Optimum design method for reactor core fusion collector

An optimized design and collector technology, applied in the direction of instruments, calculations, special data processing applications, etc., can solve the number, the location is difficult to determine, there is no evaluation basis, it is difficult to obtain core melting collectors, etc., to reduce calculations Effects on resources and computation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

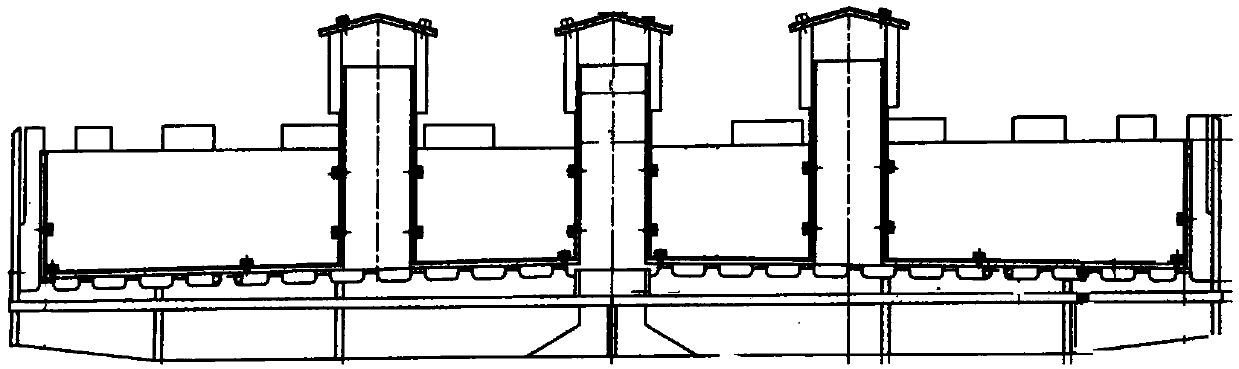

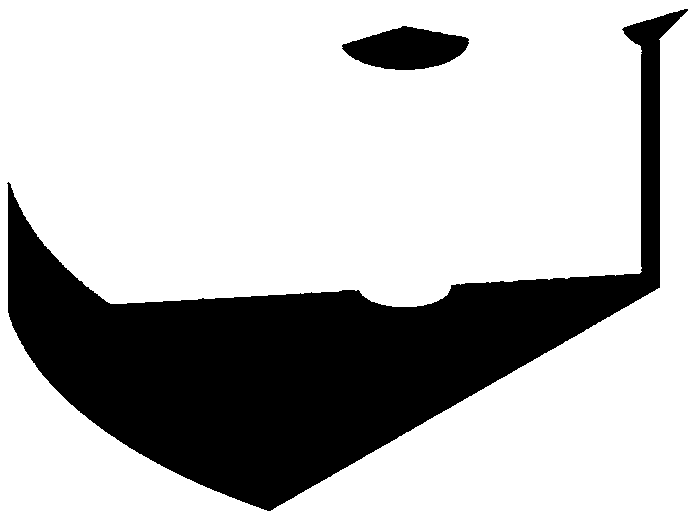

[0063] see Figure 4 , an optimal design method for a core melting collector of the present invention, the simplified core melting collector is modeled, and part of the tray is taken according to the symmetrical boundary for modeling; the melt is simplified into a cylinder, and the large grid plate Dropped to the top cover and tray of the core melting collector; the three-dimensional DEM method is used for calculation, and at least 10 sample points are evenly taken in the radial direction of the calculation result, and the dimensionless non-uniformity σ is defined to quantify the Effect of core melt collector configuration and size on thickness distribution of debris bed formation. Specific steps are as follows:

[0064] S1. According to the structure and size of the existing core melting collector, a 1:1 calculation model is established by simplifying the collector structure;

[0065] see figure 1 and figure 2 , for the convenience of modeling and simplification, the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com