Oily suspended magnesium and calcium fertilizer and preparation method and device thereof

An oil-based fertilizer technology, which is applied in the field of calcium fertilizer and its preparation and oil-based suspended magnesium, can solve the problems of easy loss, non-absorption, and waste of calcium-magnesium fertilizer applied early, and achieves avoiding precipitation and stratification, reducing waste, and absorbing and utilizing high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An oily suspended magnesium and calcium fertilizer, comprising the following components: 112g of water, 40g of magnesium hydroxide ore powder (the content of magnesium hydroxide is 87%), 3g of light calcium carbonate (the content of calcium carbonate is 99%), wetting agent MSR-TT1 4g, dispersant MSD-511 8g, xanthan gum 0.4g, aluminum magnesium silicate 4.0g, vegetable oil 20g, propylene glycol 8.0g, adjust the pH between 8.0-9.0 with potassium hydroxide.

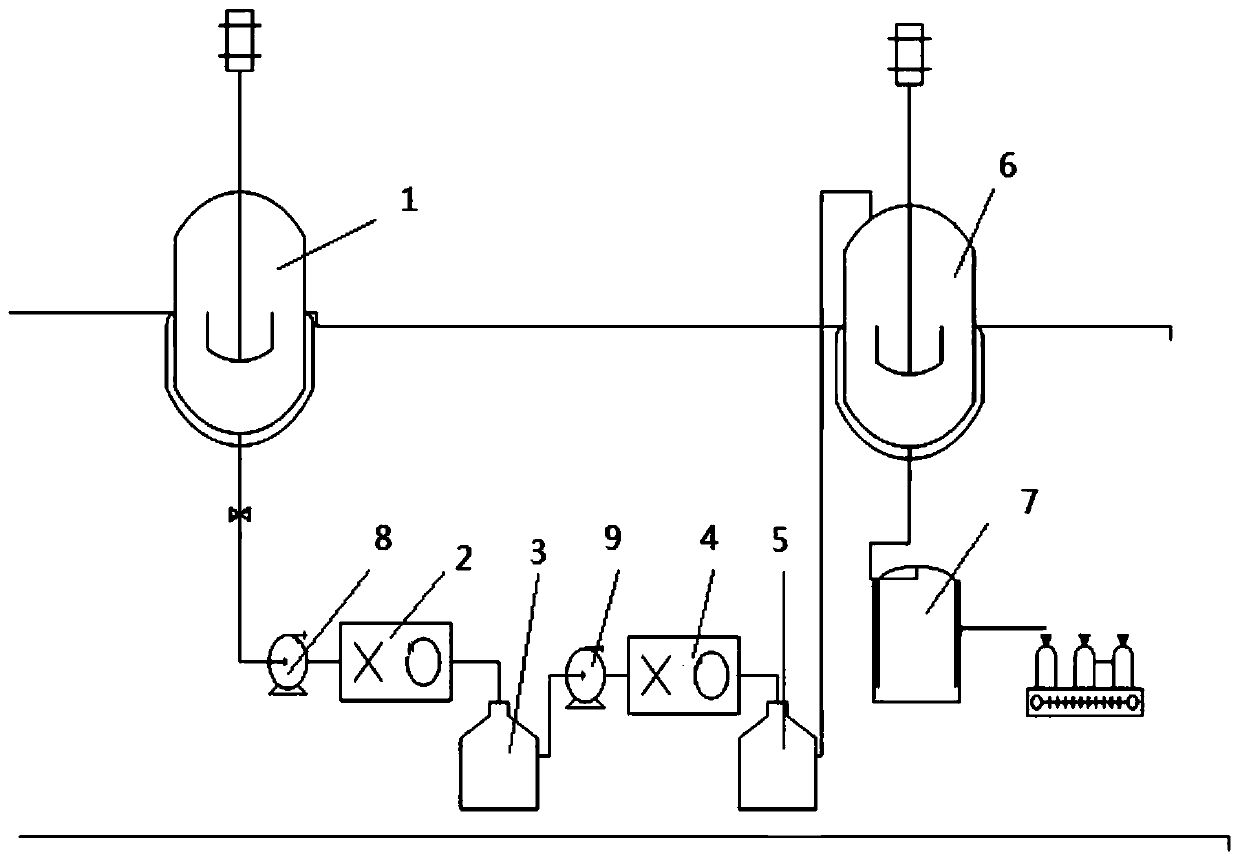

[0031] Prepare above-mentioned oily suspension magnesium, calcium fertilizer adopt such as figure 1 Described device, specific method comprises the steps:

[0032] 1) Add a specified amount of water (factory tap water) into the high-speed shearing machine 1, start the high-speed shearing machine 1, adjust the speed to 200r / min, and add the weighed magnesium hydroxide ore powder and light calcium carbonate ore powder in turn , Wetting agent MSR-TT1, dispersant MSD-511, thickener xanthan gum and aluminum magnesium sili...

Embodiment 2

[0039] The difference with embodiment 1 is:

[0040] An oily suspended magnesium, calcium fertilizer comprises the following components: water 147g, magnesium hydroxide ore powder 30g (magnesium hydroxide content is 87%), light calcium carbonate (calcium carbonate content is 99%) 1.6g, wetting Agent MSR-TT1 2g, dispersant MSD-511 4g, xanthan gum 0.2g, magnesium aluminum silicate 1.0g, vegetable oil 10g, propylene glycol 4.0g, adjust the pH between 8.0-9.0 with potassium hydroxide.

Embodiment 3

[0042] The difference with embodiment 1 is:

[0043] An oily suspended magnesium, calcium fertilizer comprises the following components: 128g of water, 34g of magnesium hydroxide ore powder (magnesium hydroxide content is 87%), light calcium carbonate (calcium carbonate content is 99%) 2.4g, wetting Agent MSR-TT1 3g, dispersant MSD-511 6g, xanthan gum 0.3g, magnesium aluminum silicate 4.0g, vegetable oil 16.0g, propylene glycol 6.0g, adjust the pH between 8.0-9.0 with potassium hydroxide.

[0044] The oily suspension magnesium and calcium fertilizers obtained in Examples 1, 2, and 3 are detected, and the results are shown in the table below. It can be seen that the products prepared in the three examples are all in a homogeneous suspension state, and have good automatic dispersion. Rates are all above 95%, and Examples 1 and 3 have reached more than 99%, and the particle size has reached nanoscale.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com