Simulation experiment method for determining average thickness of rock debris bed based on pressure difference

A technology of average thickness and simulation experiment, applied in the field of oil drilling, can solve problems such as failure, high measurement cost, inaccurate measurement, etc., and achieve the effect of simple determination method, good discrimination effect and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

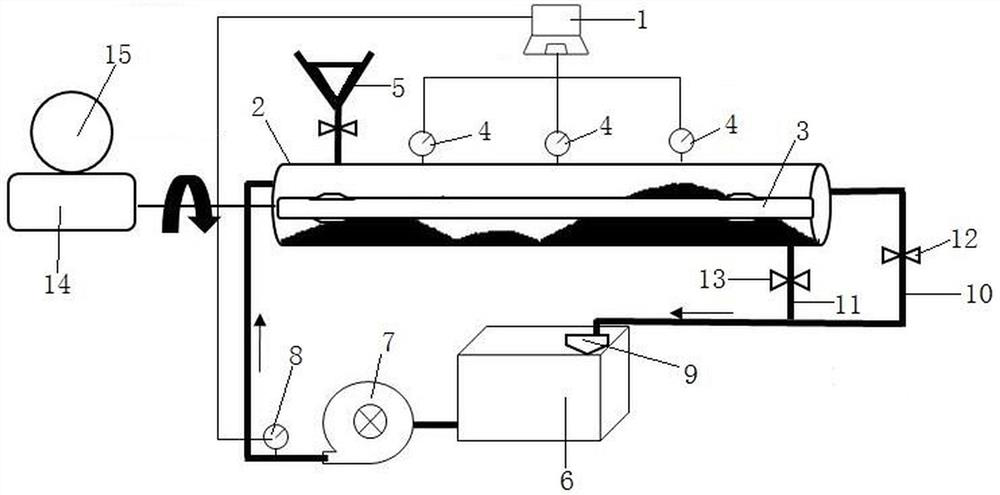

[0043] The invention discloses a simulation experiment method for judging the average thickness of a cuttings bed based on a pressure difference, which comprises the following steps:

[0044] Step 1: setting a simulated wellbore 2 including a feed end and a discharge end, setting a simulated drill string 3 in the simulated wellbore 2, and setting at least two pressure gauges 4 on the simulated wellbore 2. Wherein, the length of the simulated wellbore 2 is preferably 10-20 meters, and the number of pressure gauges 4 is preferably 3-7, which are arranged between the feed end and the discharge end as required, so as to simultaneously measure the pressure of multiple places in the simulated wellbore 2. The average thickness of the cuttings bed is measured.

[0045] Step 2: Inject drilling fluid into the simulated wellbore 2, control the rotation of the simulated drill string 3, and then inject cuttings into the simulated wellbore 2. The cuttings can be injected quantitatively or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com