Shale uniaxial compressive strength evaluation method based on rock debris micro-nano indentation experiment

A uniaxial compressive strength and indentation test technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, test material hardness, etc., can solve the problem of inability to use downhole core comprehensive testing, high risk and complicated process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

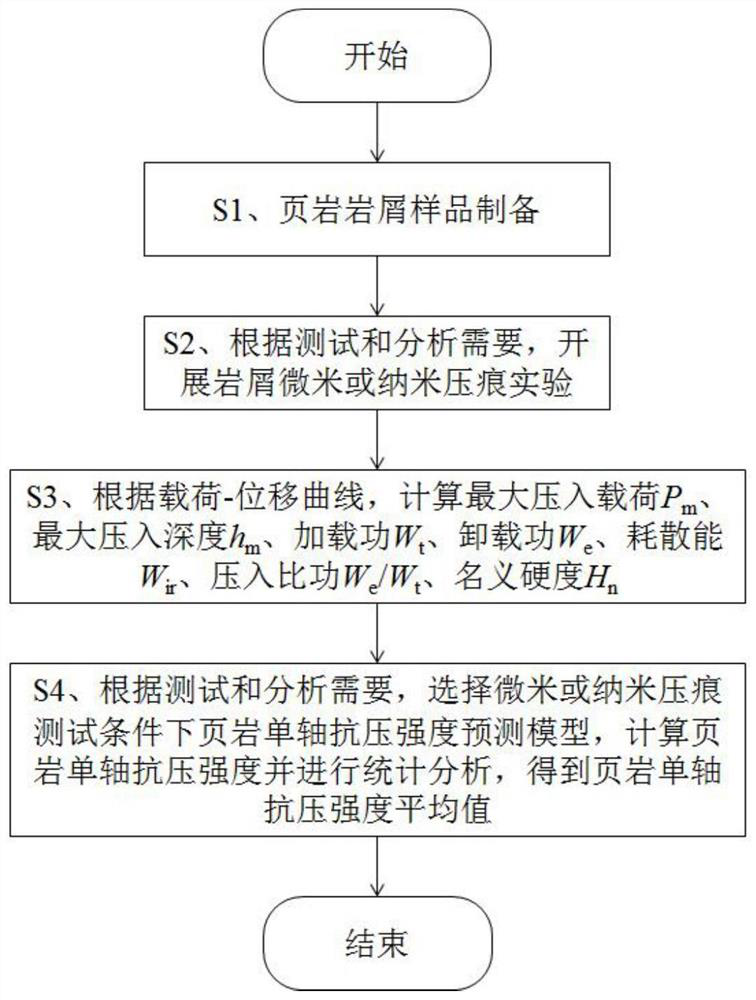

[0056] Such as figure 1 As shown, the shale uniaxial compressive strength evaluation method based on cuttings micro-nano indentation experiment of the present invention comprises the following steps:

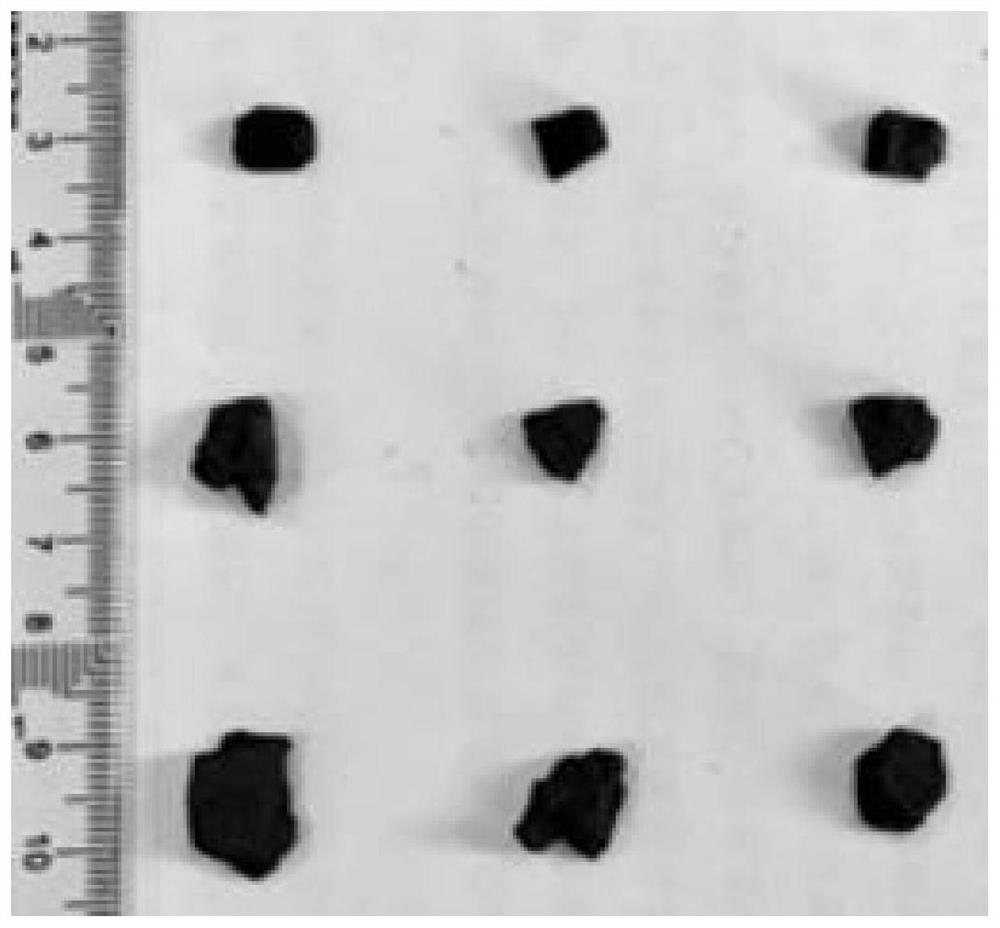

[0057] S1. Collect cuttings samples from shale reservoirs, select cuttings with regular shape, size not less than 2mm and no obvious cracks, clean the surface dust and dry them in a vacuum drying box. The processed cuttings Samples such as figure 2 shown;

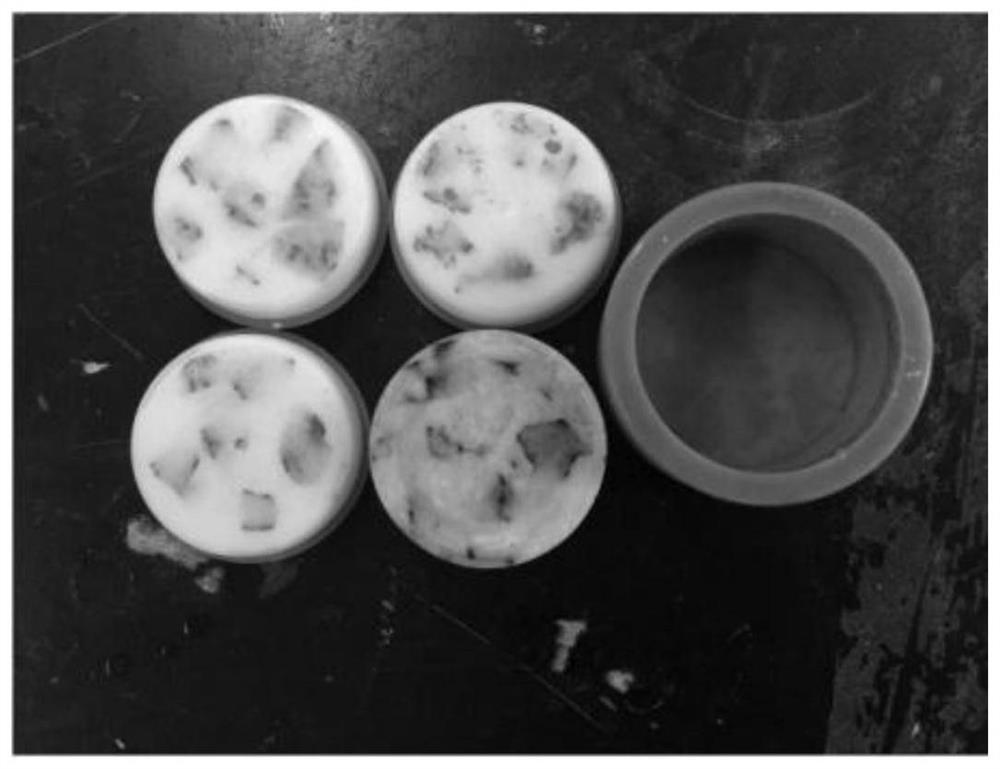

[0058] S2. Heat the epoxy resin binder and the modified amine hardener to 40°C, and then mix them according to the mass ratio of 3:1, fully fuse to form a mixed glue, and then pour it into the mold;

[0059] S3, embed the cuts sample that is screened out, make the cuts sample fully contact with the mixed glue, let it stand for more than 24 hours, and obtain the cemented cuts sample after the foam in the mixed glue is eliminated and completely cured, such as image 3 shown;

[0060] S4. After the cuttings sample is fully ...

Embodiment 2

[0090] The method for evaluating the uniaxial compressive strength of shale based on the cuttings micro-nano indentation experiment of the present invention comprises the following steps:

[0091] S10, using the same steps in Example 1 to prepare a cuttings sample of the shale reservoir;

[0092] S20. Use the Agilent U9820ANano Indenter G200 nano-indenter, select the Boss indenter, and keep the contact position between the indenter and the cuttings sample greater than 2mm from the cuttings boundary;

[0093] S30. Use the control system to make the pressure head approach the surface of the cuttings sample at a constant rate. When the pressure head is in contact with the surface of the cuttings sample, load at a constant loading rate of 20mN / min, and stop loading when the maximum load is 400mN And unload, the system automatically records the change of load and loading depth;

[0094] S40. Carry out gridded lattice experiments on the sample surface to obtain 117 sets of nanoinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com