Method for evaluating compressibility of stratified shale reservoir based on micromechanics experiment

A technology of micro-mechanics and shale reservoirs, applied in the direction of applying stable tension/pressure to test material strength, scientific instruments, strength characteristics, etc. Problems such as the difficulty in processing rock standard size cores, etc., achieve the effects of reducing dependence, speeding up the experimental test cycle, and facilitating parallel experimental analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

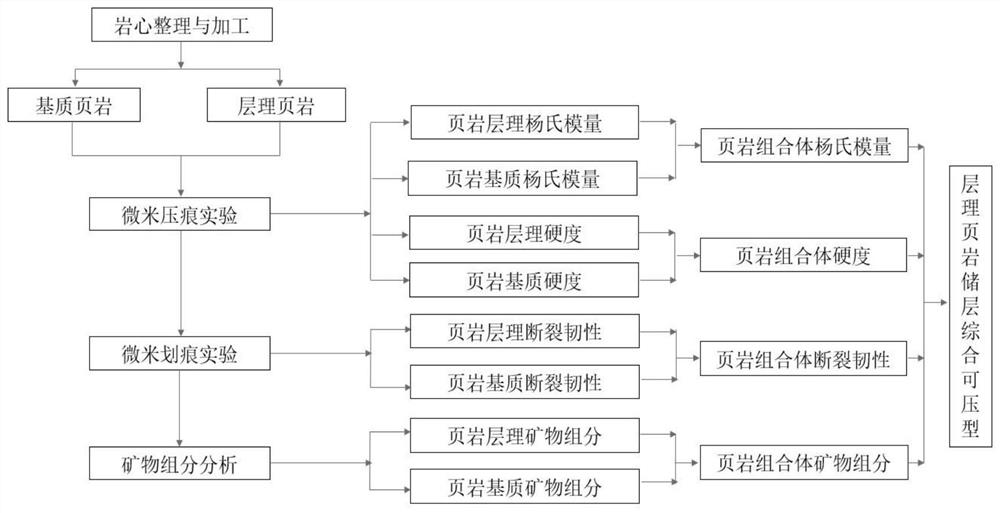

[0080] like Figure 1-8 As shown, a method for evaluating the compressibility of bedding shale reservoirs includes the following steps: Step 1, collecting shale rocks and processing shale core column samples;

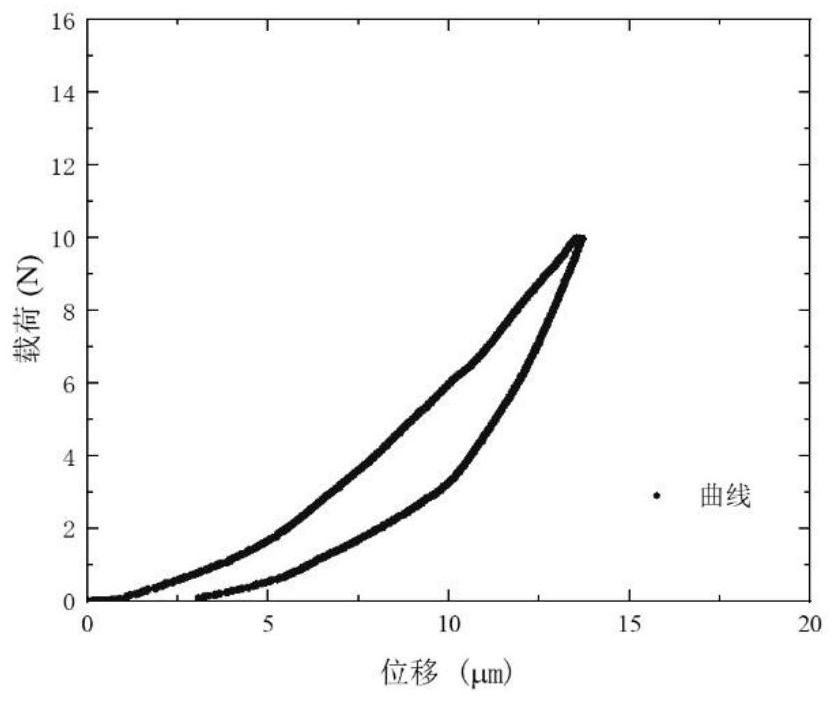

[0081] (1) Collect rock samples from the research key horizons. After selecting the test samples to be tested and processing the standard-sized core column samples, the entire rock column samples are processed separately to obtain shale bedding samples and shale matrix samples. It is used to carry out micro-indentation and micro-scratch experiments respectively, and obtain mechanical parameters of parallel experiments. The shale samples are resin-wrapped sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com