Drilling centralizer capable of removing rocks and debris beds at bottom of well

A cuttings bed and centralizer technology, applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problems of inability to remove cuttings at the bottom of the well and the cuttings bed in a timely and effective manner. rock capacity, the effect of cleaning the wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments.

[0025] The orientation words "up", "down" and "inside" and "outside" involved in the present invention are all associated with the appended figure 1 or attached figure 2 in the same orientation.

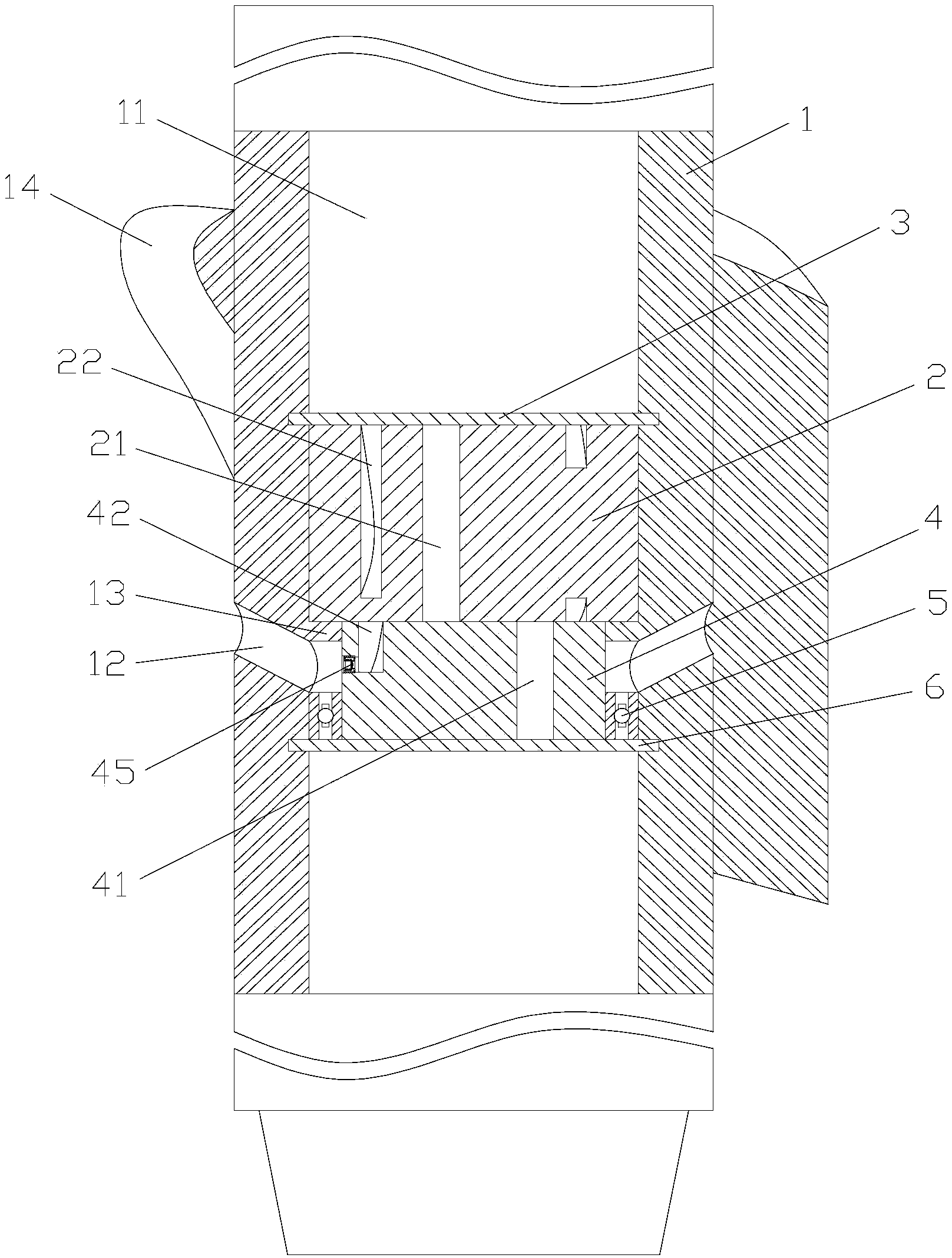

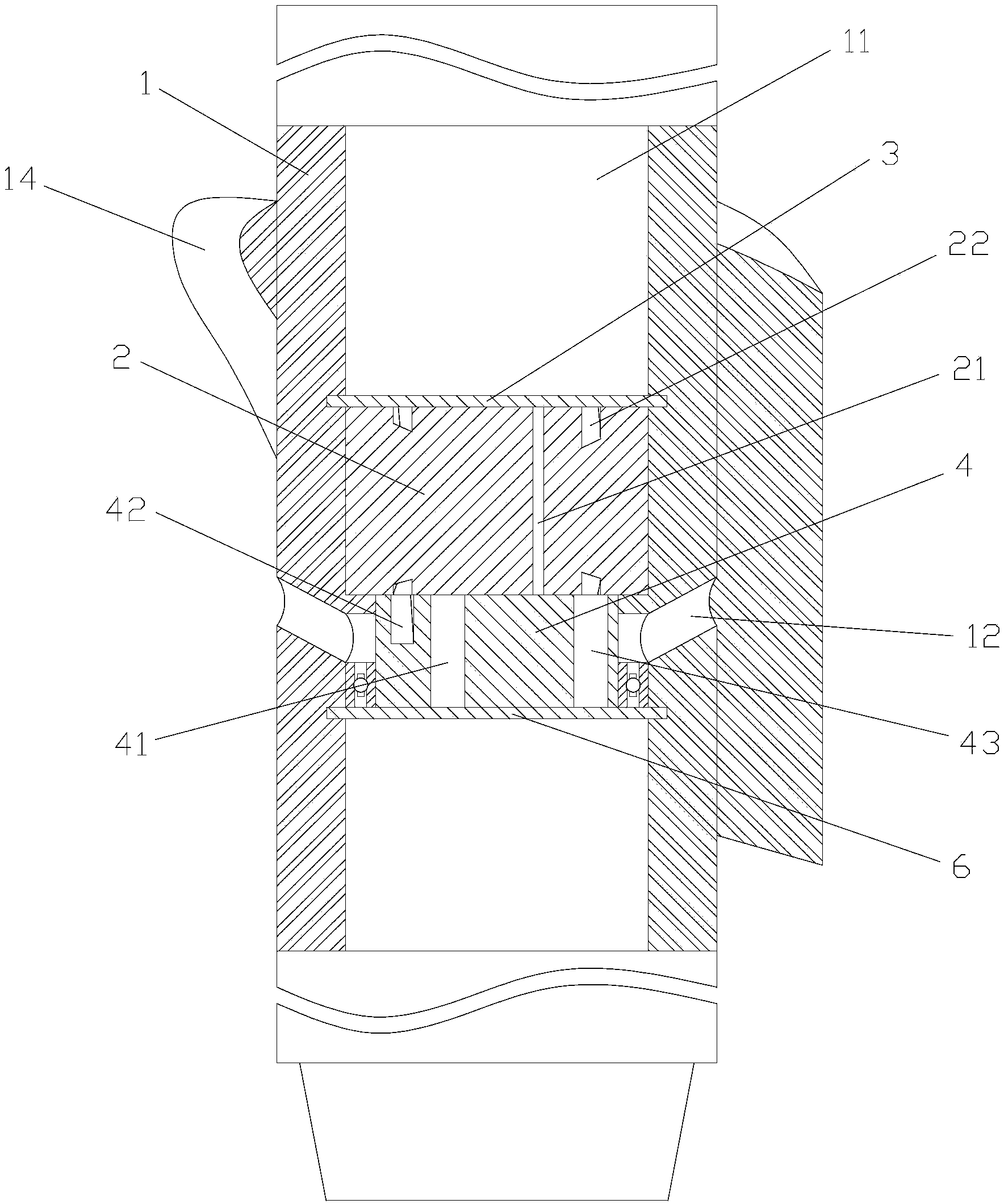

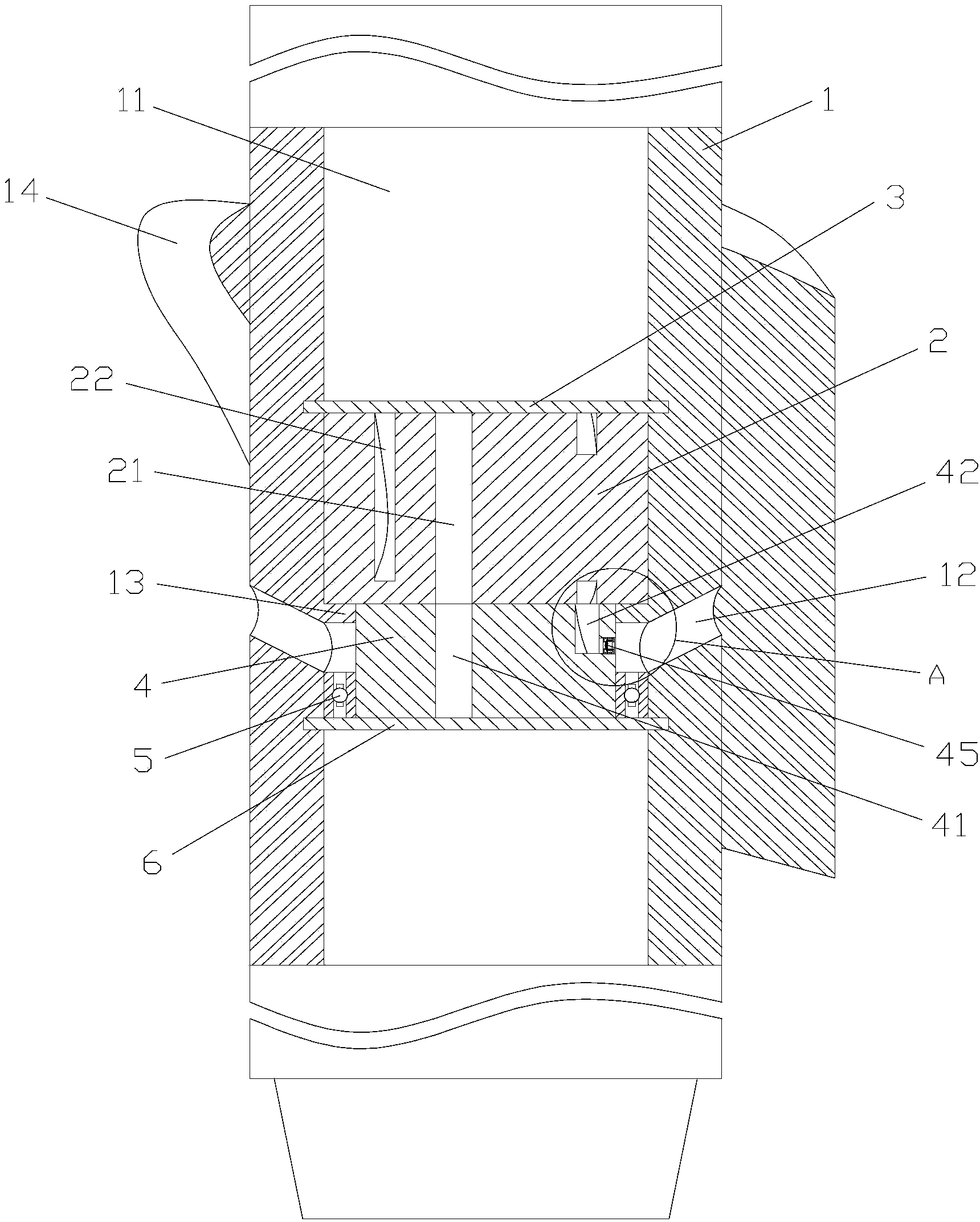

[0026] Such as Figures 1 to 8 As shown, the present invention can clear the bottom of the well and remove the cuttings bed. 6.

[0027] The casing 1 is roughly cylindrical in shape, and a through hole 11 is arranged inside the casing 1 along the axial direction. A bypass hole 12 is arranged in the middle section of the casing 1. The bypass hole 12 is arranged obliquely and communicates with the through hole 11. The bypass hole 12 extends obliquely from the outside to the inside and then extends horizontally. In this embodiment, there are 1 to 4 bypass holes 12, and the angle between the axis and the axis of the centralizer, that is, the chamfer angle is 5° to 65°. Between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com