Underground-coal-mine nearly horizontal ultra-deep hole directional drilling drill string power push system and method

A power propulsion system and directional drilling technology, applied in directional drilling, drill pipe, drill pipe, etc., can solve the problems of increased construction risk, inability to effectively transmit the propulsion force of the hole drilling rig to the drill bit, and increased friction, etc., to achieve Improve efficiency and drilling depth, improve propulsion efficiency, and reduce feed force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

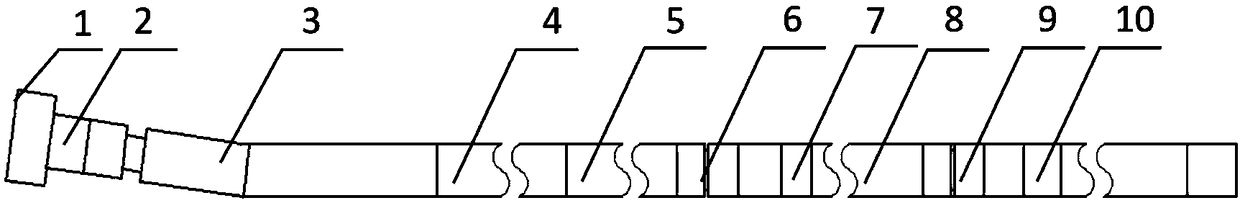

[0036] see figure 1 with 2 , shows the coal mine underground near-horizontal ultra-deep hole directional drilling drill string power propulsion system and method of the present invention.

[0037] The drill string power propulsion system for directional drilling of near-horizontal ultra-deep holes in underground coal mines includes a drill bit 1, a hydraulic auxiliary pressurizer 2, a screw motor 3, a directional drilling tool assembly 4, a first drill string group 5, a first Propeller 6, cuttings bed cleaner 7, second propeller 8, second drill string group 9 and water stool 10, the hydraulic auxiliary pressurizer 2 is installed between the drill bit 1 and the screw motor 3, so that the drill bit 1 Provides weight on bit and transmits torque.

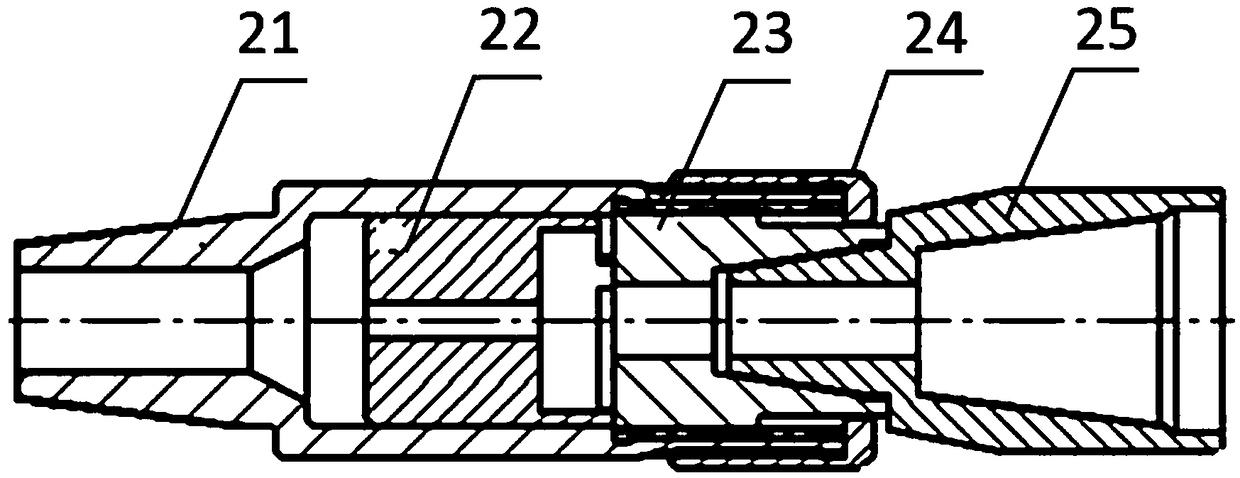

[0038] Preferably, refer to figure 2, the hydraulic auxiliary pressurizer 2 may include a housing 21, a first piston 22, a spline drive shaft 23, an end cover 24 and a first lower joint 25, and the left side of the housing 21 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com