Laser-cladding etching preparation method for 3D-printing formed part

A technology of laser cladding and 3D printing, which is applied in the direction of additive manufacturing, improvement of process efficiency, energy efficiency, etc., to achieve high degree of automation, large adjustable range of roughness and hole distribution density, improved wear resistance and lubrication performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

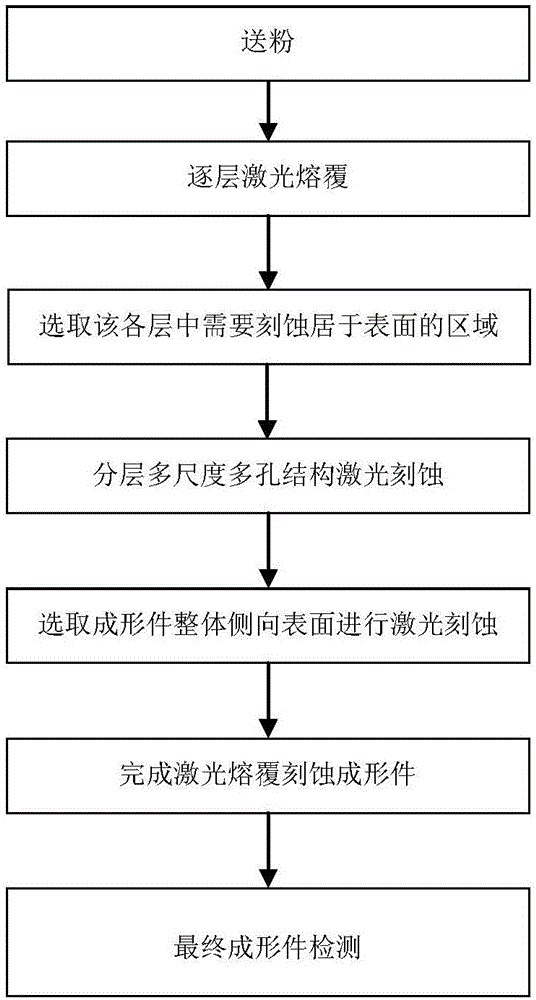

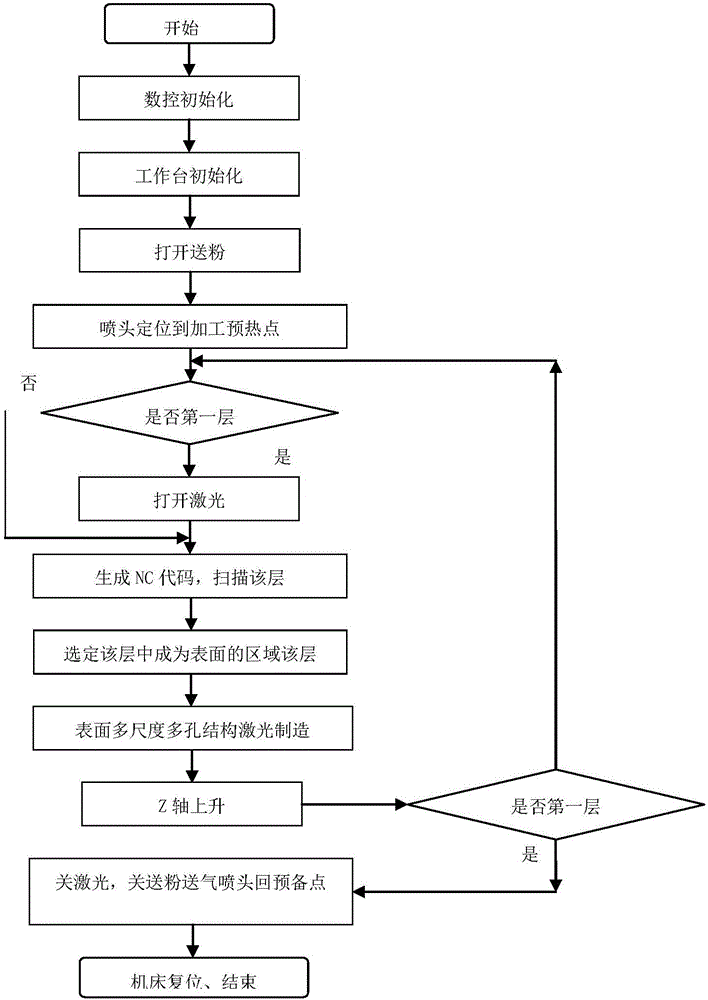

[0022] Attached below Figure 1-2 A preparation method for laser cladding and etching of 3D printed shaped parts according to the present invention will be described in detail.

[0023] A preparation method for laser cladding etching of 3D printed parts, the preparation method comprising the following steps,

[0024] 1) Powder feeding: Use acetone to clean and absolute ethanol to clean the surface of the metal or alloy substrate, and dry it with cold air; use a sandblasting machine or a polishing machine to uniformly roughen the surface of the cleaned metal or alloy substrate, so that Its surface roughness Ra<5-10μm; according to the functional design requirements of formed parts, calculate the distribution ratio of each component in the composite powder at different positions, and use a ball mill to fully and uniformly mix the composite powder, and place the mixed powder in a 100- Dry in a drying oven at 200°C for 1-1.5 hours; place the dried powder in the powder cylinder of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com