Quantitative evaluation method for borehole cleanliness based on rock debris return condition

A quantitative evaluation and cuttings technology, applied in wellbore/well components, measurement, earthwork drilling and mining, etc., can solve the problem of low cuttings weighing measurement accuracy, no cuttings volume calibration method, and no calculation results and other problems to achieve the effect of reducing operation risk, improving accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

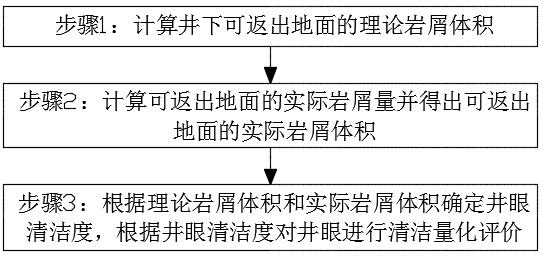

[0085] This embodiment discloses a quantitative evaluation method for wellbore cleaning based on cuttings return. The method judges the bottom cuttings by comparing the amount of cuttings returned from the ground during drilling with the theoretical amount of cuttings generated at the bottom of the well. In order to provide a basis for the identification of the shape of the cuttings bed, it can guide the optimization of ground parameters and reduce the operation risk. Such as figure 1 As shown, the method includes the following steps:

[0086] Step 1: Calculate the theoretical cuttings volume that can be returned to the surface downhole according to relevant data such as borehole diameter and borehole depth change.

[0087] The calculation method of theoretical cuttings volume described in this step is:

[0088] V 理论=pi*R 2 / 4*ΔH (1)

[0089] In formula (1), V 理论 is the theoretical cuttings volume, pi is the circumference ratio, R is the theoretical borehole diameter obt...

Embodiment 2

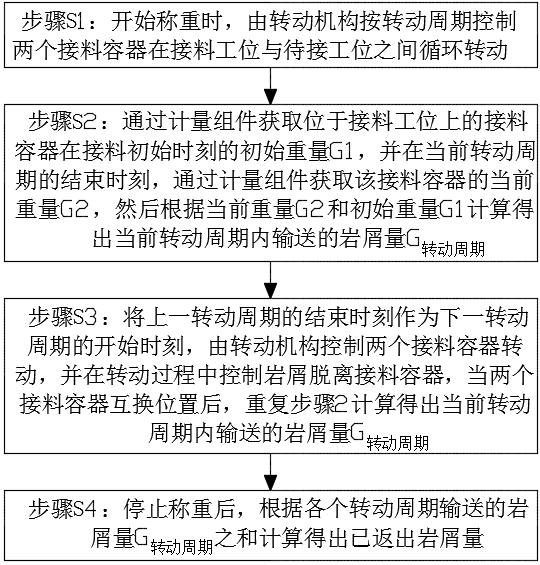

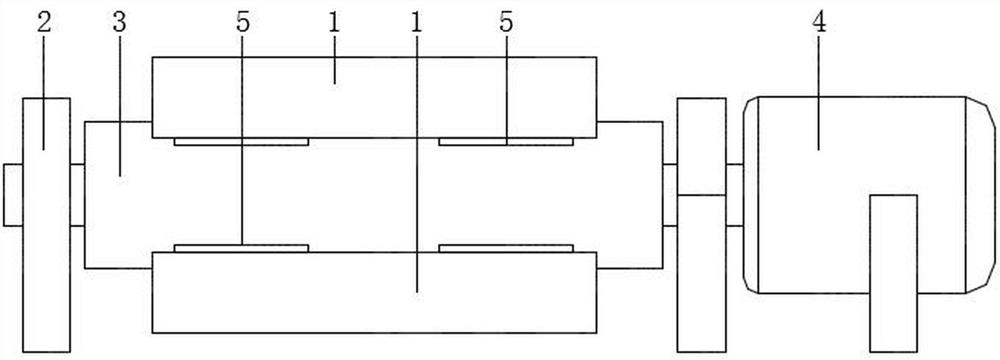

[0104] On the basis of Embodiment 1, this embodiment further limits the method for obtaining the amount of rock debris that has been returned. The acquisition method is based on the double receiving container 1 weighing the rock cuttings periodically, and can dynamically peel off the cuttings during weighing, which not only solves the technical problem that the single funnel groove cannot measure the continuously generated rock cuttings during the turning process, but also The technical problem of accumulative weighing error caused by cuttings adhesion is solved. Such as figure 2 As shown, the method for obtaining the amount of cuttings that has been returned comprises the following steps:

[0105] Step S1: Pre-set the receiving station and the waiting station at the outlet of the rock cuttings vibrating screen. When weighing starts, the rotating mechanism controls the two receiving containers 1 at the receiving station and the waiting station according to the rotation cycle...

Embodiment 3

[0113] On the basis of Example 2, this embodiment also further defines the positions of the material receiving station and the waiting station. Specifically, the material receiving station and the waiting station are respectively arranged symmetrically in the vertical direction. Above and below, and preferably the receiving station is located directly above the station to be connected. Under this condition, the rotating mechanism controls the two material receiving containers 1 to rotate circularly between the material receiving station and the waiting station. Circular weighing and rock cuttings are separated from the receiving container 1 when rotating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com