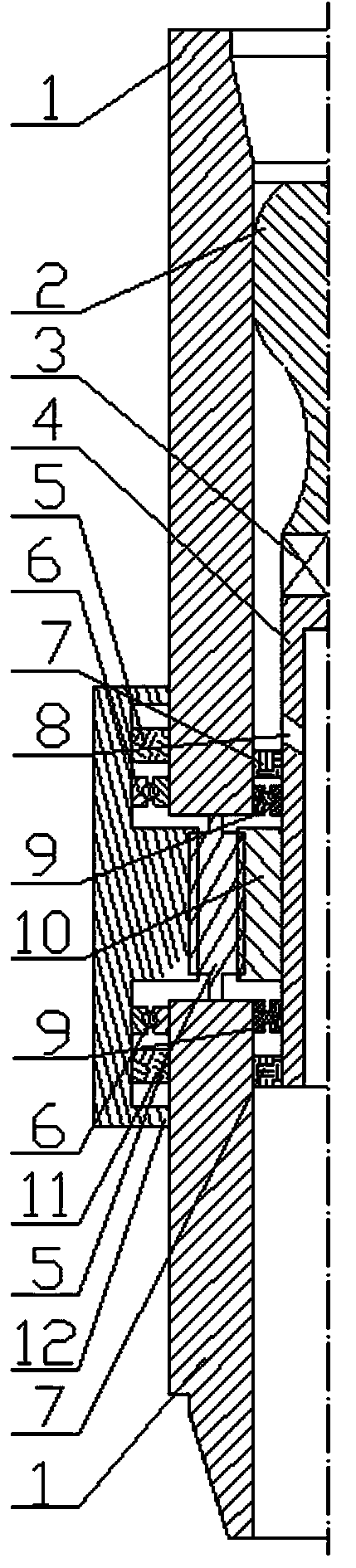

A drilling power rock debris bed eraser comprises a casing, a screw, a cardan shaft, a center shaft, a sealing device, a bearing, a by-pass hole, a driving gear, planet gears and a cutting sliding sleeve. The screw, the cardan shaft and the center shaft are installed in the casing after being connected sequentially, the center shaft is internally of a hollow structure, the by-pass hole is processed in the center shaft, the driving gear is installed on the center shaft, more than two planet gears are arranged in the circumferential direction of the casing corresponding to the driving gear, the outer portion of the casing corresponding to the planet gears is sleeved with the cutting sliding sleeve, and a cutting ridge is processed and installed on the outer portion of the cutting sliding sleeve. The driving gear, the planet gears and a protruded gear ring on an inner wall of the cutting sliding sleeve are sequentially in meshed connection. The eraser can rotatably scrape a rock debris bed when drilling fluid passes or the eraser is in a rotary drilling state or a sliding drilling state; and the drilling power rock debris bed eraser can transmit bit pressure and torque and drive a shaft bottom drill bit to break rock. The drilling power rock debris bed eraser has the advantages of being simple and reliable in structure design, convenient to process and high in transmitting torque and running stably.

Owner:CHINA PETROLEUM & CHEM CORP +1

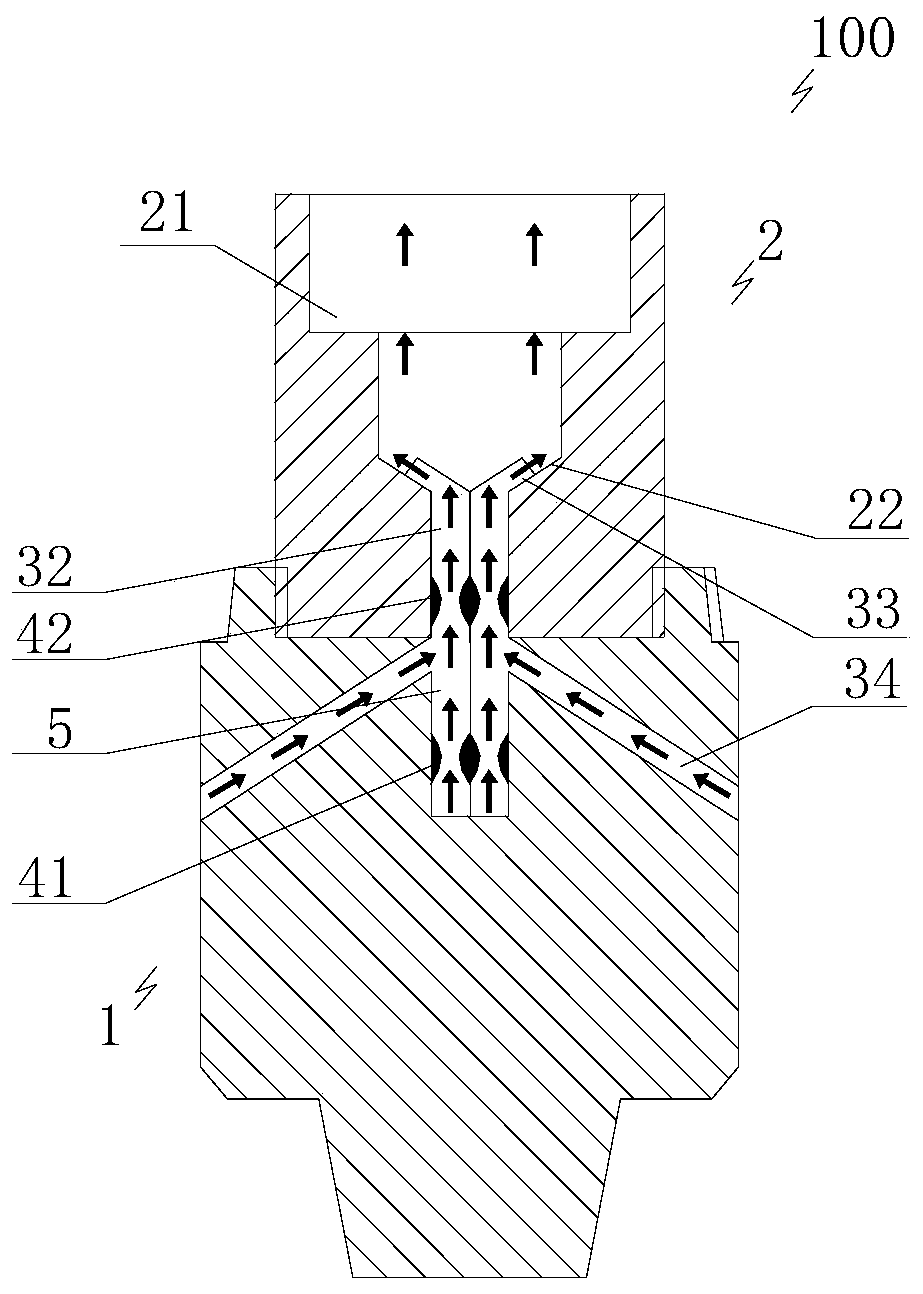

Tangential injection type whirl flow jet flow grinding drill bit for horizontal well

The invention discloses a tangential injection type whirl flow jet flow grinding drill bit for a horizontal well. The grinding drill bit mainly comprises a PDC drill bit body and is characterized in that a debris discharging groove in the gauge protection portion of the PDC drill bit body is omitted, and the PDC drill bit body is internally and additionally provided with a tangential injection type rotating jet flow sand washing device, a high-concentration turbulence sand pumping device and a jet flow smashing device. According to the tangential injection type rotating jet flow sand washing device, high-speed rotation jet flow is generated through tangential injection type rotating jet flow spray nozzles, a well bottom whirl flow field beneficial to rock debris cleaning is formed, the stress condition of well bottom rock debris is improved, and the well bottom rock debris cleaning efficiency is improved. The high-concentration turbulence sand pumping device pumps and sucks the well bottom fluid based on the principle of a sand pumping pump, the well bottom pressure difference is reduced, unbalance is achieved, and the mechanical drilling speed is increased. The jet flow smashing device effectively smashes the rock debris based on the principle of a jet mill, the rock debris carrying efficiency is improved, the rock debris bed in the horizontal well is eliminated radically, and safe and efficient drilling of the horizontal well is finally achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

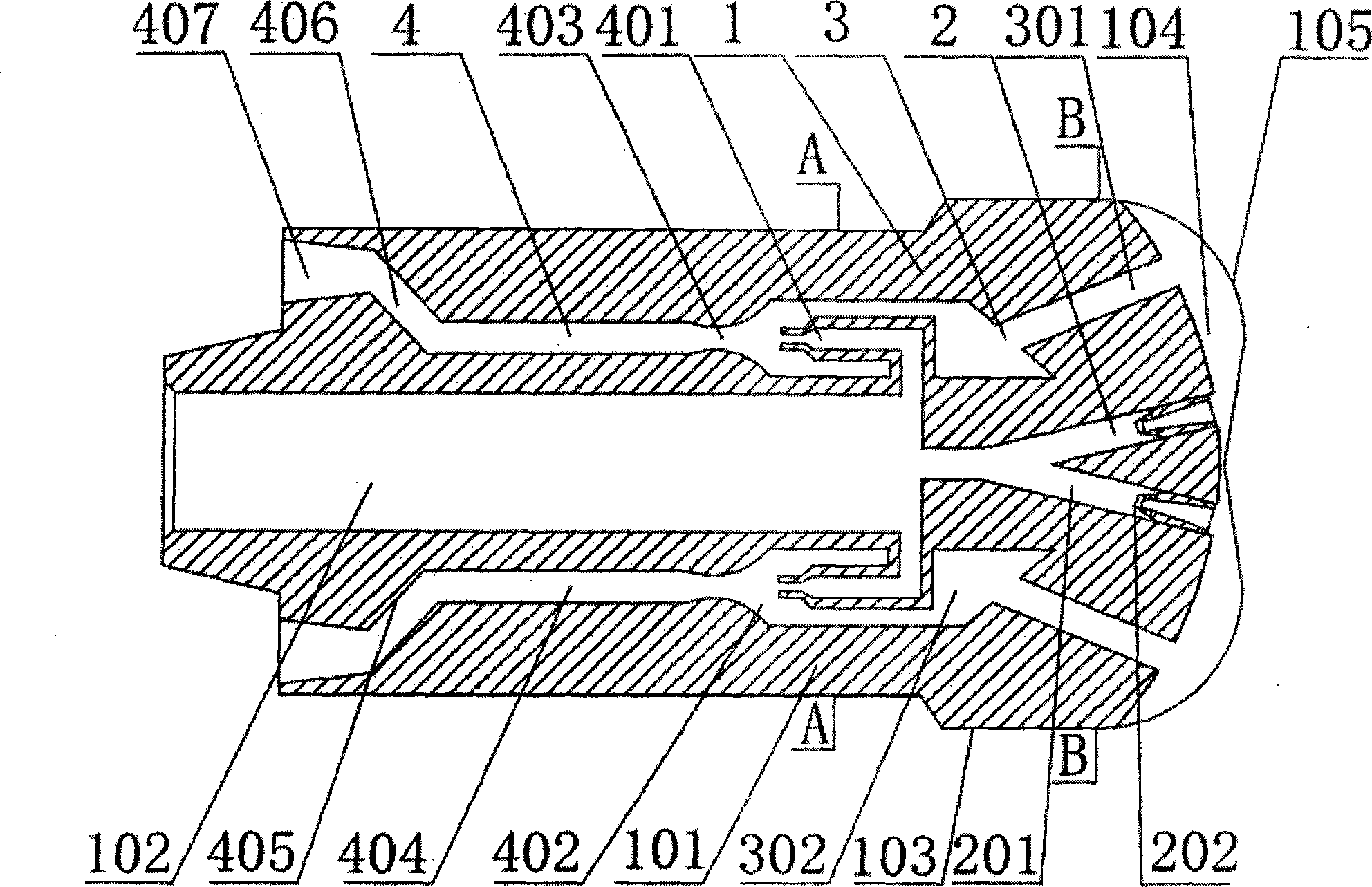

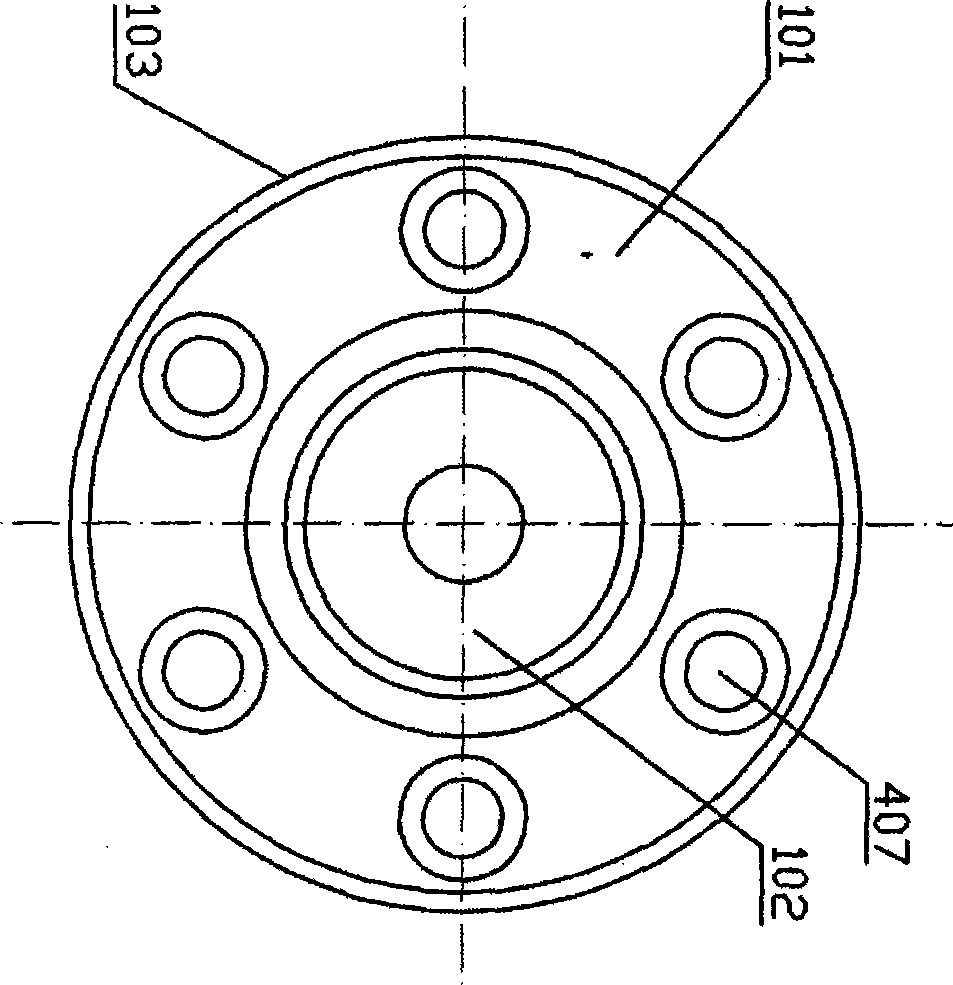

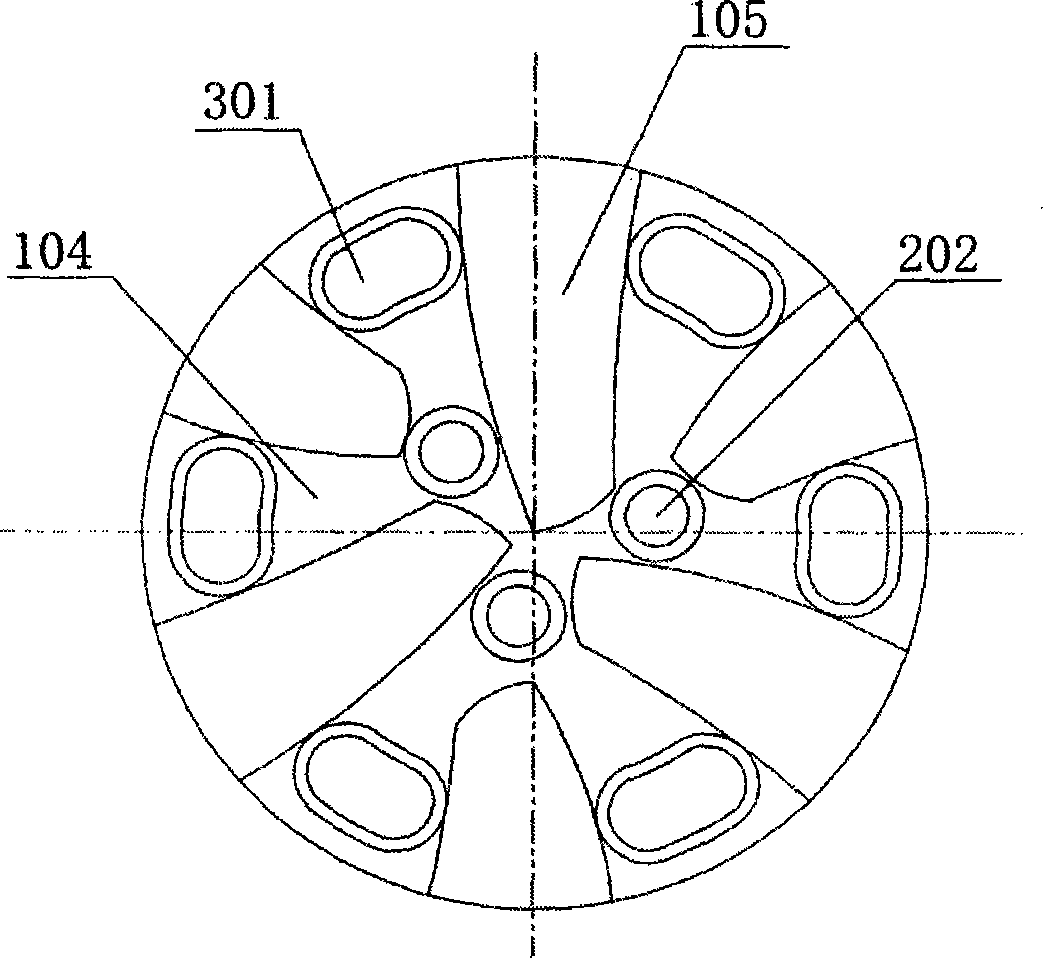

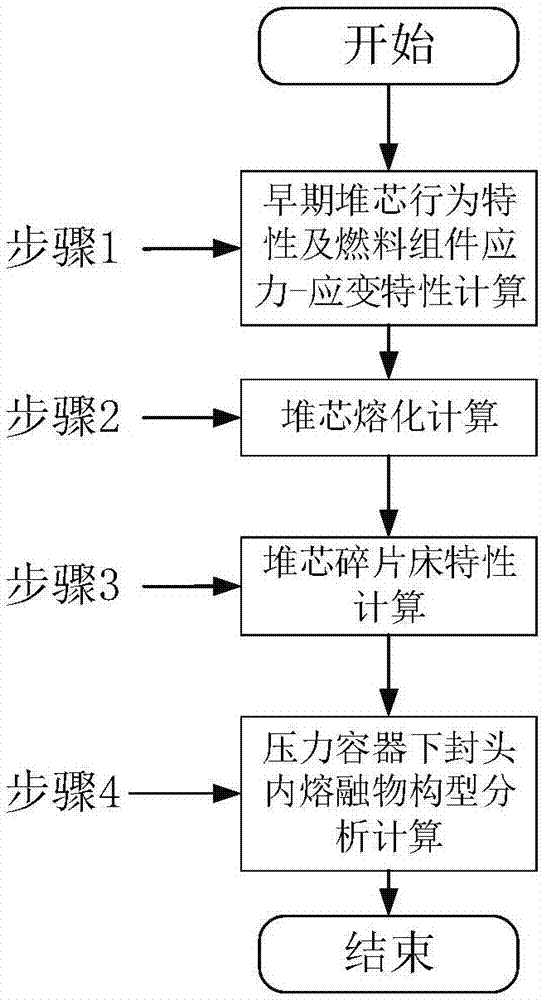

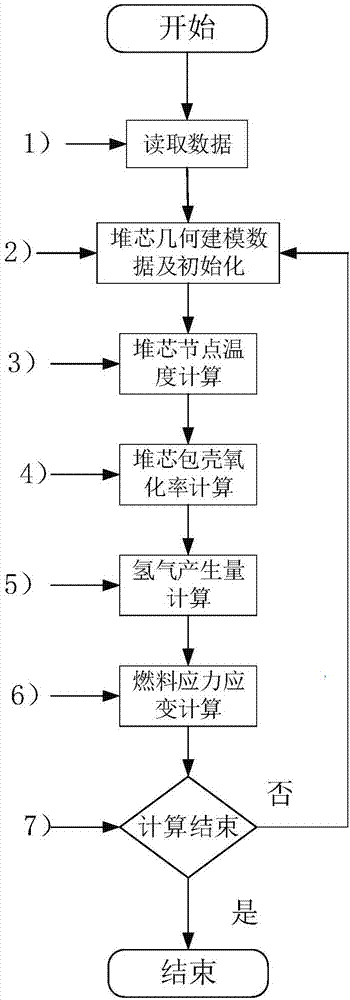

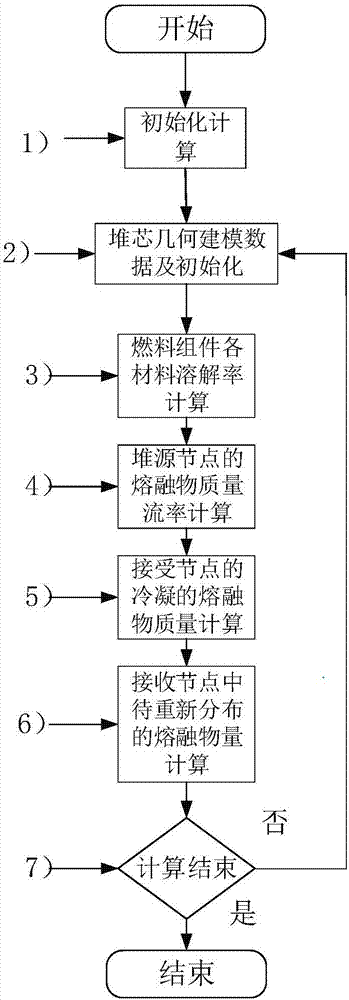

Method for analyzing severe accident of pressurized water reactor (PWR) nuclear power plant

ActiveCN107451398ASimple calculationSpecial data processing applicationsInformaticsRunge–Kutta methodPressurized water reactor

A method for analyzing a severe accident of a PWR nuclear power plant comprises: 1. calculating a behavioral characteristic of an early-stage core and a stress-strain characteristic of a fuel assembly of a severe accident; 2. calculating core melting; 3. calculating a core debris bed characteristic; and 4. analyzing and calculating a configuration of a melting matter in a head of a pressure vessel, wherein, a heat transfer between the melting matter and a surrounding material is calculated by a Runge-Kutta method at first, then steam flow that is released from the melting matter to the core during a cooling convection process is calculated, then mass and energy exchange between particles of the melting matter and a surrounding environment is calculated, and finally heat flow from a debris hard shell is calculated according to an inner temperature of the hard shell. Based on analysis of the mechanism and sequence of the severe accident of the large pressurized water reactor, management strategies and mitigation measures for severe accidents applicable to pressurized water reactors in our country are put forward, and technical support is offered for formulation of safety strategies of severe accidents of nuclear power plants in our country.

Owner:XI AN JIAOTONG UNIV

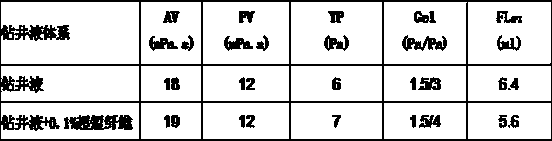

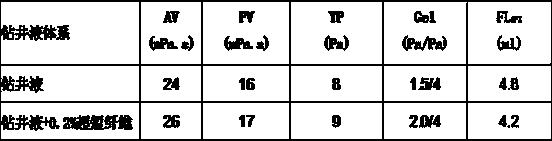

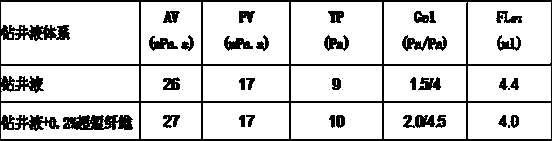

Borehole cleaning liquid and preparation method thereof

The invention relates to a borehole cleaning liquid for a petroleum exploration drilling well and a preparation method thereof. The borehole cleaning liquid is composed of bentonite base mud, at least one polymer treating agent performing a flocculation function, at least one filtrate loss reducer performing a filtrate loss reducing function, an ultra-short fiber, a weighting agent and water, wherein bentonite in the bentonite base mud accounts for 3 to 6% of the amount of water, the polymer treating agent performing the flocculation function accounts for 0.3 to 0.5% of the massic volume fraction of the base mud, the loss reducer performing the filtrate loss reducing function accounts for 0.5 to 4% of the massic volume fraction of the base mud, the ultra-short fiber accounts for 0.1 to 3% of the massic volume fraction of the base mud, and the amount of the weighting agent depends on needs. The borehole cleaning liquid can effectively suspend and carry rock debris and remove rock debris beds in the drilling process of horizontal wells and large-displacement wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

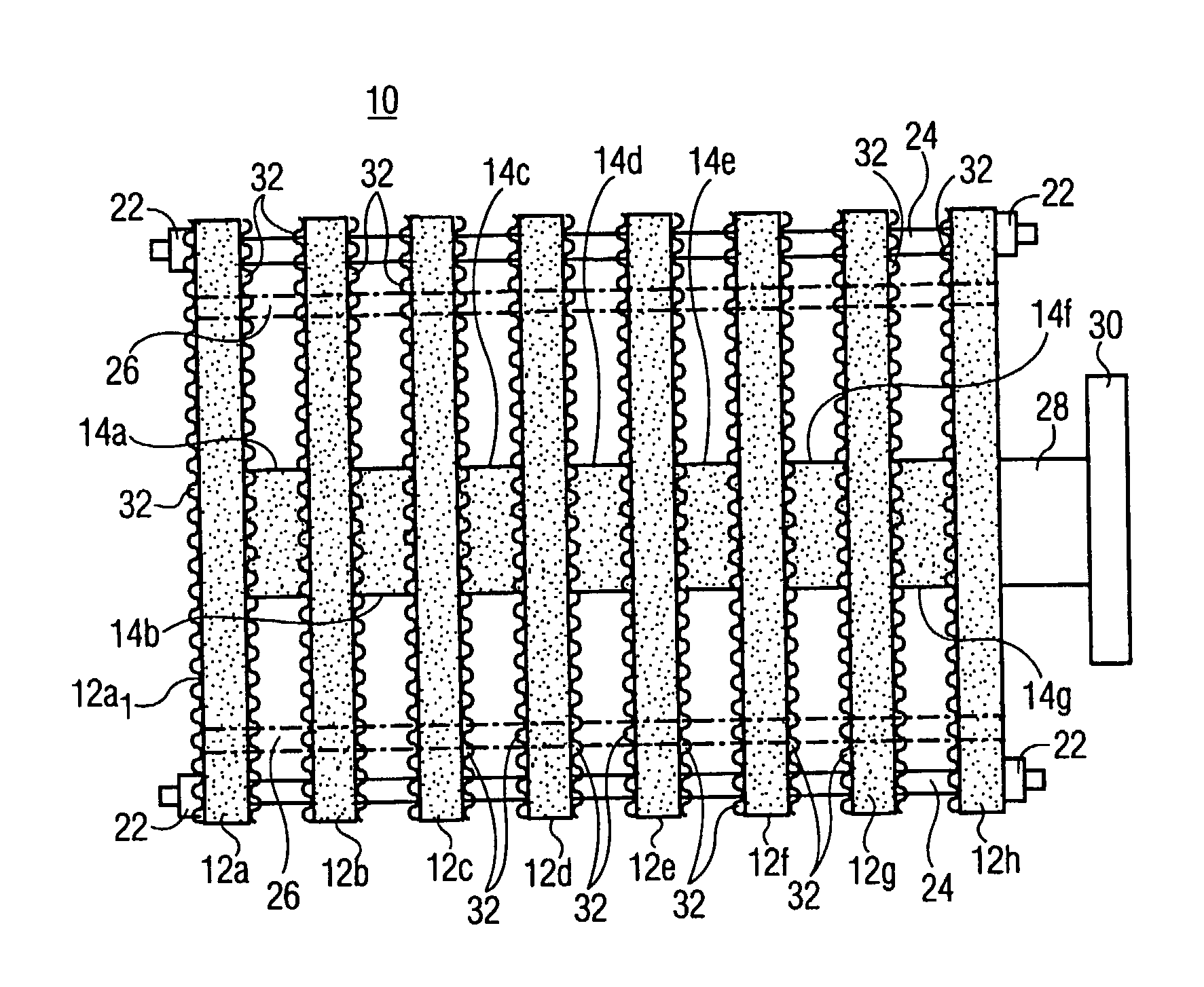

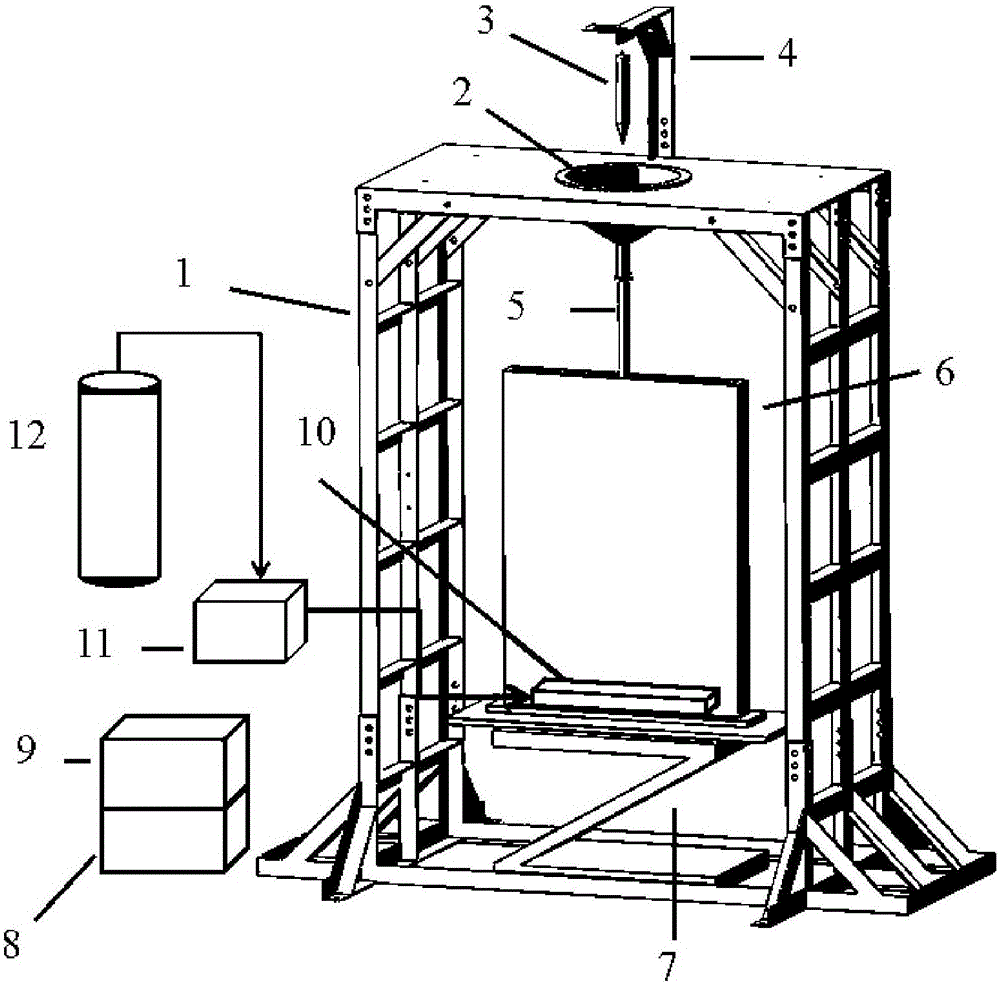

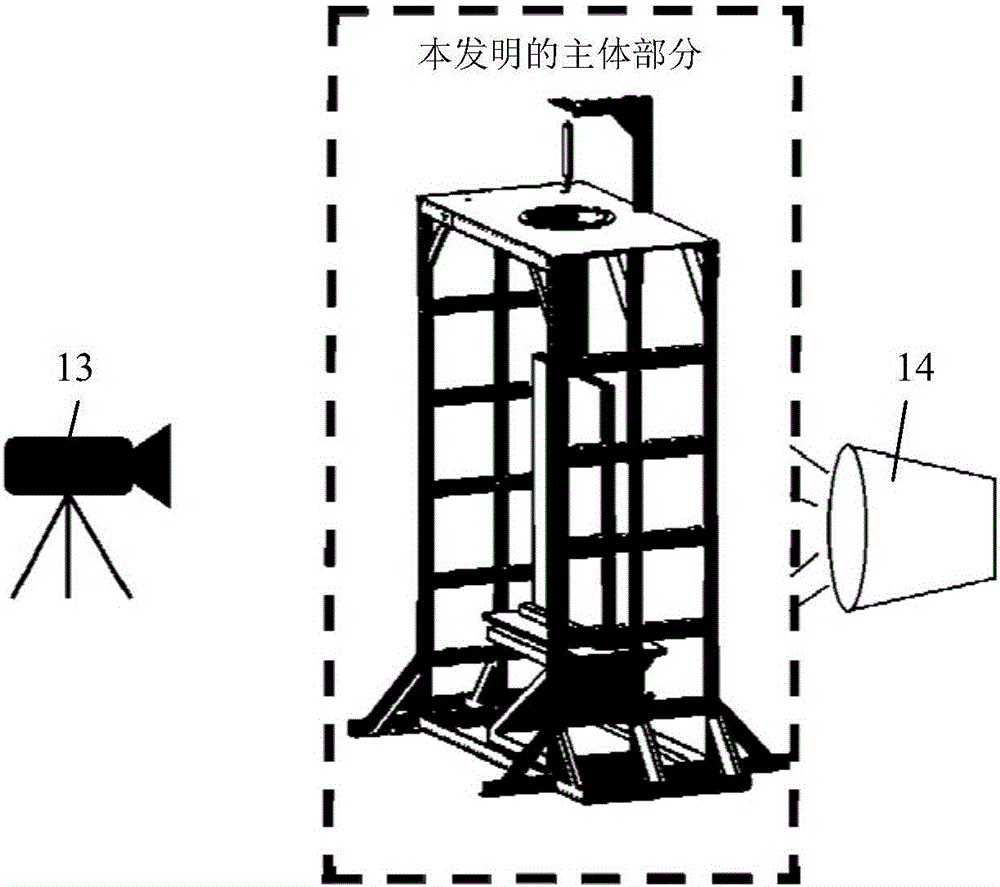

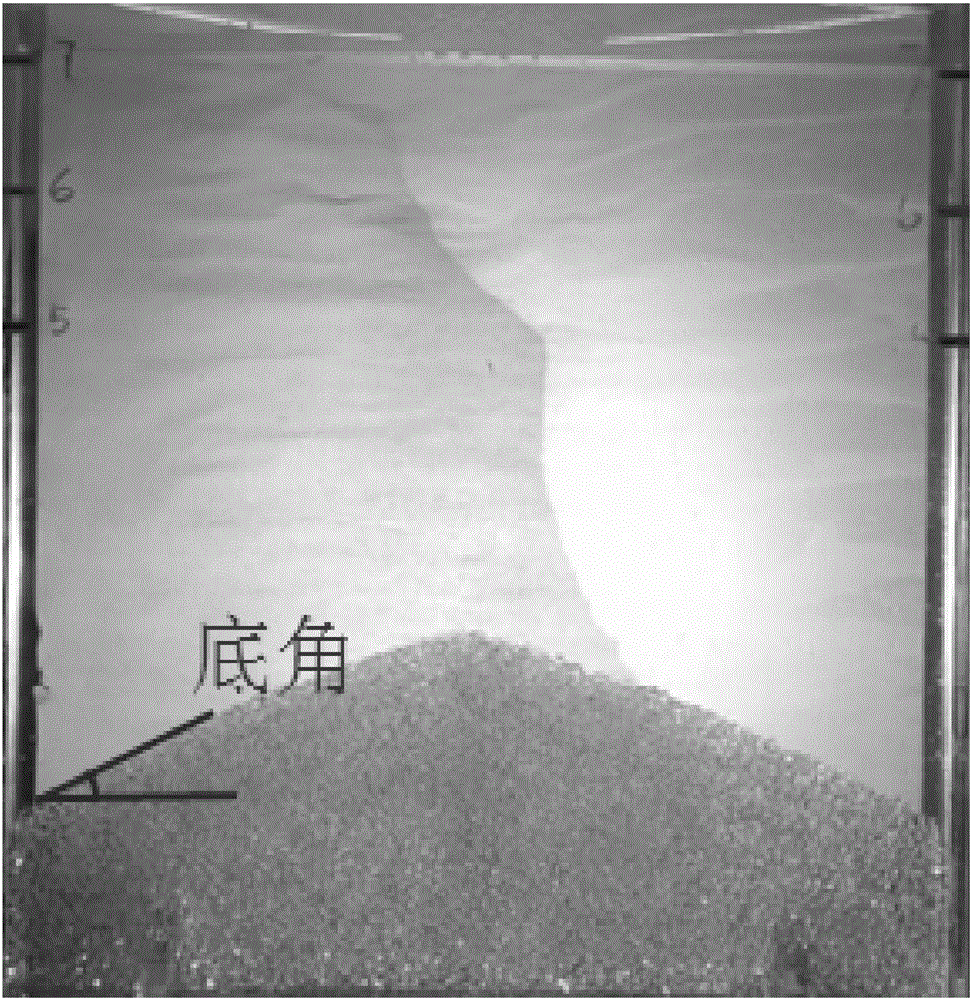

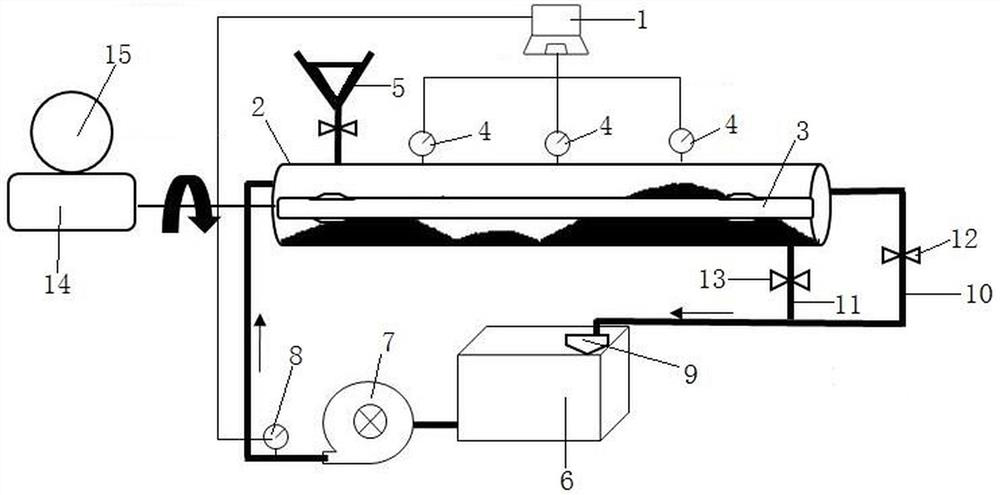

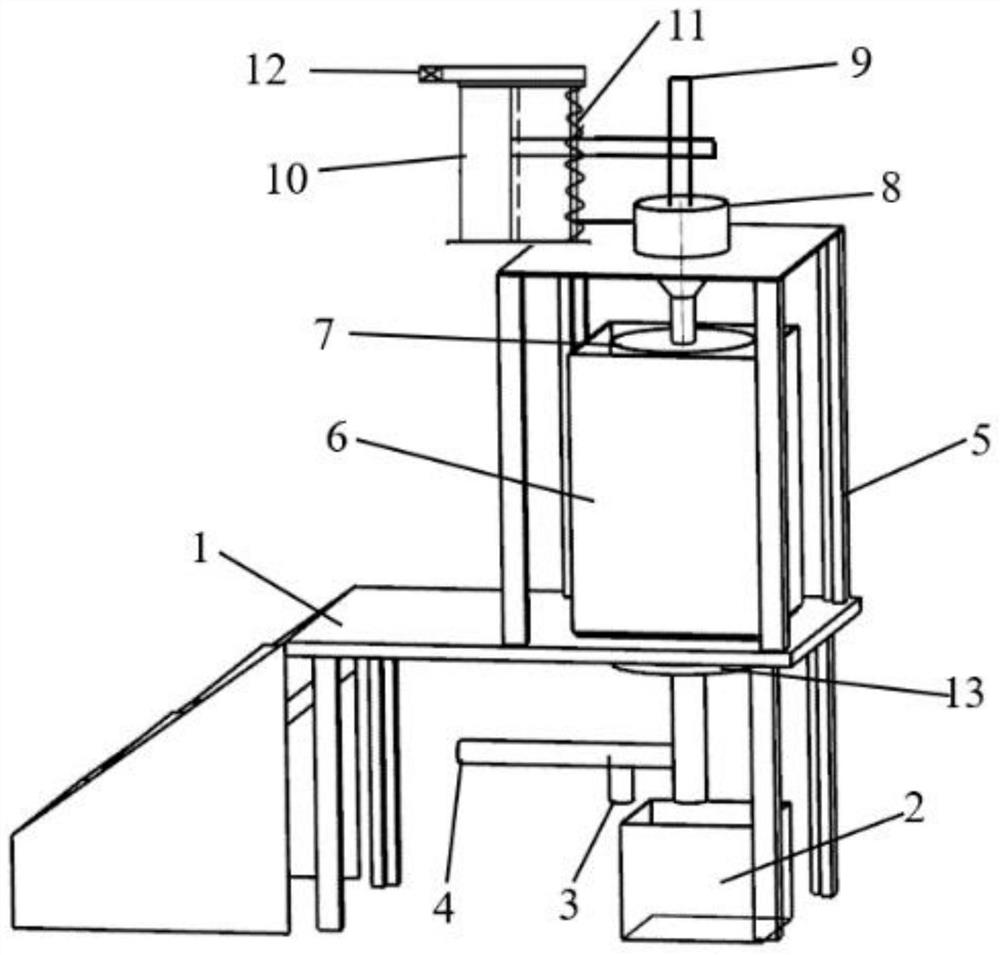

Experimental system for forming characteristic of sodium-cooled fast reactor debris bed

ActiveCN106409349AApplicable to a wide range of researchThe results of the study are comprehensiveNuclear energy generationEmergency protection arrangementsData acquisitionSodium-cooled fast reactor

The invention provides an experimental system for the forming characteristic of a sodium-cooled fast reactor debris bed. The experimental system comprises an experimental support, a particle container, a particle conduit, a visual experiment container, a particle release controller, a visual data acquisition module, an environmental parameter detection module and a decay heat simulating generator, wherein the particle container and the particle conduit support multiple release apertures and release heights, an experimental particle system comprises various debris particles with different materials, shapes and sizes, visual experimental containers with different sizes are designed for two-dimensional and three-dimensional experiments, and the particle release controller and the visual data acquisition module can acquire and store images synchronously in the whole experimental process. The experimental system can be applied to researching and analyzing the forming mechanism of the fuel particle debris bed in the sodium-cooled fast reactor core disassembly accident process. The experimental system has the advantages that the experimental process is visual, qualitative analysis is combined with quantitative analysis, multiple controllable experimental variables exist, the operation principle is simple, the system is easy to expand, stable and safe and the like.

Owner:SUN YAT SEN UNIV

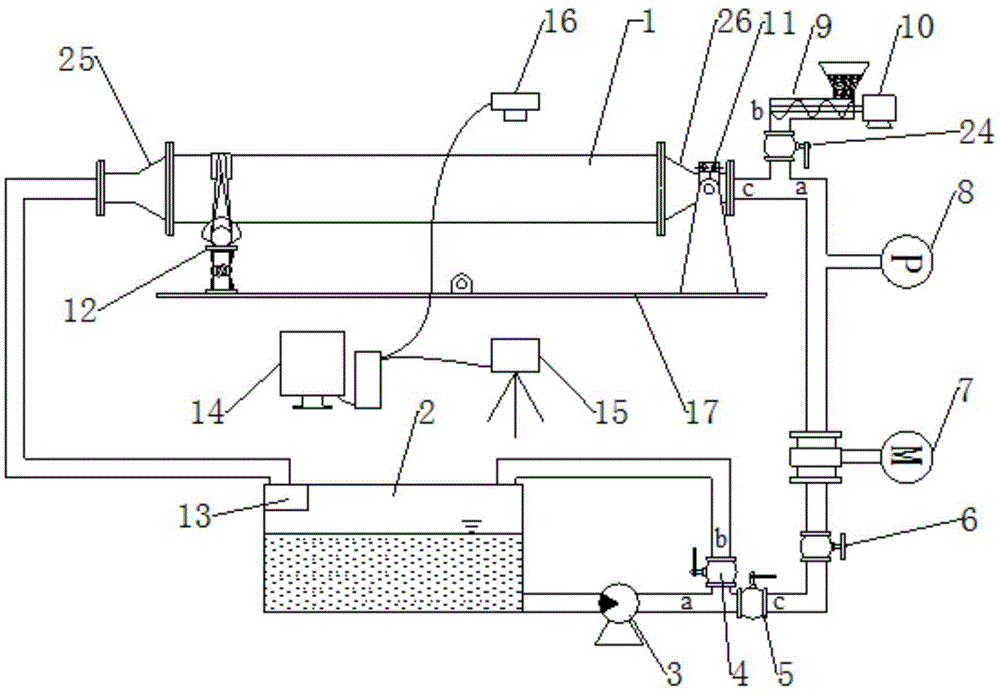

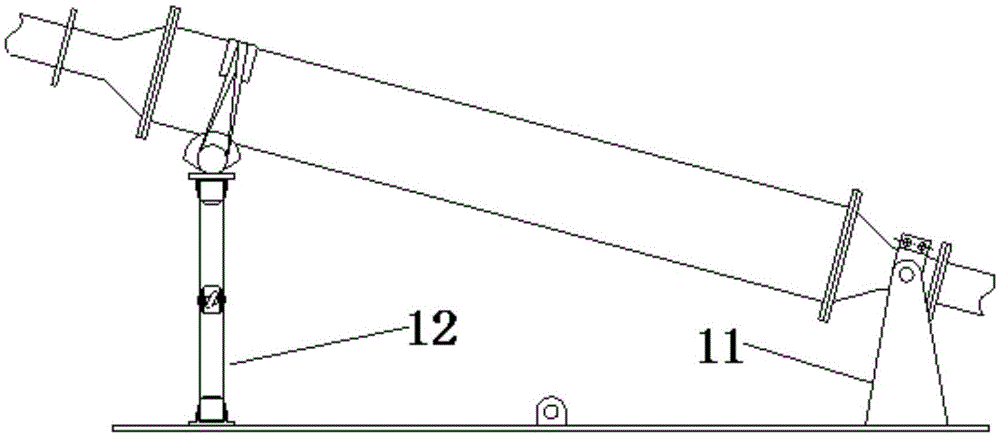

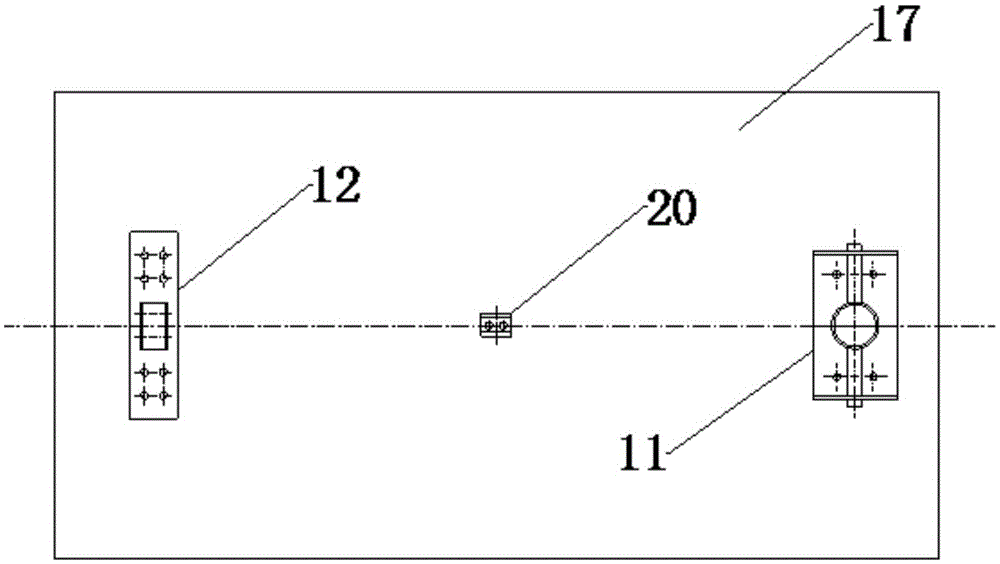

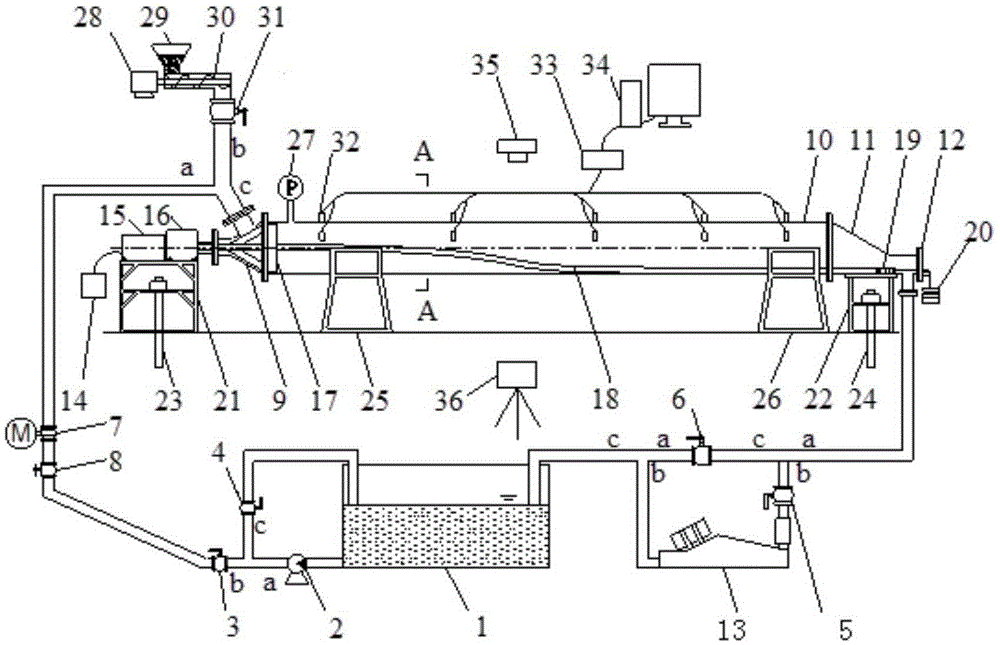

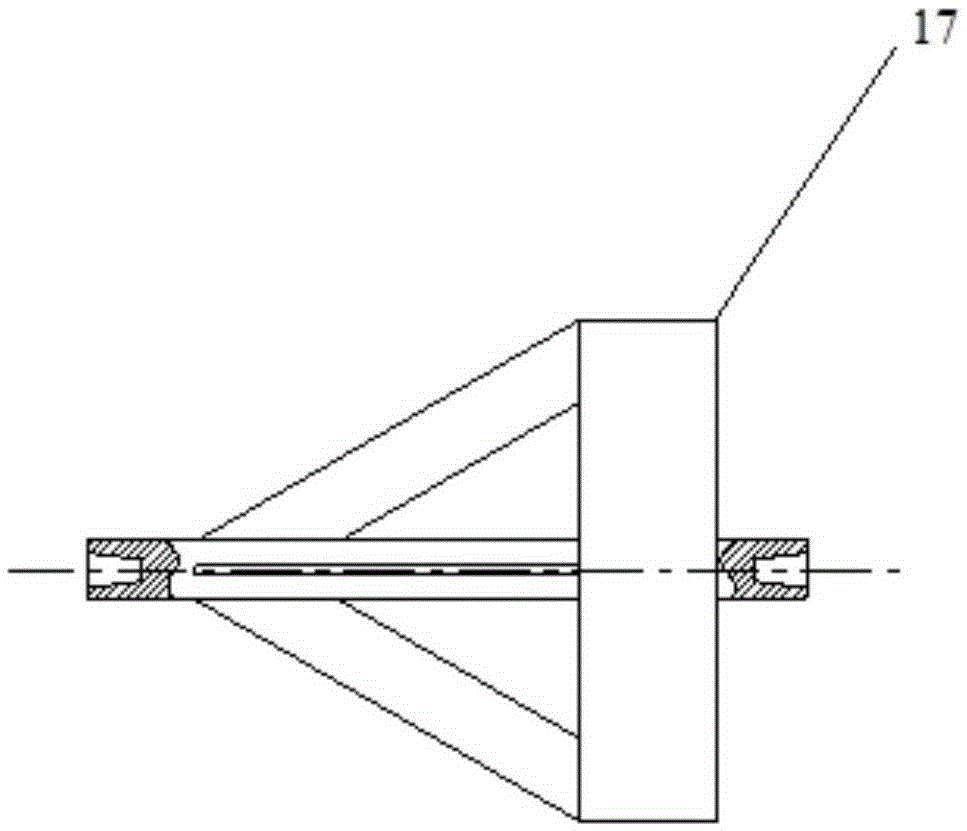

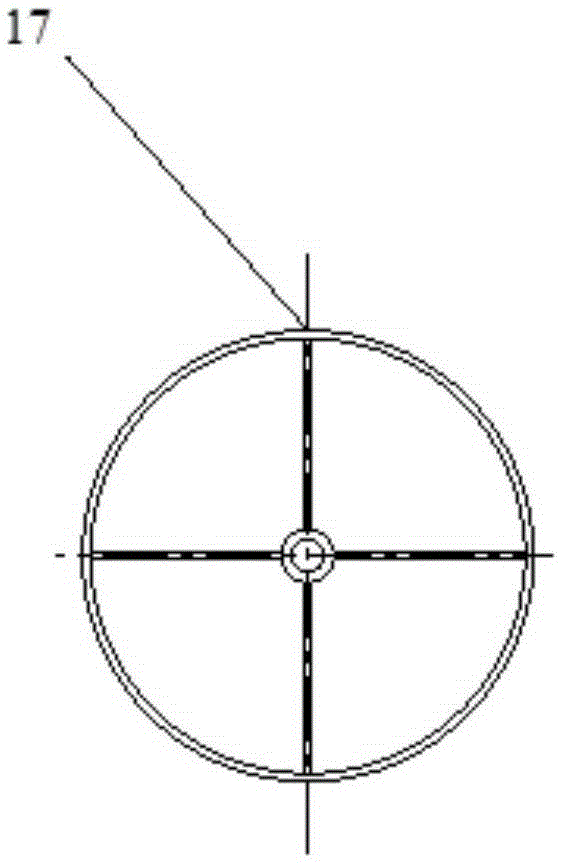

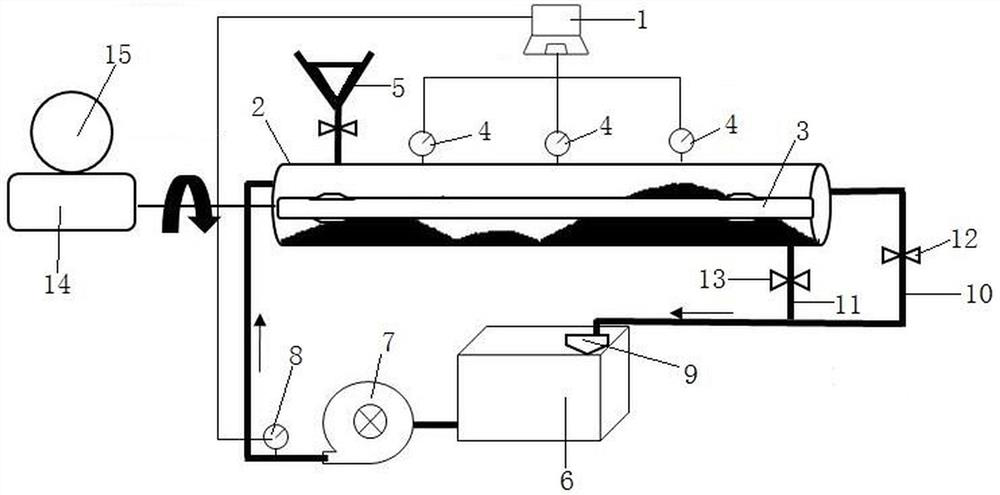

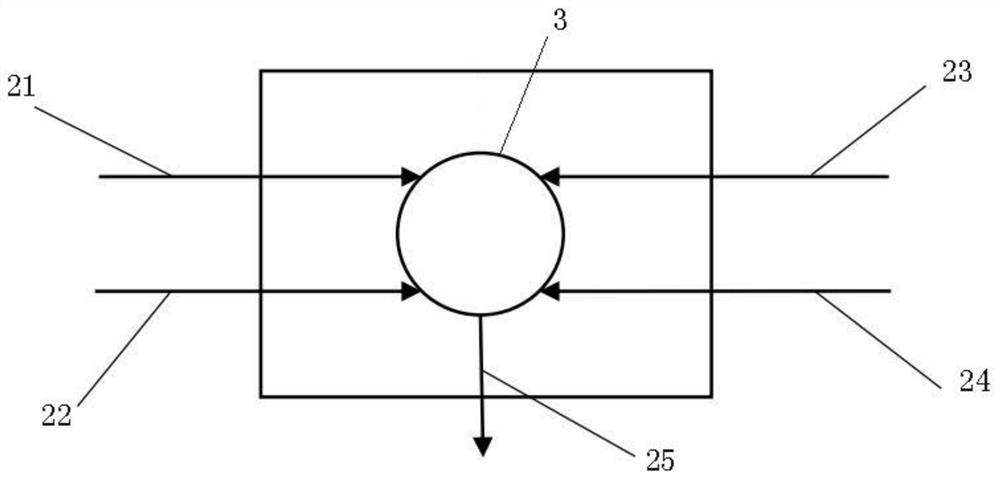

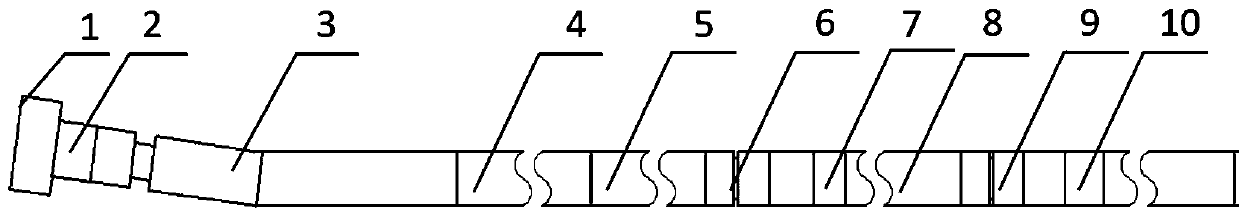

Horizontal directional drilling annular rock debris migration integration simulation experiment method and experiment apparatus thereof

ActiveCN105551362ASave experimental expensesEasy to prepareEducational modelsControl systemMotion simulation

The invention provides a horizontal directional drilling annular rock debris migration integration simulation experiment method. The method comprises processes of initializing an apparatus, adjusting a slurry input speed, adjusting a rock debris injection speed, inclining a transparent pipeline, changing the debris with different grain sizes, vertically placing the pipeline and the like. The method is characterized by observing formation of a rock debris bed in the transparent pipeline; shooting a horizontal photograph and a vertical photograph of the rock debris bed in the transparent pipeline; measuring slurry pressure and a slurry flow in the transparent pipeline; and recording a total addition amount of the rock debris so as to analyze rock debris migration. The invention simultaneously provides an experiment apparatus based on the above method. The apparatus comprises the transparent pipeline used for observation, a slurry feeding system connected to the transparent pipeline, a rock debris injection system connected to the slurry feeding system and an inclination control system arranged outside the transparent pipeline. A motion state of the rock debris under different penetrating angle and unearthed angle conditions can be simulated, and migration simulation of the rock debris bed and single rock debris motion simulation are completed in a same set of system and experiment cost is saved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

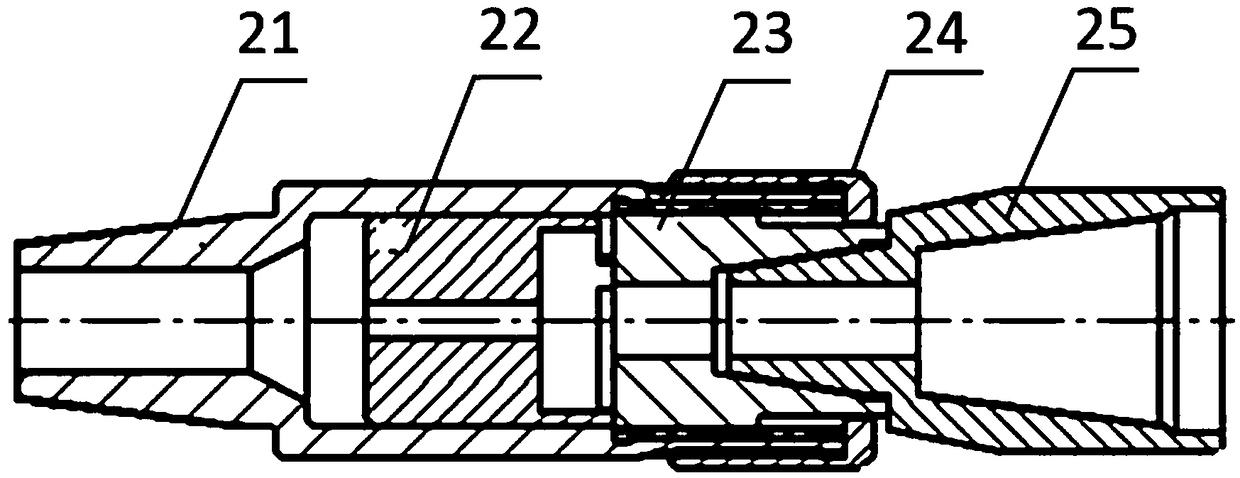

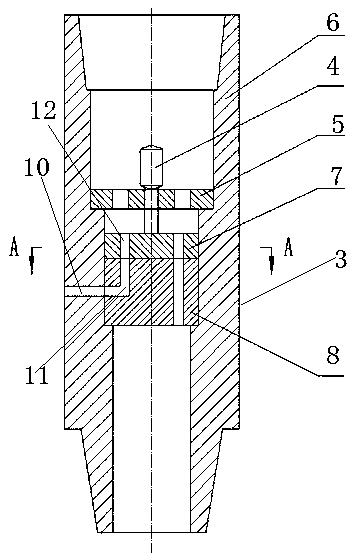

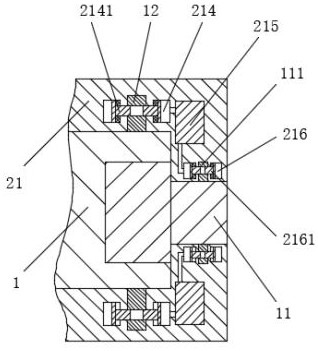

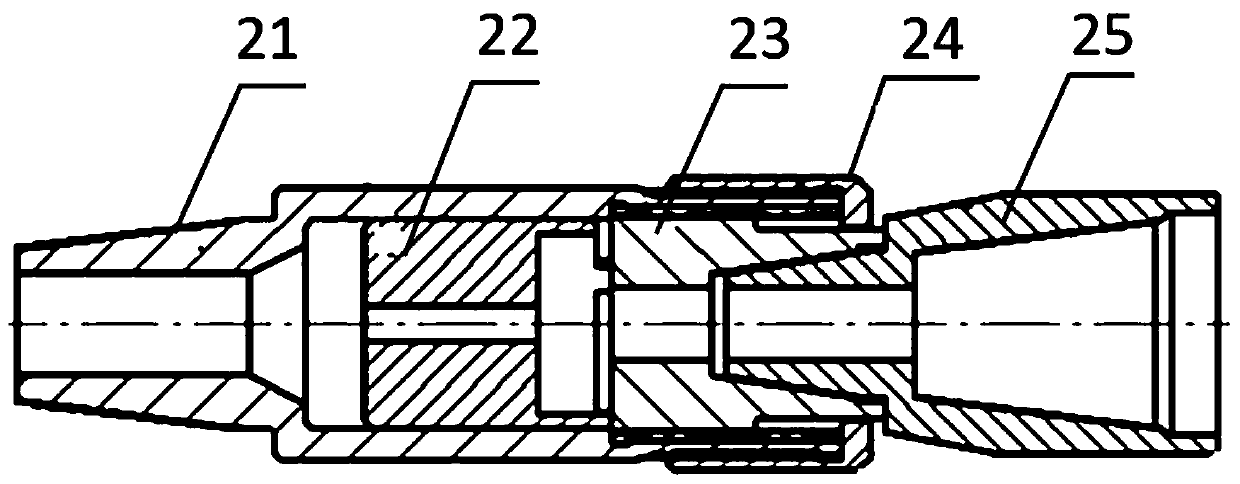

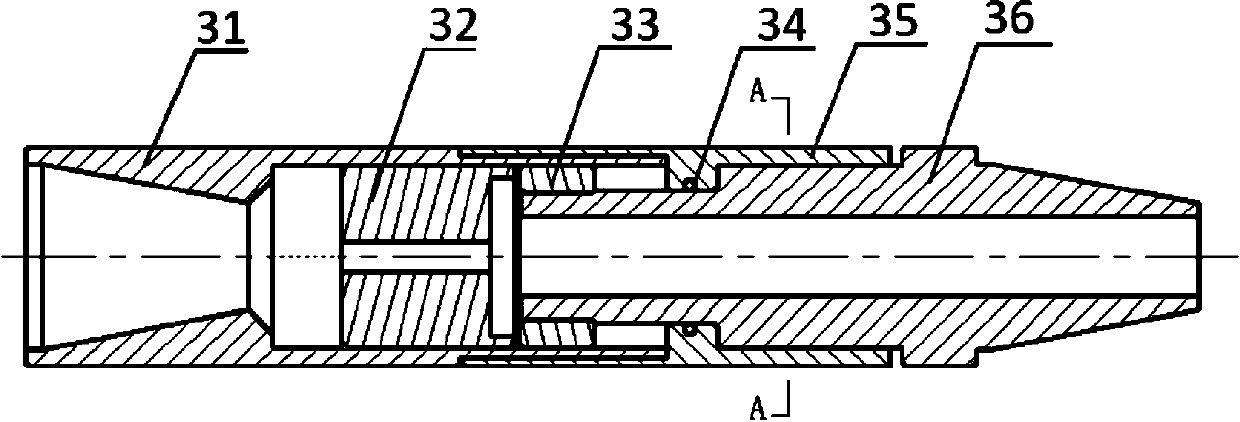

Drilling centralizer capable of removing rocks and debris beds at bottom of well

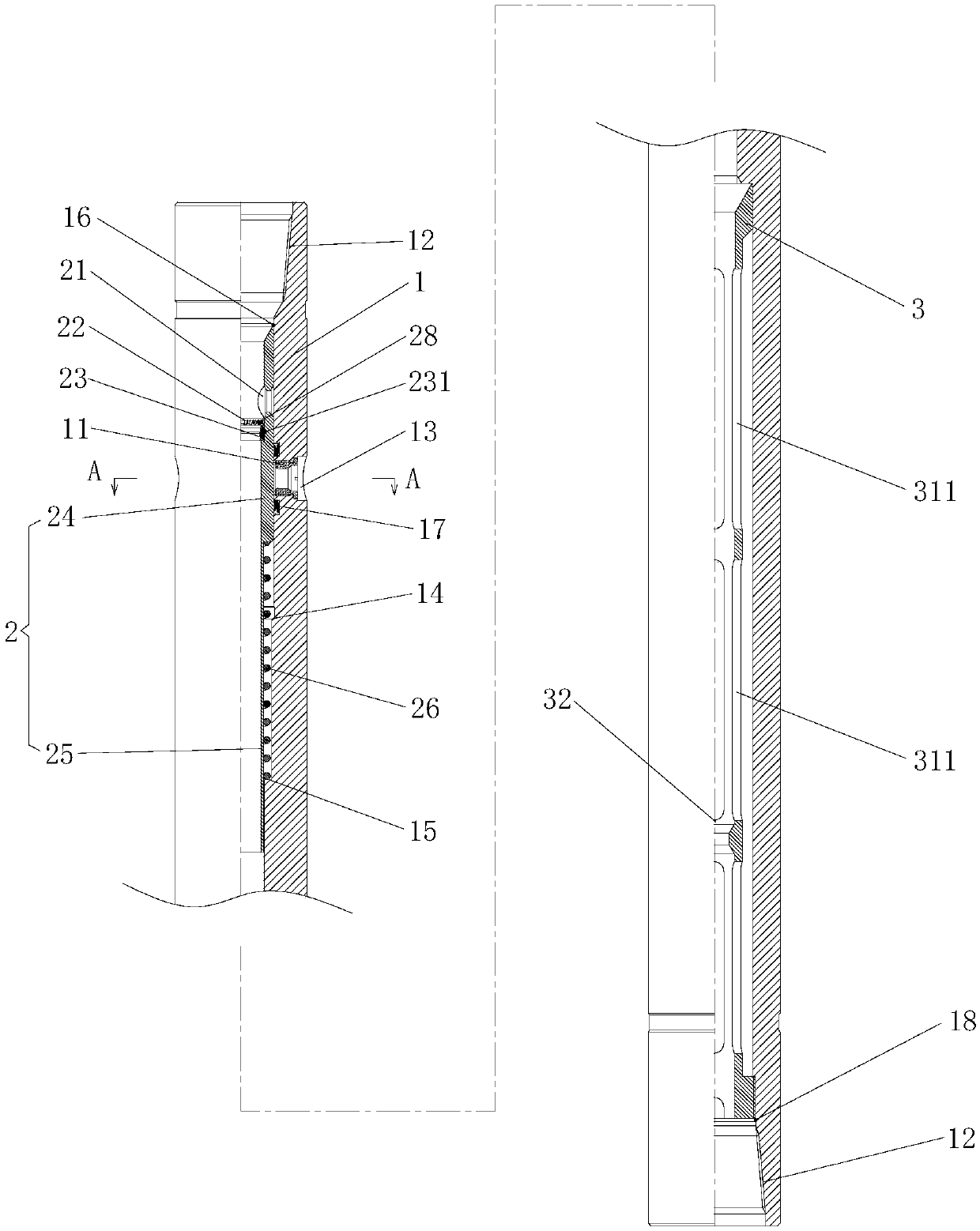

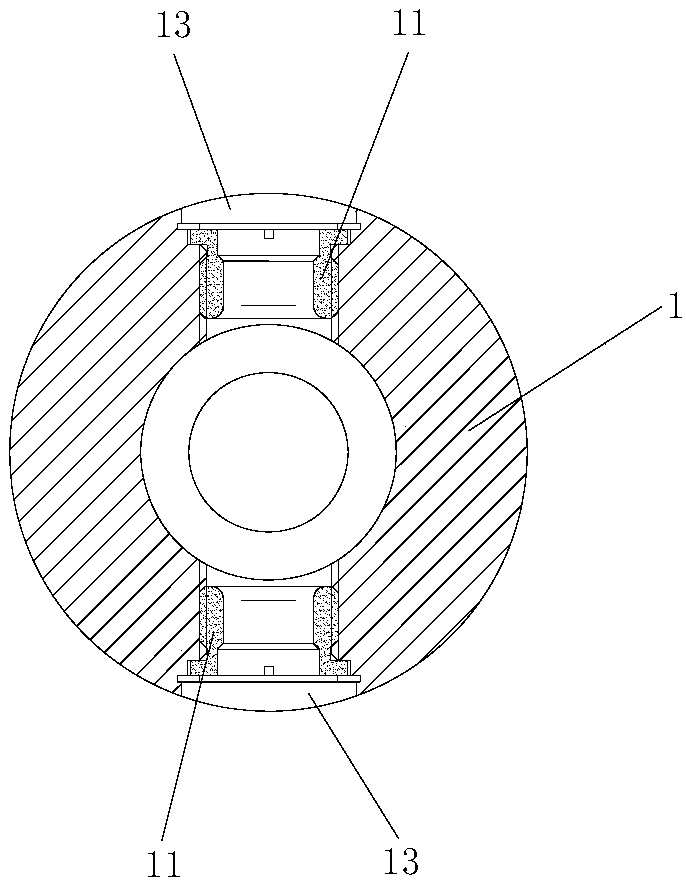

InactiveCN103352663AImprove rock clearing abilityEfficient flipDrilling rodsConstructionsWell drillingEngineering

The invention relates to a drilling centralizer capable of removing rocks and debris beds at the bottom of a well. The drilling centralizer comprises a shell, a stator, a rotor, an upper clamping ring and a lower clamping ring, wherein the shell is internally provided with through holes, and the wall of the shell is provided with knife wings and bypass holes; one end of a stator is axially limited by the upper clamping ring, and the other end of the stator is contacted and connected with one end of the rotor; the other end of the rotor is axially limited by the lower clamping ring and is also sheathed with a rolling bearing; the stator comprises a stator middle flow channel and stator draining channels; the rotor comprises a rotor middle flow channel, rotor side flow channels and rotor driving flow channels; the rotor side flow channels are positioned between every two adjacent rotor driving flow channels and are opposite to the rotor middle flow channel; one end of each rotor driving flow channel is radially provided with a pressure releasing hole; the pressure releasing holes are respectively communicated with the bypass holes and the rotor driving flow channels intermittently in the rotating process of the rotor and are also internally matched with one-way valves. The drilling centralizer has the advantages that the structure is simple, not only can the rock removing capability at the bottom of the well be greatly improved, but also the debris beds can be well damaged and removed, so that the purpose of cleaning a wellbore is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

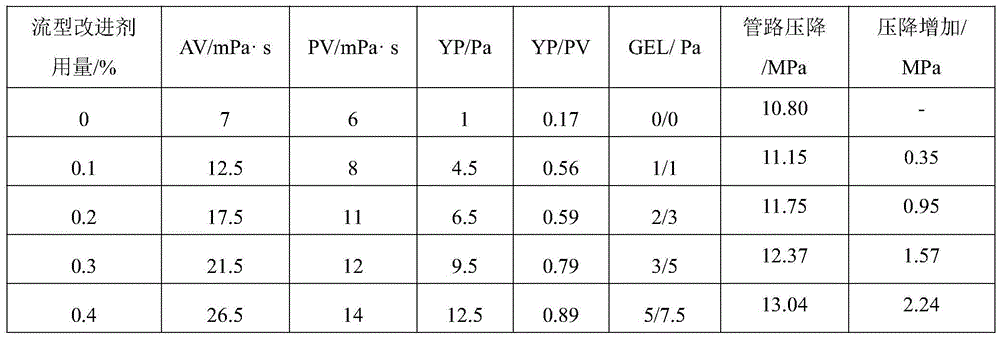

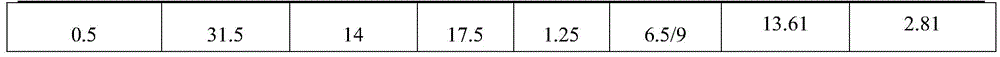

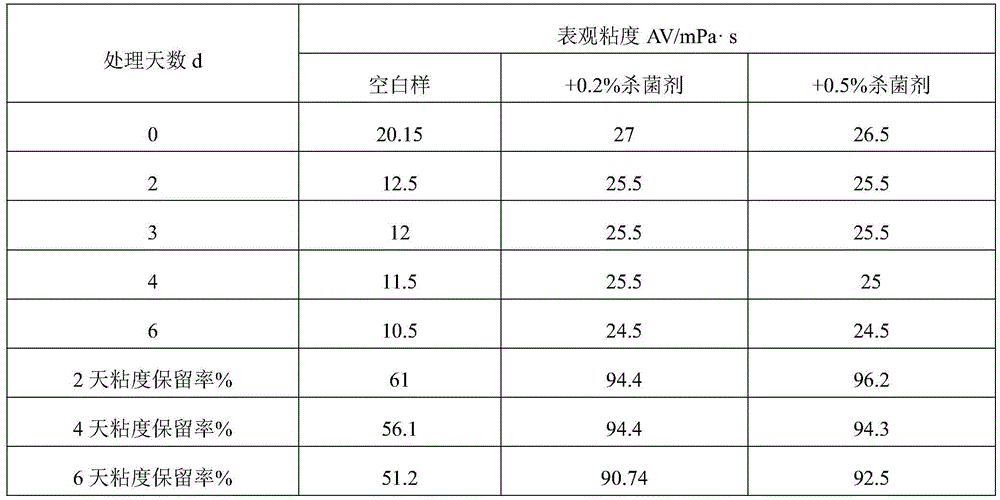

Coiled tubing drilling-plug liquid system and preparing method thereof

ActiveCN105419755ASimple compositionEasy to use on siteDrilling compositionCoiled tubingRubber sheet

The invention discloses a coiled tubing drilling-plug liquid system and a preparing method thereof. The coiled tubing drilling-plug liquid system is prepared from, by weight, 0.1-0.5 part of flow type improver, 0.25-0.3 part of a polymer thickening agent, 0.1-0.3 part of composite synergist, 0.1-0.5 part of bactericide and 0.02-0.1 part of an antifoaming agent with water serving as a dispersion medium. After the system is used, the effect of carrying bridge plug debris and fracture sand of suspension of drilling-plug liquid is good, and the drilling-plug liquid to which 0.5% flow type improver is added enables rubber sheets, composite material debris and fracture sand to be suspended, so that formation of a horizontal well rock debris bed is reduced, and frequent trip and even drilling tool jamming accidents are avoided; moreover, at the downhole temperature, viscosity and the shear retention rate of the system are high, which is beneficial for the horizontal section annular space to carry suspended debris and the fracture sand. The system is simple in formula, easy to dissolve and prepare, environmentally friendly, free of toxicity and easy to construct on site, the use amount is small, and the influence on pressure drop of a coiled tubing pipeline is small.

Owner:CHINA PETROCHEMICAL CORP +3

Underground-coal-mine nearly horizontal ultra-deep hole directional drilling drill string power push system and method

ActiveCN108868605AImprove drilling efficiencyAdd depthDrilling rodsDirectional drillingContact frictionCoal

The invention relates to an underground-coal-mine nearly horizontal ultra-deep hole directional drilling drill string power push system and method. The push system at least comprises a drill bit, a hydraulic auxiliary pressurizer, a screw motor and directional drill tool assembly, a first drilling string set, a first pusher, a rock debris bed cleaner, a second pusher, a second drilling string setand a water pump which are arranged in sequence. According to the system, efficient application of drilling pressure during underground-coal-mine ultra-deep hole directional drilling and safe, stableand efficient pushing of drill strings are achieved, and the problem is solved that due to contact friction resistance generated during bending deformation of the drill strings in a long-distance nearly horizontal directional hole, the pushing force of a port drilling machine cannot be effectively transmitted to a drill bit; the problem is solved that increasement of friction resistance and construction risks is caused by deposition of rock debris during nearly horizontal hole-in slide drilling, and the system has important significance on increasement of directional drilling depth and improvement in deep hole directional drilling.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

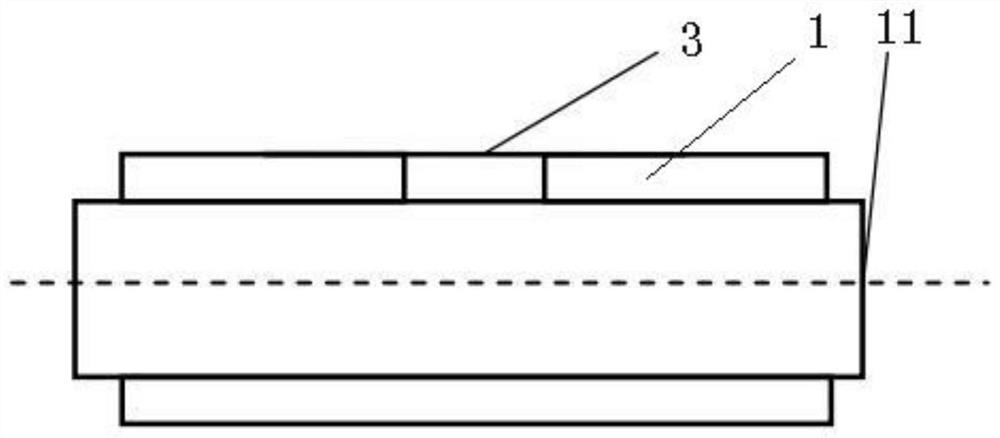

Annular multi-field coupling simulation drilling experiment method and apparatus through horizontal directional drilling

ActiveCN105390060ARealize non-contact annular flow field monitoringExperimental results are reliableEducational modelsMulti fieldDirectional drilling

The invention provides an annular multi-field coupling simulation drilling experiment method through horizontal directional drilling. The method comprises the steps: building an experiment environment, conducting state initialization, and conducting mutual coupling motion analysis between a drilling rod and slurry, between a drilling rod and rock debris and among slurry, a drilling rod and rock debris by adjusting the slurry input speed, adjusting rock debris injection speed and changing the mass of a weighting counterweight. The invention also provides an annular multi-field coupling simulation drilling experiment apparatus through horizontal directional drilling. The apparatus comprises a slurry circulatory system, a drilling tool revolution system, a rock debris injection system, a slurry flow field monitoring system and an image processing system. The distribution situation of annular slurry flow fields, the spatial movement form of a drilling rod and the motion state of a rock debris bed can be collected and analyzed in real time according to mutual coupling interaction among a drilling rod, rock debris and slurry in an annular space during horizontal directional drilling (HDD).

Owner:新疆鼎立非开挖工程有限公司

A method for determining the heat transfer and drying point of a debris bed after a serious accident of a sodium cooled fast reactor

ActiveCN109033529ASimple calculationDesign optimisation/simulationSpecial data processing applicationsEngineeringSodium-cooled fast reactor

A method for determining the heat transfer and drying point of a debris bed after serious accident of sodium-cooled fast reactor features that boundary conditions of debris bed aft serious accident ofreactor are determined and grid is divided according to energy equation of temperature distribution. Then the equivalent thermal conductivity of the debris bed is calculated for the non-boiling state, boiling state and drying state respectively. Then, the equivalent thermal conductivity of the debris bed in the channel region where the debris particles are cracked by steam extrusion is calculatedwhen the debris bed is superheated locally. Finally, the initial conditions and boundary conditions are set to calculate the next time step temperature and the equivalent thermal conductivity of eachgrid, and the temperature distribution of the debris bed and the location of the drying point at each time point are finally obtained. A simple equivalent thermal conductivity model is used to calculate the complex energy transfer process in the debris bed, and the equivalent thermal conductivity of the debris bed adopts different calculation modes according to different working conditions, and finally the temperature distribution at each time in the cooling process of the debris bed of the sodium-cooled fast reactor and the position of the debris bed drying point when the cooling is insufficient are obtained.

Owner:XI AN JIAOTONG UNIV

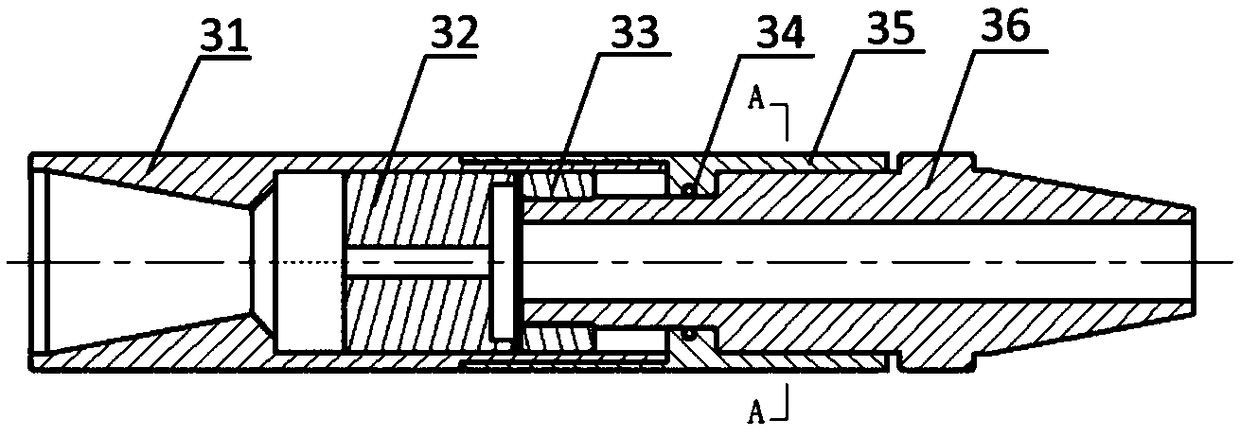

Intelligent rock debris removing device

PendingCN110541681AMeet actual needsEasy to cleanCleaning apparatusFlushingWell drillingThrust bearing

The invention relates to a removing device, in particular to an intelligent rock debris removing device. The intelligent rock debris removing device is composed of a sleeve, an upper connector, a lower connector, a flow distribution assembly and scraper blades; a port of one end of the sleeve is internally provided with the upper connector through a thread, and a port of the other end of the sleeve is internally provided with the lower connector through a thread; the position, between the lower connector and the upper connector, of the sleeve is movably sleeved with the flow distribution assembly through a thrust bearing; an installation flange is arranged in the sleeve and internally provided with installation cavities in a radial shape, and the installation cavities communicate with theflow distribution assembly; and the scraper blades are installed in the installation cavities, springs are arranged between the scraper blades and the sleeve, and the ends of the scraper blades extendto the outside of the sleeve. The intelligent rock debris removing device has the characteristics of being capable of removing only the bottom rock debris bed and good in removing effect, the problems that an existing removing device is unthorough in removing and poor in removing effect are solved, and the requirements of drilling engineering are met.

Owner:YANGTZE UNIVERSITY

Device capable of improving extending limit of coiled tubing

InactiveCN105863527ARaise the extension limitReduce frictionDrilling rodsDrilling casingsImpellerStatic friction

The invention discloses a device capable of increasing the extension limit of a coiled tubing, which is provided with a vibration nipple and a modulating nipple; Drill assembly connection. The axial vibration energy of the tool of the present invention can convert the static friction between the coiled tubing and the well wall into sliding friction, reduce the friction between the coiled tubing and the well wall, and can improve the extension limit of the coiled tubing; the axial vibration of the tool can promote The movement of cuttings prevents the formation of cuttings beds, smooths the wellbore, and prevents downhole complexity; the impeller with through holes ensures that there is always fluid passing through the tool, which will not affect the use of downhole power drilling tools and measuring tools, while preventing The destructive effect of water hammer is eliminated; the present invention has simple structure, few components, and ensures the reliability of the tool.

Owner:SOUTHWEST PETROLEUM UNIV

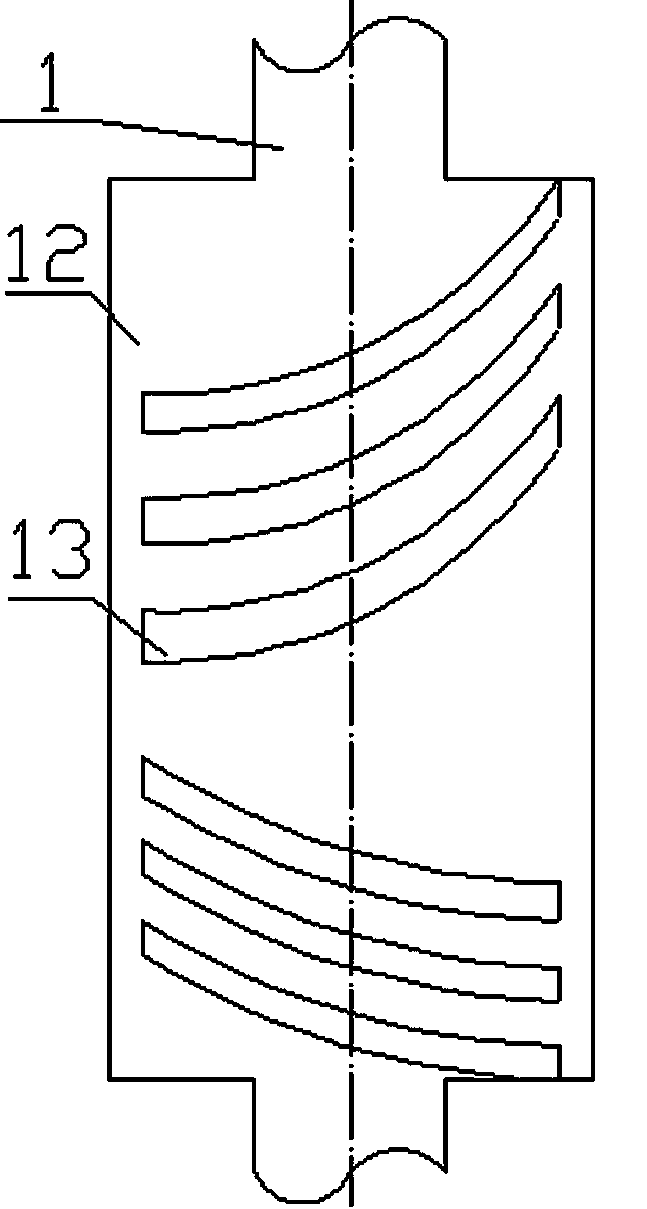

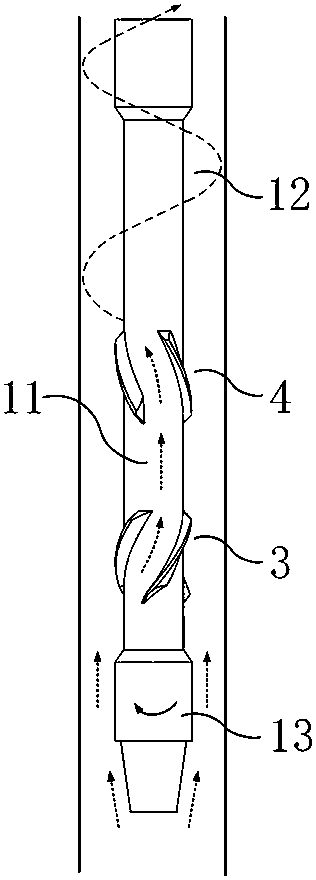

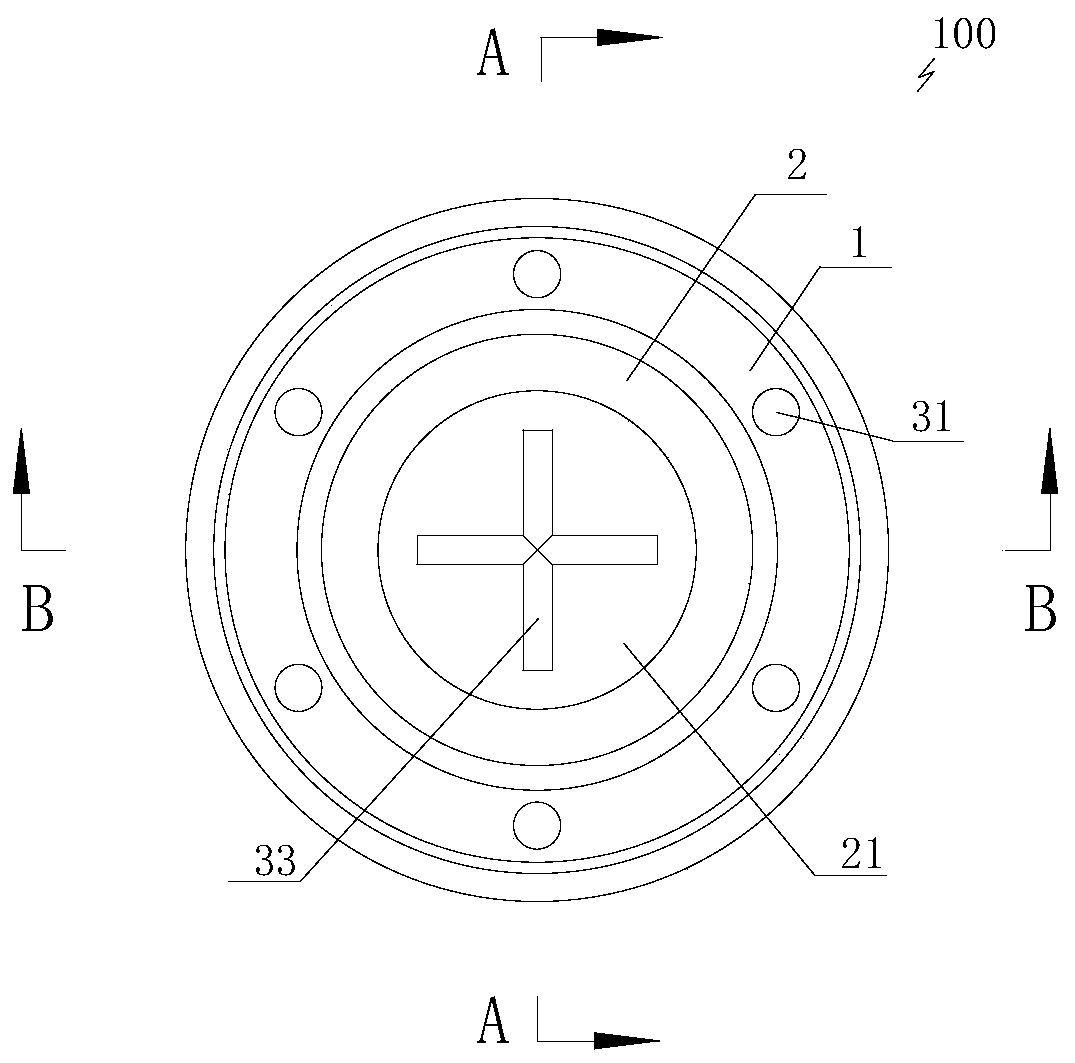

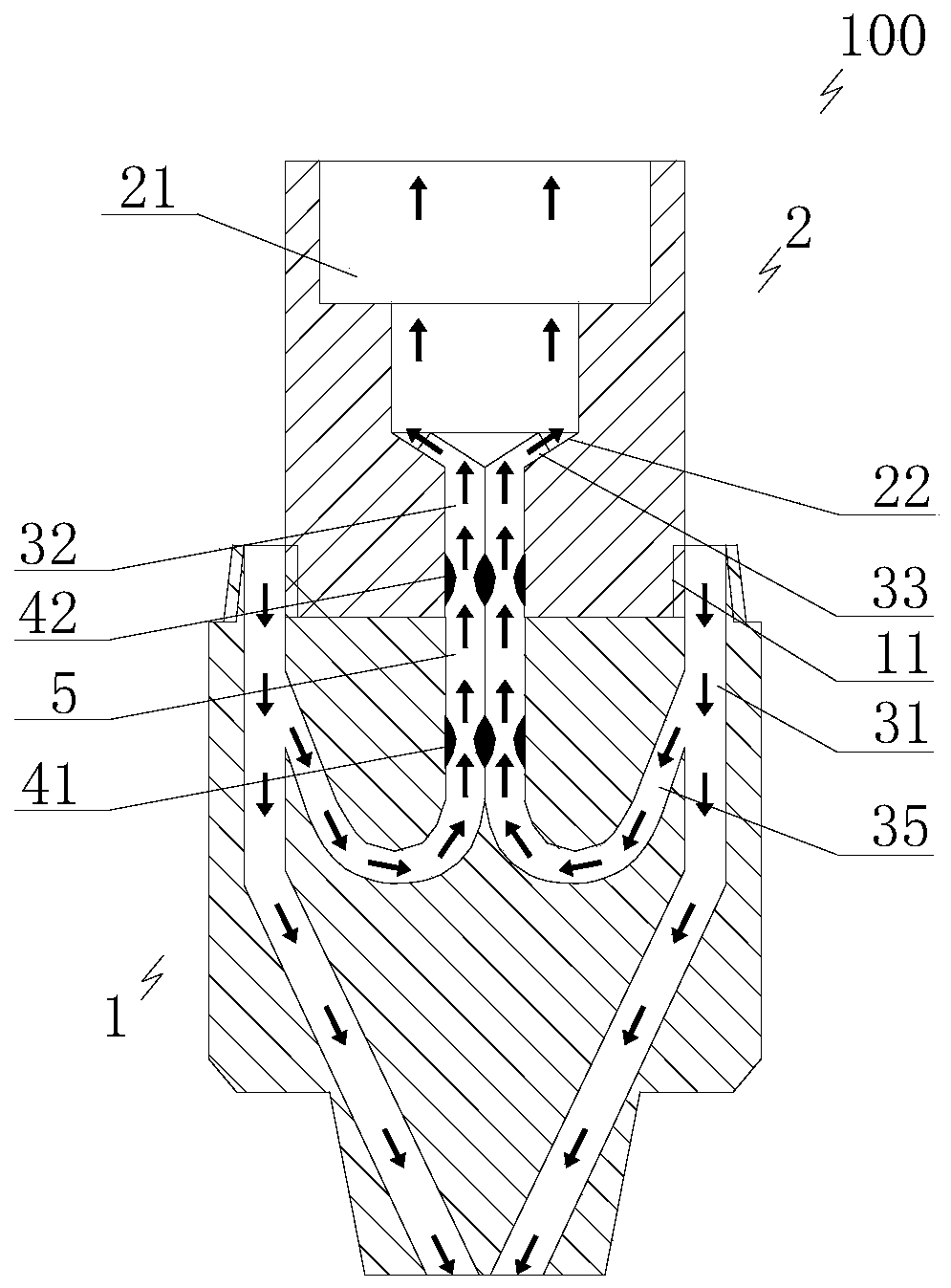

Fixing guide vane wheel type whirl flow jet flow grinding drill bit for horizontal well

The invention discloses a fixing guide vane wheel type whirl flow jet flow grinding drill bit for a horizontal well. The grinding drill bit mainly comprises a PDC drill bit body and is characterized in that a debris discharging groove in a gauge protection portion of the PDC drill bit body is omitted, and the PDC drill bit body is internally and additionally provided with a fixing guide vane wheel type rotating jet flow sand washing device, a high-concentration turbulence sand pumping device and a jet flow smashing device. According to the fixing guide vane wheel type rotating jet flow sand washing device, high-speed rotating jet flow is generated through fixing guide vane wheel rotating jet flow spray nozzles, a well bottom whirl flow field beneficial to sand cleaning is generated, the stress condition of well bottom rock debris is improved, and the well bottom rock debris cleaning efficiency is improved. The high-concentration turbulence sand pumping device pumps and sucks the well bottom fluid based on the principle of a sand pumping pump, the well bottom pressure difference is reduced, unbalance is achieved, and the mechanical drilling speed is increased. The jet flow smashing device effectively smashes the rock debris based on the principle of a jet mill, the rock debris carrying efficiency is improved, the rock debris bed in the horizontal well is eliminated radically, and safe and efficient drilling of the horizontal well is finally achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Circulating plugging-while-drilling device

PendingCN109931019ASolve plugging while drillingSolve cleanupFlushingWell/borehole valve arrangementsWell drillingEngineering

The invention provides a circulating plugging-while-drilling device. The circulating plugging-while-drilling device comprises an outer cylinder, a hole-opening sliding sleeve and a ball basket; at least one bypass nozzle is arranged on the outer cylinder; the hole-opening sliding sleeve is inserted into the outer cylinder in an axial-moving manner, can plug the at least one bypass nozzle, and is provided with fluid flow holes capable of being communicated with the bypass nozzle; a ball catching claw and a ball seat are connected in the hole-opening sliding sleeve; the ball catching claw is positioned at the upper end of the ball seat; the fluid flow holes are positioned above the ball catching claw; and the ball basket is connected in the outer cylinder in a penetrating way, is positionedbelow the hole-opening sliding sleeve, and is provided with at least one hole-opening groove group. The circulating plugging-while-drilling device provided by the invention has the advantages that thetechnical problems of plugging-while-drilling and cleaning of a rock debris bed in a drilling process can be effectively solved, and the drilling time and cost can be greatly reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

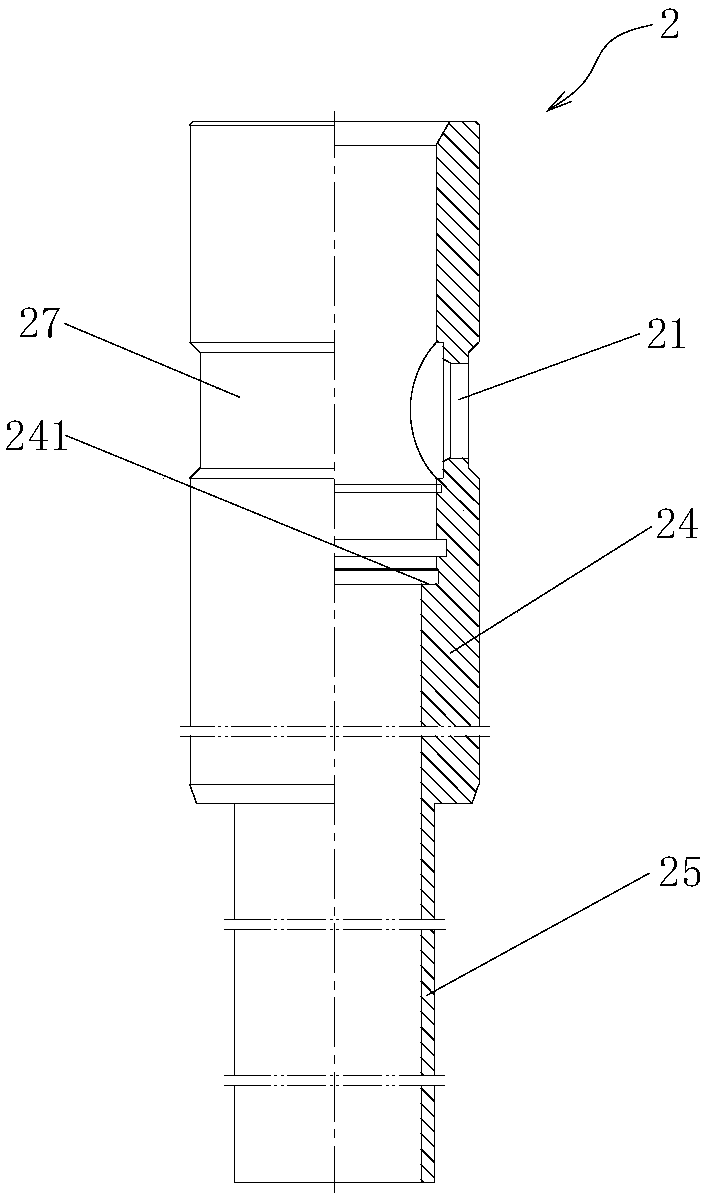

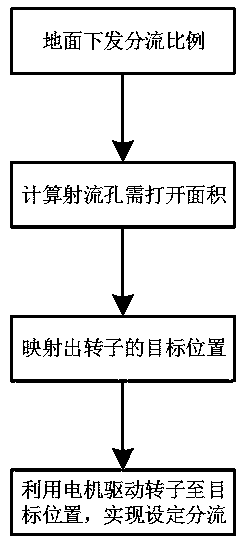

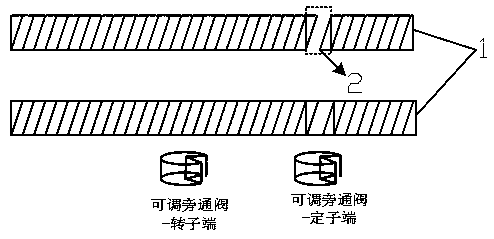

Jet flow adjusting method for rotary steering downhole jam releasing

ActiveCN111502547ARealize the solution cardSolve the stuck drill problemLiquid/gas jet drillingDirectional drillingJet flowWell drilling

The invention discloses a jet flow adjusting method for rotary steering downhole jam releasing, and relates to the technical field of oil well downhole drilling equipment. The jet hole with the adjustable area is designed in a drill column of the rotary steering downhole equipment, and when engineering technicians consider that an downhole rock debris bed is seriously accumulated, an instruction is issued, the flow dividing proportion of the jet hole is determined, the equivalent runner area of a drilling tool is set, the opening area of the jet hole is calculated, part of drilling fluid passes through the jet hole and is combined with rotation of the drill column, and rotating jet flow is formed to destroy a peripheral rock debris bed, so that the rotary steering tool is jam released. Themethod is easy to control and high in jamming releasing capacity, and the drill jamming problem of the downhole rotary steering tool can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

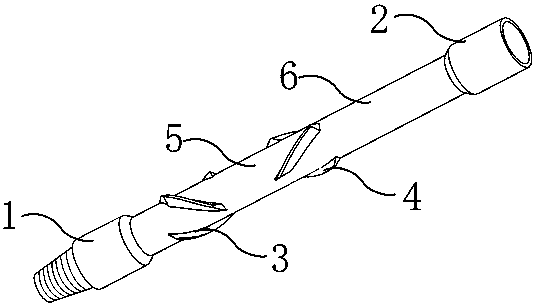

Combined rock debris cleaning tool with positively and reversely spiral blades

The invention relates to a combined rock debris cleaning tool with positively and reversely spiral blades. The combined rock debris cleaning tool with positively and reversely spiral blades comprisesa body. A positively spiral blade group and a reversely spiral blade group are arranged on the body. The upper end of the body is equipped with a female thread joint. The lower end of the body is provided with a male thread joint. The positively spiral blade group is located on one side approaching a male joint. The spacing distance between the positively spiral blade group and the male thread joint is front blade pitch. The reversely spiral blade group is arranged above the positively spiral blade group. The spacing distance between each positively spiral blade and each reversely spiral bladeis blade group spacing distance. The female thread joint is arranged above the reversely spiral blade group. The spacing distance between the reversely spiral blade group and the female joint is backblade pitch. Drilling fluid passing channels are formed between two adjacent positively spiral blades or two reversely spiral blades. After the reversely spiral blade group rotates, spiral vortex-creating influence is acted upon rock debris and drilling fluids behind. Therefore, formation of rock debris beds and sand hills is inhibited. Accordingly, cleaning efficiency of rock debris is increased.

Owner:NORTHEAST GASOLINEEUM UNIV

Optimum design method for reactor core fusion collector

ActiveCN108897950AReduce computing resourcesReduce computing timeGeometric CADSpecial data processing applicationsEngineeringDesign methods

The invention discloses an optimum design method for a reactor core fusion collector. Modeling is conducted on a simplified reactor core fusion collector, and according to the symmetrical border, modeling is conducted on part of trays; a fusant is simplified to a cylindrical shape, the initial condition is set as complete fusion of a box of fuel elements, and the fused fuel elements fall from a big grid plate to a top cover of the reactor core fusion collector and the trays; a three-dimensional DEM method is adopted for calculation, at least ten sample points are uniformly taken from the calculated result in the radial direction, and non-dimensional unevenness sigma is defined to quantize the influences of different structures and sizes of reactor core fusion collectors on the distributionof the forming thickness of a debris bed. Through simplified modeling, the required time of DEM modeling calculation is greatly reduced, the calculation accuracy is ensured, the determination difficulty of calculation parameters is reduced, and definition unevenness provides basis for the design optimization of reactor core fusion collectors.

Owner:XI AN JIAOTONG UNIV

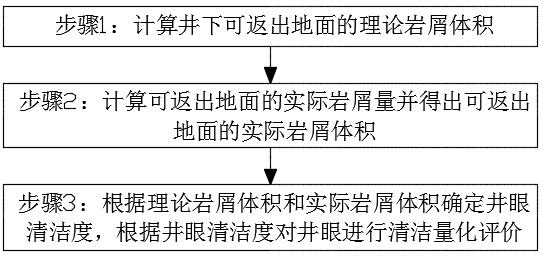

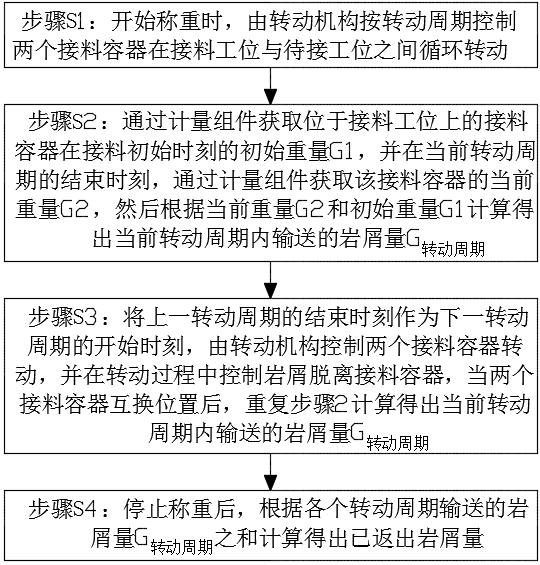

Quantitative evaluation method for borehole cleanliness based on rock debris return condition

The invention discloses a borehole cleanliness quantitative evaluation method based on a rock debris return condition. The method comprises the following steps that step 1, a theoretical rock debris volume capable of returning to the ground under a well is calculated; 2, the returned rock debris amount which has returned to the ground in the drilling process and the to-be-returned rock debris amount which is late to return to the ground after drilling is stopped are obtained, the actual rock debris amount which can return to the ground is obtained according to the returned rock debris amount and the to-be-returned rock debris amount, and the actual rock debris volume which can actually return to the ground is obtained according to the actual rock debris amount; and 3, the borehole cleanliness is determined according to the theoretical rock debris volume and the actual rock debris volume, and borehole cleanliness is quantitatively evaluated according to the borehole cleanliness. According to the method, the shaft bottom rock debris accumulation condition can be judged by comparing the amount of rock debris returned from the ground in the drilling process with the amount of rock debris generated at the shaft bottom theoretically, a basis is provided for rock debris bed form judgment, ground parameter optimization is guided, and the operation risk is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

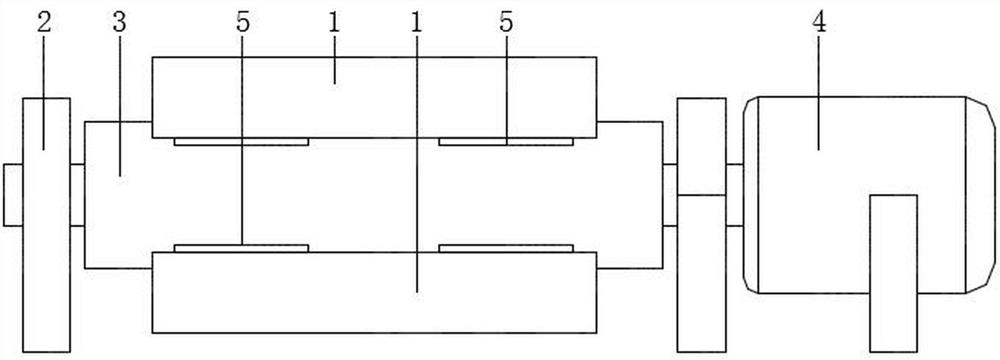

Simulation experiment method for determining thickness of rock debris bed based on measurement of fluid speed

PendingCN111997602AThickness effective discriminationLow costSurveyFlushingHorizontal wellsComputational simulation

The invention discloses a simulation experiment method for determining a thickness of a rock debris bed based on measurement of a fluid speed. The method comprises the following steps that 1, a simulated wellbore, a simulated drill string and a flow meter are arranged; 2, a drilling fluid is injected into the simulated wellbore, the simulated drill string is controlled to rotate, a reinjection mechanism injects rock debris into the simulated wellbore, and then a discharging rate of a drilling fluid injection mechanism and a flow rate of the drilling fluid are obtained separately; 3, a cross-sectional area of annulus corresponding to the flow meter in the wellbore are simulated according to the discharging rate and the flow rate; 4, a ratio of the rock debris bed in an area corresponding tothe flow meter in the simulated wellbore to the simulated wellbore according to an inner diameter of the simulated wellbore, an outer diameter of the simulated drill string and the cross-sectional area obtained in the third step; and 5, the thickness of the rock debris bed in the area corresponding to the flow meter in the simulated wellbore is calculated according to the internal diameter of thesimulated wellbore and the ratio of the rock debris bed to the simulated wellbore obtained in the step 4. The method can determine the thickness of the rock debris bed in a water-based / oil-based drilling fluid state at a low cost, and can effectively provide guidance for horizontal well rock debris bed research.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

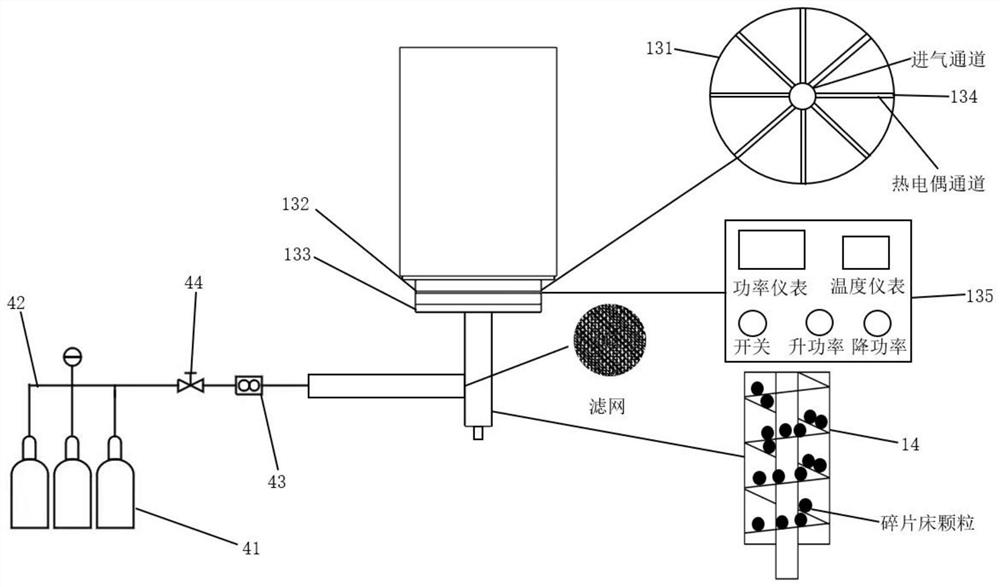

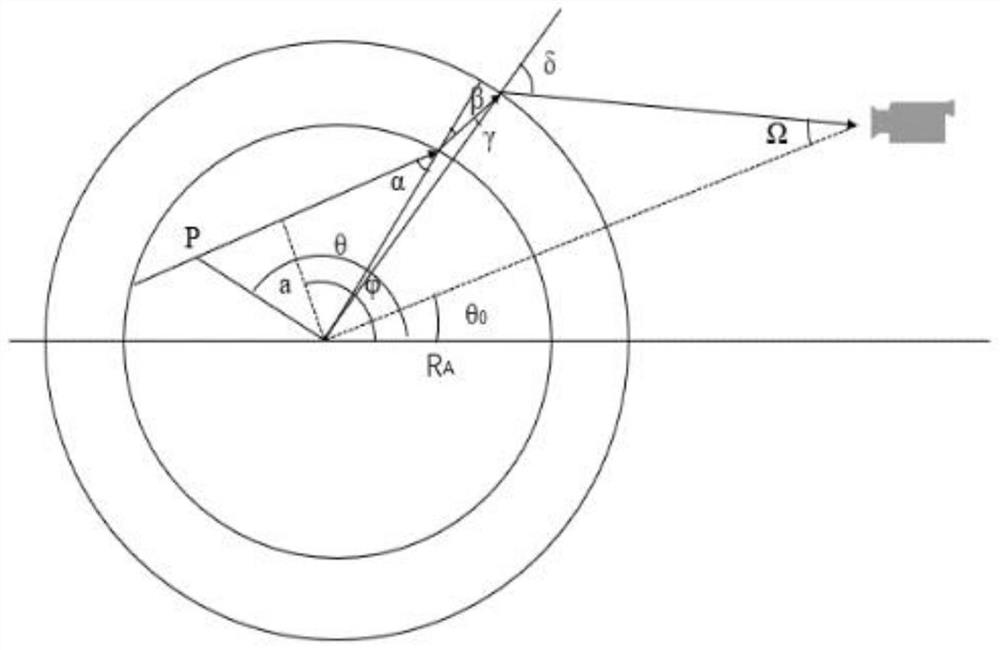

Multifunctional sodium-cooled fast reactor debris bed simulation device and light refraction compensation measurement method

PendingCN114121321AAchieving Accurate MeasurementsAchieving processing powerNuclear energy generationNuclear monitoringCollection systemData acquisition

The invention discloses a multifunctional sodium-cooled fast reactor debris bed simulation device and a light refraction compensation measurement method. Comprising an experimental device supporting platform, and a telescopic supporting platform, a data acquisition system, a fragment bed particle release system, a dry particle collection system, a visual fragment bed particle container, a light refraction compensation container and a fragment bed heating and gas injection mixing system which are arranged on the experimental device supporting platform, wherein the light refraction compensation container is located outside the visual fragment bed particle container and integrally arranged in the telescopic supporting platform, and the fragment bed particle release system is located above the telescopic supporting platform and right faces the visual fragment bed particle container. The fragment bed heating system and the dry particle collecting system are sequentially arranged below the experimental device supporting platform, the fragment bed heating system is connected with the visual fragment bed particle container, and the dry particle collecting system is connected with the gas injection system. Model support is provided for development and verification of large-scale safety analysis programs, angle data of the simulation device are accurately extracted through light refraction compensation measurement, and a correction scheme can be provided for observation and detection of industrial actual cylindrical containers.

Owner:SHANGHAI JIAO TONG UNIV

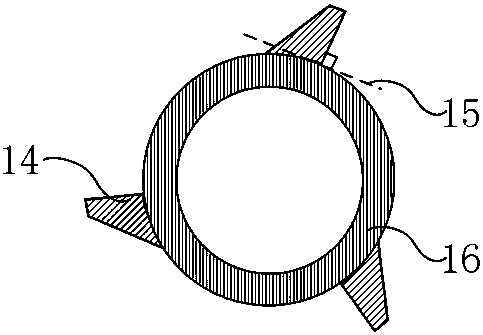

Cam type rock debris cleaning tool

ActiveCN113266310AImprove practicalitySimple structureCleaning apparatusFlushingMining engineeringHorizontal wells

The invention relates to a cam type rock debris cleaning tool, and belongs to the technical field of horizontal well rock debris cleaning equipment. An upper connector is installed at one end of a shell body in a threaded mode, a lower connector is installed at the other end of the shell body in a threaded mode, a center hole is eccentrically formed in the shell body in the axial direction, and an eccentric shaft is movably installed in the center hole through an upper bearing piece and a lower bearing piece; and assembling grooves are symmetrically formed in the circumference, corresponding to the eccentric shaft between the upper bearing piece and the lower bearing piece, of the shell body, and cleaning mechanisms are installed in the assembling grooves, and are in contact connection with the eccentric shaft. A spoiler of the tool has a directional rock debris cleaning function, when the spoiler rotates to the bottom of an annulus, the spoiler automatically stretches out to clean a rock debris bed, so that rock debris at the bottom of the annulus is scraped to a high-speed area on the upper portion of the annulus by the device, moreover, when the device rotates to the high-speed area on the upper portion of the annulus, the spoiler automatically retracts to prevent the rock debris in the high-speed area on the upper portion of the annulus from being scraped to the bottom of the annulus, and meanwhile, the spoiler does not have a balling phenomenon, so that the drilling efficiency and economic benefits are effectively improved.

Owner:YANGTZE UNIVERSITY

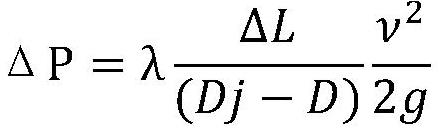

Simulation experiment method for determining average thickness of rock debris bed based on pressure difference

PendingCN111997603AAccurate calculation of average thicknessEffective discrimination of average thicknessSurveyFlushingDischarge rateMechanics

The invention discloses a simulation experiment method for determining an average thickness of a rock debris bed based on pressure difference. The simulation experiment method comprises the followingsteps that 1, a simulated wellbore, a simulated drill string and at least two pressure gauges are arranged; 2, drilling fluid is injected into the simulated wellbore, the simulated drill string is controlled to rotate, rock debris is injected into the simulated wellbore, a discharge rate for injecting the drilling fluid and pressure values detected by the pressure gauges are separately obtained, and a pressure difference between the two adjacent pressure gauges is obtained; 3, an average flow rate of the drilling fluid between the two adjacent pressure gauges is calculated according to the result of the step 2; 4, an average cross-sectional area of an annulus between the two adjacent pressure gauges is calculated according to the result of the third step; 5, an average ratio of a rock debris bed to the simulated wellbore between the two adjacent pressure gauges is calculated according to the result of the fourth 2; and 6, an average thickness of the rock debris bed between the two adjacent pressure gauges is calculated according to the result of the step 5. According to the method, the average thickness of the rock debris bed in a water-based / oil-based drilling fluid state is determined according to the pressure difference, the cost is lower and the determining effect is better.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Debris bed breaker utilizing annular fluid

ActiveCN114320234AGuaranteed to workQuick destructionCleaning apparatusDirectional drillingAir pumpPressure sensing

The invention discloses a cuttings bed breaker using annulus fluid, which comprises a fixed rod and a breaker body, the breaker body comprises a connecting pipe, a breaker shell, a rotating pipe and a drill bit, the connecting pipe is arranged on the fixed rod, and the rotating pipe is arranged on the breaker shell. The breaker shell is fixedly installed at the end, away from the fixing rod, of the connecting pipe, and a plurality of sets of third breaking heads are arranged on the breaker shell. A detection device and a pressure sensing device are additionally arranged on an existing cuttings bed breaker, and the thickness of a cuttings bed can be detected through the detection device; the length, extending out of the destructor shell, of the third crushing head can be controlled through the magnetic field generator, the destructor body can be controlled to be connected with the fixing rod or the driving device through the air pump, and the purpose of destructing the cuttings bed can be achieved through the third crushing head and the destructor body; through the pressure sensing device, on one hand, drilling fluid can be prevented from entering the well wall, and on the other hand, the magnetic field generator and the air pump can work.

Owner:NANTONG YONGDA PIPE IND

Underground auxiliary rock carrying tool and method

ActiveCN112483031ARealize automatic start and stopEasy to installSurveyDisloding machinesScreeUltrasonic generator

Owner:CHINA PETROLEUM & CHEM CORP +1

Drill string power propulsion system and method for directional drilling of near-horizontal ultra-deep holes in underground coal mines

ActiveCN108868605BImprove drilling efficiencyAdd depthDrilling rodsDirectional drillingContact frictionCoal

A drill string power propulsion system and method for directional drilling in a near-horizontal ultra-deep hole in a coal mine. A thruster, a cuttings bed cleaner, a second thruster, a second drill string group and a water stool; the present invention realizes the efficient application of drilling pressure and the safety, stability, and Efficient propulsion, solving the problem that the propulsion force of the hole drilling machine cannot be effectively transmitted to the drill bit caused by the contact friction caused by the bending deformation of the drill string in the long-distance near-horizontal directional hole, and solving the problem caused by cuttings during sliding drilling in the near-horizontal hole The problem of increased friction and increased construction risk caused by sedimentation is of great significance for improving the depth of directional drilling and the efficiency of deep hole directional drilling.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

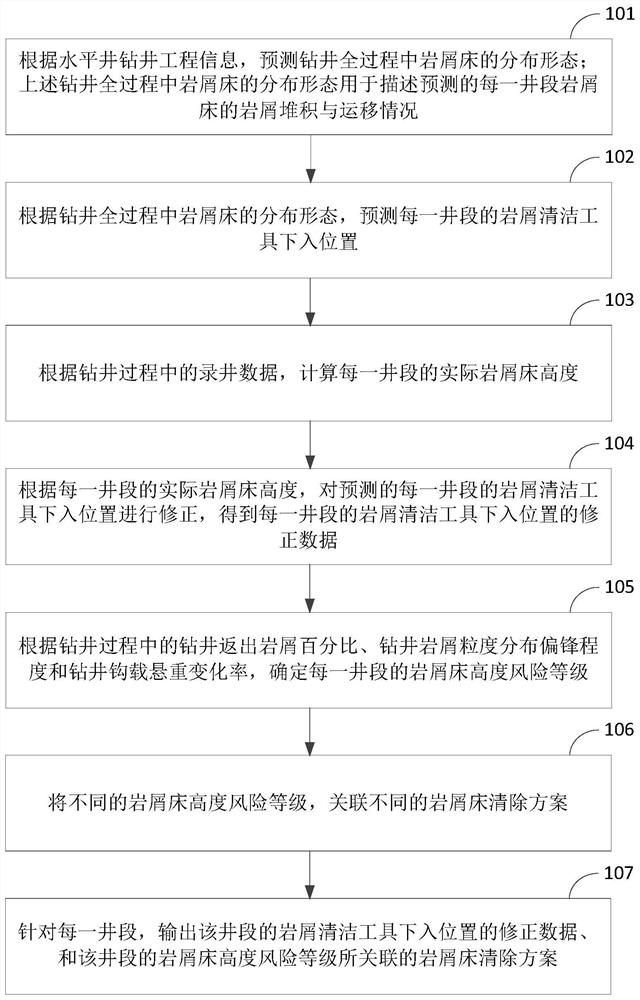

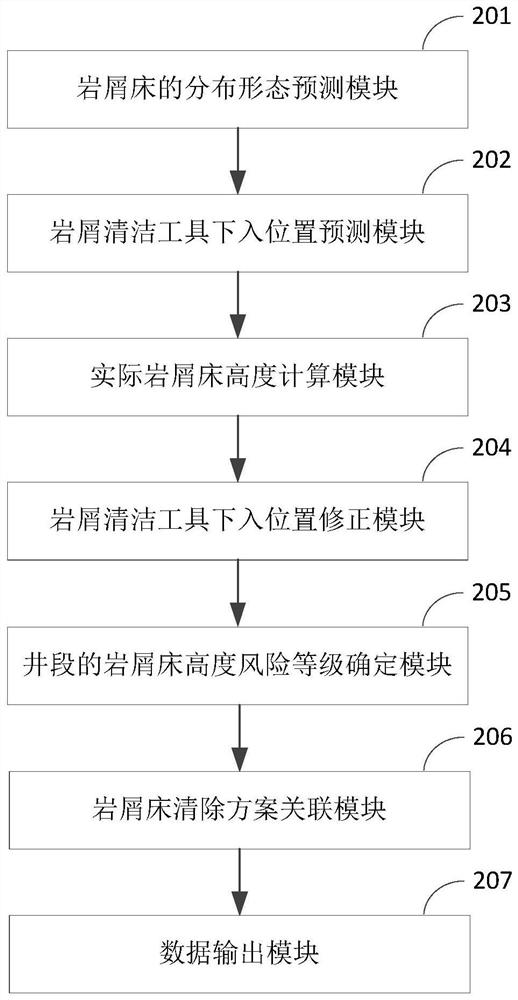

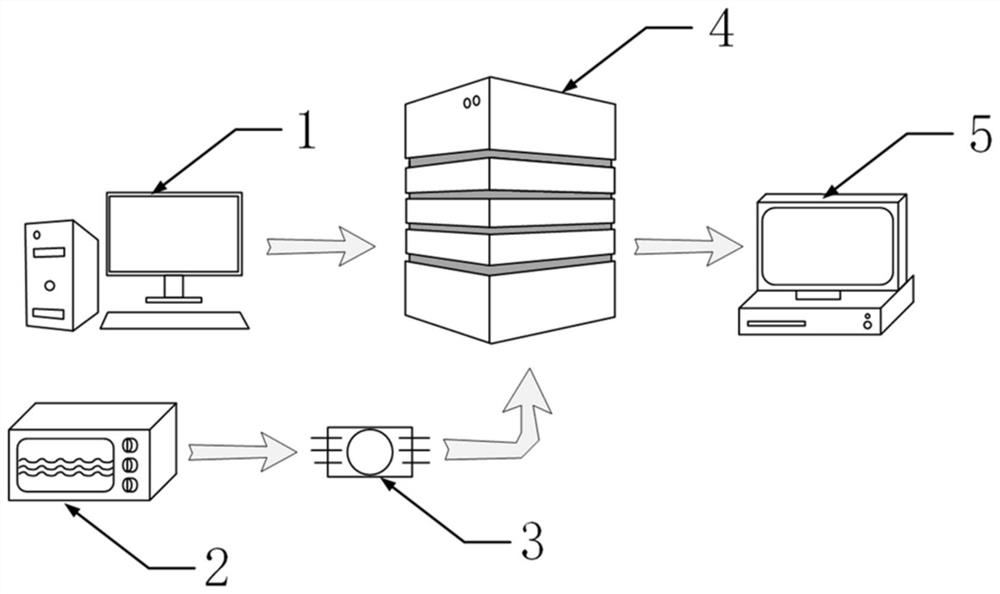

Horizontal well cuttings bed treatment method and device

PendingCN114382427ASolve the accumulationImprove accuracySurveyConstructionsRisk levelMining engineering

The invention discloses a horizontal well cuttings bed processing method and device.The method comprises the steps that according to horizontal well drilling engineering information, the distribution pattern of a cuttings bed in the whole drilling process is predicted, and the tripping-in position of a cuttings cleaning tool of each well section is predicted; calculating the actual cuttings bed height of each well section; the predicted tripping-in position of the rock debris cleaning tool of each well section is corrected; according to the drilling return rock debris percentage, the drilling rock debris particle size distribution offset degree and the drilling hook load hanging load change rate in the drilling process, the rock debris bed height risk grade of each well section is determined; associating different cuttings bed height risk grades with different cuttings bed clearing schemes; and for each well section, outputting the correction data of the tripping-in position of the cuttings cleaning tool of the well section and the cuttings bed clearing scheme associated with the cuttings bed height risk level of the well section. The accuracy and efficiency of horizontal well cuttings bed treatment can be improved, and the problem of accumulation of the horizontal well cuttings bed is effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A concentric tube cuttings suction and crushing device suitable for dual-gradient drilling

ActiveCN108915619BRealize the reverse jetReduce formation rateFlushingGrain treatmentsWell drillingHorizontal wells

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com