Rock slag quartz content testing system and method for TBM

A quartz content and testing system technology, applied in measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of rough comprehensive evaluation model, limited result accuracy, and inability to real-time feedback, and achieve automatic acquisition function , The effect of reducing dust pollution and easy on-site application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

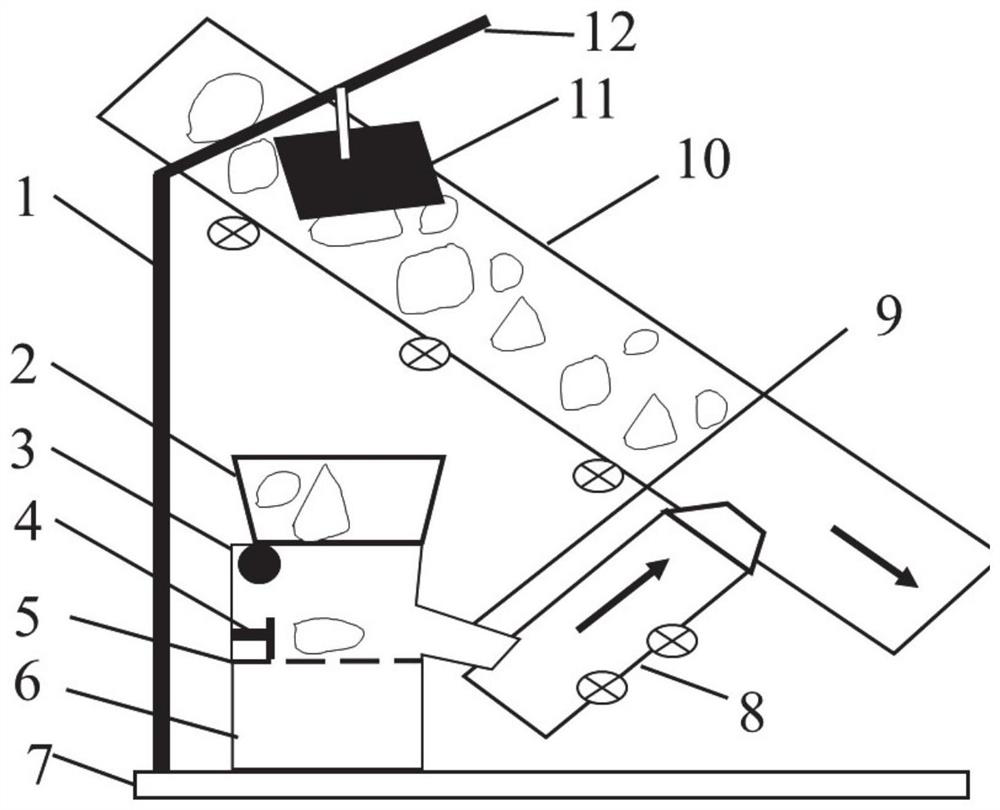

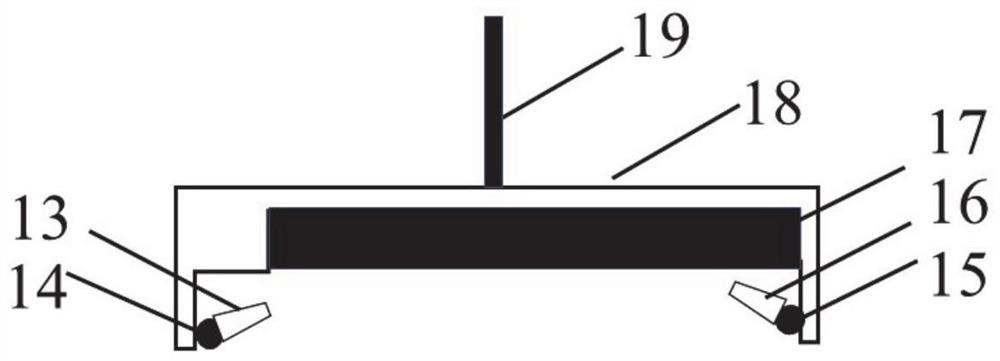

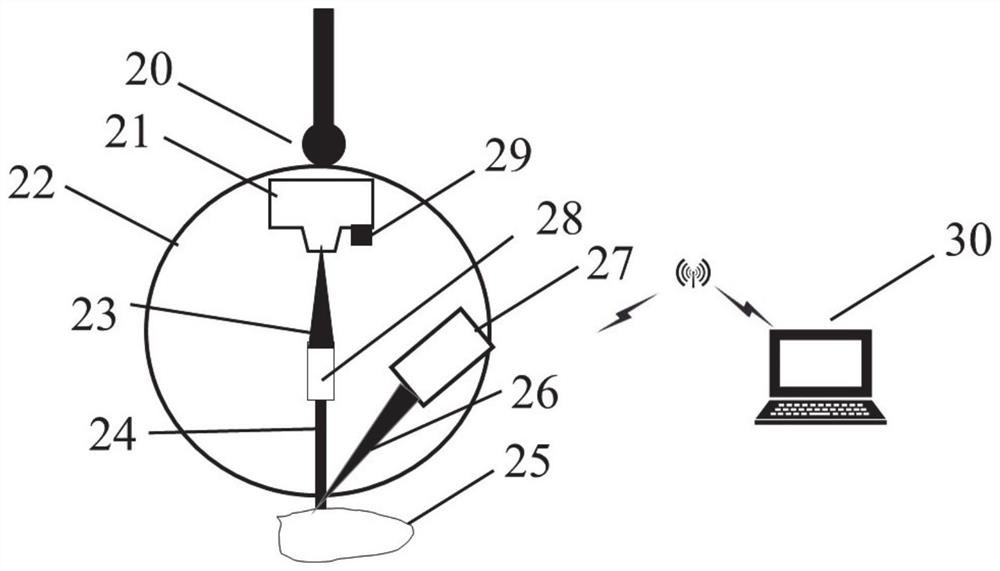

[0049] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, Embodiment 1 of the present disclosure provides a rock slag quartz content testing system for TBM, including a base 7 and a control terminal 30 arranged close to the TBM conveyor belt, and at least the base 7 is fixed with the control terminal 30 respectively. 30 communication cuttings sample picking mechanism 11 and X-ray fluorescence spectroscopic analysis mechanism 3;

[0050] The cuttings sample picking mechanism 11 realizes the picking, cleaning, drying and transferring of the cuttings samples respectively, and is used to pick up the cuttings samples from the TBM conveyor belt 10 and transmit them to the X-ray fluorescence spectrum analysis mechanism 3. The control terminal 30 according to the received Fluorescence spectrum information is used to measure the quartz content of rock slag, and the test results of the measured quartz content of cuttings are analyzed and transmitted to the TBM analysis a...

Embodiment 2

[0067] Embodiment 2 of the present disclosure provides a method for testing the content of rock slag quartz for TBM, using the rock slag quartz content test system for TBM described in Embodiment 1 of the present disclosure, including the following steps:

[0068] The cuttings sample is picked up from the TBM conveyor belt by the cuttings sample picking mechanism, moved to the X-ray fluorescence spectroscopic analysis mechanism and cleaned and dried;

[0069] Obtain the X-ray fluorescence spectrum of the cuttings surface through the X-ray fluorescence spectrum analysis mechanism, determine the mineral composition content according to the X-ray fluorescence spectrum database comparison, and calculate the quartz content index K;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com