Patents

Literature

119 results about "Lithic fragment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithic fragments, or lithics, are pieces of other rocks that have been eroded down to sand size and now are sand grains in a sedimentary rock. They were first described and named (in their modern definitions) by Bill Dickinson in 1970. Lithic fragments can be derived from sedimentary, igneous or metamorphic rocks. A lithic fragment is defined using the Gazzi-Dickinson point-counting method and being in the sand-size fraction. Sand grains in sedimentary rocks that are fragments of larger rocks that are not identified using the Gazzi-Dickinson method are usually called rock fragments instead of lithic fragments. Sandstones rich in lithic fragments are called lithic sandstones.

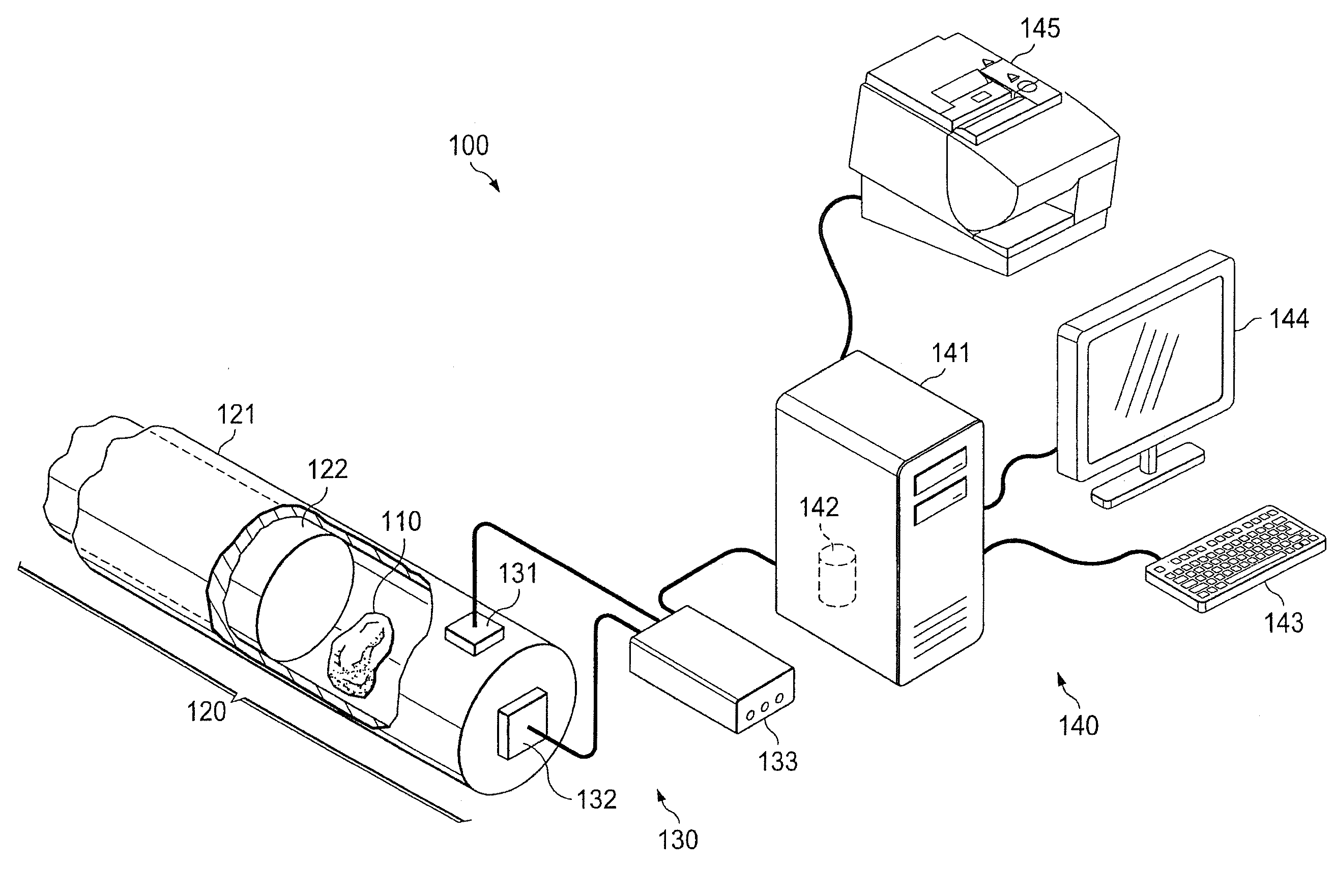

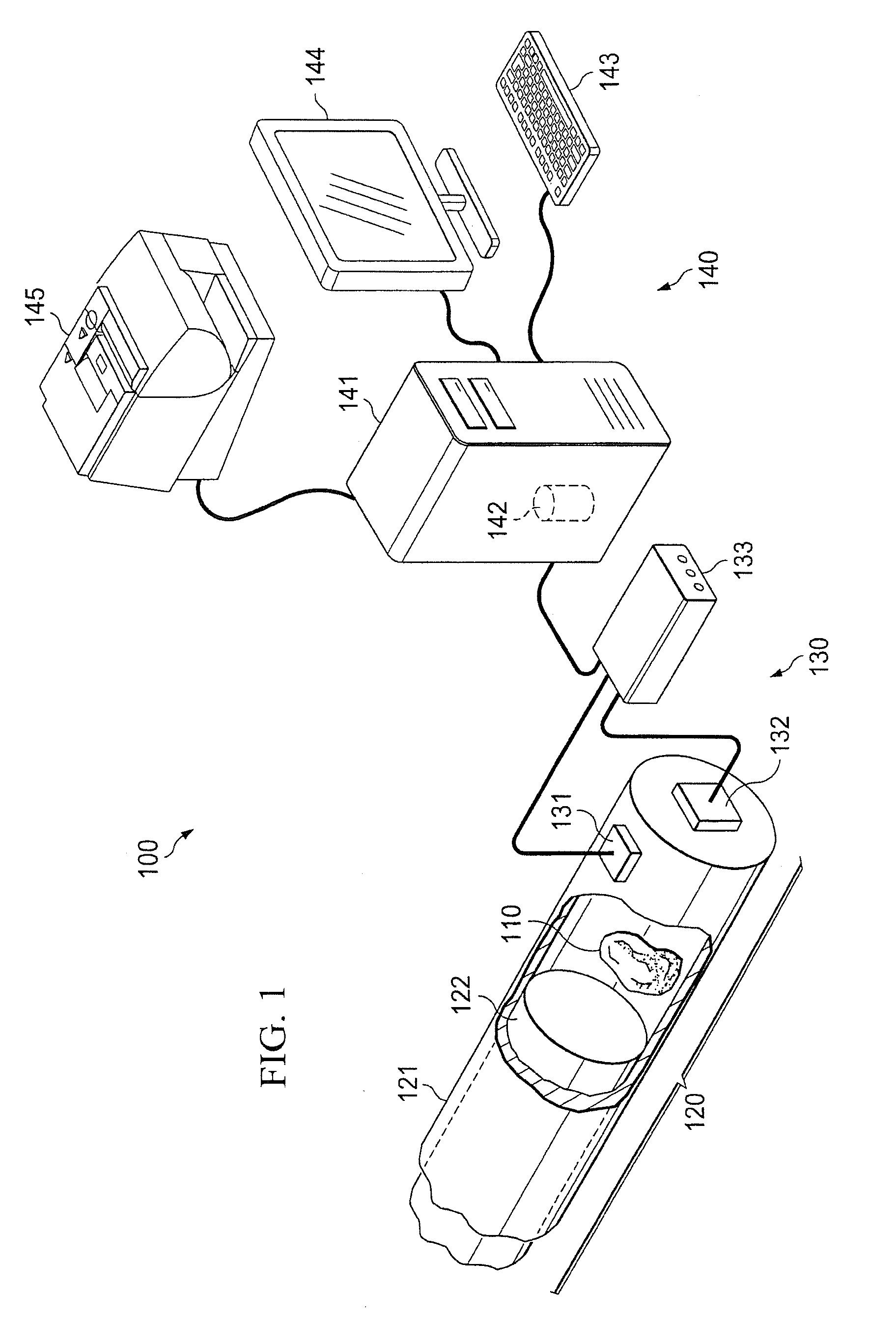

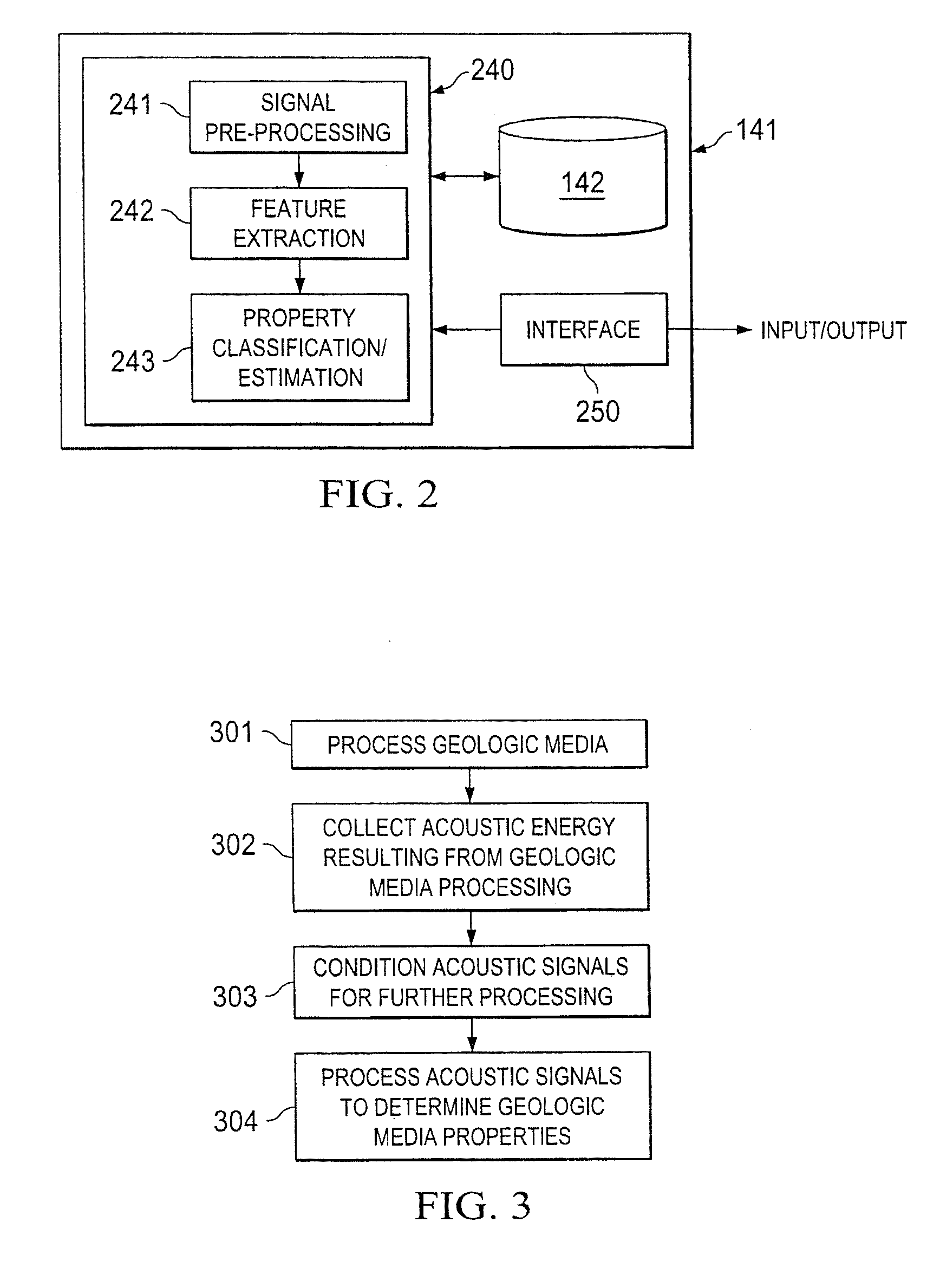

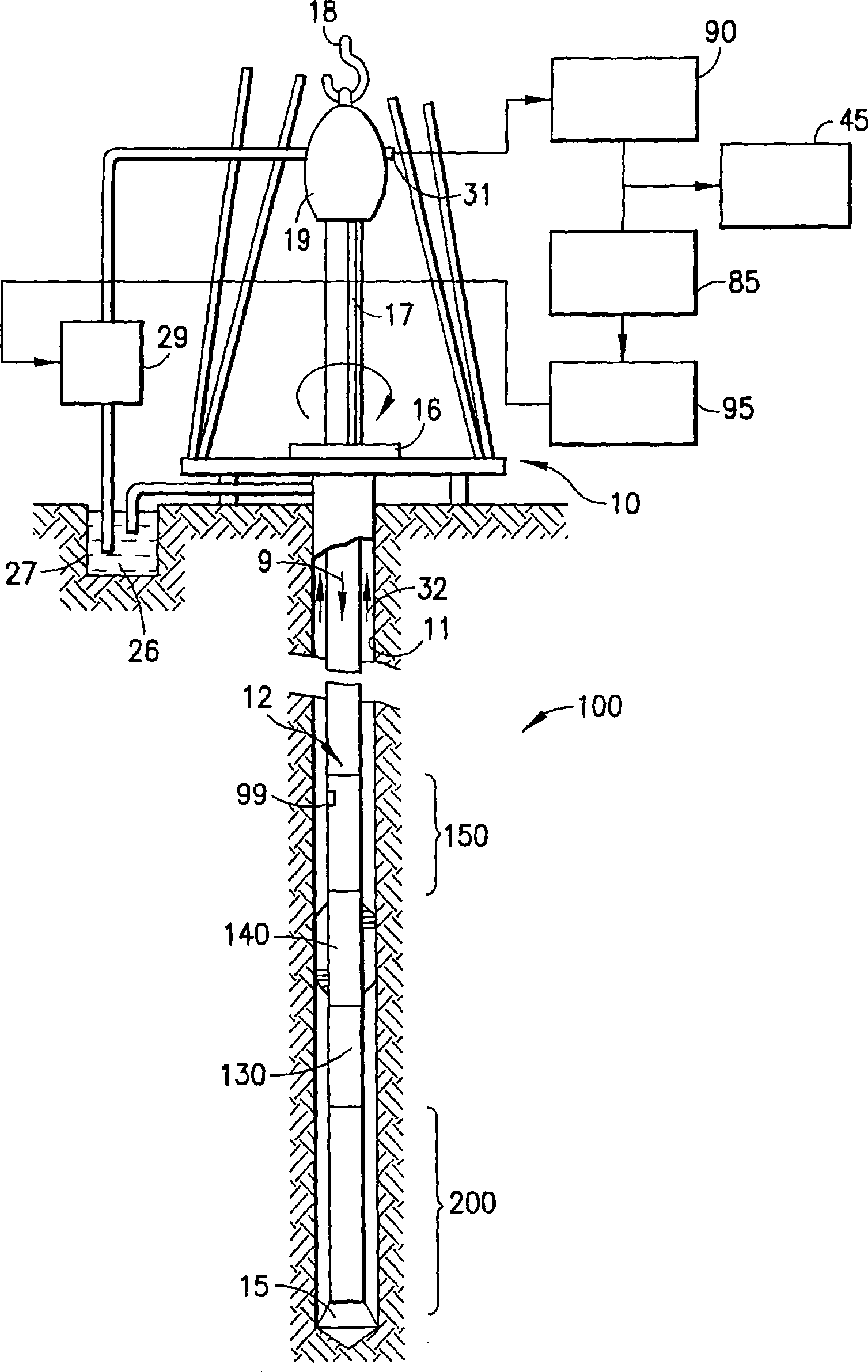

Systems and Methods For Determining Geologic Properties Using Acoustic Analysis

ActiveUS20110066390A1Increase the number ofFast analysisMaterial analysis using acoustic emission techniquesFlow propertiesTime informationLithology

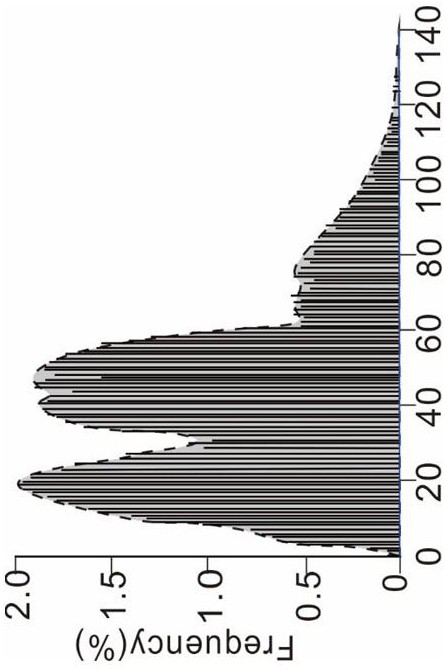

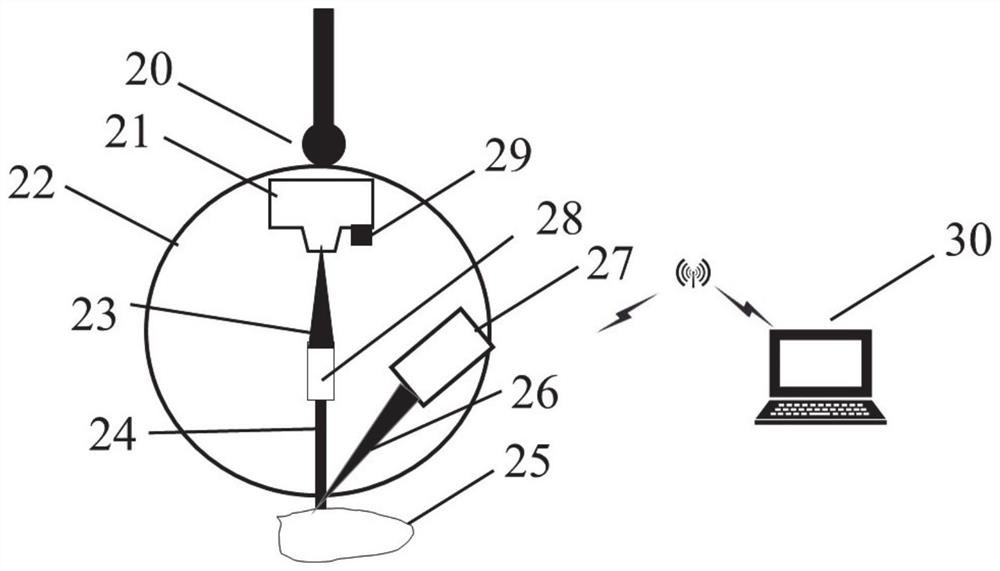

Systems and methods which determine geologic properties using acoustic analysis are shown. Acoustic signals are collected during processing (e.g., crushing, shearing, striking, compressing, etc.) of geologic media, such as rock samples, for determining geologic properties according to embodiments. The acoustic signals collected may include frequency information, amplitude information, time information, etc. which may be utilized in determining geologic properties, such as geologic media properties (e.g., mineralogy, porosity, permeability, sealing capacity, fracability, compressive strength, compressibility, Poisson's Ratio, Youngs Modulus, Bulk Modulus, Shear Modulus), geologic structure properties (e.g., lithology, seal quality, reservoir quality), geologic acoustic properties (e.g., acoustic logging effectiveness, acoustic response, natural or harmonic frequencies, etc.). Embodiments may be used to provide determination of geologic properties from a variety of geologic media samples, such as cuttings, core samples, etc.

Owner:EXXONMOBIL UPSTREAM RES CO

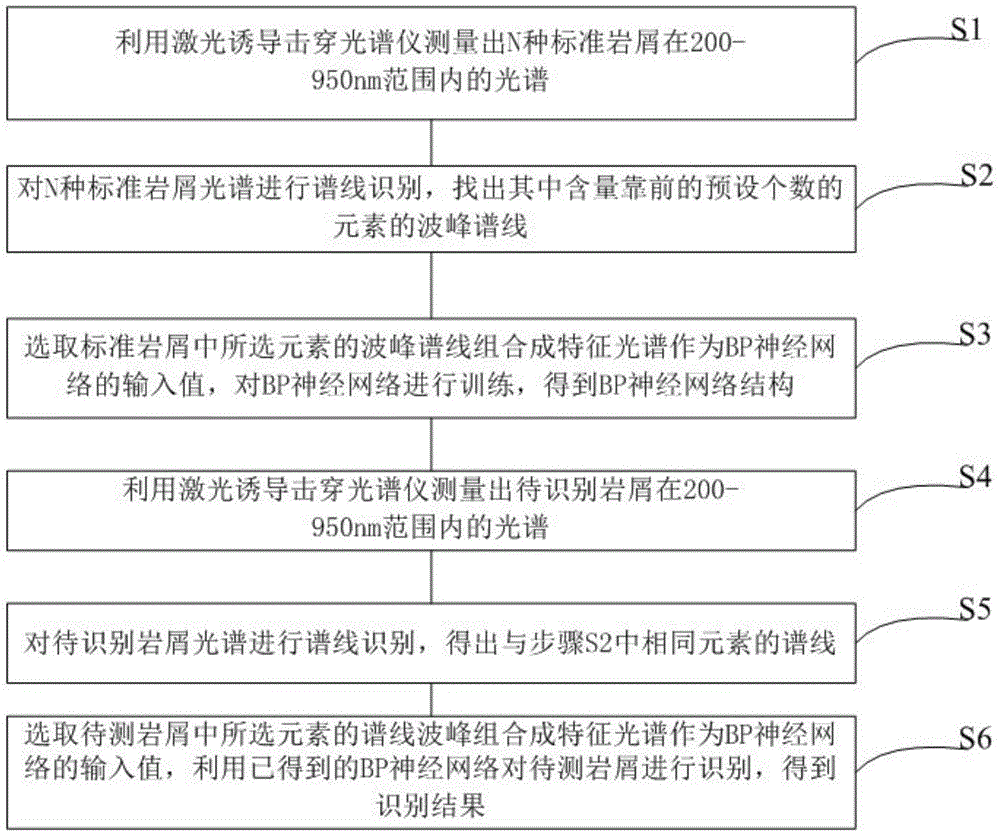

Multi-element wave peak-based laser-induced breakdown spectroscopy rock fragment type identification method

InactiveCN104964950AExtension of timeTaking into account the efficiency of data processing and the accuracy of recognition resultsAnalysis by material excitationPhysicsRock fragment

The invention provides a rock fragment type identification method. The method comprises the following steps: 1, measuring the spectra of N standard rock fragments in a range of 200-950nm by using a laser-induced breakdown spectrograph; 2, carrying out spectral line identification on the spectra of the N standard rock fragments, and finding out the wave peak spectral lines of a preset number of elements with the top contents; 3, combining the wave peak spectral lines of the selected elements in the standard rock fragments to form a characteristic spectrum as the input value of a BP nerve network, and training the BP nerve network to obtain a BP nerve network structure; 4, measuring the spectrum of a rock fragment to be identified in the range of 200-950nm by using the laser-induced breakdown spectrograph; 5, carrying out spectral line identification on the spectrum of the rock fragment to be identified to obtain spectral lines of elements same to the elements in step 2; and 6, combining the spectral line wave peaks of the selected elements in the rock fragment to be identified as the input value of the BP nerve network, and identifying the rock fragment to be identified by using the obtained BP nerve network to obtain an identification result.

Owner:YANGTZE UNIVERSITY

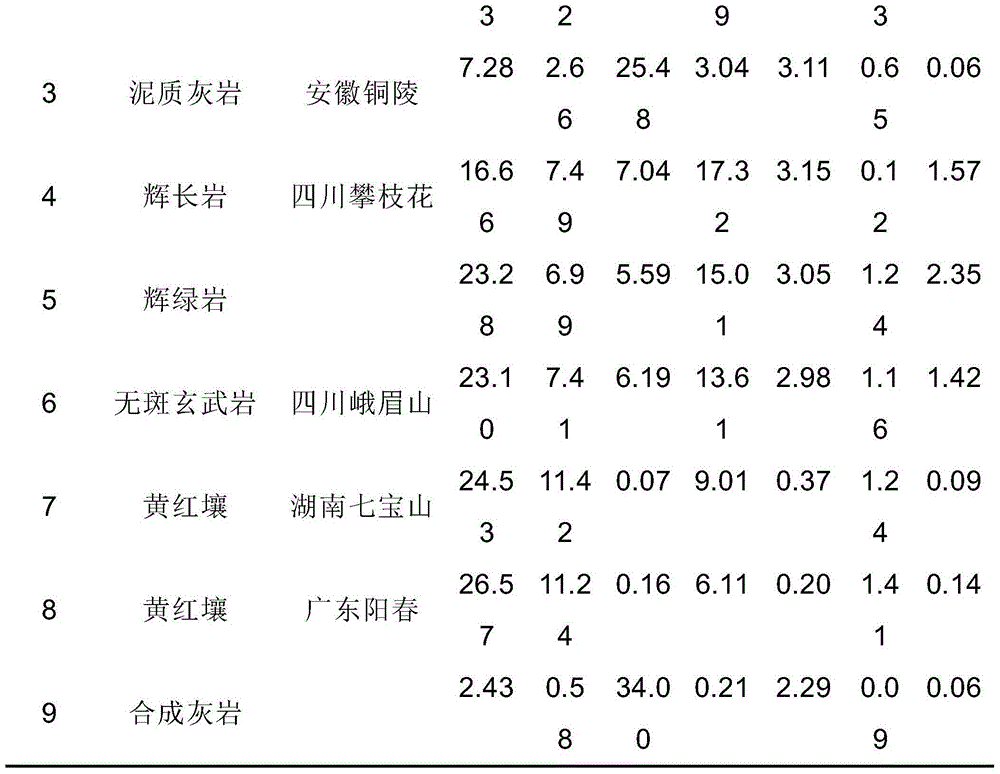

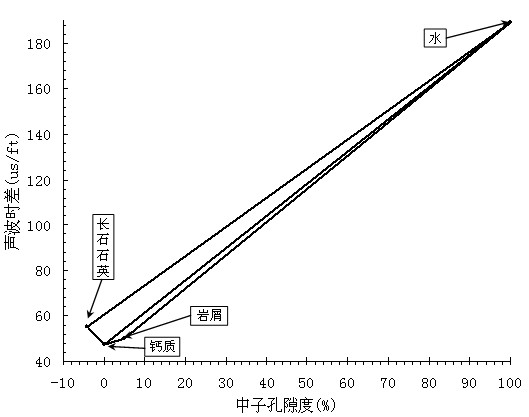

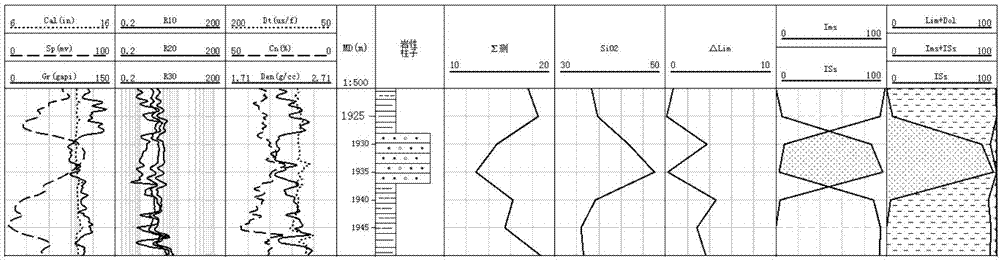

Complex lithology clastic rock stratum constituent logging processing method

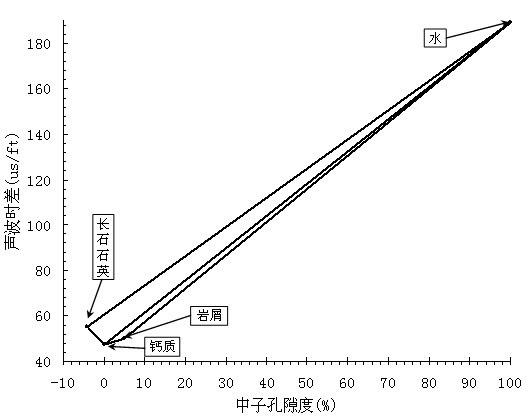

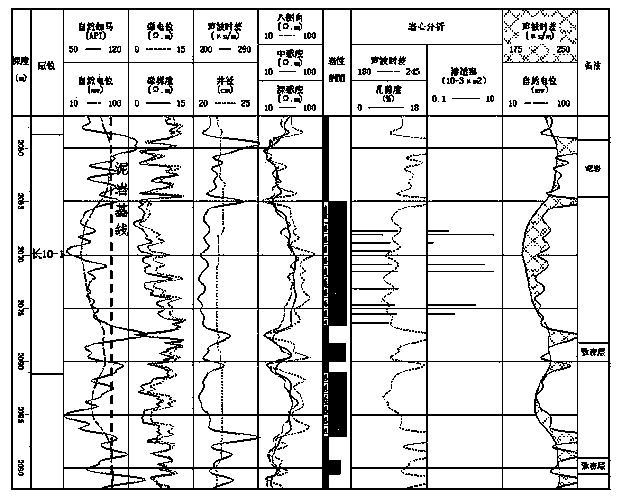

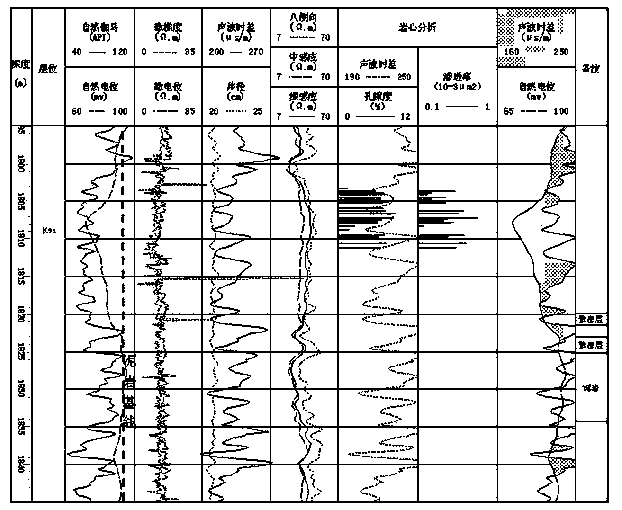

The invention discloses a complex lithology clastic rock stratum constituent logging processing method which comprises the following steps: determining whether a stratum contains coal according to logging curve characteristics and respectively processing stratigraphic classification according to the situation that whether the stratum contains coal; calculating the contents of feldspar quartz, coal and porosity when the stratum contains coal; and calculating the contents of the feldspar quartz, calcium, rock debris and the porosity by applying a mixed lithology calculation method when the stratum contains no coal. The complex lithology clastic rock stratum constituent logging processing method solves the problems of coal-bearing stratum identification and coal-bearing stratum constituent calculation and also solves the problem of calculating three rock constituents in the coal-free stratum and the porosity by applying two porosity logging curves.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Method for quickly identifying clastic rock reservoir based on two well log overlapped picture

InactiveCN103711482AConsider featuresPorosity SensitiveBorehole/well accessoriesRock coreWell logging

A method for quickly identifying a clastic rock reservoir based on a two well log overlapped picture includes the following steps that (1) according to a clastic rock stratum, an interval transit time parameter and a spontaneous potential parameter of the clastic rock stratum are obtained in a drilling hole through a logging instrument; (2) a relatively thick mud rock development section and a possible compact layer section are determined by referring to rock core or cutting logging data obtained through a special sampler in the drilling hole, and a mud rock base line is determined by combination with a spontaneous potential logging curve; (3) the spontaneous potential logging curve and an interval transit time curve are overlapped in the reverse direction according to a logging curve overlapping principle, and it is required that the two logging curves are basically overlapped on the mud rock base line portion and the compact layer section; (4) in the overlapped picture of the spontaneous potential logging curve and the interval transit time curve, an amplitude difference between the two curves on the separation portion of the two curves is determined according to the overlapping and separation relation between the two curves, and whether the storage physical property of the reservoir is good or not is judged according to the amplitude difference of the two curves. The method has the advantages of being easy and convenient to use, high in identification accuracy and high in speed.

Owner:SHANDONG UNIV OF SCI & TECH +1

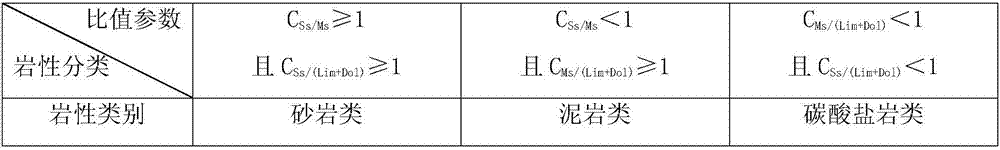

Method for identifying lithologic characteristics of sand mudstone through rock mineral composition inversion method based on XRF well logging

InactiveCN107489417AEliminate the influence of human subjective judgment factorsRapid identification, interpretation and evaluation of lithologyBorehole/well accessoriesLithologyWell logging

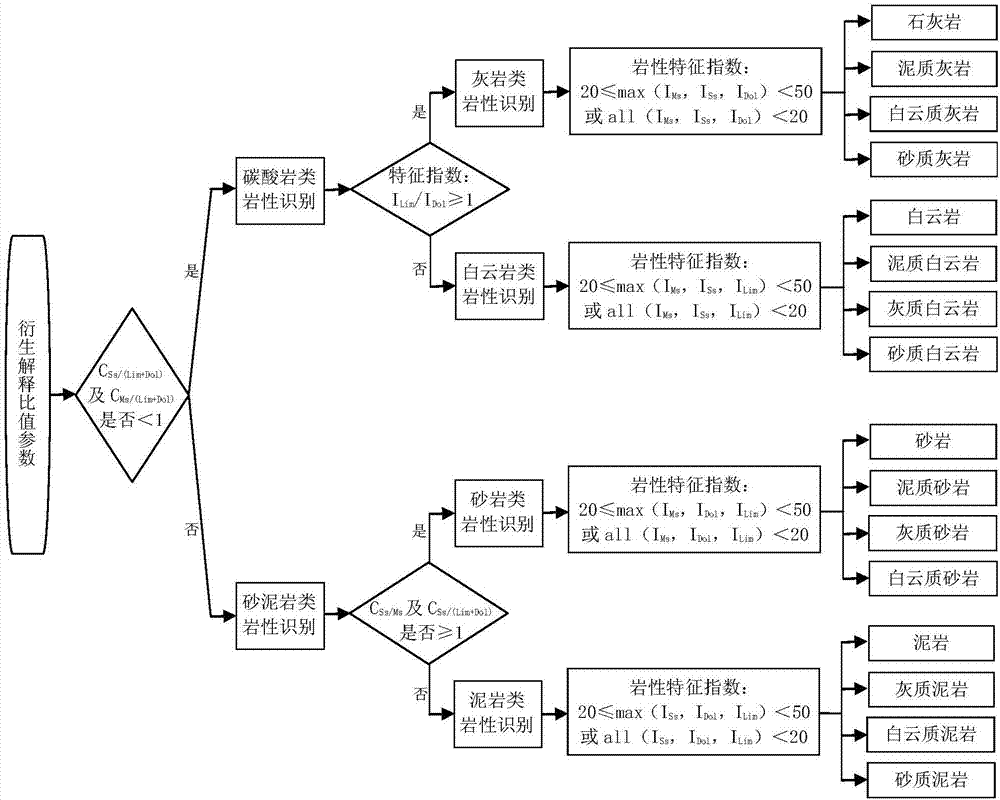

The invention discloses a method for identifying lithologic characteristics of sand mudstone through a rock mineral composition inversion method based on XRF well logging. The method comprises the main steps that firstly, the theoretical basis and the interpretation principle of inversion of rock mineral compositions of the sand mudstone are built; and then, lithologic characteristic quantity parameters, lithologic characteristic quantity indexes and derivative interpretation ratio parameters are calculated, an evaluation standard and a parameter combination for identifying the lithologic characteristics of the sand mudstone are built, and an interpretation evaluation model and procedures for identifying the lithologic characteristics of the sand mudstone are built. The influence of man-made subjective judgment factors is eliminated greatly, and rapid and quantitative lithologic characteristic identifying and evaluation are achieved; and by using the method for identifying the lithologic characteristics of the sand mudstone through the rock mineral composition inversion method based on XRF well logging, the problems that under the rapid well drilling condition, the well drilling parameter characteristic is unapparent, rock debris is fine and mixed, and lithologic characteristic identification is difficult and has the large errors can be well solved, and a reliable reference basis is provided for discovery displaying and rapid interpretation of oil gas, decision-making management for subsequent exploratory development and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

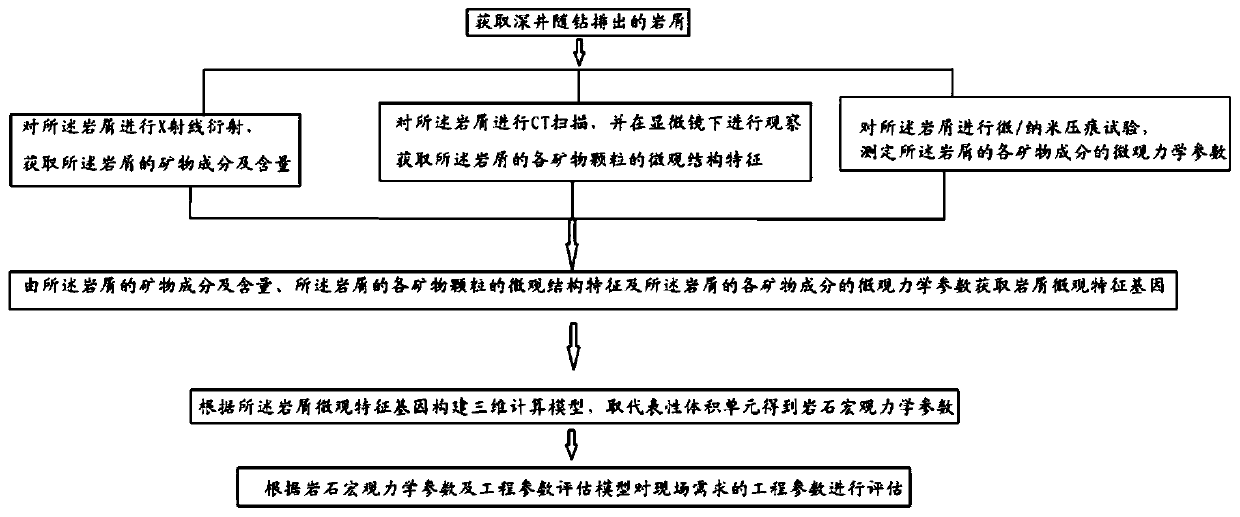

Rock mechanics and reservoir engineering parameter evaluation method

InactiveCN111257536AImprove accuracyImprove estimation accuracyEarth material testingMicro structureWell drilling

The invention discloses a rock mechanics and reservoir engineering parameter evaluation method, and belongs to the technical field of rock mechanics. The rock mechanics and reservoir engineering parameter evaluation method comprises the following steps: performing X-ray diffraction on rock debris to obtain mineral components and contents of the rock debris; performing CT scanning on the rock debris, performing observation under a microscope, and obtaining the microstructure characteristics of all mineral particles of the rock debris; carrying out a micro / nano indentation test on the rock debris, and determining the micromechanical parameters of each mineral component of the rock debris; constructing a three-dimensional calculation model according to the rock debris microcosmic characteristic gene, and taking a representative volume unit to obtain rock macromechanics parameters; and evaluating the engineering parameters of the field requirements according to the rock macromechanics parameters and the engineering parameter evaluation model. The rock mechanics and reservoir engineering parameter evaluation method can effectively and accurately obtain engineering parameters required onsite and is of great significance to design and optimization of on-site drilling and fracturing engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Carbonatite lithology identification method

ActiveCN106703794ASimple and fast operationLithology identification results are accurateAnalysis by material excitationBorehole/well accessoriesDolostoneLithology

The invention discloses a carbonatite lithology identification method, and belongs to the technical field of petroleum and gas exploration and development. The carbonatite lithology identification method includes the steps that the Ca element content and Mg element content in a rock debris sample are detected, and the ratio of Ca element content to the Mg element content is calculated according to the formula R=Ca / Mg; when R is larger than 59.4, carbonatite is pure limestone; when R is larger than 10.8 and smaller than or equal to 59.4, the carbonatite is limestone containing dolomite; when R is larger than 4.7 and smaller than or equal to 10.8, the carbonatite is dolomite limestone; when R is larger than 2.6 and smaller than or equal to 4.7, the carbonatite is calcite dolomite; when R is larger than 1.8 and smaller than or equal to 2.6, the carbonatite is dolomite containing calcite; when R is larger than or equal to 1.8, the carbonatite is pure dolomite. The carbonatite lithology identification method is easy to operate, accurate in lithology identification result, capable of correctly guiding deploy of a petroleum and gas horizontal well of a carbonatite reservoir and increasing economic benefits of petroleum and gas exploitation of the carbonatite reservoir.

Owner:CHINA PETROCHEMICAL CORP +4

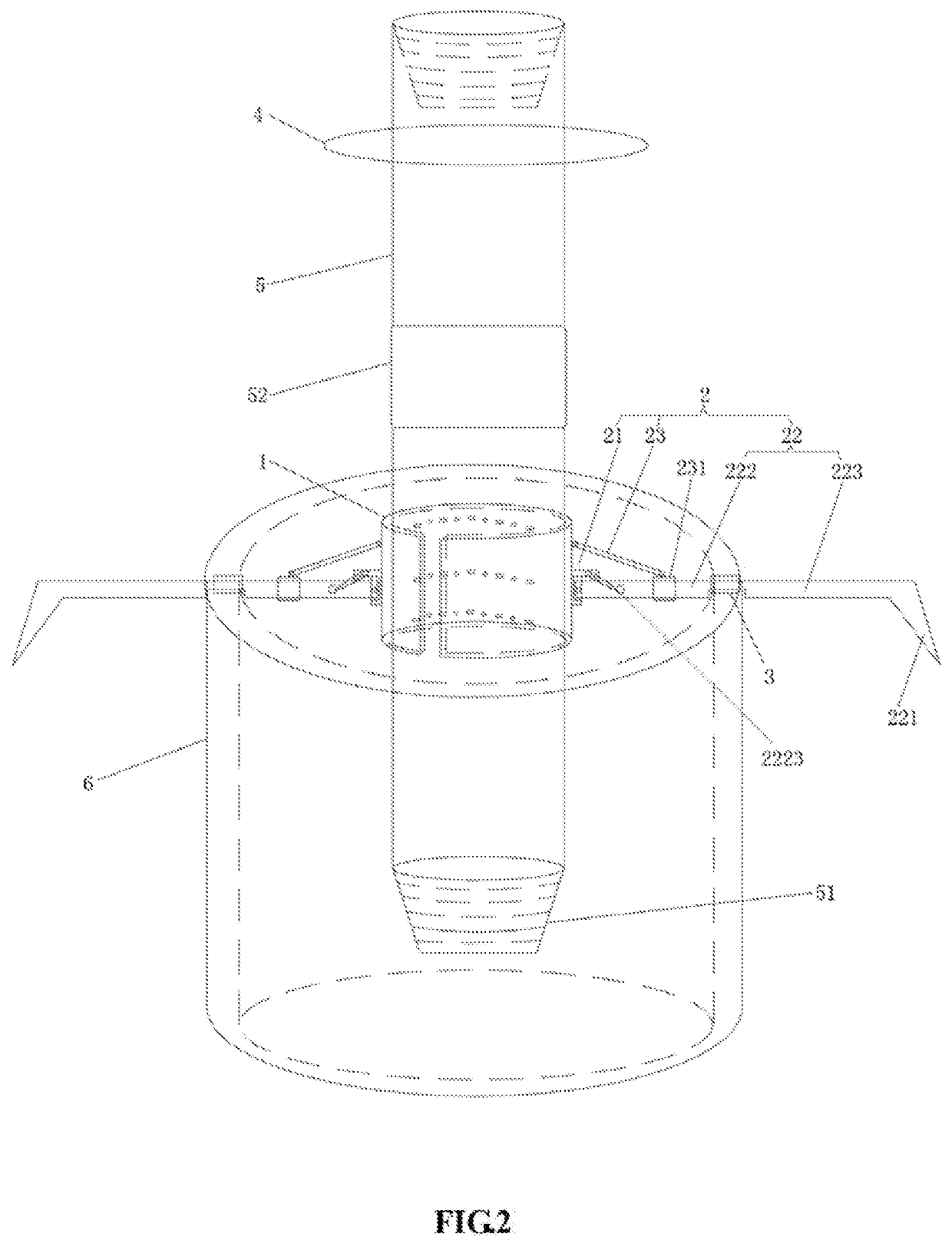

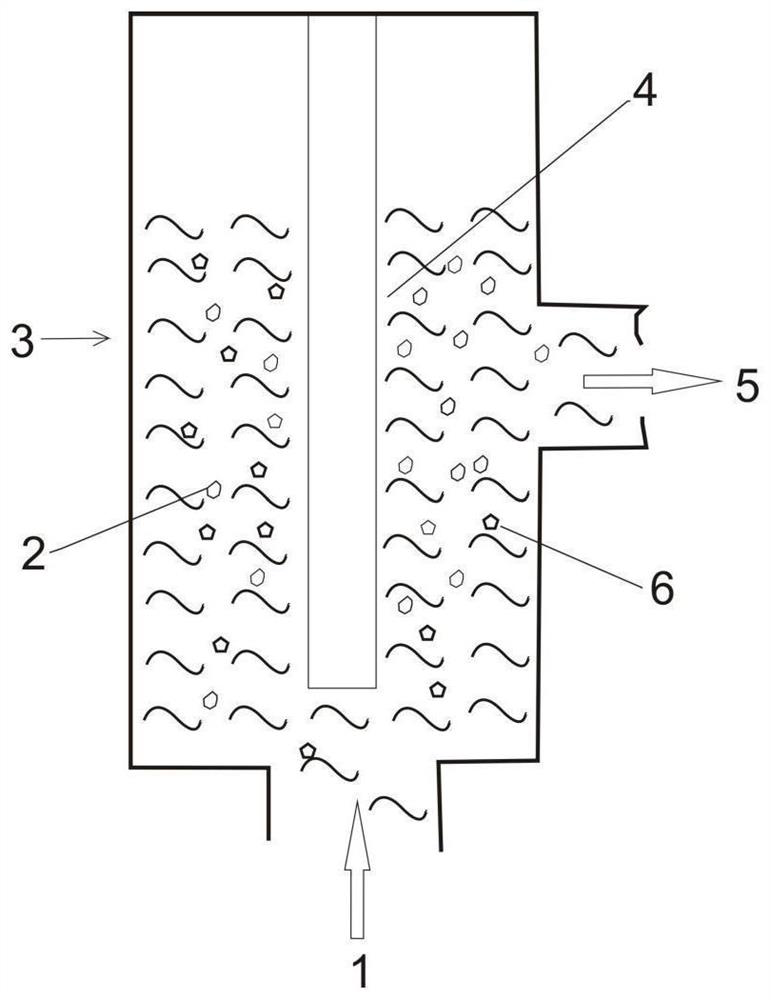

Horizontal directional drilling annular rock debris migration integration simulation experiment method and experiment apparatus thereof

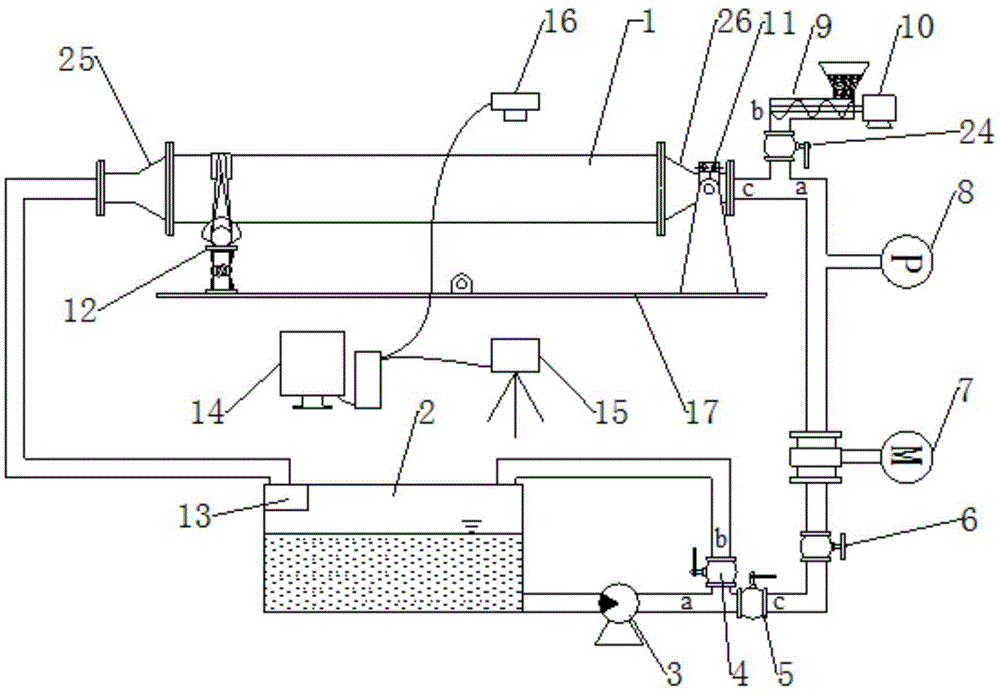

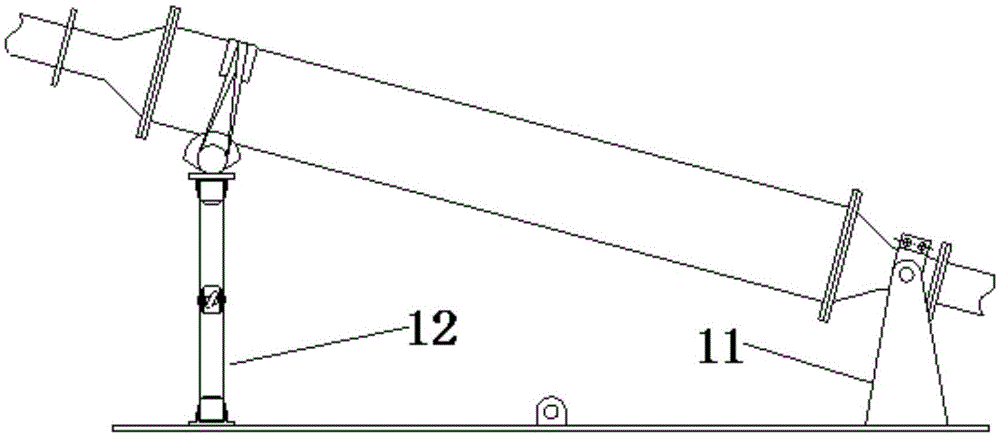

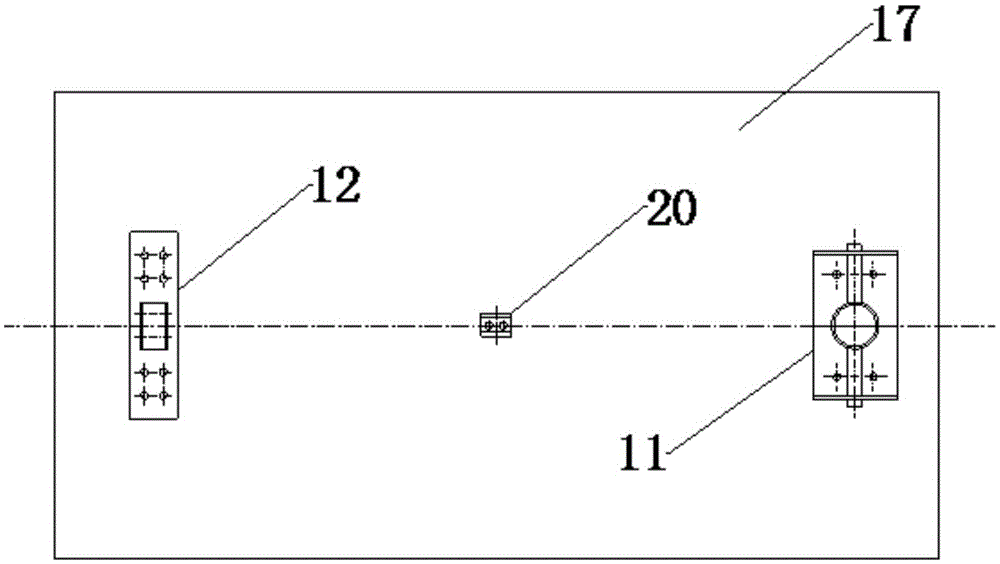

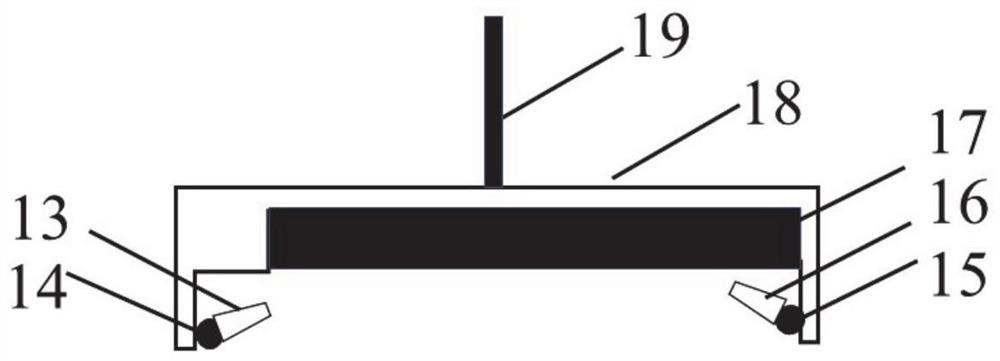

ActiveCN105551362ASave experimental expensesEasy to prepareEducational modelsControl systemMotion simulation

The invention provides a horizontal directional drilling annular rock debris migration integration simulation experiment method. The method comprises processes of initializing an apparatus, adjusting a slurry input speed, adjusting a rock debris injection speed, inclining a transparent pipeline, changing the debris with different grain sizes, vertically placing the pipeline and the like. The method is characterized by observing formation of a rock debris bed in the transparent pipeline; shooting a horizontal photograph and a vertical photograph of the rock debris bed in the transparent pipeline; measuring slurry pressure and a slurry flow in the transparent pipeline; and recording a total addition amount of the rock debris so as to analyze rock debris migration. The invention simultaneously provides an experiment apparatus based on the above method. The apparatus comprises the transparent pipeline used for observation, a slurry feeding system connected to the transparent pipeline, a rock debris injection system connected to the slurry feeding system and an inclination control system arranged outside the transparent pipeline. A motion state of the rock debris under different penetrating angle and unearthed angle conditions can be simulated, and migration simulation of the rock debris bed and single rock debris motion simulation are completed in a same set of system and experiment cost is saved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

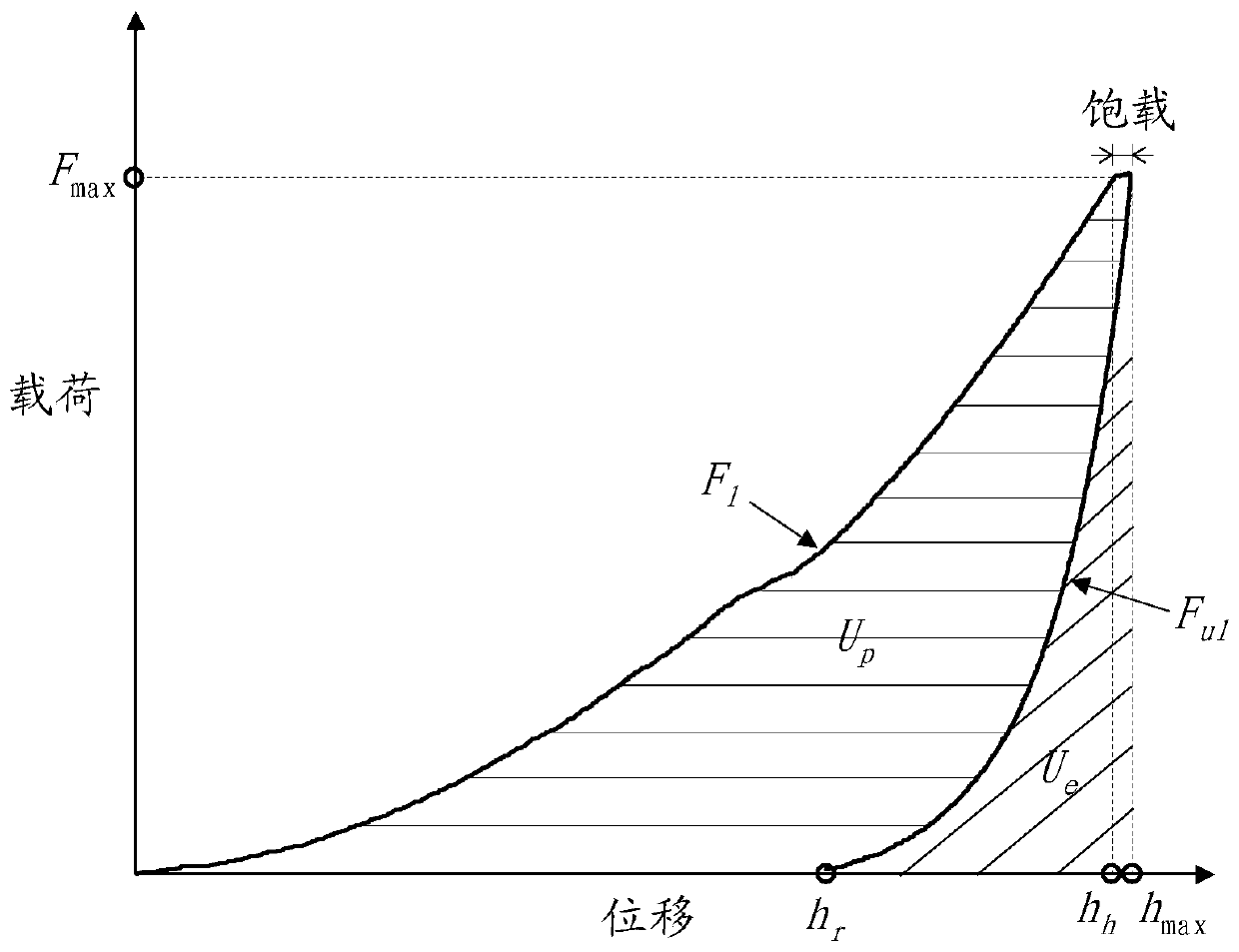

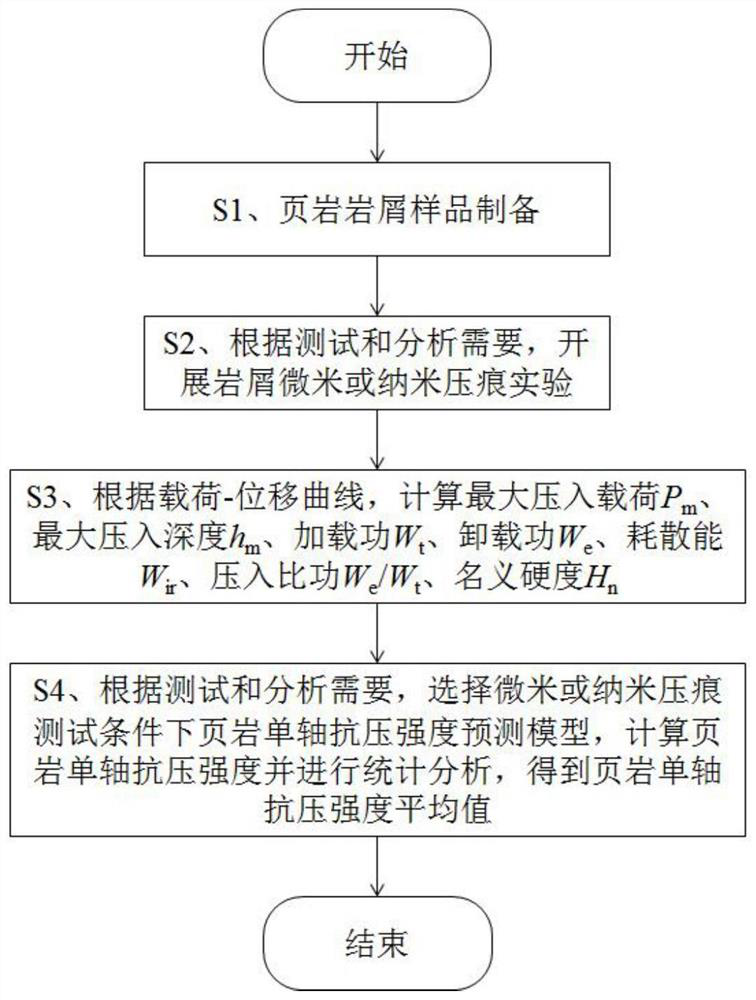

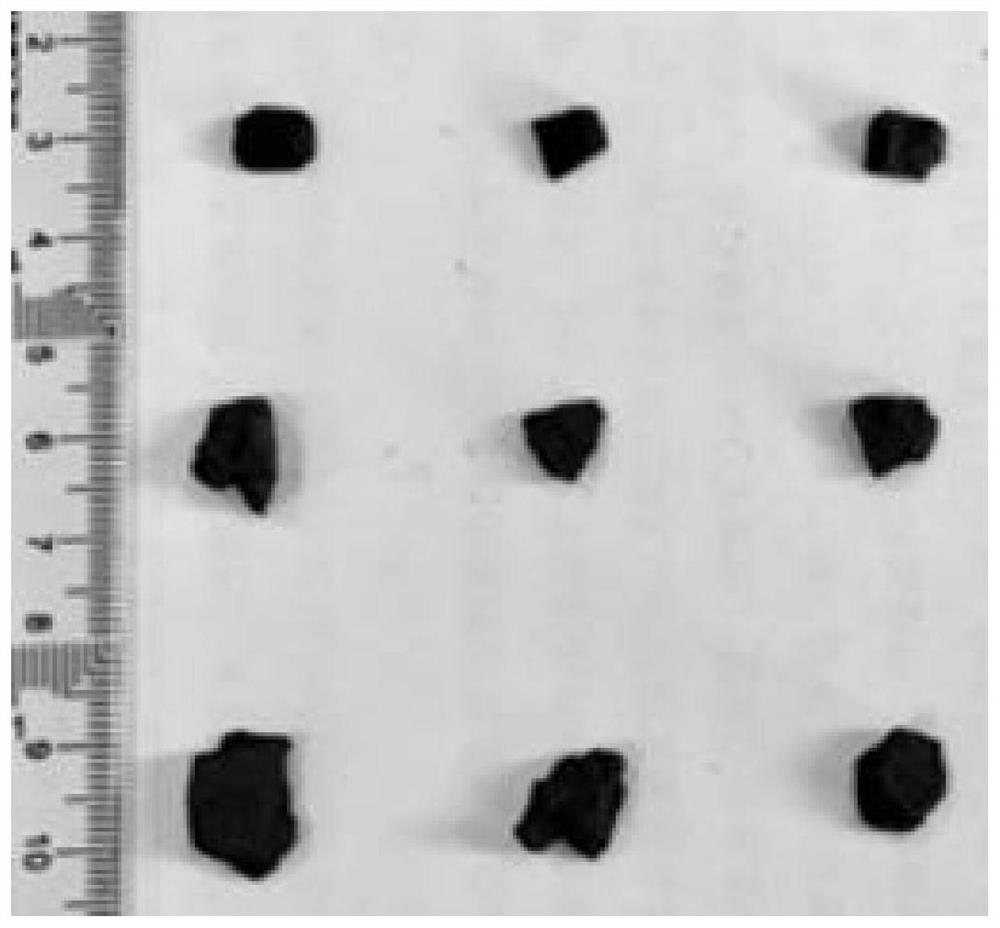

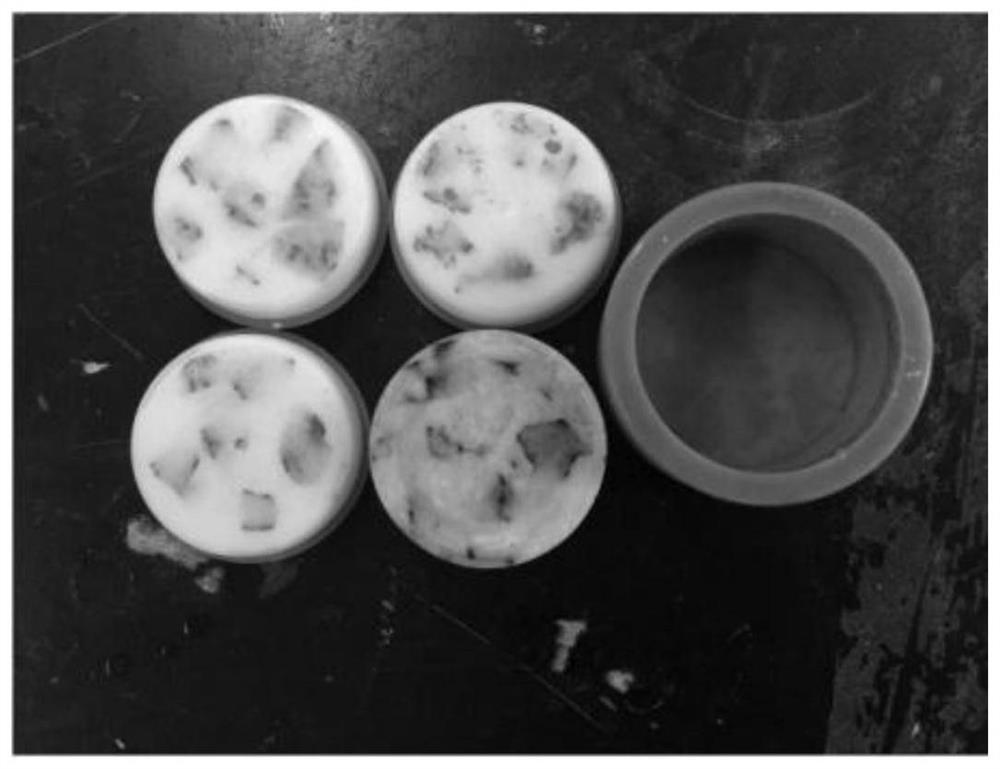

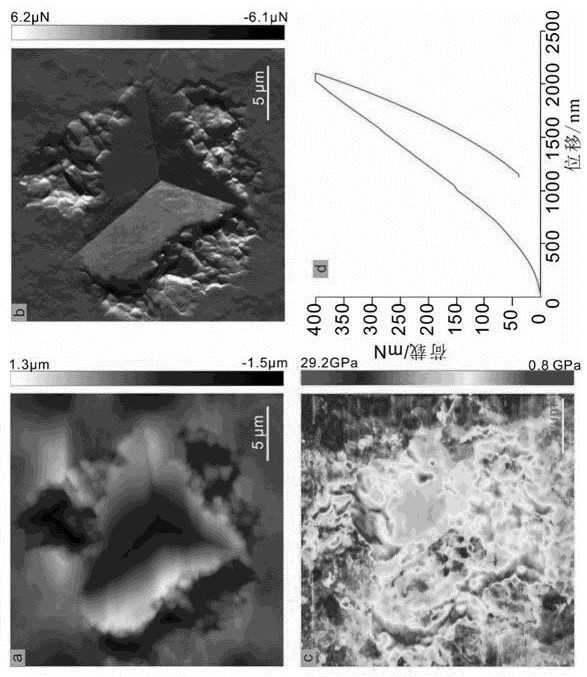

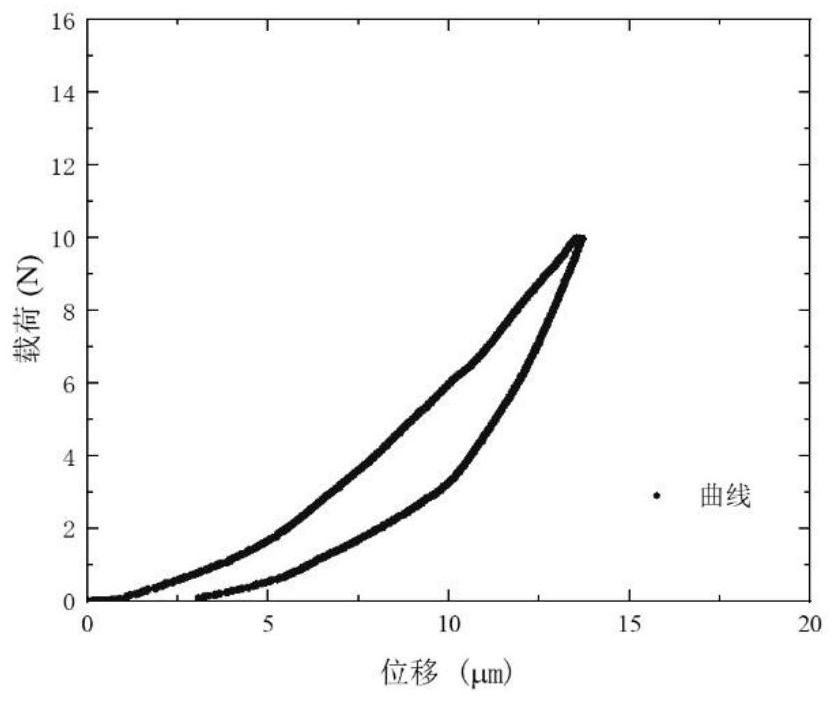

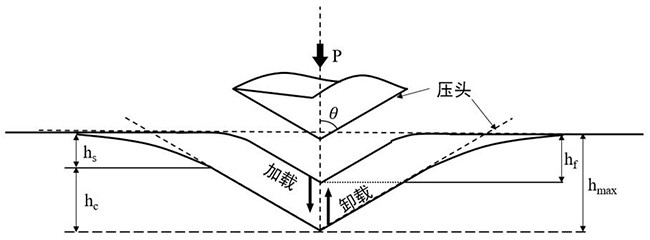

Shale uniaxial compressive strength evaluation method based on rock debris micro-nano indentation experiment

ActiveCN112179770AAchieve forecastEffective guidance designPreparing sample for investigationMaterial strength using tensile/compressive forcesMicro nanoHorizontal wells

The invention discloses a shale uniaxial compressive strength evaluation method based on a rock debris micro-nano indentation experiment, and the method comprises the following steps: collecting rockdebris of a target shale reservoir, and treating the surface of a rock debris sample by adopting a three-ion beam cutting instrument, so that the surface becomes a flat and smooth high-quality section; carrying out a rock debris micron or nano indentation experiment on the treated rock debris sample to obtain a plurality of groups of indentation experiment load displacement curve graphs; and calculating the shale uniaxial compressive strength of the shale reservoir. According to the method, the shale debris micro-nano indentation experiment is carried out, indentation load depth curves under different scales are obtained, micromechanics parameters of shale are obtained through calculation, a relation model between uniaxial compressive strength and the micromechanics parameters is established, prediction of macromechanics parameters of shale is achieved, and the method is suitable for large-scale popularization and application. Therefore, shale mechanical parameters of the shale horizontal well are accurately obtained; basic parameter bases are provided for drilling, well completion and hydraulic fracturing of the shale gas horizontal well, and design and construction of drilling, well completion and hydraulic fracturing of the shale gas horizontal well can be effectively guided.

Owner:SOUTHWEST PETROLEUM UNIV

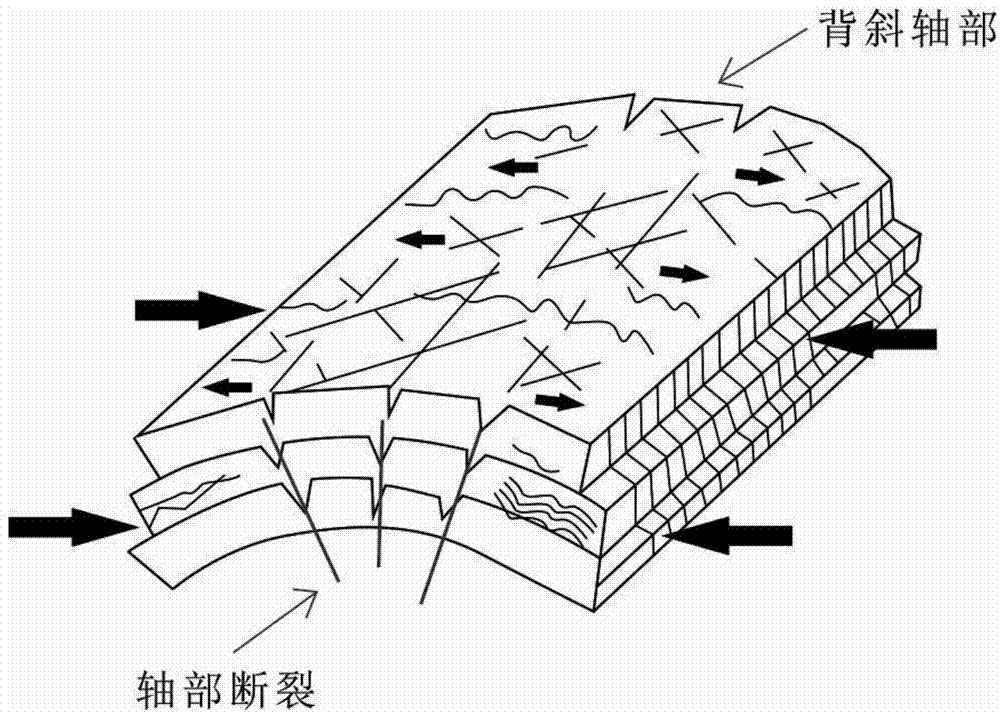

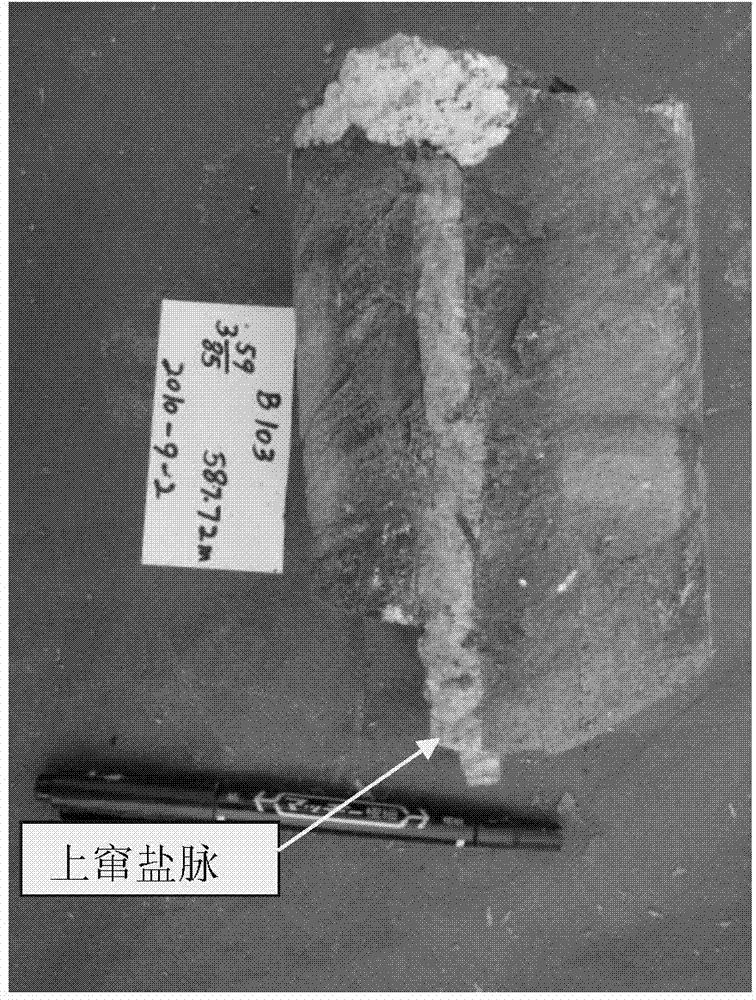

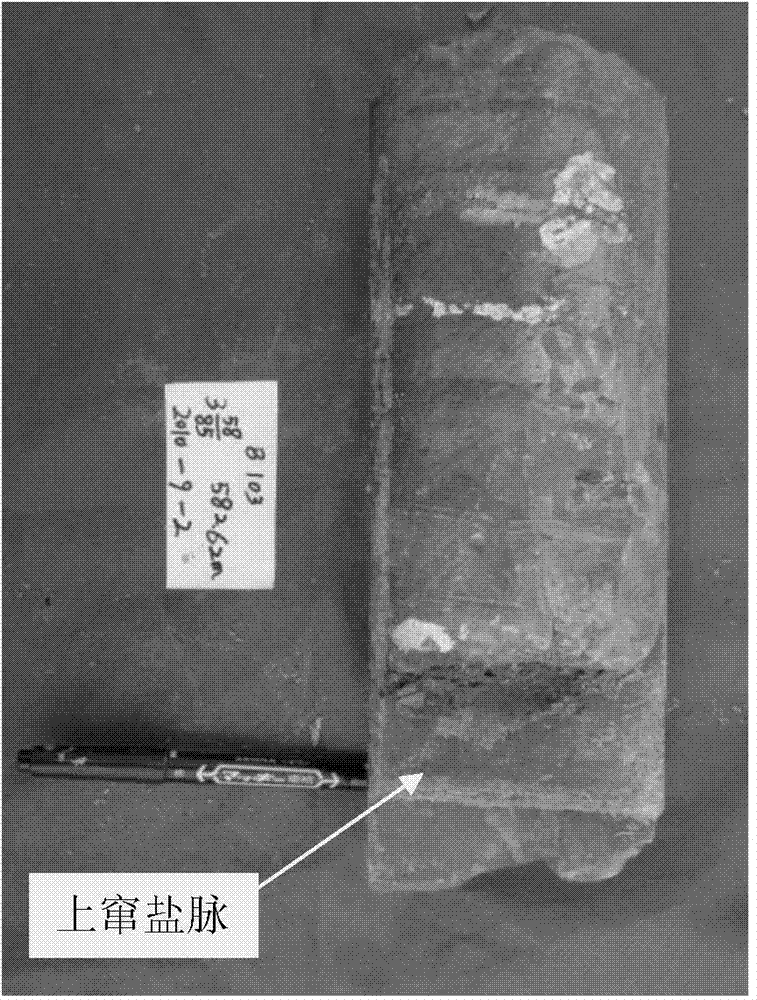

Method for searching for deeply-buried solid sylvite ore deposit

ActiveCN104730592AReduce prospecting costsImprove the accuracy of prospectingNuclear radiation detectionRock coreWell drilling

The invention provides a method for searching for a deeply-buried solid sylvite ore deposit and belongs to the mineral exploitation technology. The method includes the steps that firstly, the exploration drilling positions are arranged, wherein an anticline structure is found in a predicted sylvite ore deposit exploratory area, the highest point and the second high point are determined in the axial direction of the anticline structure, and the positions of drilling holes are arranged; secondly, drilling and sampling are conducted, wherein ore samples are acquired after drilling operation and drilling liquid does not contain potassium ions; thirdly, judgment is conducted, wherein ore samples acquired after drilling are observed, whether a lode containing potassium is found or not and whether a potassium-containing index occurs or not are judged; if an observation result in the third step shows the potassium-containing index, the exploratory area can be drilled continuously; if the observation result does not show the potassium-containing index, drilling operation is stopped, and the first step, the second step and the third step are conducted on another sylvite ore deposit exploratory area, wherein observation of the ore samples acquired after drilling means that drilling mud samples, rock debris samples and / or rock core and dyke samples are observed. By the adoption of the method, ore searching cost can be effectively reduced and the ore searching success rate of concealed potassium ores can be increased.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

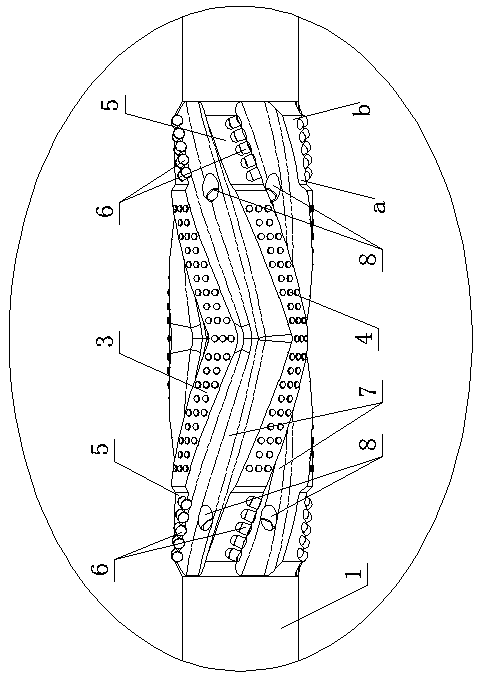

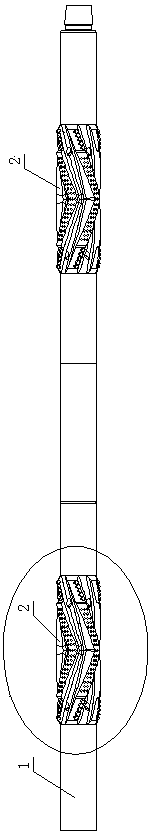

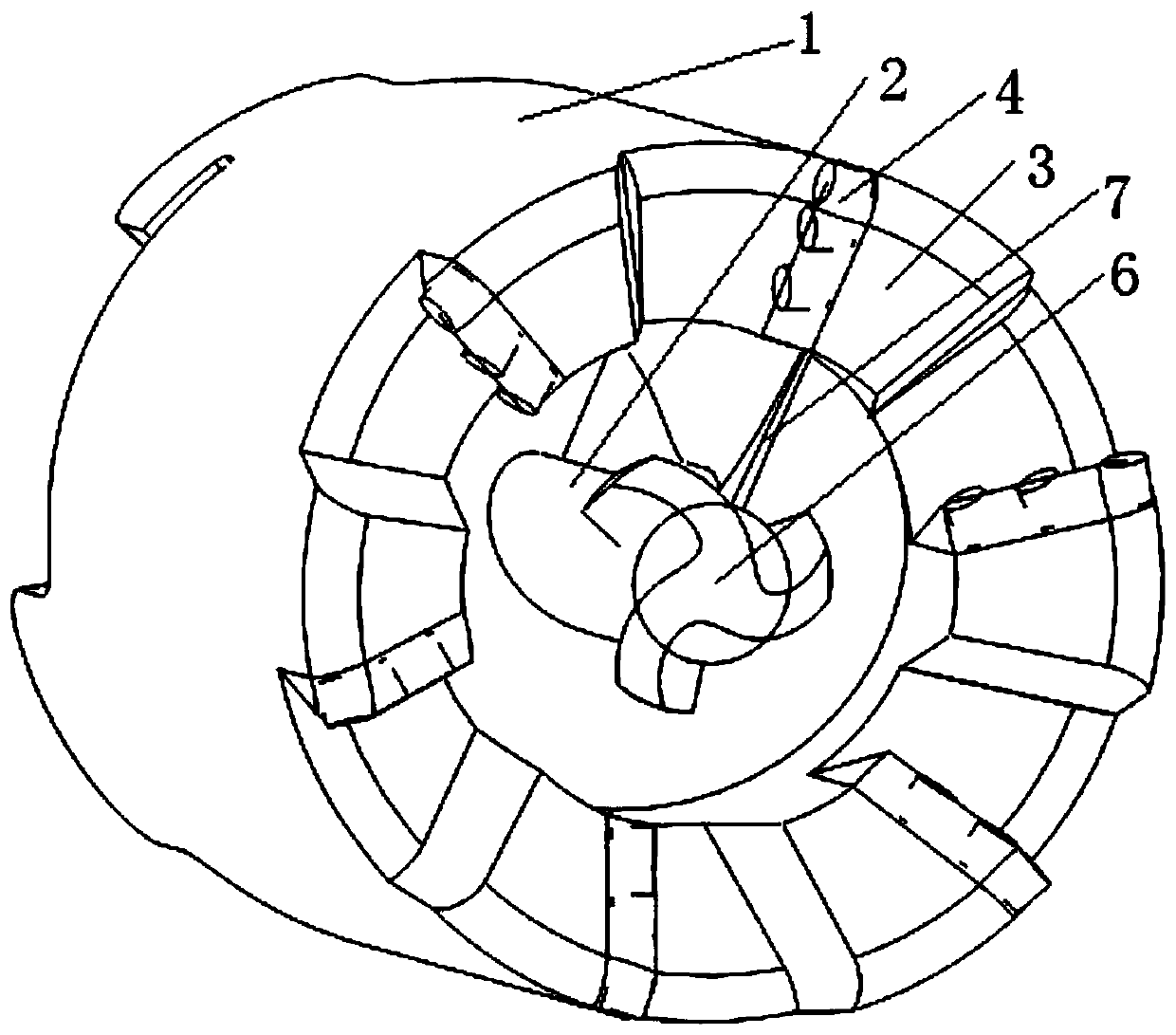

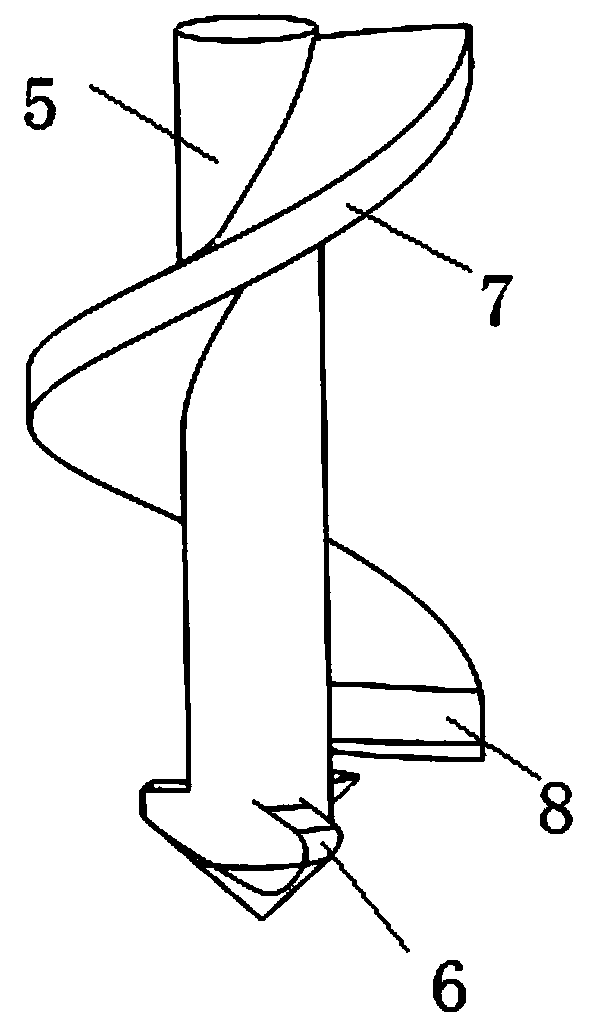

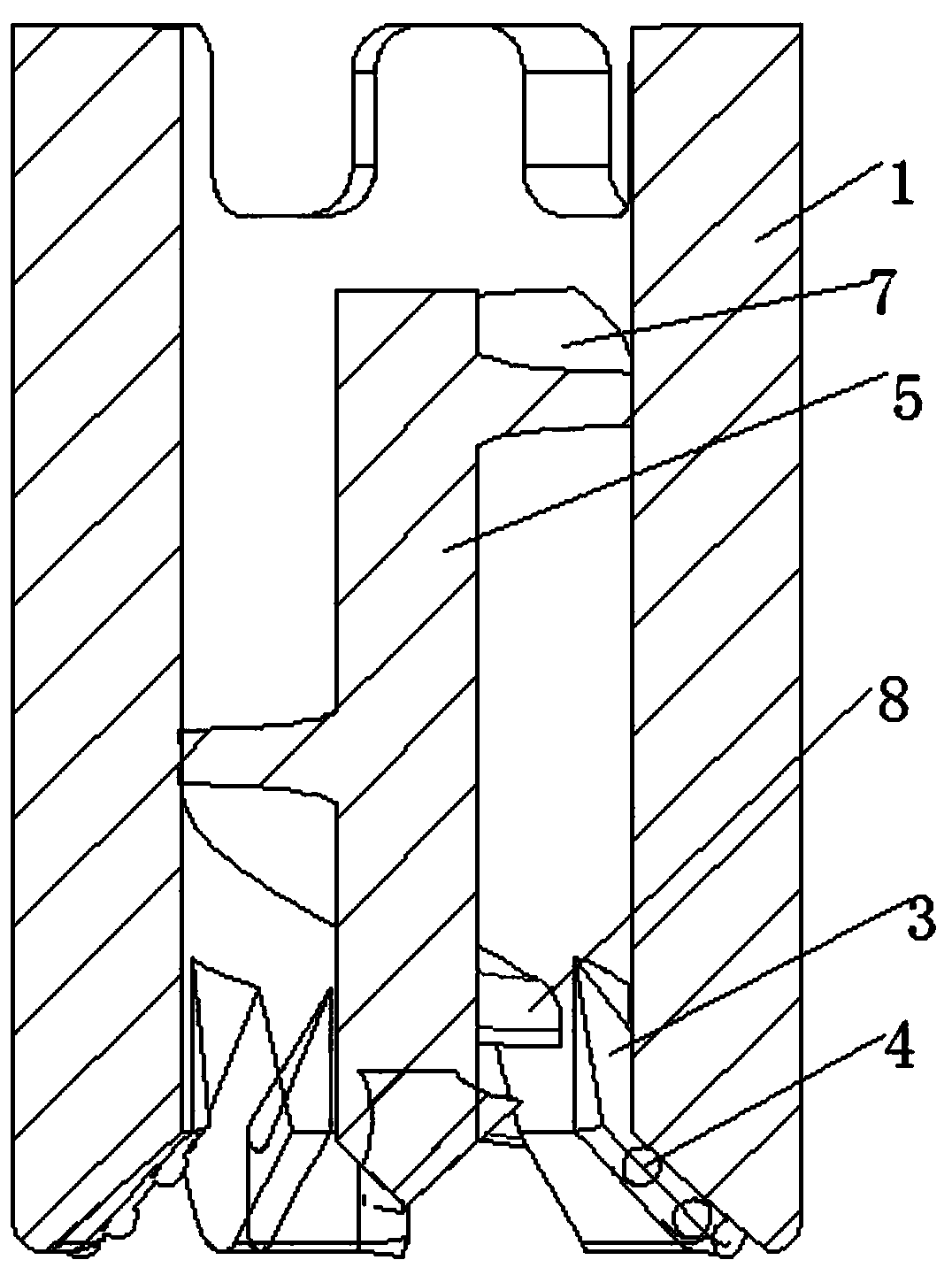

Integrated drilling tool for crushing and cleaning drilling borehole rock debris deposit bed

InactiveCN110886582AReasonable structural designPrevent subsidenceDrilling rodsCleaning apparatusMining engineeringAlloy

The invention discloses an integrated drilling tool for crushing and cleaning a drilling borehole rock debris deposit bed, and relates to the field of drilling tools. A scraping and cleaning short joint is a columnar pipe body, more than one convex edge spiral wing is longitudinally arranged on the annular wall of the scraping and cleaning short joint, the convex edge spiral wings are longitudinally arranged in a V-shaped circumferential interval mode, hard alloy convex blocks are evenly distributed on the edge faces of the convex edge spiral wings, the two ends of each V-shaped convex edge spiral wing are connected with cutting edges which are sunken inwards and warped outwards, and columnar cutting teeth are arranged on the surfaces of the cutting edges; and a V-shaped sunken flow guidegroove is formed between every two adjacent V-shaped convex edge spiral wings, and liquid flow nozzles which communicate with the interior of a pipe are arranged at the two ends of each flow guide groove. The V-shaped sunken flow guide grooves rotate along with a drilling rod, so that drilling fluid generates severe turbulence, and sedimentation of rock debris particles in a well section is effectively prevented; and meanwhile, formed rock debris bed particles can be efficiently stirred, and the stirred rock debris particles are captured by the flow guide grooves, then brought into a suspension layer with a high annular flow rate and thrown to a high-side annulus and a farther distance.

Owner:HELI TECH ENERGY CO LTD

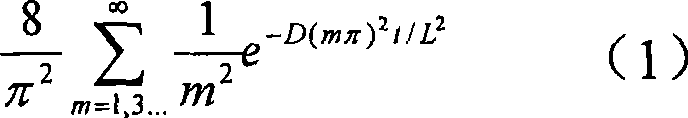

While-drilling down-hole measurement for substance in stratum

The invention relates to a method which utilizes drilling fluid which flows downwards along with a drilling string and comes out along with the drill bit with rock debris produced by drilling stratum and then returns to the surface of the earth from an annular space between the drilling string and a drilling well to measure matters in the stratum at the periphery of an earth drilling well drilled by the drill bit at the end part of the drilling string, comprising the following steps: waiting for that any matter dissolved in the drilling mud is substantially balanced with any matter in the stratum rock debris; and then measuring matters dissolved in the drilling fluid underground.

Owner:PRAD RES & DEV LTD

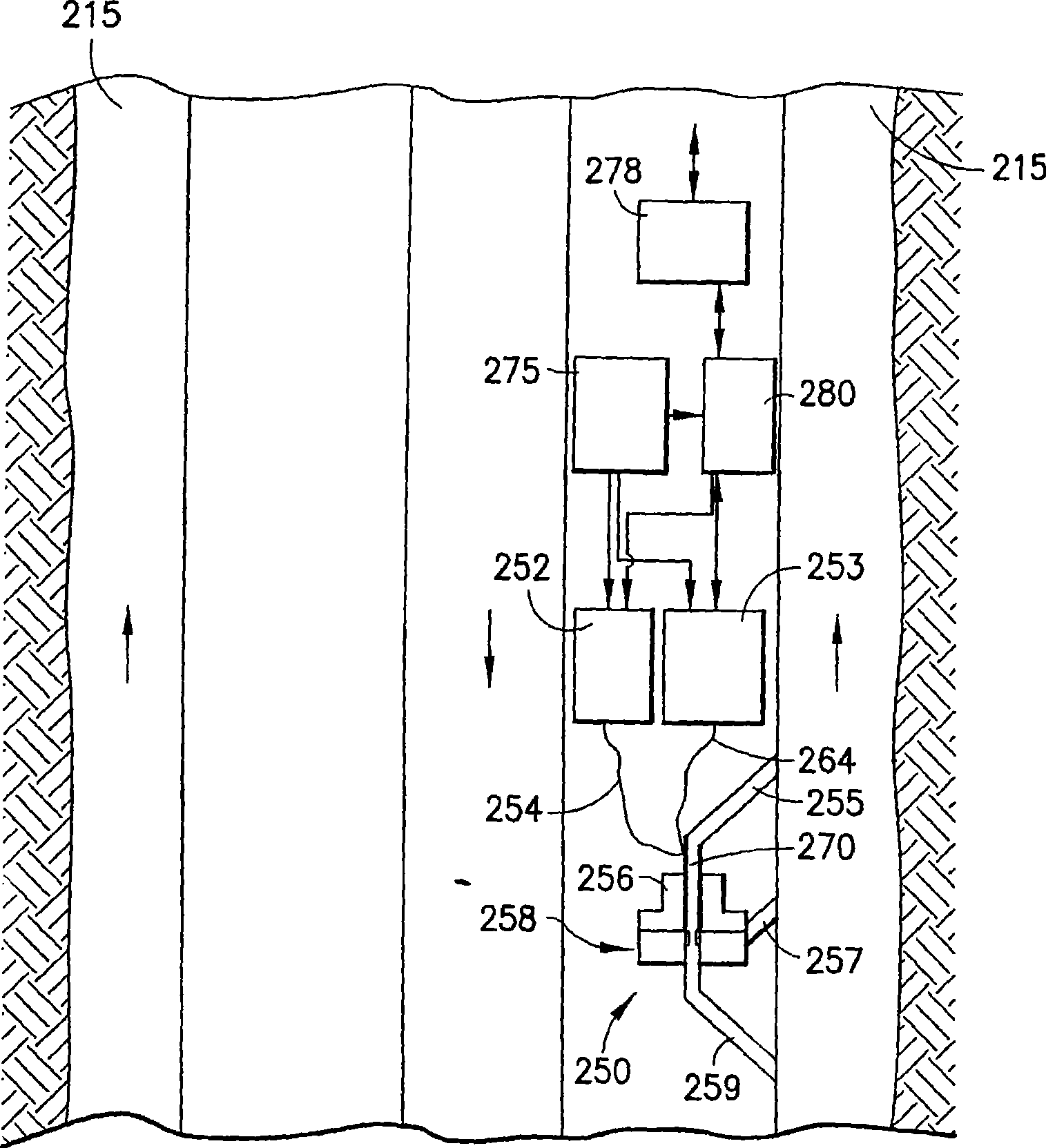

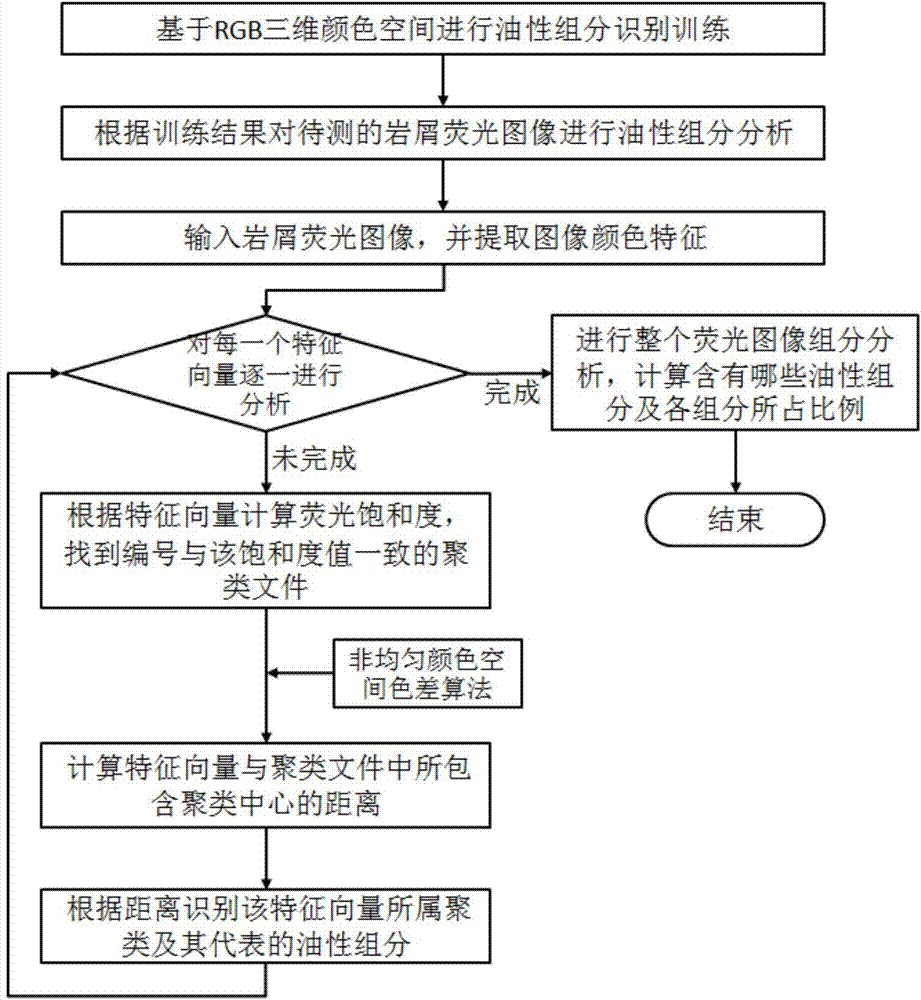

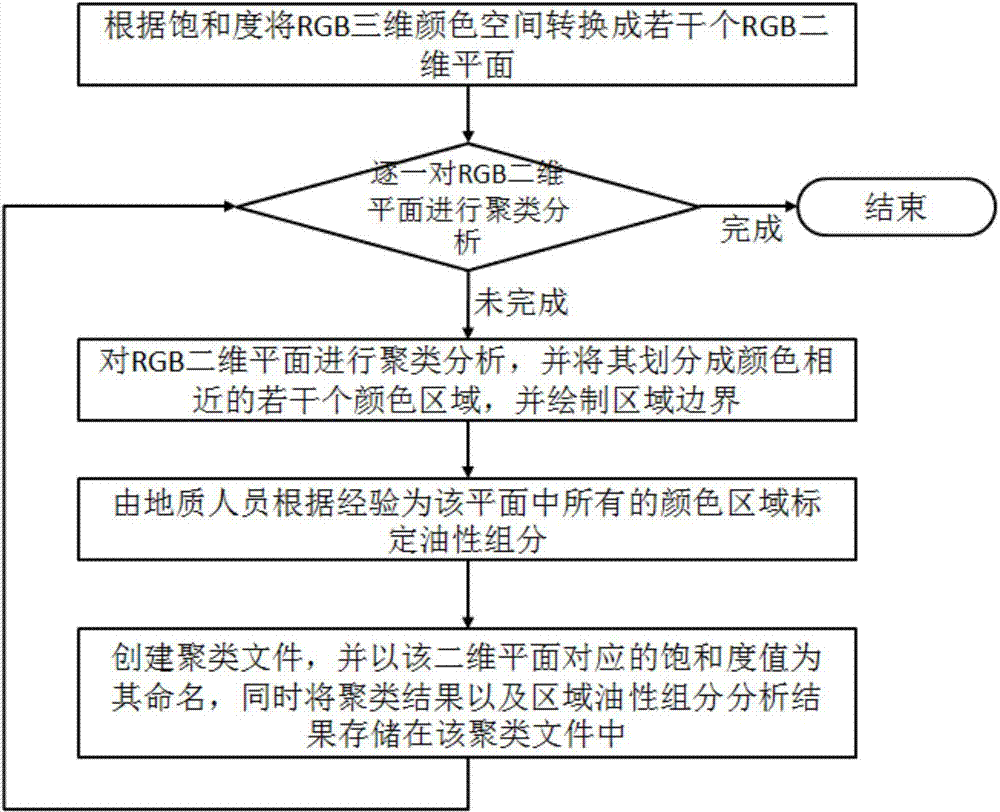

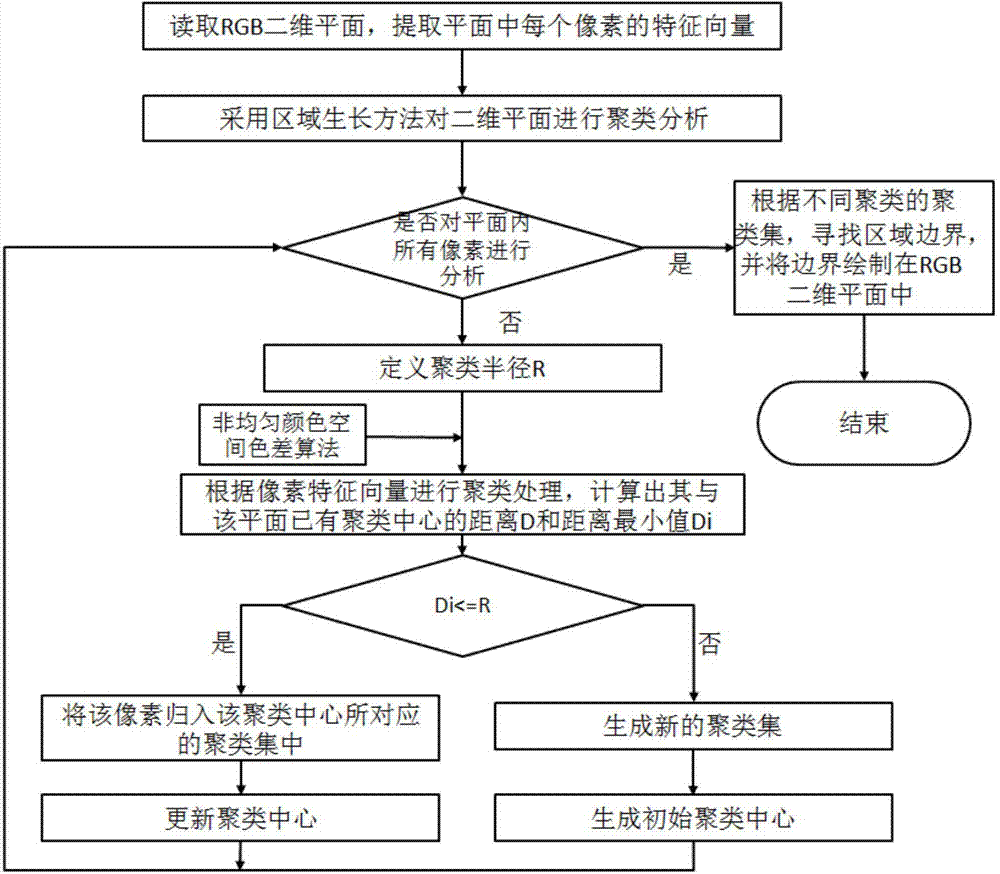

Method for rapidly analyzing rock debris fluorescence image

ActiveCN103927547AReduce workloadImprove accuracyImage analysisCharacter and pattern recognitionWell loggingGeological exploration

The invention relates to a method for rapidly analyzing a rock debris fluorescence image. The method comprises the following steps that (1) oily component identification training is carried out on the basis of RGB three-dimensional color space, so that a clustering file is obtained; (2) oily component analysis is carried out on the rock debris fluorescence image to be tested according to the clustering file obtained in the step (1). The oily component analysis process specifically comprises the following steps that (2.1) color feature extraction is carried out on the input rock debris fluorescence image to be tested, and a feature vector array is generated; (2.2) each feature vector in the feature vector array is analyzed; (2.3) after analysis work of all the feature vectors in the feature vector array is accomplished, oily components contained in the rock debris fluorescence image and the proportions of the oily components are obtained through calculation. According to a rock debris fluorescence layered clustering method based on non-uniform color space color difference calculation, the oily component identification result and the rock debris fluorescence image analysis result are accurate, oily component identification and rock debris fluorescence image analysis are rapid, the requirement of geological staff of an offshore platform for intelligentized well logging can be met, and therefore the method for rapidly analyzing the rock debris fluorescence image can be widely applied to the geological exploration and development process.

Owner:CNOOC ENERGY TECH & SERVICES +1

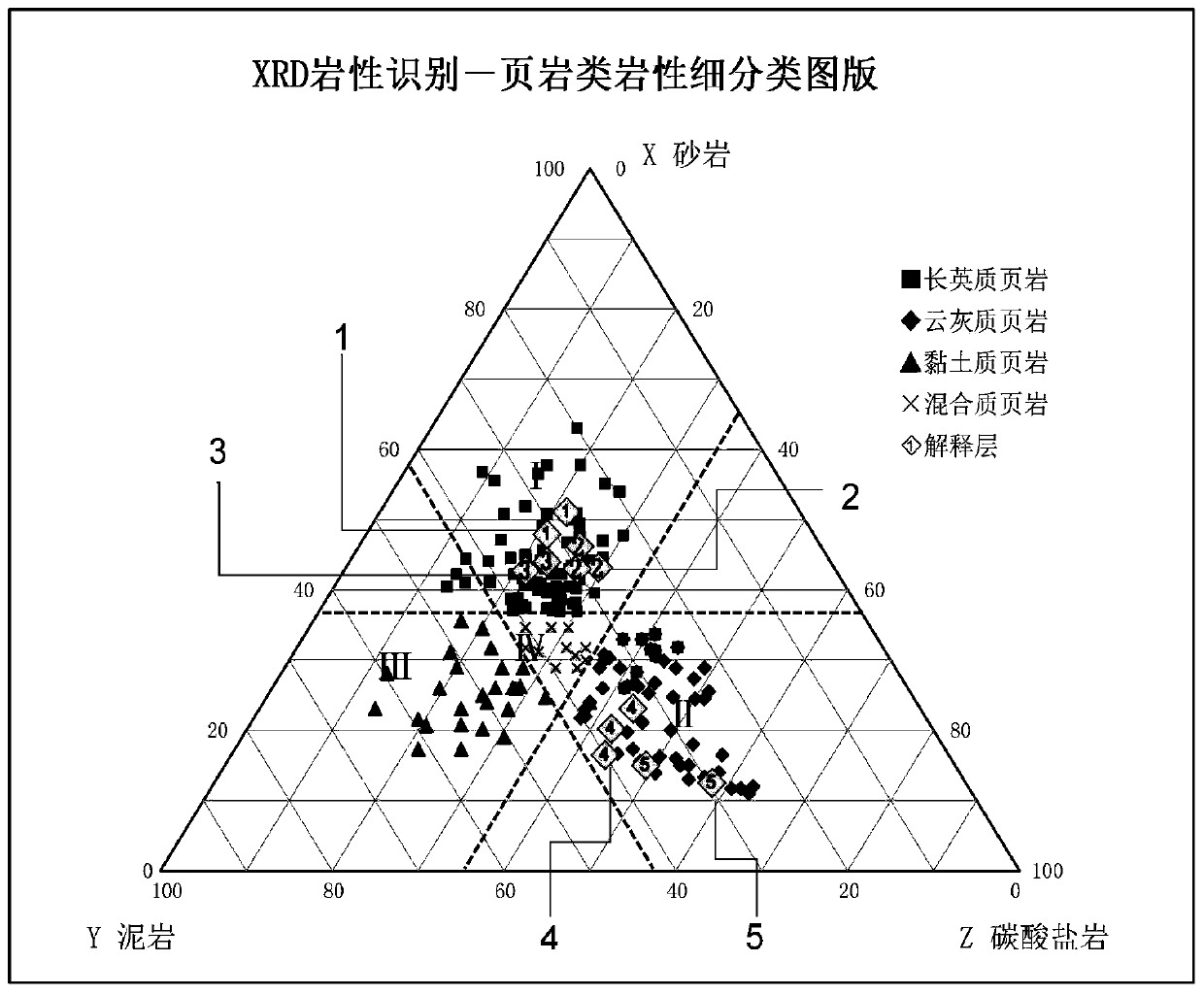

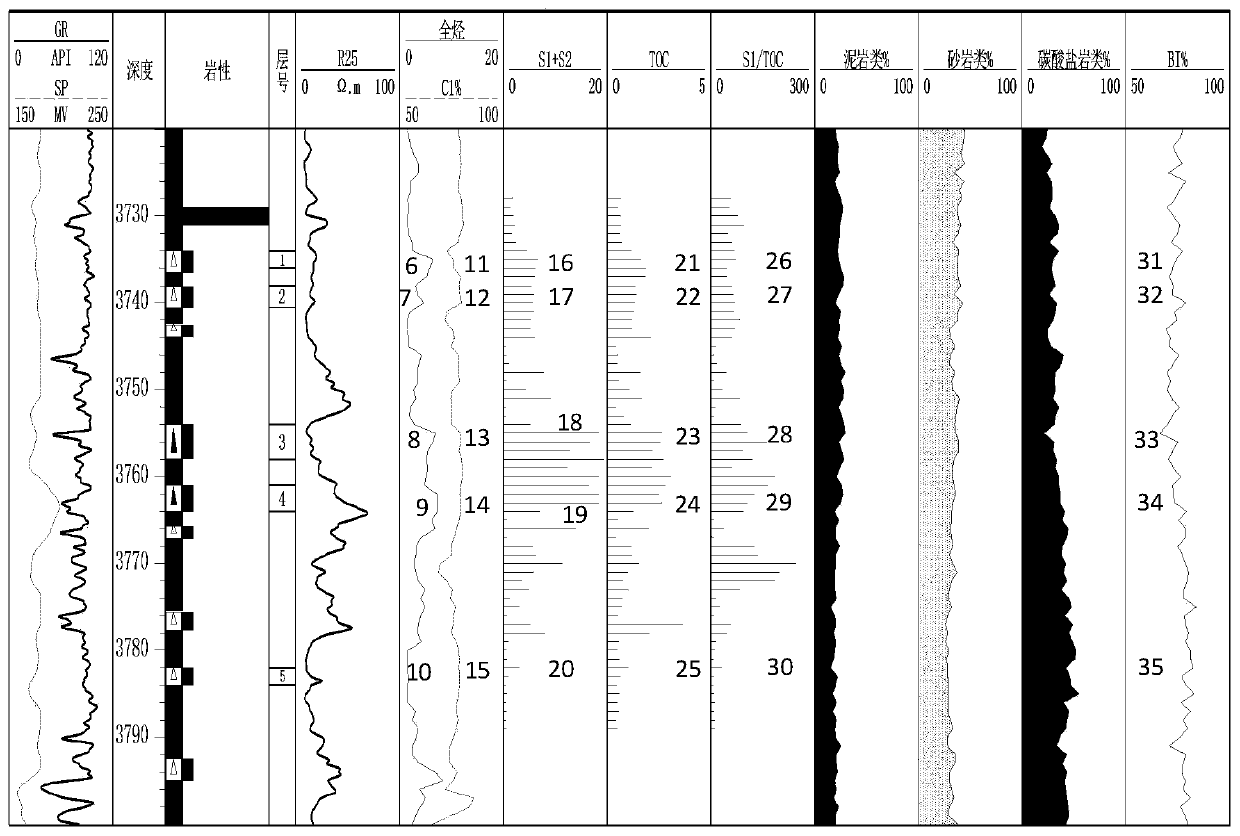

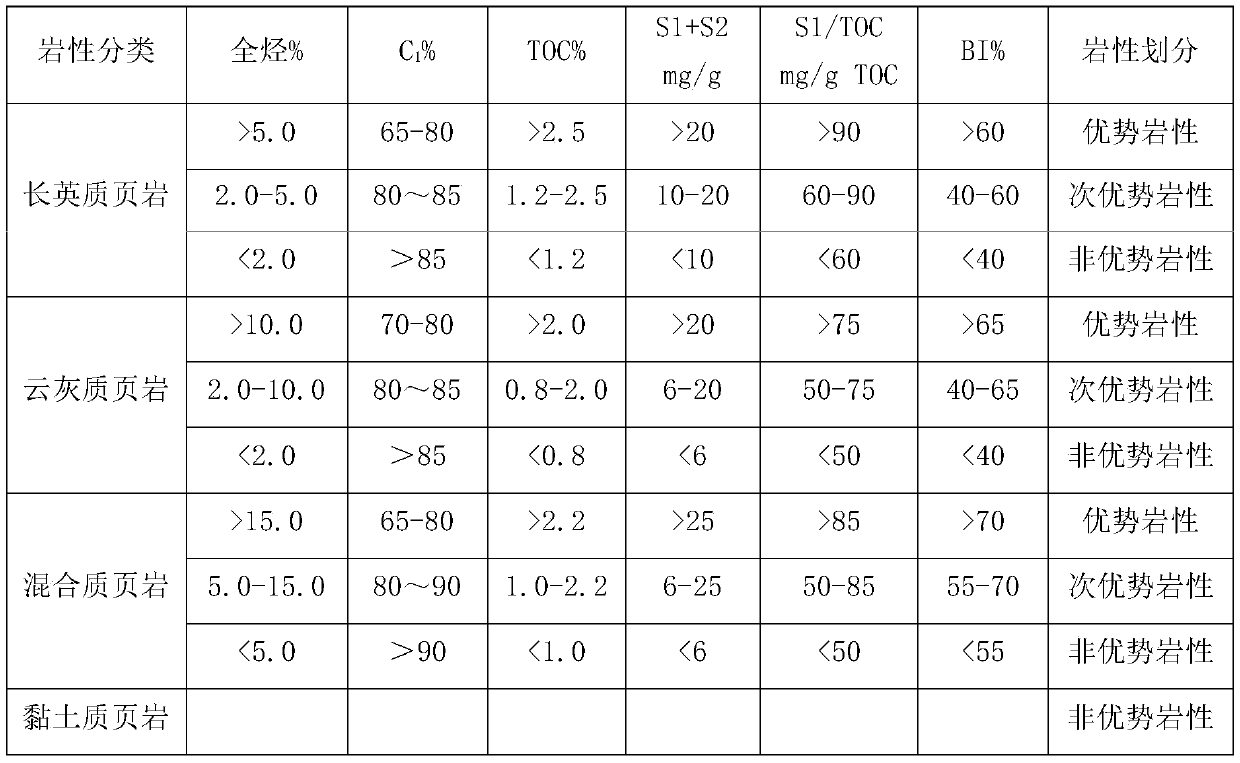

Fine identification method for advantageous lithology of shale oil

ActiveCN110965999AImprove the overall efficiency of exploration and developmentImprove efficiencyBorehole/well accessoriesLithologyRock core

The invention discloses a fine identification method for the advantageous lithology of shale oil. The fine identification method for the advantageous lithology of the shale oil comprises the steps that three main mineral components are selected to establish a board chart according to X-ray diffraction mineral component data of lithic fragment or core sample minerals in a shale bed section, and fine division of the shale type lithology is achieved; and the shale stratum advantageous lithology division standard is established according to gas logging parameters, rock pyrolysis analysis and brittleness index data. According to the fine identification method for the advantageous lithology of the shale oil, the board chart is established through the X-ray diffraction mineral component data to distinguish the lithology, and the advantageous lithology of a shale stratum is judged by combining the gas logging parameters, rock pyrolysis analysis and the brittleness index data; firstly, the problem that denomination of the shale oil lithology is not clear is well solved, and the lithology can be accurately identified; and secondly, the data capable of identifying the advantageous lithology in the lithology are provided for oil testing and stratum selecting, the result meets the engineering service needs, and a reliable basis is provided for efficient oil and gas resource development of the shale stratum.

Owner:CNPC BOHAI DRILLING ENG +1

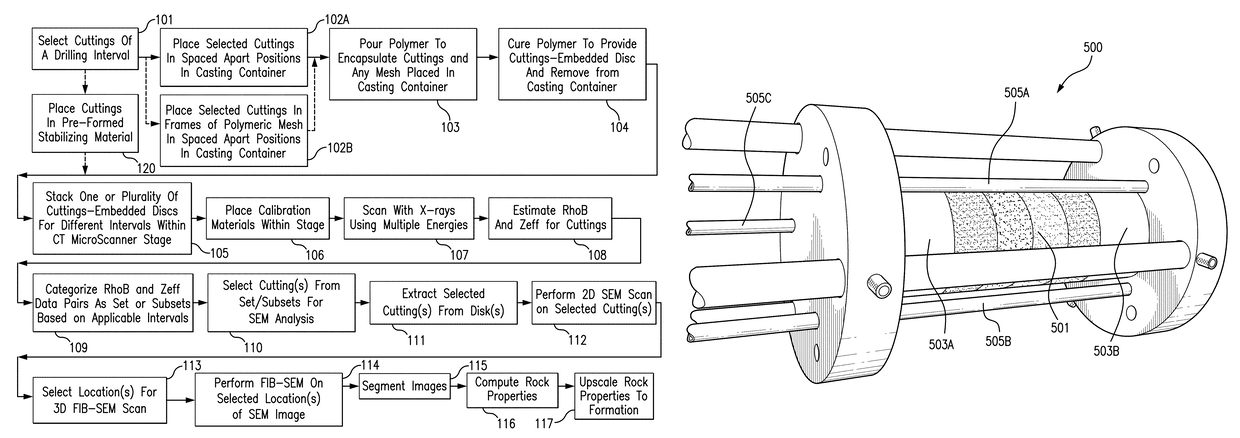

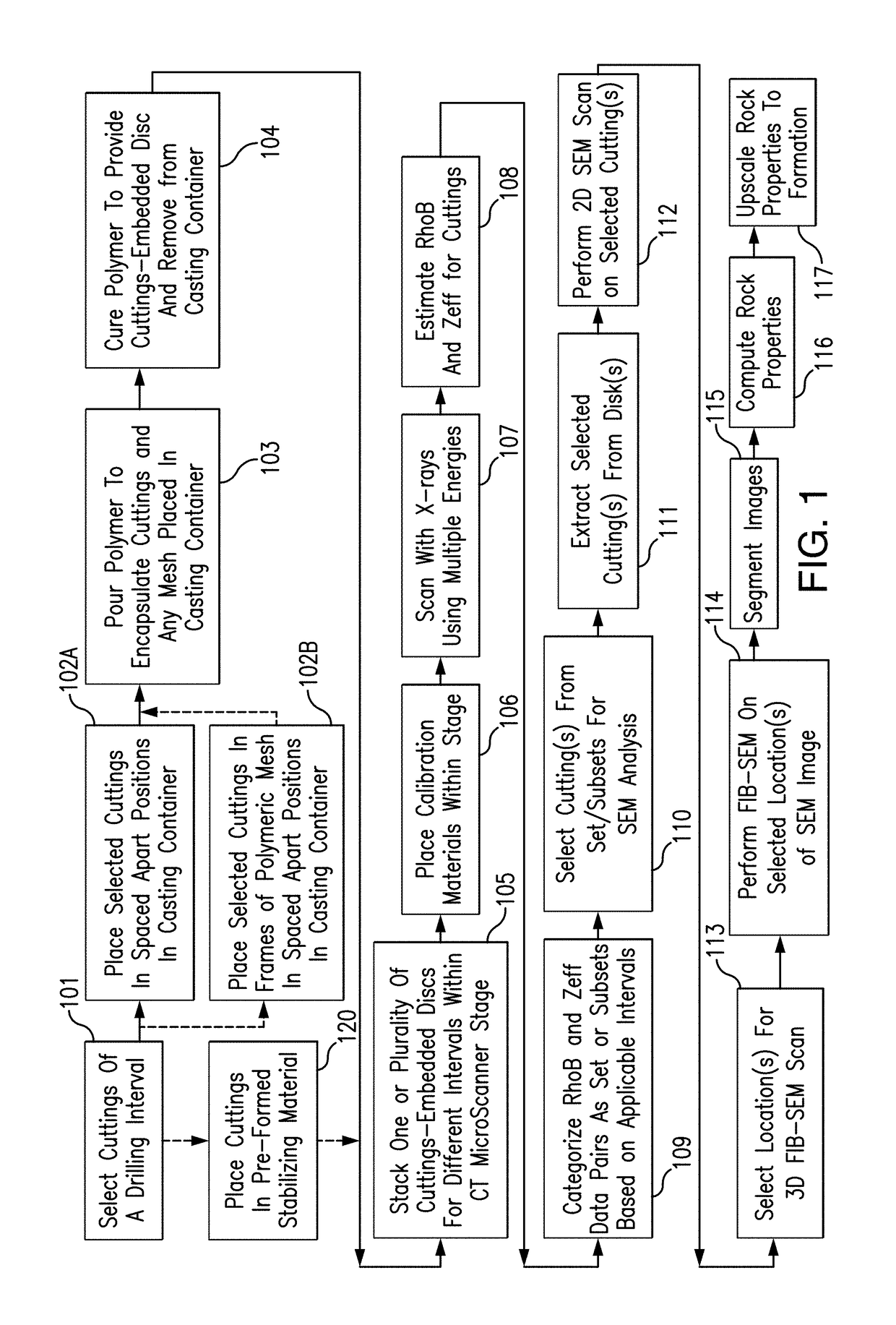

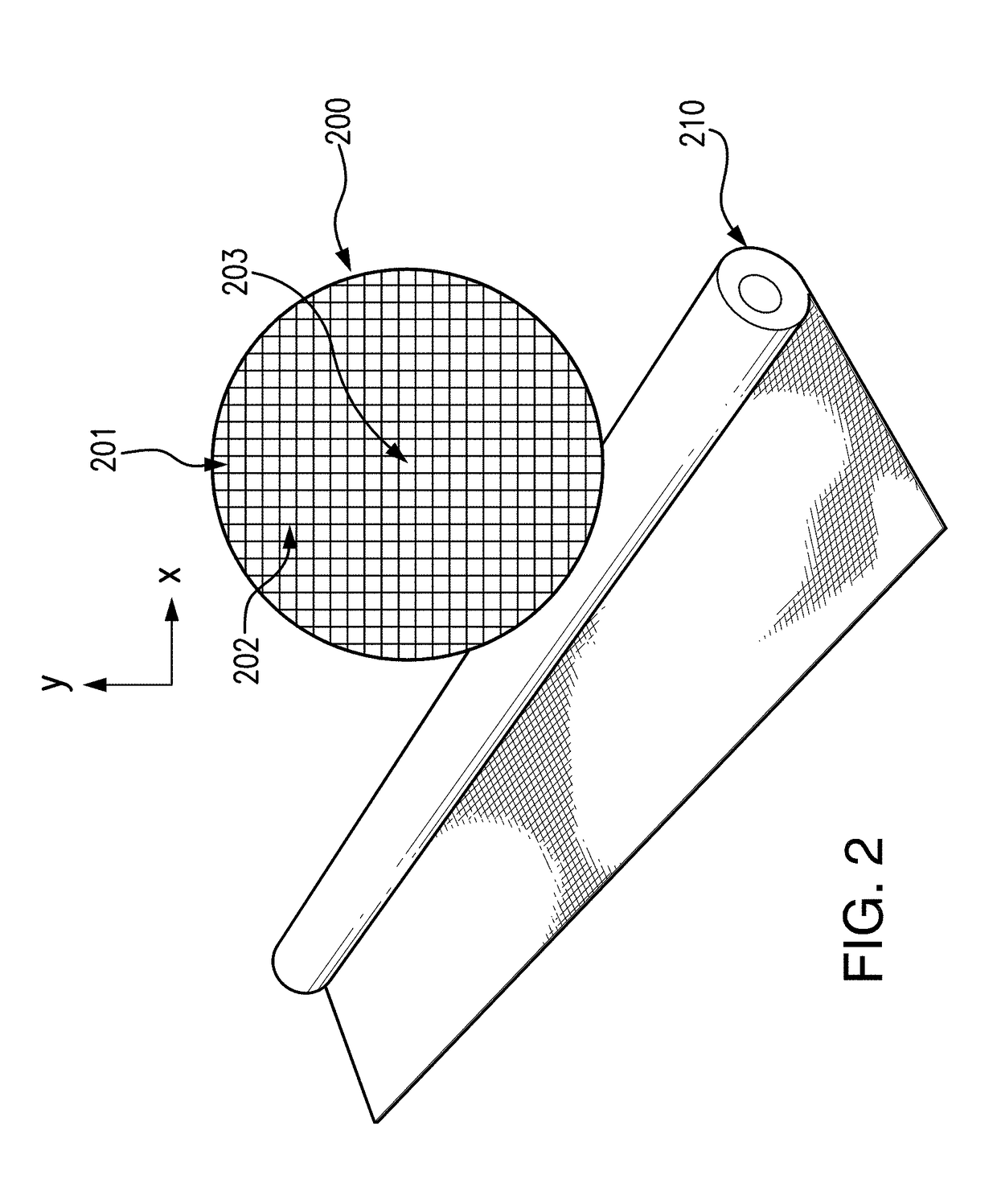

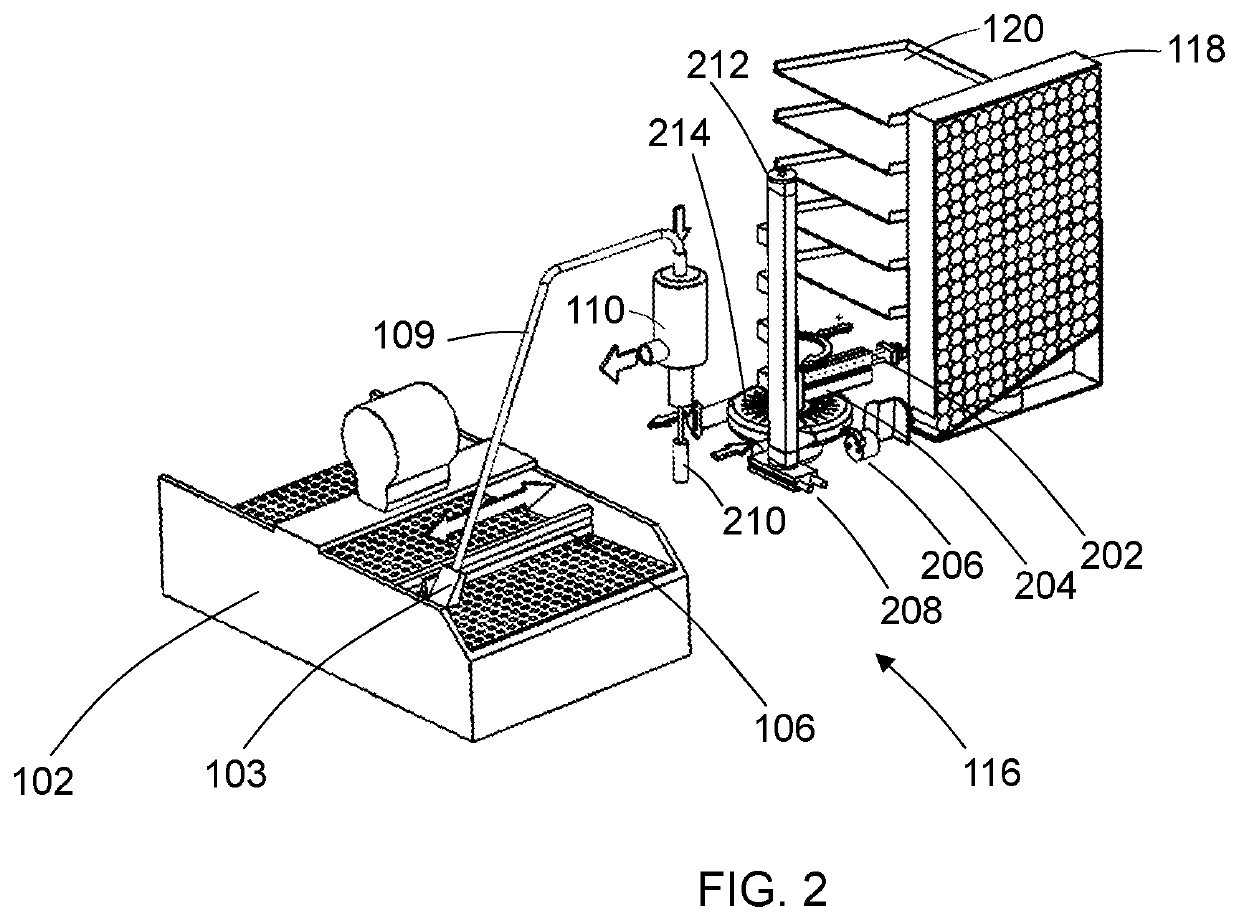

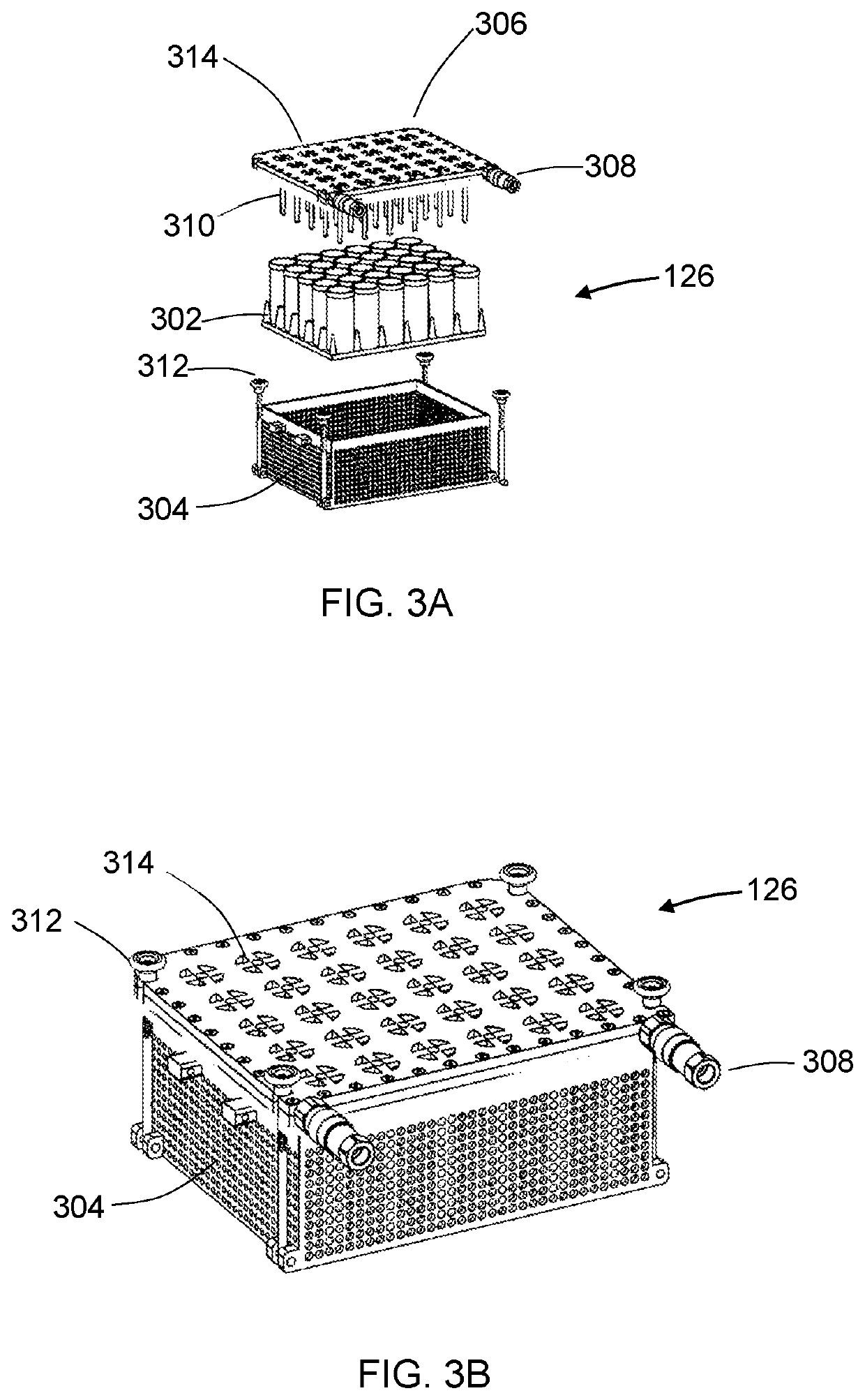

Method and system for multi-energy computer tomographic cuttings analysis

ActiveUS9746431B2Improved processing and analysisRadiation/particle handlingPreparing sample for investigationPorous mediumWell drilling

A method and a system are provided to prepare a plurality of cuttings or other rock fragments or other porous media, such as cuttings from a drilling interval or multiple intervals, for computer tomographic scanning at the same time. A method and system also are provided to allow organization of mass quantities of cuttings or other rock fragments obtained from intervals of a well to more accurately categorize the cuttings to assist selections thereof for more detailed digital rock analysis, such as using SEM and FIB-SEM systems, are provided. A method and system also are provided to allow characterization of facies occurrence frequency of a depth interval using drill cuttings or other rock fragments. Computerized systems, computer readable media, and programs for performing the methods are also provided.

Owner:HALLIBURTON ENERGY SERVICES INC

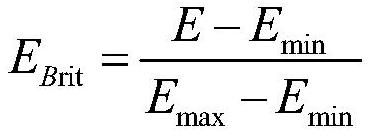

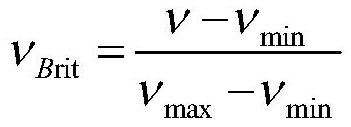

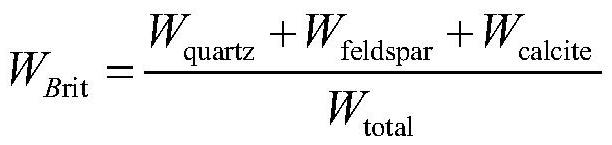

Rock brittleness evaluation method based on while-drilling rock debris logging data

ActiveCN113138107AReduced cost of coring operationsThe brittleness evaluation results are accuratePreparing sample for investigationEarth material testingRock coreWell logging

The invention relates to a rock brittleness evaluation method based on while-drilling debris logging data. The rock brittleness evaluation method comprises the steps: 1, obtaining three-dimensional digital rock core microscopic parameters according to the while-drilling debris logging data of a to-be-logged well; 2, generating a three-dimensional digital rock core sample according to the obtained microscopic parameters of the rock debris while drilling; 3, carrying out a uniaxial or triaxial compression numerical experiment on the three-dimensional digital rock core sample to obtain a three-dimensional digital rock core stress-strain curve, and calculating the elastic modulus and Poisson's ratio of the rock core; 4, calculating a normalized elastic modulus, a poisson ratio and a brittle mineral proportion; 5, calculating and obtaining a brittleness index comprehensively considering rock mineral components and mechanical properties; and 6, selecting rock debris while drilling of different well depths of the to-be-measured well, repeating the steps 1 to 5, and calculating to obtain the rock brittleness index of the reservoir section distributed continuously along the well depth. According to the method, coring operation is not needed, the influence of brittle mineral composition and rock elastic parameters on the brittleness is comprehensively considered, and the reservoir rock brittleness evaluation result is more accurate.

Owner:NORTHEAST GASOLINEEUM UNIV

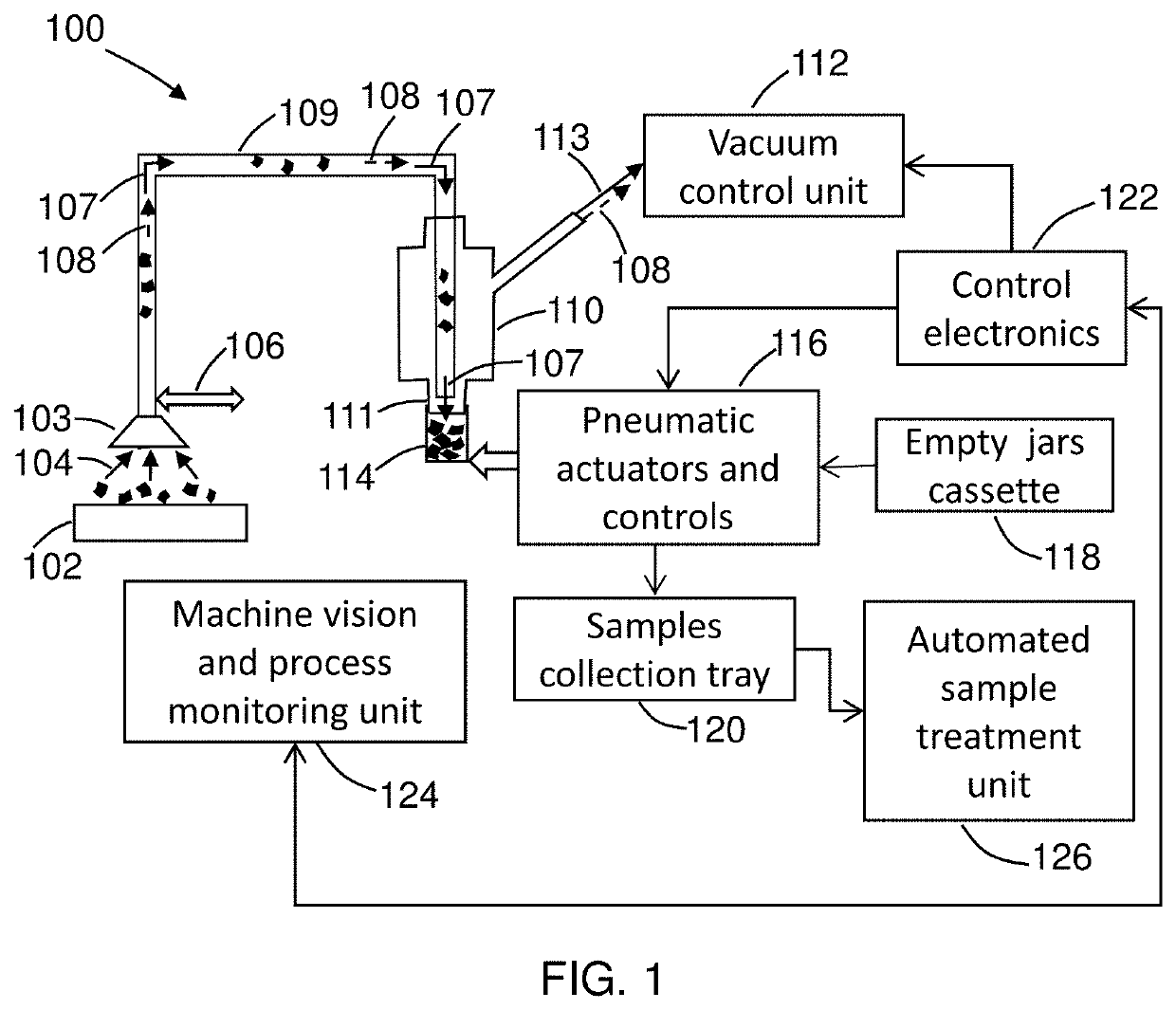

Apparatus for collecting samples of drill cuttings and method of use

An apparatus and a method for surface logging include a vacuum assisted transfer of drill cuttings from a shale shaker to sample jars. The cuttings samples are used for measurements to characterize formations in which a wellbore is drilled. The apparatus has an adjustable suction line that can be used to control moisture on the surface of the drill cuttings fragments. The method includes an automated sample collection and a high throughput sample treatment (e.g., washing or / and a controllable drying) to increase value of measurements.

Owner:STEPANOV VITAL +2

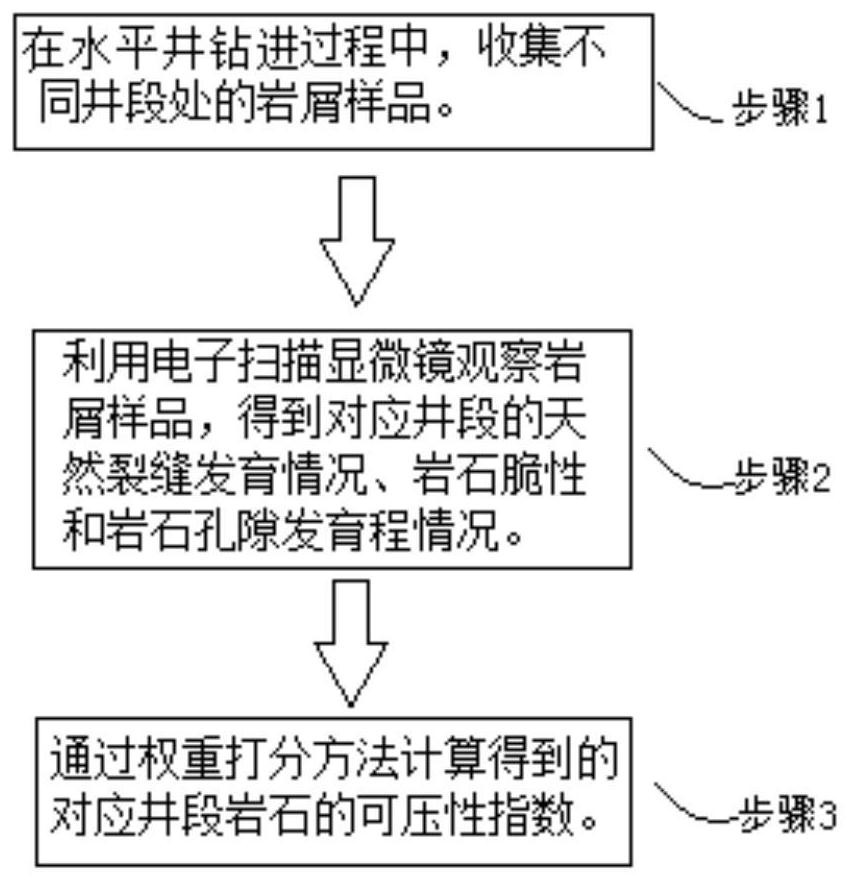

Method for judging compressibility of rocks in different well sections of horizontal well for developing natural fractured reservoir

The invention provides a method for judging compressibility of rocks in different well sections of a horizontal well for developing a natural fractured reservoir. The method for judging the compressibility of the rocks in different well sections of the horizontal well with the natural fractures comprises the steps that 1, in the drilling process of the horizontal well, rock debris samples at the different well sections are collected; 2, the rock debris samples are observed by using an electron scanning microscope to obtain the natural fracture development condition, the rock brittleness and the rock pore development process condition of the corresponding well section; and 3, the compressibility index of the rocks in the corresponding well section is calculated through a weight scoring method. According to the method, the rock debris samples of the whole horizontal section are collected and analyzed, the compressibility index of the rocks of the horizontal sections is obtained, then the compressibility distribution of the rocks of the horizontal sections is determined, the position with the high compressibility index can be selected as much as possible in the follow-up fracturing design to set a perforation point, and the fracturing segmented optimization design is completed.

Owner:PETROCHINA CO LTD

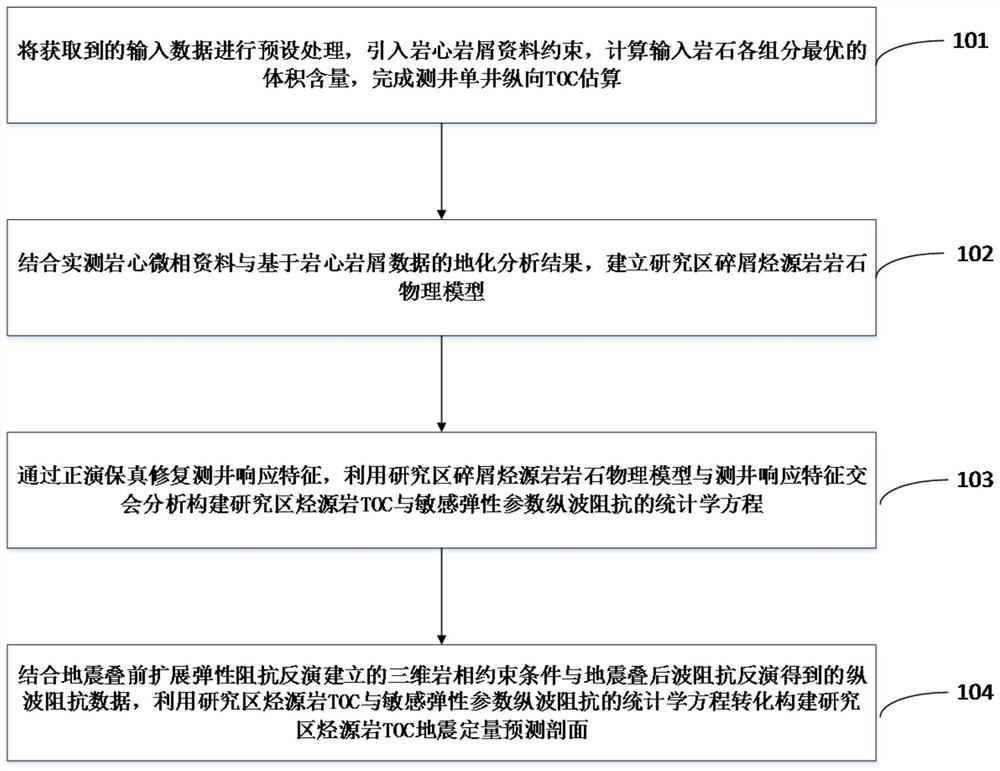

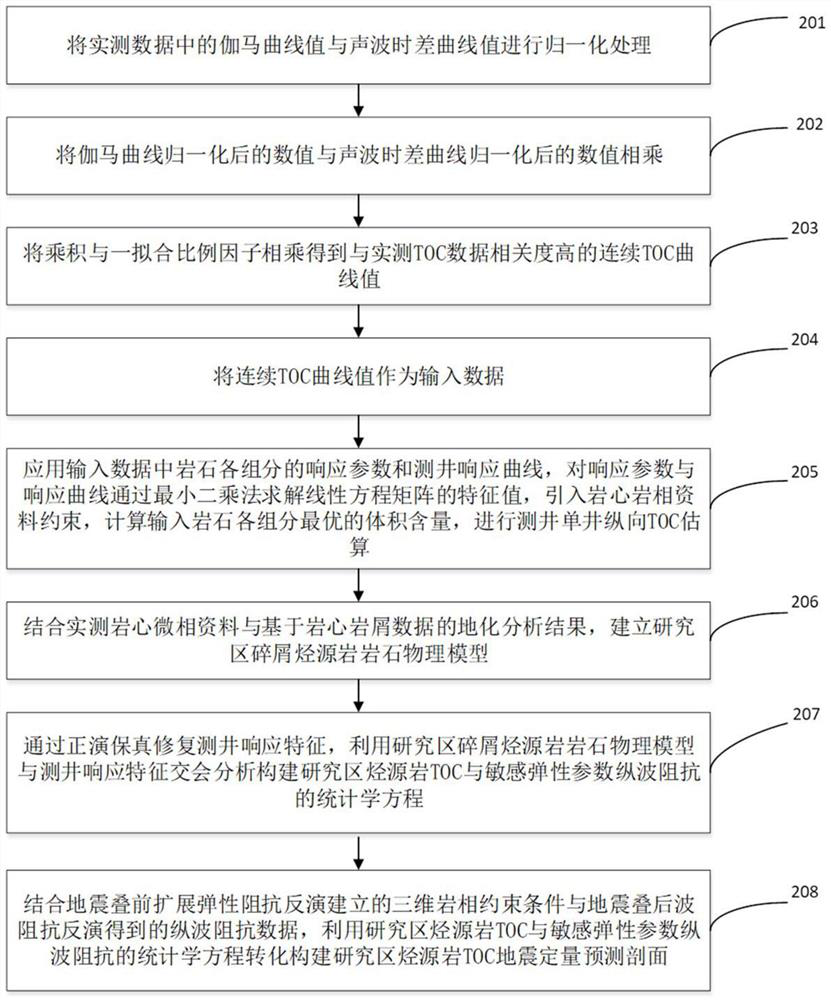

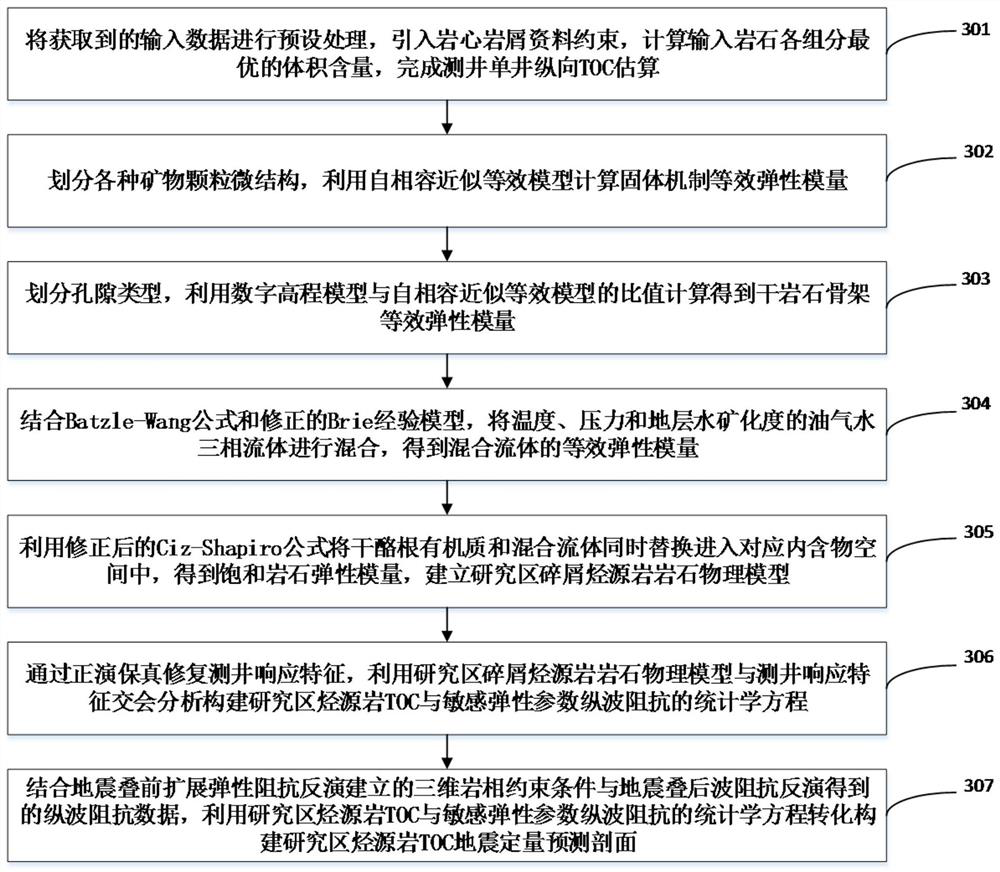

Geophysical Quantitative Prediction Method, Device, Equipment and Storage Medium of Source Rock Organic Carbon

ActiveCN110501744BHigh precisionImproving the Accuracy of Quantitative Earthquake PredictionMaterial testing goodsSeismic signal processingRock coreWell logging

The embodiment of the present invention discloses a geophysical quantitative prediction method, device, equipment and storage medium of source rock organic carbon. The method includes: pre-processing the obtained input data, introducing the constraints of the measured core cuttings data, calculating the optimal volume content of each rock component, and completing the single well longitudinal TOC estimation; combining the measured core microfacies data with the core-based Based on the geochemical analysis results of cuttings data, a petrophysical model of clastic source rocks in the study area was established; the logging response characteristics were repaired through forward modeling and fidelity, and the TOC sensitive statistical equation of the source rocks in the study area was constructed by cross-analysis of petrophysics; Pre-stack inversion establishes three-dimensional lithofacies constraints, combined with the P-wave impedance data obtained by post-stack inversion, and uses TOC sensitive statistical equation transformation to construct a source rock TOC seismic quantitative prediction section. The technical scheme of the embodiment of the present invention achieves the effect of improving the seismic quantitative prediction accuracy of source rock organic carbon while taking into account the effect of realization efficiency.

Owner:SHANGHAI BRANCH CHINA OILFIELD SERVICES

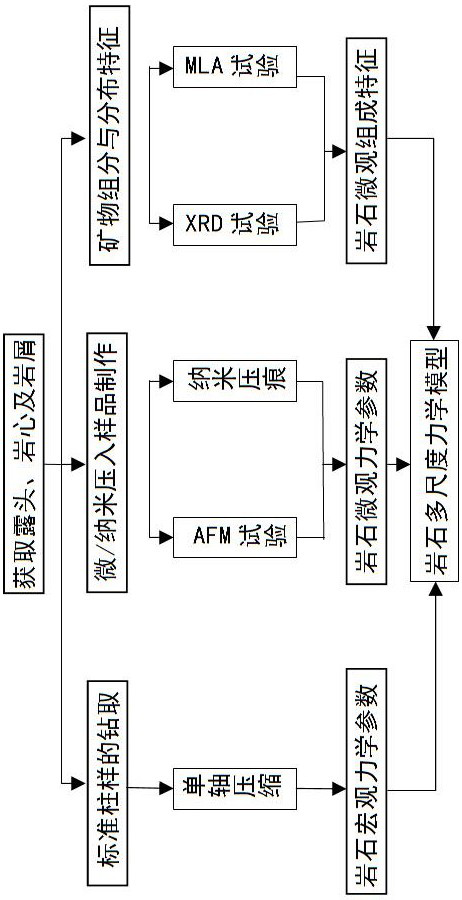

Method for determining macroscopic modulus of shale through fine/micro mechanical test

PendingCN113029746AFast Prediction of Elastic ModulusTo overcome the poor timeliness of preparationMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesMacroscopic scaleYoung's modulus

A method for determining the macroscopic modulus of shale through a fine / micro mechanical test comprises the following steps: obtaining a macroscopic test result through a uniaxial compression test, and sequentially carrying out nanoindentation test and atomic force microscope test on a rock slice to obtain the Young modulus of a sample under the microscopic scale and the microscopic scale, and carrying out coupling analysis on the obtained data and carrying out macro-scale upgrading. Herein, results of the nanoindentation and the atomic force microscope are first analyzed to determine the fine / microscale modulus of the shale; and then, based on MLA result, the mineral compositions is classified according to modulus difference, and t mechanihecal parameters under a microscopic scale and a microscopic scale are updated by adopting a Mori-Tanaka homogenization method so as to determine the macroscopic modulus of the shale. The method can be used for rapidly predicting the mechanical parameters such as the elastic modulus and the hardness of the material, the rock debris can be used for performing MLA, AFM and nanoindentation tests in the drilling process to obtain macroscopic mechanical parameters, the test cost is reduced, and the test period is greatly shortened.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

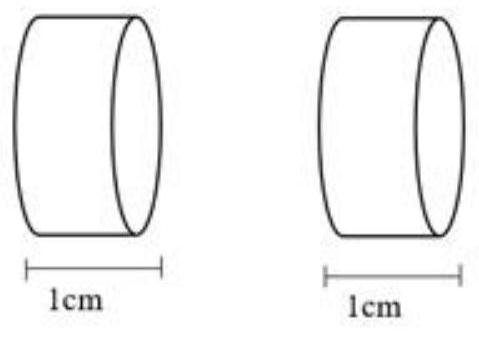

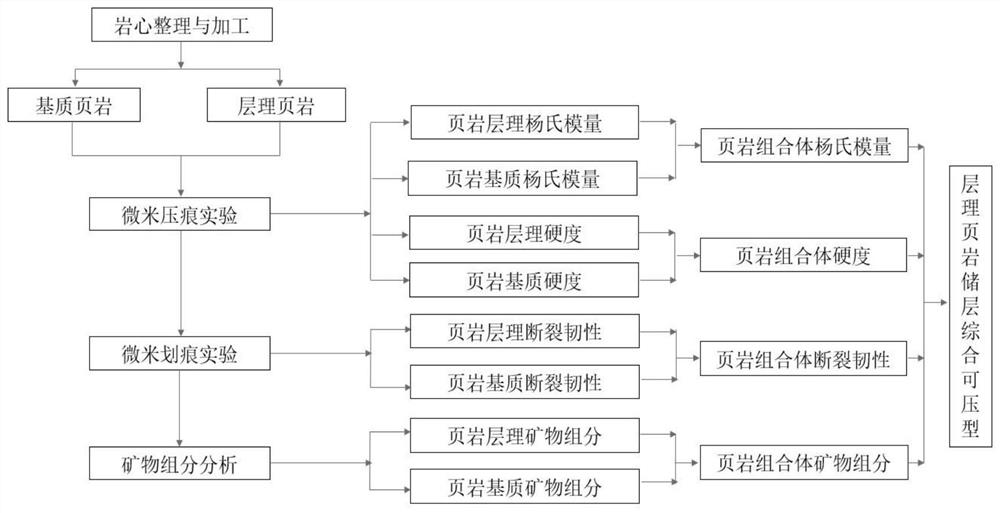

Method for evaluating compressibility of stratified shale reservoir based on micromechanics experiment

ActiveCN114018697ARepeatableReduce dependenceMaterial strength using tensile/compressive forcesInvestigating material hardnessRock coreEngineering

The invention discloses a method for evaluating the compressibility of a stratified shale reservoir based on a micromechanics experiment. The method comprises the following steps: collecting a standard shale rock column sample, and processing the shale rock column sample to respectively obtain a shale stratified test pattern and a shale matrix test pattern; carrying out polishing treatment; carrying out a micrometer indentation experiment on the processed shale core, and obtaining the hardness parameters and Young modulus of shale bedding and a shale matrix; enabling the processed shale core to be subjected to a micron scratch experiment, and obtaining fracture toughness parameters of a shale bedding and a shale matrix; observing the drilled stratified shale sample, and obtaining the stratified thickness through statistical geology and fractal theory calculation; carrying out mineral component analysis on the shale debris to obtain shale mineral component characteristics; the method comprises the following steps: constructing a physical model of the bedding shale combination, carrying out scale upgrading and calculation on rock mechanical parameters to obtain parameters of the bedding shale combination, and obtaining comprehensive evaluation indexes of the compressibility of the bedding shale through a combination weight method to carry out compressibility judgment on a region to be fractured.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Rock elastic parameter determination method based on while-drilling rock debris logging data

ActiveCN113138106AReduced cost of coring operationsEnables quantitative characterizationPreparing sample for investigationEarth material testingRock coreWell logging

The invention relates to a rock elastic parameter determination method based on while-drilling rock debris logging data. The method comprises the steps: 1, obtaining three-dimensional digital rock core microscopic parameters according to the while-drilling rock debris logging data to be logged; 2, generating a three-dimensional digital rock core sample according to the obtained microscopic parameters of the rock debris while drilling; 3, carrying out a uniaxial or triaxial compression numerical experiment on the three-dimensional digital rock core sample to obtain a three-dimensional digital rock core stress-strain curve, and calculating the elastic modulus and Poisson's ratio of the rock core; and 4, selecting rock debris while drilling of different well depths of the to-be-measured well, and repeating the steps 1 to 3 to obtain the continuous rock elasticity modulus and Poisson's ratio of the to-be-measured well distributed along the well depths. According to the method, continuous rock elasticity modulus and Poisson's ratio distributed along the well depth can be obtained by analyzing while-drilling rock debris data along the well depth and carrying out numerical simulation, and the problem that basic data of whole-well rock mechanical calculation is missing can be effectively solved.

Owner:NORTHEAST GASOLINEEUM UNIV

Dry-drilling drill bit and using method thereof

InactiveCN111236850AImprove construction efficiencyAvoid enteringDrill bitsBorehole/well accessoriesLithologyWell drilling

The invention relates to the technical field of soft-formation anhydrous environment drilling construction, in particular to a dry-drying drill bit and a using method thereof. The dry-drying drill bitis a hollow cylindrical structure; a drilling and milling head is fixedly connected to the center position in a hollow cylindrical structure of the dry-drying drill bit; and the drill bit end part ofthe drilling and milling head abuts against the drill bit end part of the dry-drying drill bit. The dry-drying drill bit can take out rock debris from the center part of the drill bit without drilling fluid, transmits the rock debris into a sand catching basket above the drill bit, and returns to ground; a rock layer, around the periphery of the dry-drying drill bit, of the hollow cylindrical structure is firstly crushed by the dry-drying drill it, and the drilling and milling head crushes a rock layer on the middle part of the hollow cylindrical structure while height reaches the drill bit end part of the drilling and milling head; and the rock debris is transmitted into the sand catching basket above the drill bit, and returns to ground. The dry-drying drill bit disclosed by the invention is suitable for drilling construction of a surface layer with low drilling speed requirements and relatively soft lithology, and is high in construction efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

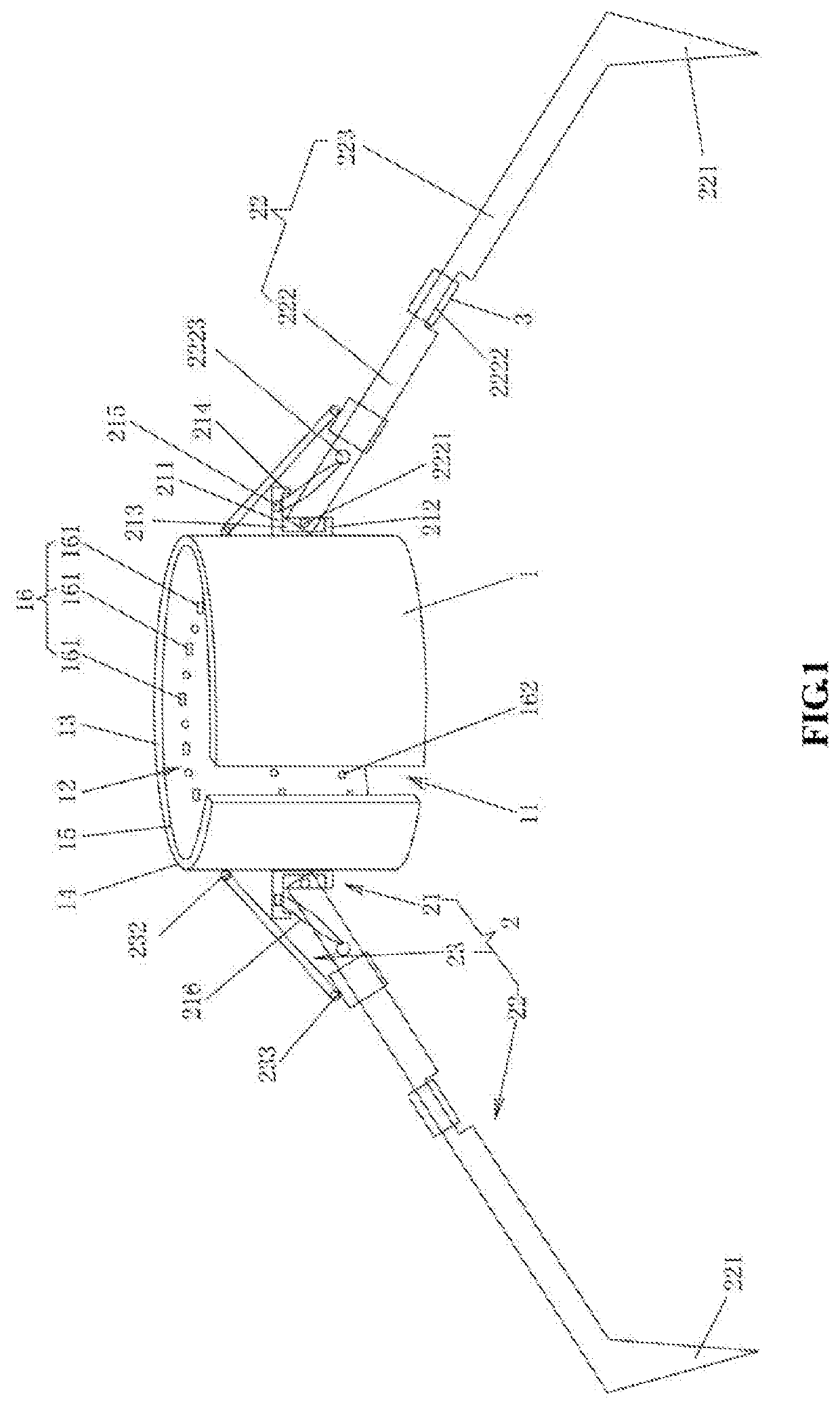

Apparatus and method for cleaning rock debris when deep-water surface drilling is done

ActiveUS20200072003A1Reduce operational riskReduce difficultyEarth drilling toolsDrill bitsMining engineeringWell drilling

The present disclosure provides an apparatus and method for cleaning rock debris when deep-water surface drilling is done. The apparatus for cleaning rock debris when deep-water surface drilling is done comprises: an open barrel having an open through groove which is axially provided; a plurality of debris cleaning mechanisms connected to the open barrel at an interval in a circumferential direction of the open barrel, wherein each of the debris cleaning mechanisms comprises: a fixed block connected to an outer wall of the open barrel; a debris cleaning leg having one end rotatably connected to the fixed block, and the other end provided with a debris cleaning impeller; and a pull rod having one end connected to the outer wall of the open barrel above the fixed block, and the other end movably connected to the debris cleaning leg. The present disclosure not only cleans a large amount of rock debris accumulated around the seabed surface conduit while drilling is done in the deep-water surface drilling process, but also achieves the purpose of continuous working in the deep-water surface drilling process, without the need of frequent tripping in and out in midway to adjust the position of the apparatus for cleaning rock debris when deep-water surface drilling is done.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

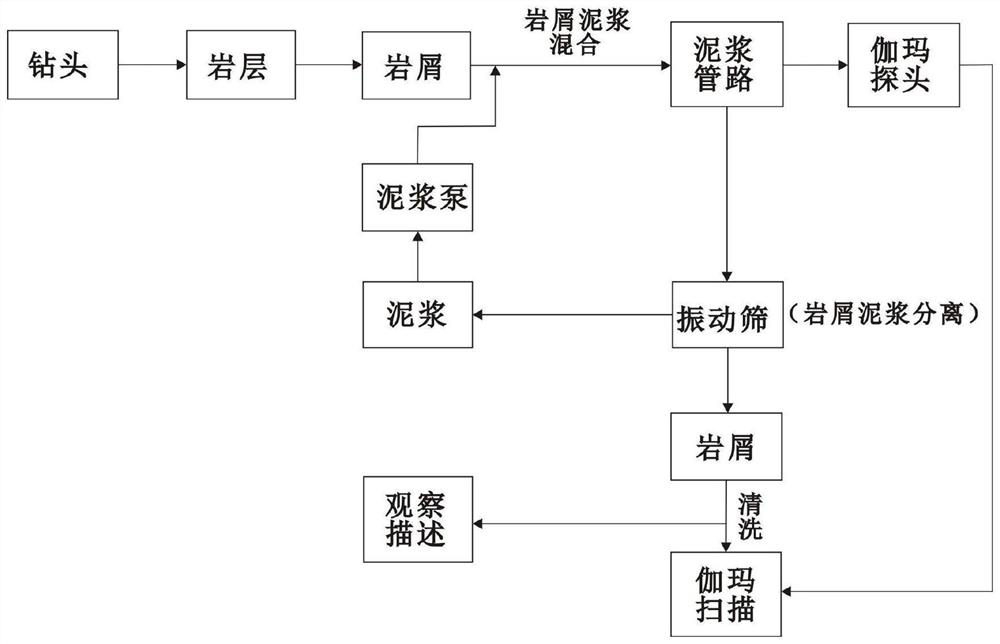

Comprehensive logging method for in-situ leaching sandstone type uranium ore

PendingCN114235871AImprove exploration efficiencyImprove drilling efficiencyMaterial analysis using wave/particle radiationLithologyData acquisition

The invention discloses a comprehensive logging method for in-situ leaching sandstone type uranium ore. The method comprises the following steps: a, core-free drilling; b, rock debris logging; c, drilling fluid logging; d, X-ray diffraction total rock mineral analysis; carrying out X-ray diffraction total rock mineral analysis; e, performing natural gamma measurement; f, data acquisition; the data acquisition unit is used for acquiring measurement parameters in a drill hole; and according to the collected data, lithology is determined, and a specific stratum is divided. According to the method, the mode of combining the core-free drilling technology and the rock debris logging technology is adopted, drilling construction is carried out through the core-free drilling technology, then the target mine is found through the rock debris logging technology, the drilling efficiency is improved, and the effect of fast and direct prospecting is achieved.

Owner:核工业二三〇研究所

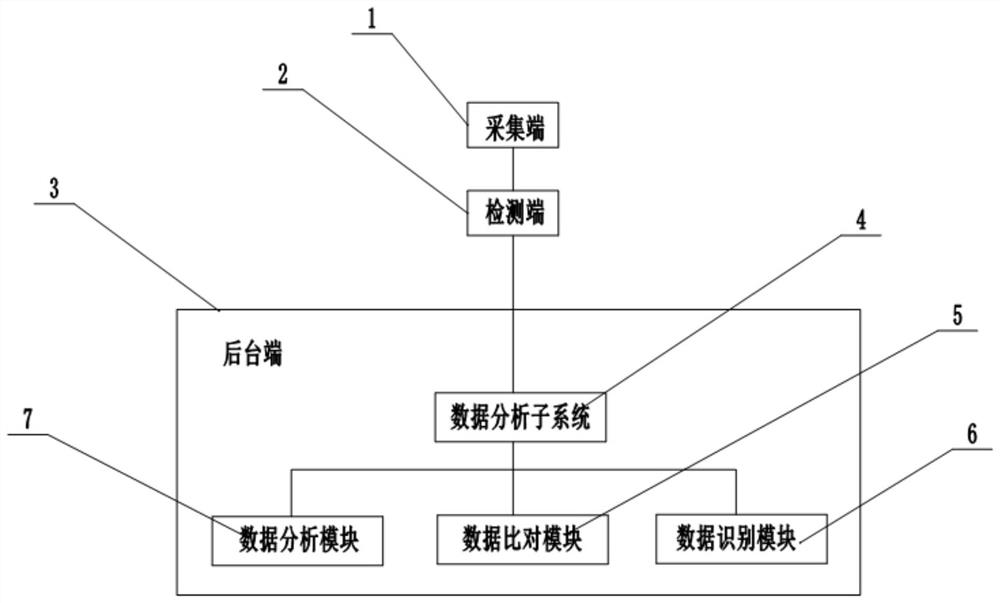

Rock debris logging detection system

ActiveCN112901156AFast and effective accurate identificationBorehole/well accessoriesWell drillingPetroleum oil

The invention relates to the technical field of petroleum drilling, and particularly relates to a rock debris logging detection system. The rock debris logging detection system comprises a collecting end, a detecting end and a background end, wherein a plurality of collecting units of the collecting end are used for collecting rock debris samples of all stratums; the detecting end is used for detecting the rock debris samples of the stratums at all depth points and generating rock debris detection information; the background end is used for receiving and processing the rock debris detection information from the detecting end; a data analysis subsystem of the background end can calculate the total value of element radioactive energy according to the rock debris detection information of the stratums at all the depth points and draw a to-be-compared stratum map; and a data comparison module of the data analysis subsystem can extract a to-be-compared stratum curve in the to-be-compared stratum map, calculate curve similarity values of the to-be-compared stratum curve and all reference stratum property curves and output corresponding stratum properties according to a reference stratum property map of the reference stratum property curve closest to the to-be-compared stratum curve.

Owner:思凡(上海)石油设备有限公司 +1

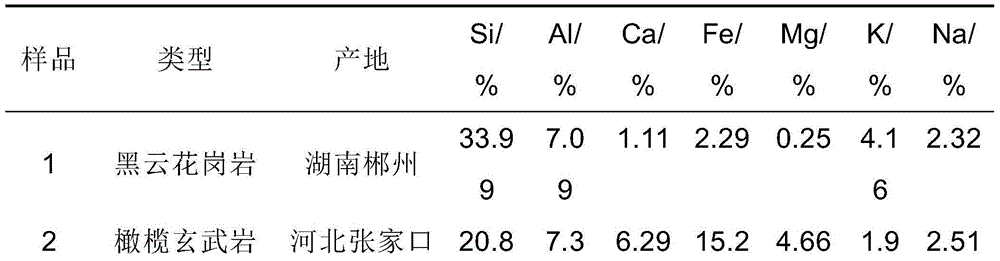

A Method for Evaluating Rock Drillability Using Element Content of Cuttings

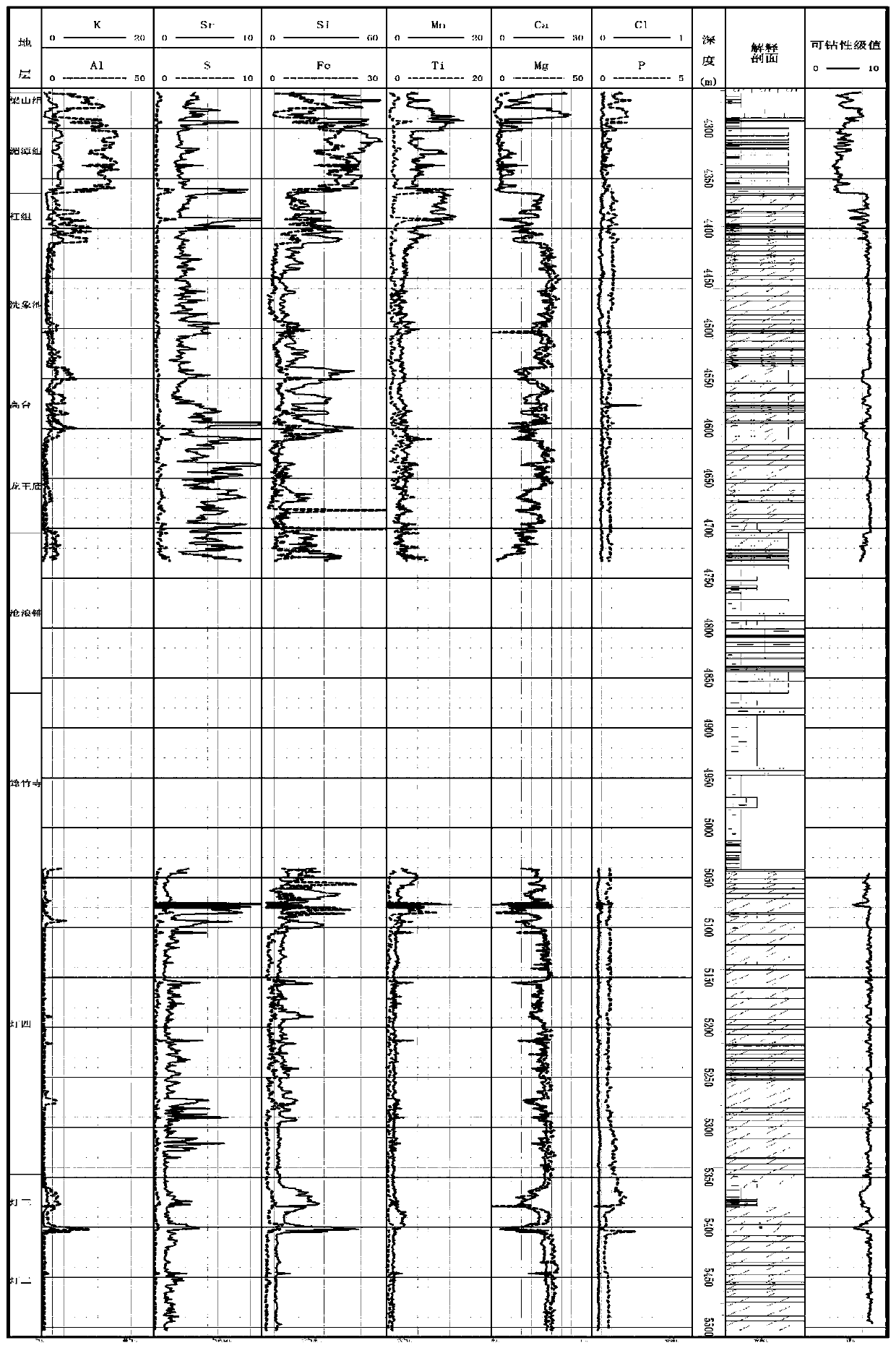

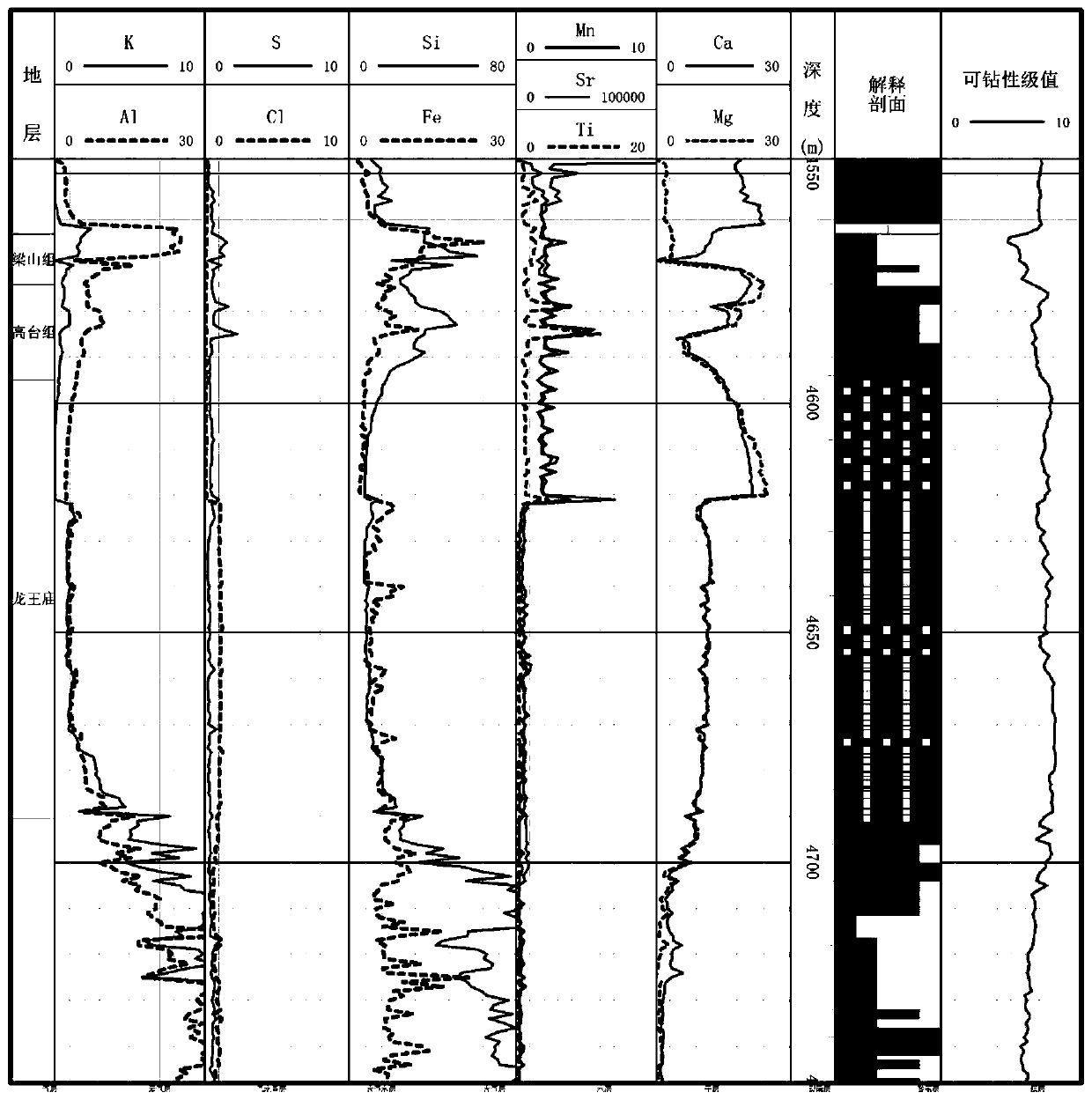

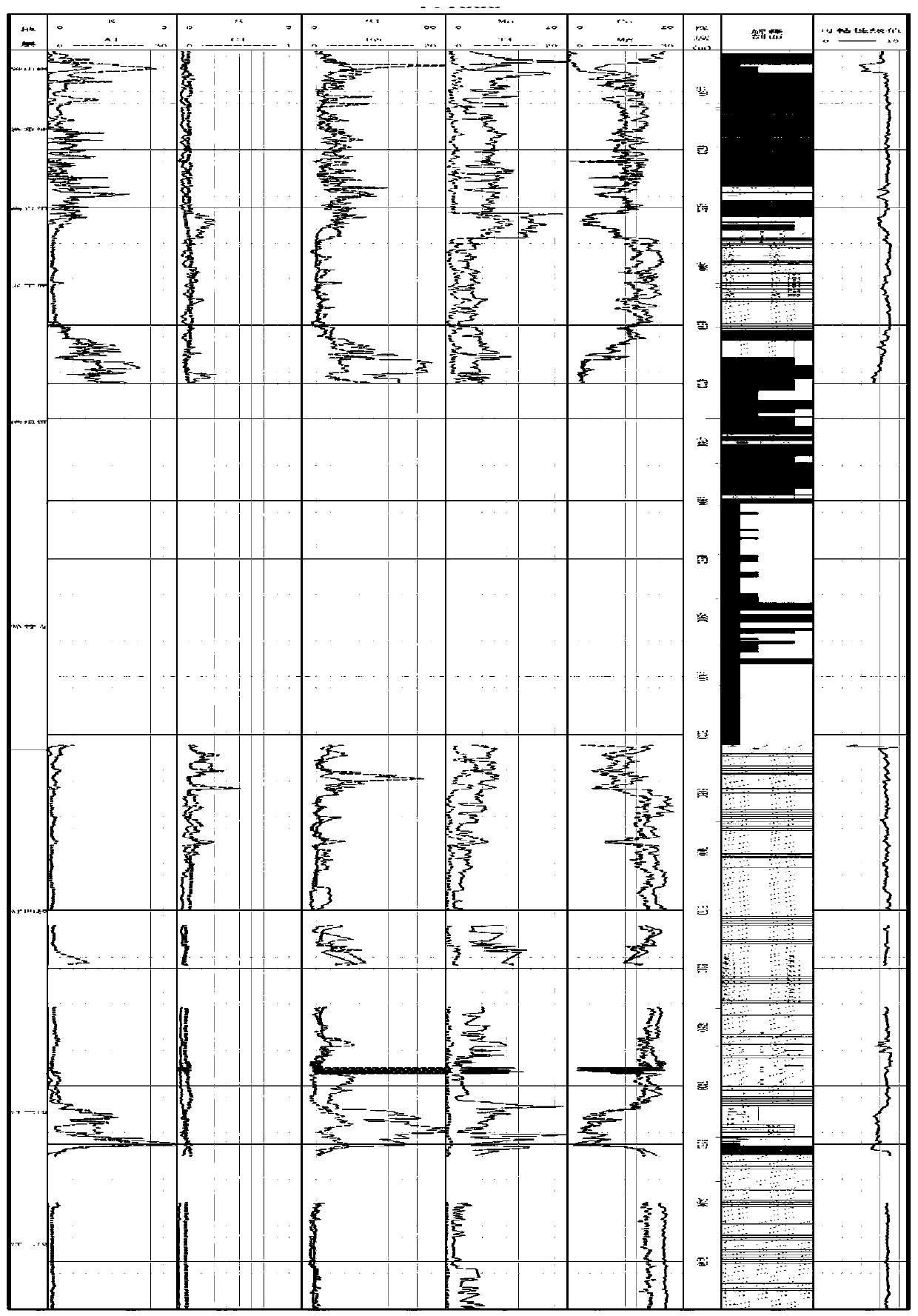

The invention provides a method for evaluating the rock drillability by using rock debris element contents, and relates to the field of geological exploration. The method is low in cost, simple and convenient to operate and high in real-time performance, and has important significance for drill bit selection, drilling parameter optimization and drilling cost reduction. The method for evaluating the rock drillability by using the rock debris element contents specifically comprises the steps of analyzing main chemical compositions and contents thereof of the rock, measuring chemical element compositions and contents thereof of drilling rock debris in an area to be measured, screening 10-12 elements which are most related with the lithology, drawing an element content and lithologic section of each stratum, and acquiring a curve variation diagram of a rock drillability grade value by using logging information; further screening out 7 elements related with the rock drillability from the above 10-12 elements according to the curve variation diagram, performing regression analysis according to the element content and drillability grade value data of the curve variation diagram, and acquiring a calculation model for evaluating the rock drillability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

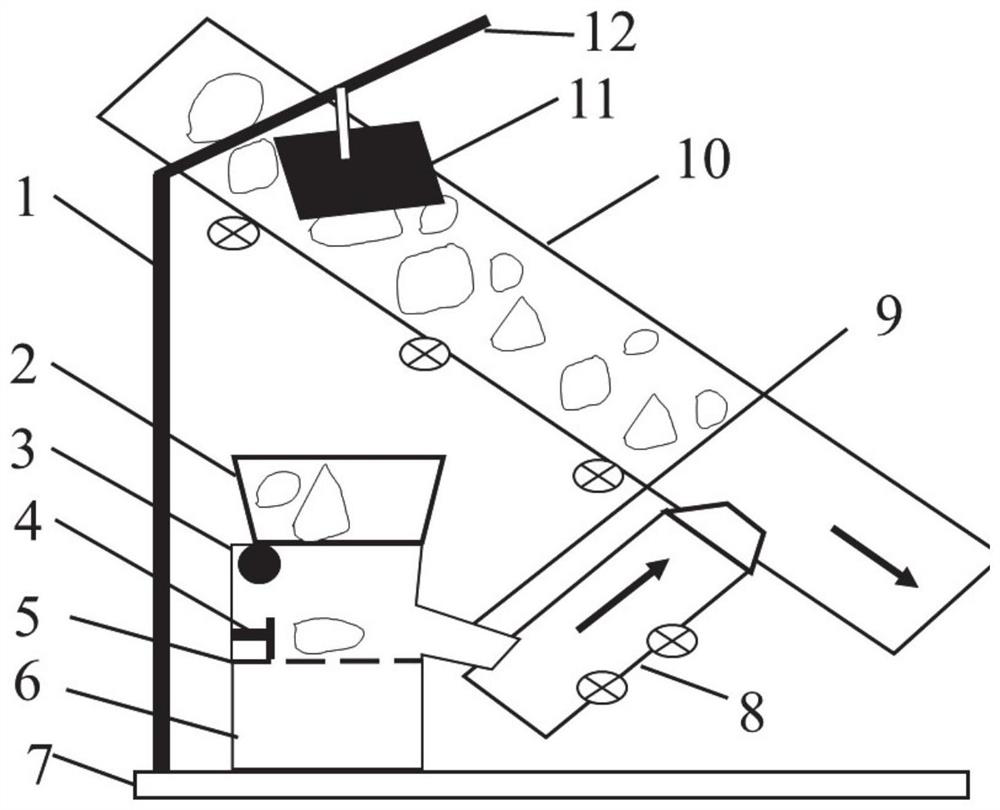

Rock slag quartz content testing system and method for TBM

ActiveCN112666197AImprove automationEasy to integrateMaterial analysis using wave/particle radiationFluorescence spectraConveyor belt

The invention provides a rock slag quartz content testing system and method for a TBM. The rock slag quartz content testing system comprises a base and a control terminal which are arranged at the position close to a TBM conveyor belt, wherein the base is at least fixedly provided with a rock debris sample pickup mechanism and an X-ray fluorescence spectrum analysis mechanism which communicate with the control terminal; and the rock debris sample pickup mechanism is used for picking up a rock debris sample from the TBM conveyor belt and transmitting the rock debris sample to the X-ray fluorescence spectrum analysis mechanism, and the control terminal is used for determining the content of rock debris quartz according to the received fluorescence spectrum information. The content of quartz or other minerals in rock slag in TBM tunneling can be obtained in real time, so that the quality of rock mass before drilling is accurately evaluated, the quality grade of the rock mass before drilling can be forecasted, an unfavorable geologic body in front of a tunnel face can be found in time, a construction scheme can be optimized according to a real-time test result, and reference is provided for guaranteeing tunnel construction safety.

Owner:SHANDONG UNIV +1

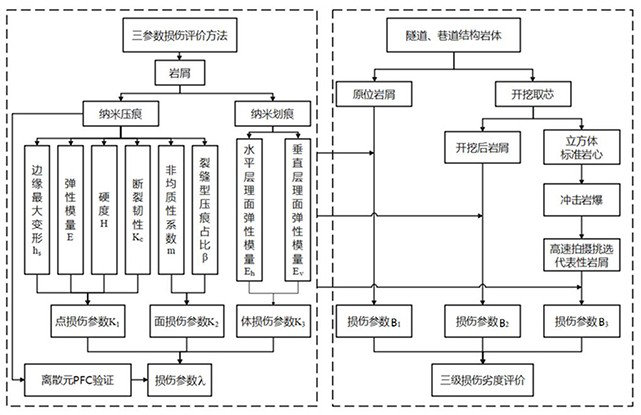

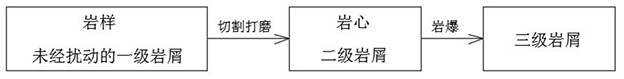

Method for evaluating rockburst local damage deterioration based on nanoindentation experiment

ActiveCN113935101AAccurate Damage AssessmentGeometric CADDesign optimisation/simulationUniaxial compressionRock core

The invention discloses a method for evaluating rockburst local damage deterioration based on a nanoindentation experiment. The method comprises the following steps: acquiring a rock sample and first-grade rock debris; cutting and grinding the rock sample to take a rock core, and collecting secondary rock debris generated in the cutting and grinding process; carrying out three-direction six-surface loading on the processed rock sample, inflating the processed rock sample when a certain load is loaded, carrying out precise blasting to carry out a rock burst impact test, and selecting third-stage rock debris in the rock burst impact test; polishing the three kinds of rock debris, and obtaining a sample with high flatness; respectively acquiring point damage parameters, surface damage parameters and body damage parameters of the three kinds of rock debris; constructing a standard rock core model and performing uniaxial compression to obtain a fracturing effect, and performing simulation inversion for multiple times to obtain a rock brittleness index; respectively calculating debris damage degrees of the three rock debris through three-parameter damage evaluation; according to the method, the rock debris is subjected to micromechanical property analysis through the nano indentation and the nano scratch to obtain three-layer damage parameters, and rock damage evaluation and damage deterioration are accurately obtained.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

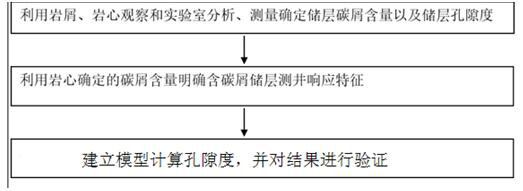

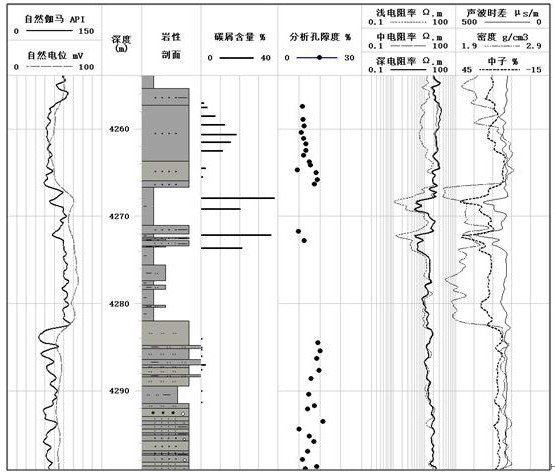

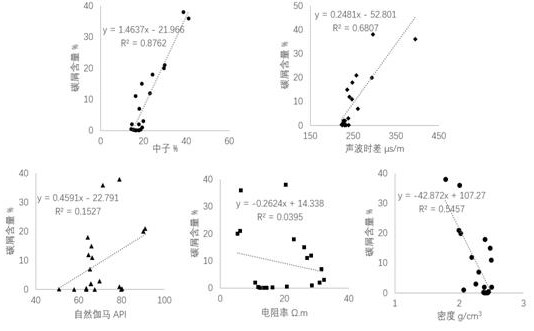

Method for calculating porosity of carbon-scrap-containing clastic rock reservoir through geophysical logging

PendingCN113720745AImprove consistencyImprove the accuracy of physical property evaluationPermeability/surface area analysisGeological measurementsPorosityWell logging

The invention relates to the technical field of petroleum geology exploration and development, in particular to a method for calculating porosity of a carbon-scrap-containing clastic rock reservoir through geophysical logging. According to the method, comprehensive analysis is carried out on the reservoir carbon scrap content obtained according to the rock debris, well drilling coring and laboratory measurement data, logging recognition characteristics of the carbon scrap-containing clastic rock reservoir are determined, the porosity calculation model is established, and the obtained porosity value is high in accuracy. According to the method, the reservoir physical property evaluation precision is obviously improved, a good application effect is achieved, and a reliable basis is provided for petroleum and development.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com