Borehole cleaning liquid and preparation method thereof

A technology for cleaning liquids and boreholes, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as narrow application range, and achieve the effect of high-efficiency suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

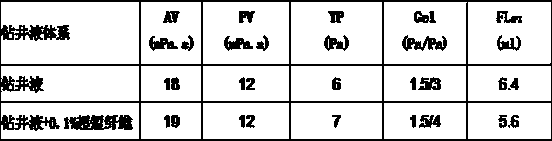

[0026] First, add bentonite to water, configure bentonite base slurry with a bentonite content of 3%, and cure for 24 hours. Then add 0.3% polyacrylamide dry powder and 0.5% carboxymethylcellulose sodium salt (low viscosity) in sequence, and stir at high speed for 20 minutes. Finally, add 0.1% ultra-short fibers with a length of 2 mm and a diameter of 5 μm, and stir at high speed for 20 minutes. The rheological properties and API filtration loss were measured at room temperature, and the experimental results are shown in Table 1.

[0027] Table 1

[0028]

Embodiment 2

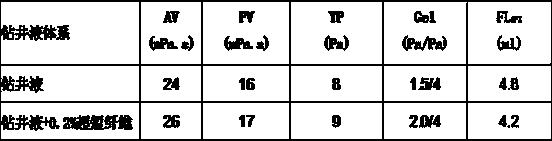

[0030] First, add 0.15-0.3% sodium carbonate to water, then add bentonite, prepare bentonite base slurry with 6% bentonite content, and cure for 24 hours. Then add 0.5% potassium polyacryloylate, 2% carboxymethyl sulfonated phenolic resin SMP-2 and 2% hydrolyzed polyacrylonitrile ammonium salt in sequence, stir at high speed for 8 minutes step by step during the addition process, and then add 50% recrystallized stone. Finally, add 3% ultra-short fibers with a length of 20 mm and a diameter of 50 μm, and stir at high speed for 10 min. The rheological properties and API filtration loss were measured at room temperature, and the experimental results are shown in Table 2.

[0031] Table 2

[0032]

Embodiment 3

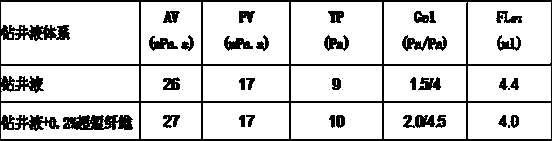

[0034] First, a bentonite base slurry with a mass fraction of 4% was prepared and cured for 30 hours. Then add 0.3% polyacrylamide dry powder and 2% carboxymethylsulfonated phenolic resin SMP-2 in sequence, and stir at high speed for 20 minutes. Finally, add 0.2% ultra-short fibers with a length of 5 mm and a diameter of 10 μm, and stir at high speed for 20 minutes. The rheological properties and API fluid loss were measured at room temperature, and the experimental results are shown in Table 3.

[0035] table 3

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com