Integrated drilling tool for crushing and cleaning drilling borehole rock debris deposit bed

A technology of bed breaking and wellbore rock, which is applied in the field of integrated drilling tools, can solve problems such as the misalignment of the axis of the drilling tool and the axis of the wellbore, failure to meet the requirements of well washing and carrying rock, and drill sticking to achieve enhanced wear resistance , prevention of subsidence and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

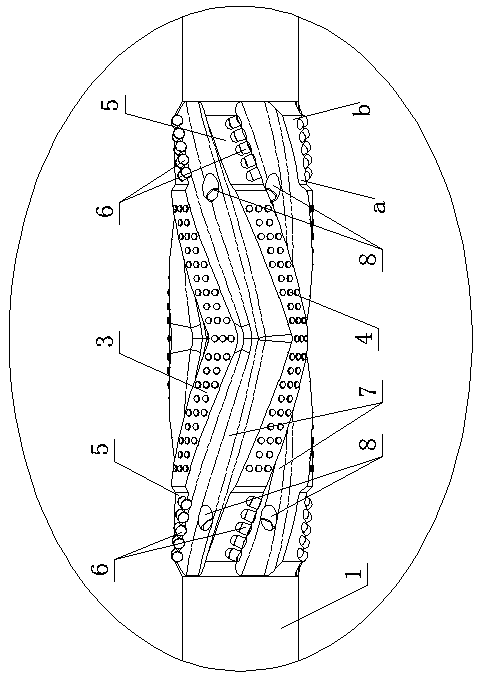

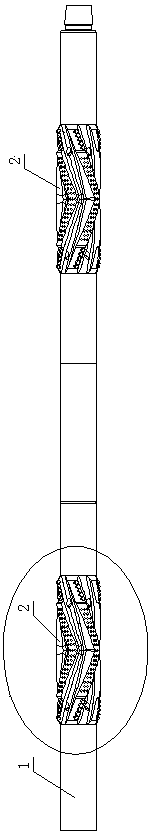

[0013] Such as Figure 1-2 As shown, the integrated drilling tool for crushing and cleaning of drilling wellbore cuttings sedimentation bed of the present invention is composed of at least one scraping and cleaning short connection 2 connected in series between drill pipes 1.

[0014] The scraping and cleaning short-circuit 2 is a cylindrical tube body whose outer diameter is slightly larger than the outer diameter of the drill rod 1 connected at both ends. 3 to 9 ribs are arranged longitudinally on the ring wall of the scraping and cleaning short-circuit 2. Spiral wing 3, the ribbed spiral wing 3 is arranged in a longitudinal V-shaped circumferential interval, and its edge surface is evenly distributed with cemented carbide bumps 4, the ribbed spiral wing 3 has a 45° chamfer near the middle end surface, each Both ends of the V-shaped spiral wing 3 are connected with cutting edges 5 that are recessed and warped. Each cutting edge 5 is a homeopathic extension of the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com