Drilling power rock debris bed eraser

A power-while-drilling and cuttings bed technology, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of affecting drilling efficiency, collapsing blocks in soft strata, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

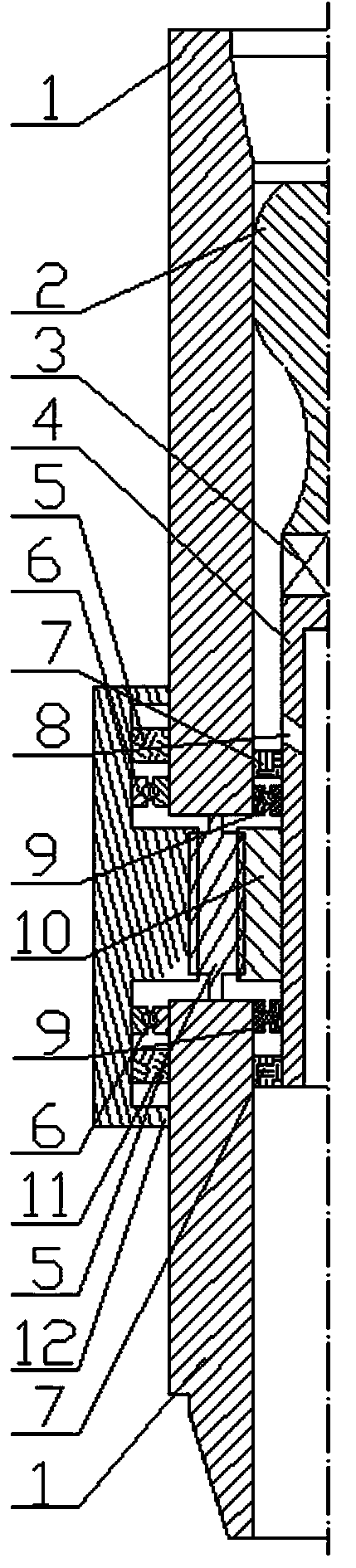

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

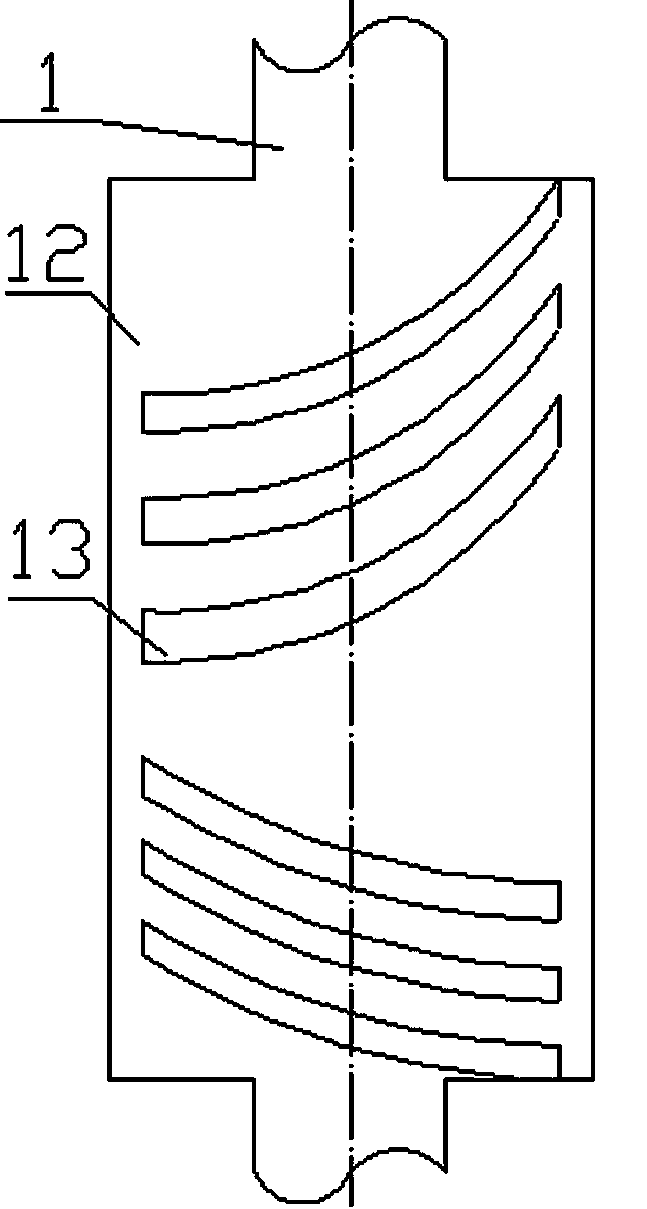

[0016] Such as figure 1 , the screw 2, the cardan shaft 3 and the central shaft 4 are installed inside the housing 1, the sealing device 7 and the bearing 9 are installed between the central shaft 4 and the inner wall of the housing 1, the bypass hole 8 is processed on the central shaft 4, and the central shaft 4 The interior is a hollow structure, the driving gear 10 is installed on the central shaft 4, and the three planetary gears 11 are installed in the housing 1, and are evenly distributed at 120 degrees. The driving gear 10 meshes with the three planetary gears 11 at the same time, and the cutting sliding sleeve 12 Installed outside the casing 1, the sealing device 5 and the bearing 6 are installed between the cutting sliding sleeve 12 and the outer wall of the casing 1, and the inner wall of the cutting sliding sleeve 12 is processed with a ring gear and meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com