Multifunctional sodium-cooled fast reactor debris bed simulation device and light refraction compensation measurement method

A sodium-cooled fast reactor and simulation device technology, applied in reactors, nuclear power generation, nuclear reactor monitoring, etc., can solve the problem of inability to track the formation and leveling process of molten matter, interfere with experimental results, and fail to simulate the formation and leveling of debris beds. Research and measurement of overall characteristics Angle deviation and other problems, to achieve the effect of convenient heat conduction and uniform gas injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

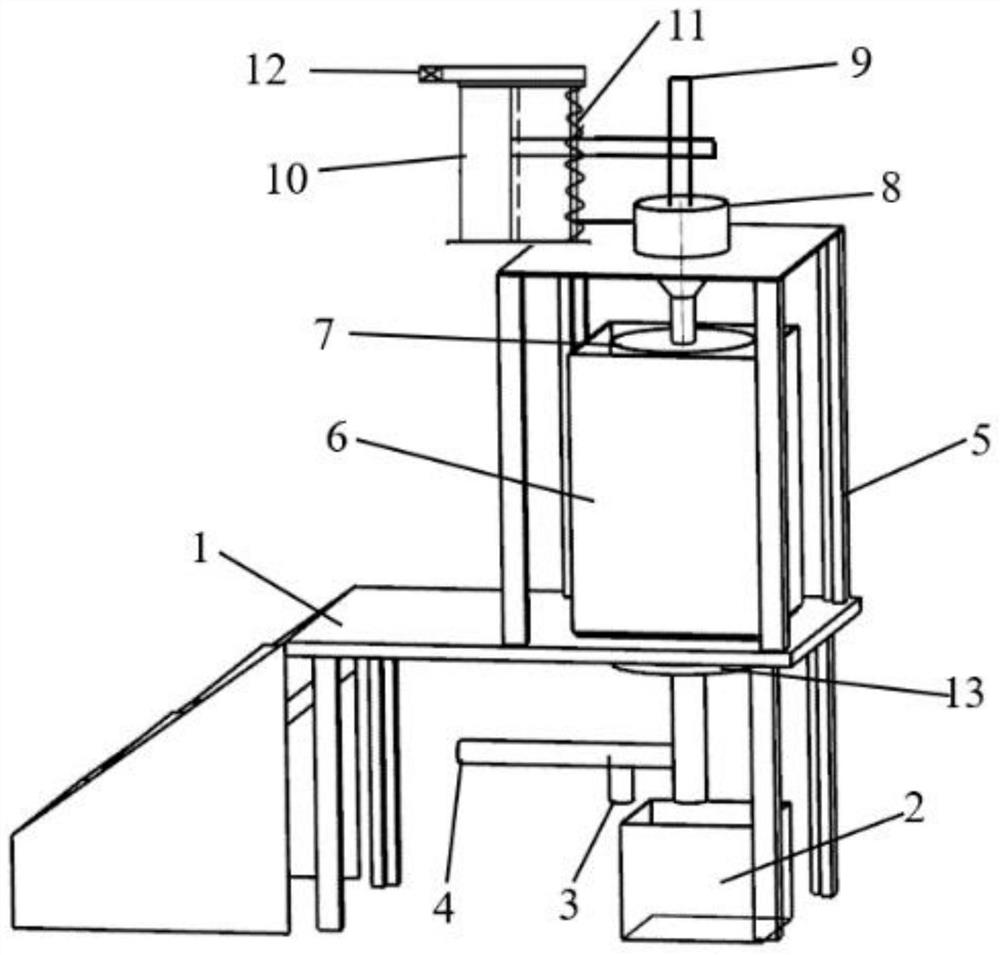

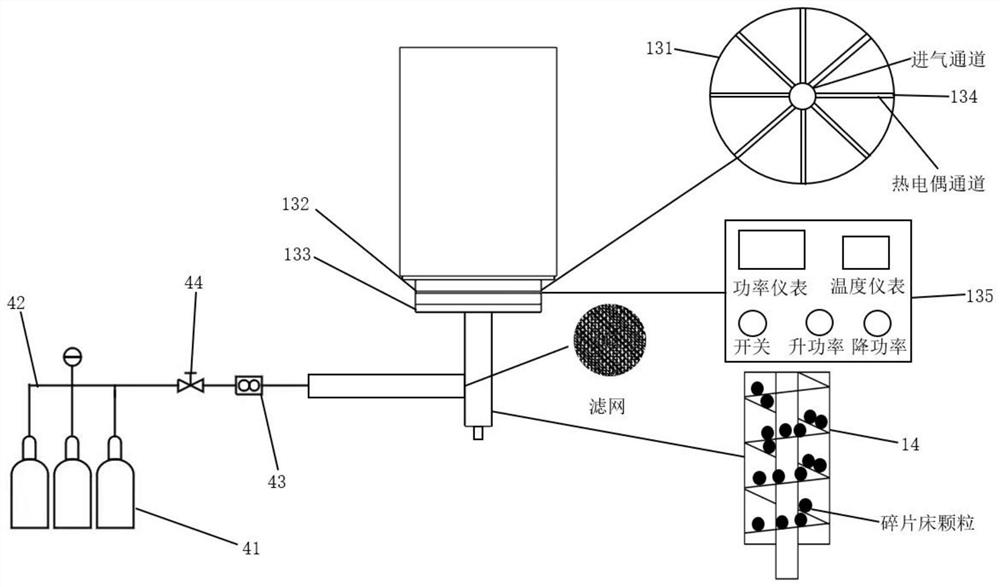

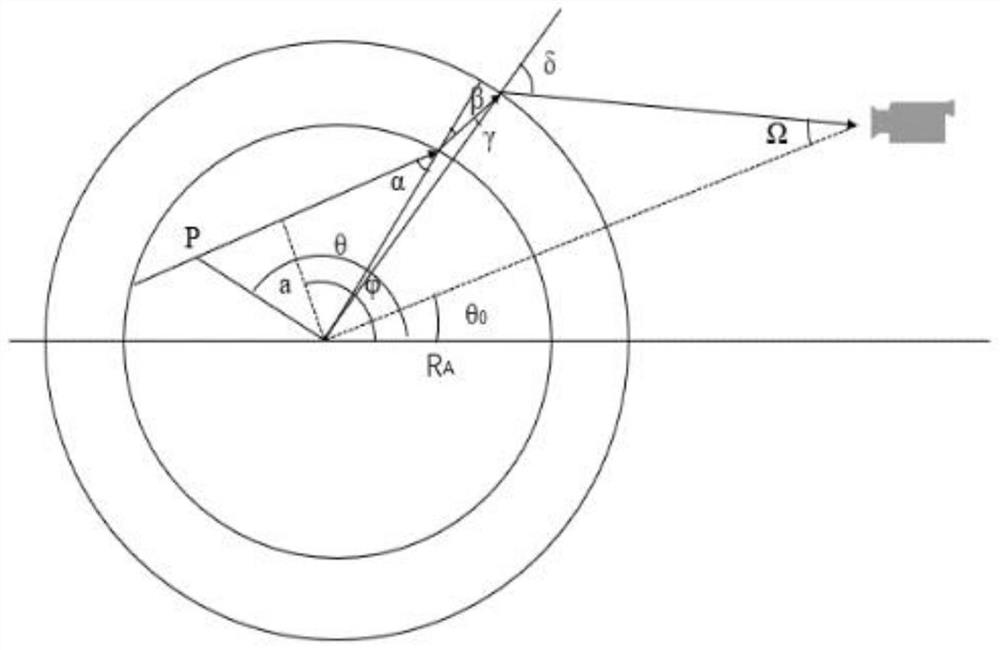

[0018] Such as figure 1 As shown, this embodiment relates to a multifunctional sodium-cooled fast reactor debris bed simulation device with a correction function, including: an experimental device support platform 1 and a retractable support platform 5 arranged thereon, a data acquisition system, Fragment bed particle release system, dry particle collection system 2, visualized fragment bed particle container 7, light refraction compensation container 6, debris bed heating system 13 and gas injection system 4, wherein: light refraction compensation container 6 is located in the visualized debris bed particle container 7 It is externally and integrally arranged in the retractable support platform 5, the debris bed particle release system is located above the retractable support platform 5 and is facing the visualized debris bed particle container 7, and the debris bed heating system 13 and the dry particle collection system 2 are sequentially arranged on the The support platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com