Fixing guide vane wheel type whirl flow jet flow grinding drill bit for horizontal well

A technology for guiding impellers and horizontal wells, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc. It can solve the problems of timely cleaning of cuttings at the bottom of the well, reduction of drilling fluid flow at the bottom of the well, and reduction of the number of water holes in the drill bit. Improve the efficiency of rock cleaning, reduce the final velocity of settlement, and increase the effect of flushing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

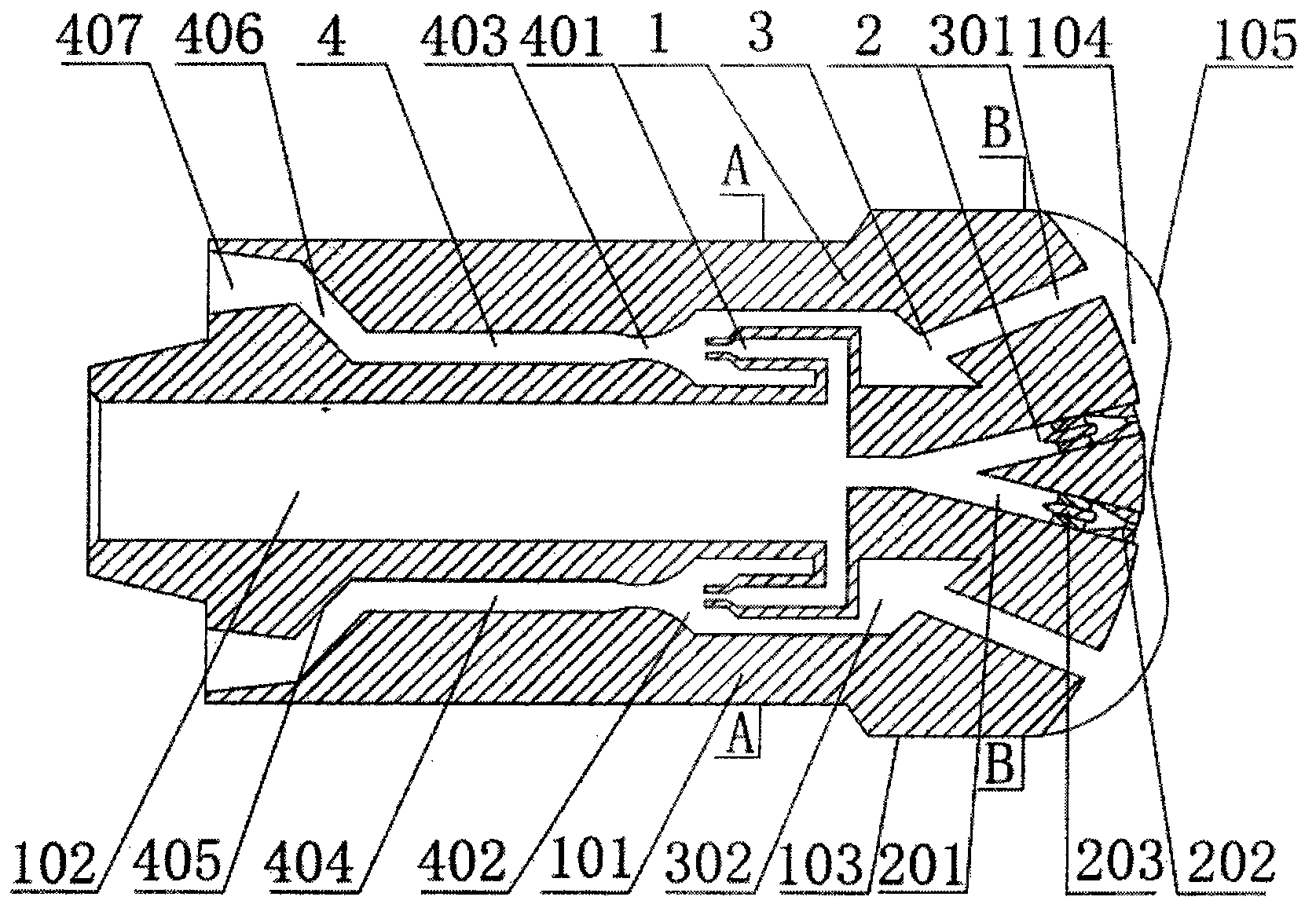

[0024] Below in conjunction with accompanying drawing, illustrate the specific embodiment that the present invention proposes, structure, feature and effect thereof, detailed description is as follows:

[0025] The horizontal well fixed guide impeller type swirl jet mill drill bit includes PDC drill bit 1, fixed guide impeller type rotary jet sand washing device 2, high concentration turbulent sand pumping device 3, and jet crushing device 4.

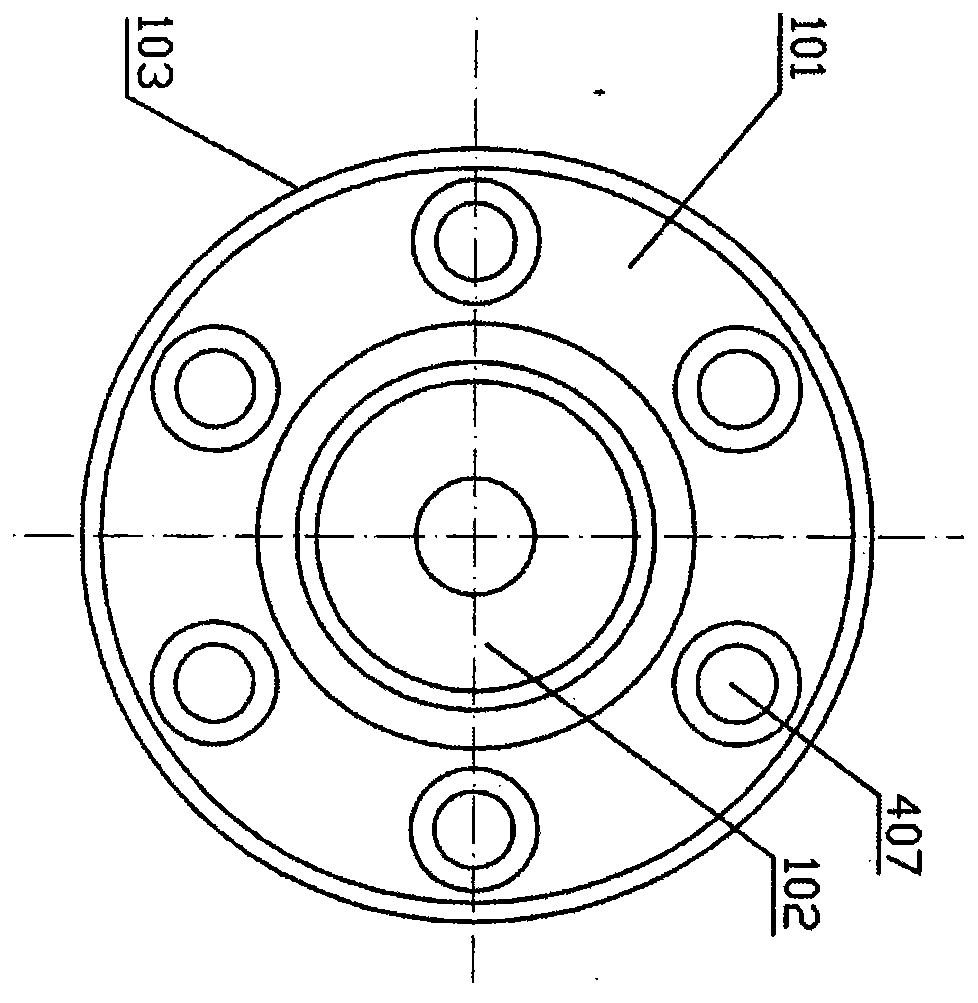

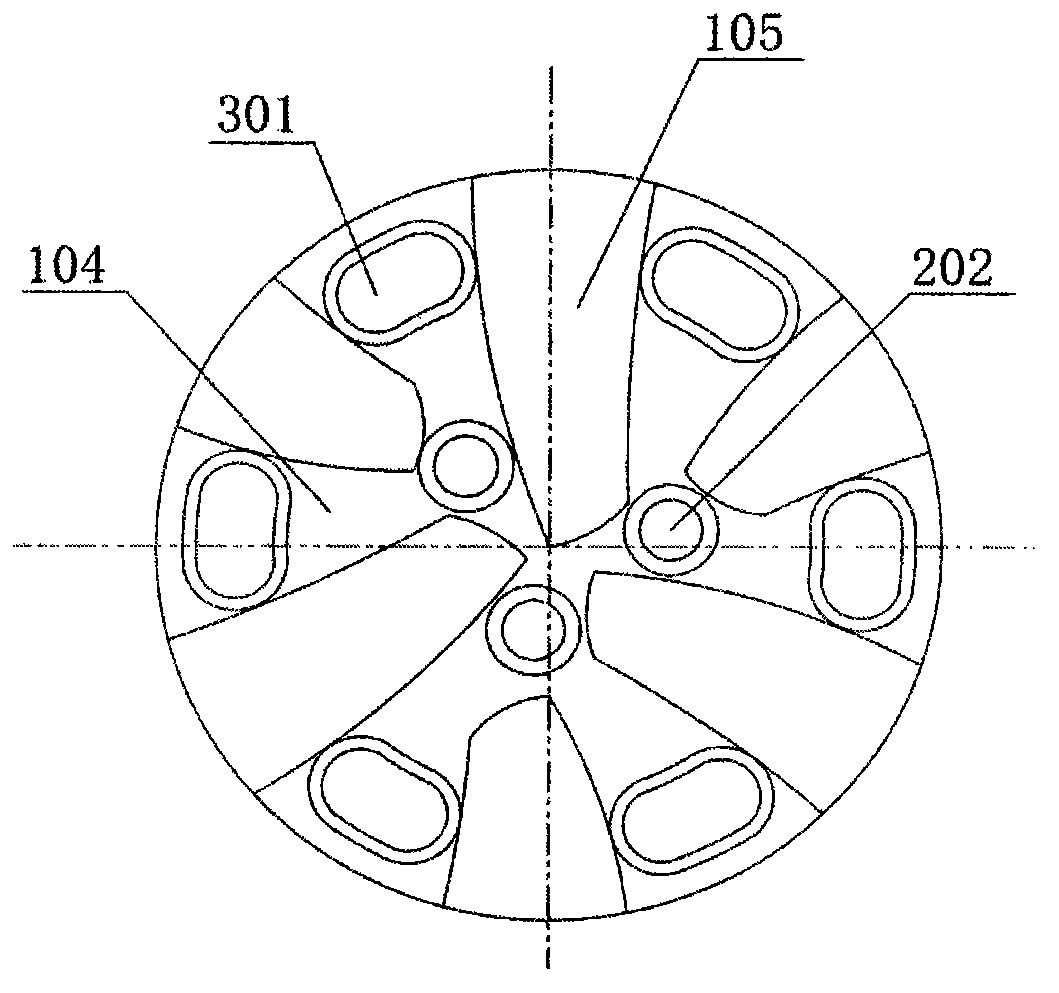

[0026] The PDC drill bit includes a drill bit body 101, a main flow channel 102, a gauge 103, a chip removal groove 104 at the end of the drill bit, and a PDC blade 105; the PDC blade 105 is the working part of the horizontal well fixed guide impeller type swirl jet mill bit for cutting rocks, The surface is covered with PDC cutting teeth; the chip flute 104 at the end of the drill bit is arranged between the PDC blades 105;

[0027] The fixed guide impeller type rotary jet sand washing device 2 includes a bottom hole cuttings stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com