While-drilling down-hole measurement for substance in stratum

A material and formation technology, applied in the field of downhole measurement, can solve the problem of neglecting the cross flow in the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

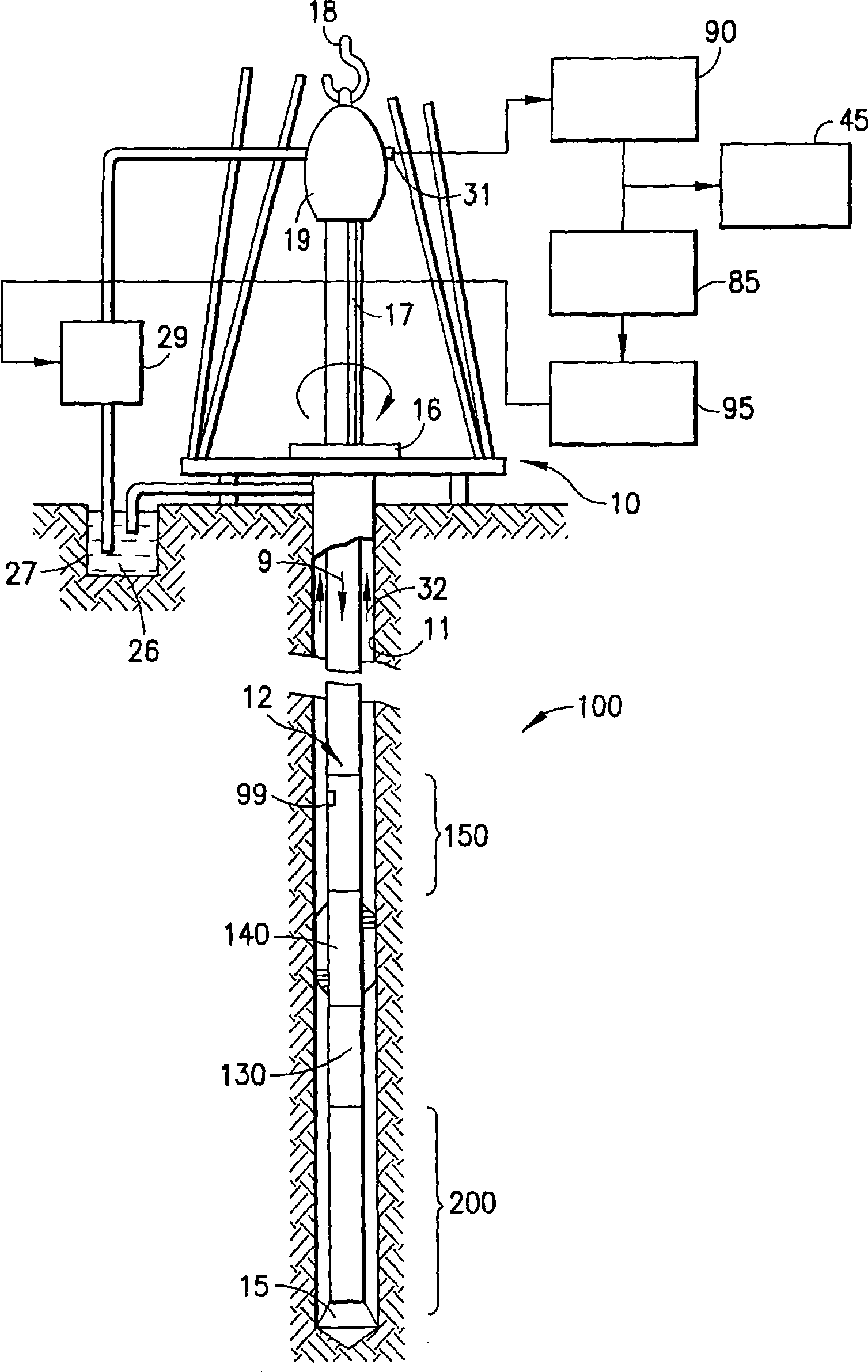

[0019] refer to figure 1 , shows a measurement-while-drilling device that may be used in a practical embodiment of the invention. [As used herein, unless otherwise indicated, measurement while drilling (also referred to as measurement while drilling or logging while drilling) is intended to include: Borehole Cords) for measurements in Earth boreholes. ] The platform and iron tower 10 are located above a borehole 11 formed in the earth using rotary drilling. A drill string 12 is suspended within the borehole and includes a drill bit 15 at its lower end. A drill string 12 and a drill bit 15 attached thereto are rotated by means of a rotary table 16 (powered by means not shown) engaging a drive drill rod 17 at the upper end of the drill string. The drill string hangs from a hook 18 attached to a moving block (not shown). The drive rod is connected to the hook via a swivel 19 which allows the drill string to rotate relative to the hook. Alternatively, the drill string 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com