Coiled tubing drilling-plug liquid system and preparing method thereof

A drilling plug and system technology, applied in the field of oil and gas field exploration, can solve the problems of high drilling and grinding construction parameters, high performance requirements of drilling plug liquid, poor carrying suspension effect, resistance when drilling, and achieve high antibacterial efficiency and low cost , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

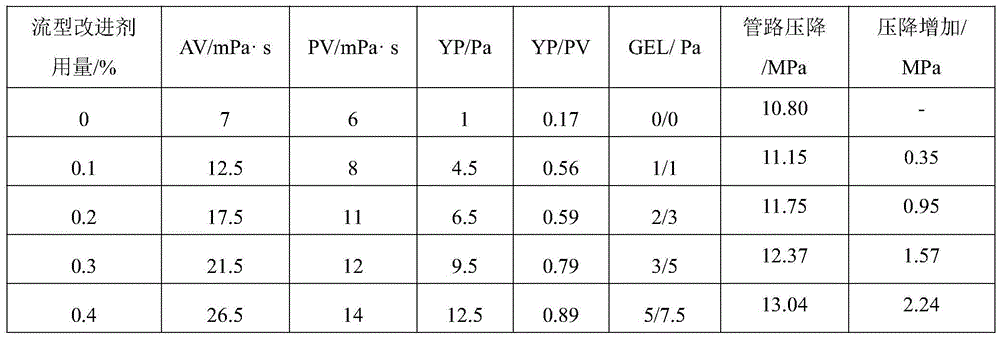

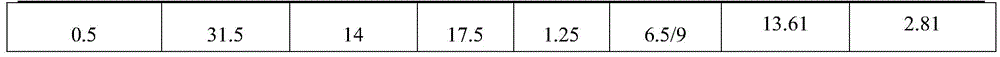

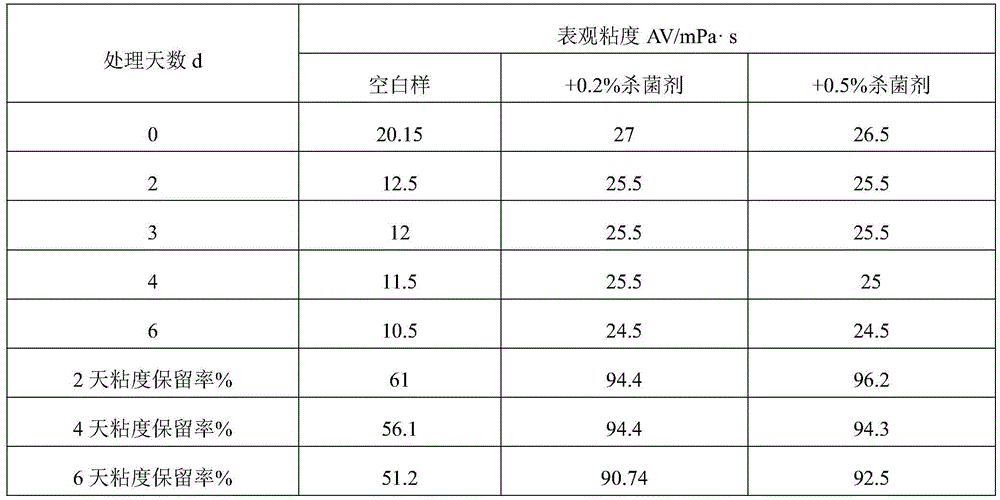

Examples

Embodiment 1

[0026] Measure 100 parts of clear water, under high-speed stirring (8000r / min), add 0.25 parts of low-molecular polymer thickener and stir for 10 minutes; then add 0.1 parts of compound synergist and stir for 10 minutes; add 0.1 parts of Bactericide, after the solution is evenly stirred and stabilized, add 0.1 part of flow pattern improver and stir for 5 minutes; finally add 0.02 part of defoamer and stir for 5 minutes; the high-efficiency suspended drilling liquid mother solution can be formed.

Embodiment 2

[0028] Measure 100 parts of clear water, under high-speed stirring (8000r / min), add 0.25 parts of low-molecular polymer thickener and stir for 10 minutes; then add 0.15 parts of compound synergist and stir for 10 minutes; add 0.3 parts Bactericide, then after the solution is stirred evenly and stably, add 0.3 parts of flow pattern improver and stir for 5 minutes; finally add 0.04 parts of defoamer and stir for 5 minutes; the high-efficiency suspended drilling liquid mother solution can be formed.

Embodiment 3

[0030] Measure 100 parts of clear water, under high-speed stirring (8000r / min), add 0.25 parts of low-molecular polymer thickener and stir for 10 minutes; then add 0.2 parts of compound synergist and stir for 10 minutes; add 0.4 parts of Bactericide, then after the solution is evenly stirred and stabilized, add 0.4 parts of flow pattern improver and stir for 5 minutes; finally add 0.08 parts of defoamer and stir for 5 minutes; the high-efficiency suspended drilling liquid mother solution can be formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com