Sealing device for jet engine oil chamber

A technology of sealing device and turbojet, which is applied in the direction of engine sealing, engine components, machines/engines, etc., can solve the problems of reducing the efficiency of brush seals, reducing efficiency, and oil coking, so as to prevent sticking together and improve Efficacy and life, little effect on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

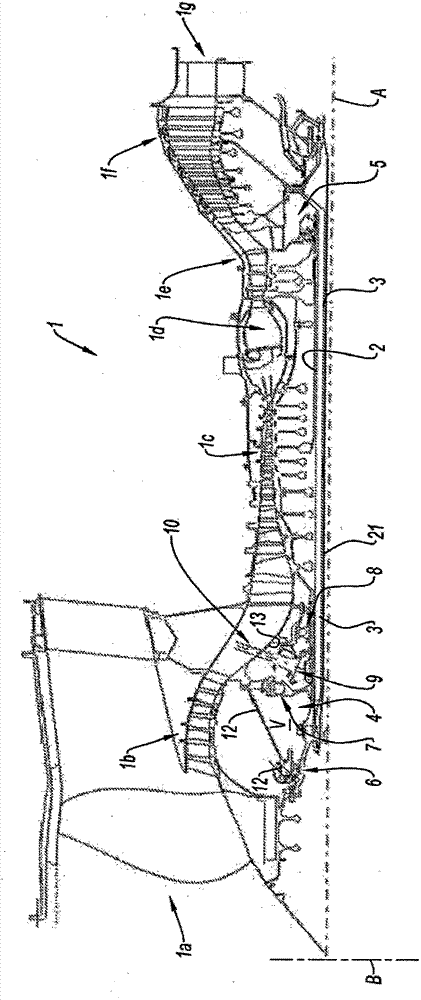

[0032] refer to figure 1 A turbojet engine 1 according to a first embodiment of the invention conventionally comprises a fan 1a, a low-pressure compressor 1b, a high-pressure compressor 1e, a combustion chamber 1d, a high-pressure turbine 1e, a low-pressure turbine 1f and an exhaust nozzle 1g. The high-pressure compressor 1e and the high-pressure turbine 1e are connected through a high-pressure shaft 2 and form a high-pressure core with it. The low-pressure compressor 1b and the low-pressure turbine 1f are connected via a low-pressure shaft 3 and form a low-pressure core therewith.

[0033] The turbojet engine 1 comprises static (or fixed) components and rotating components constituting in a known manner the different functional parts mentioned above.

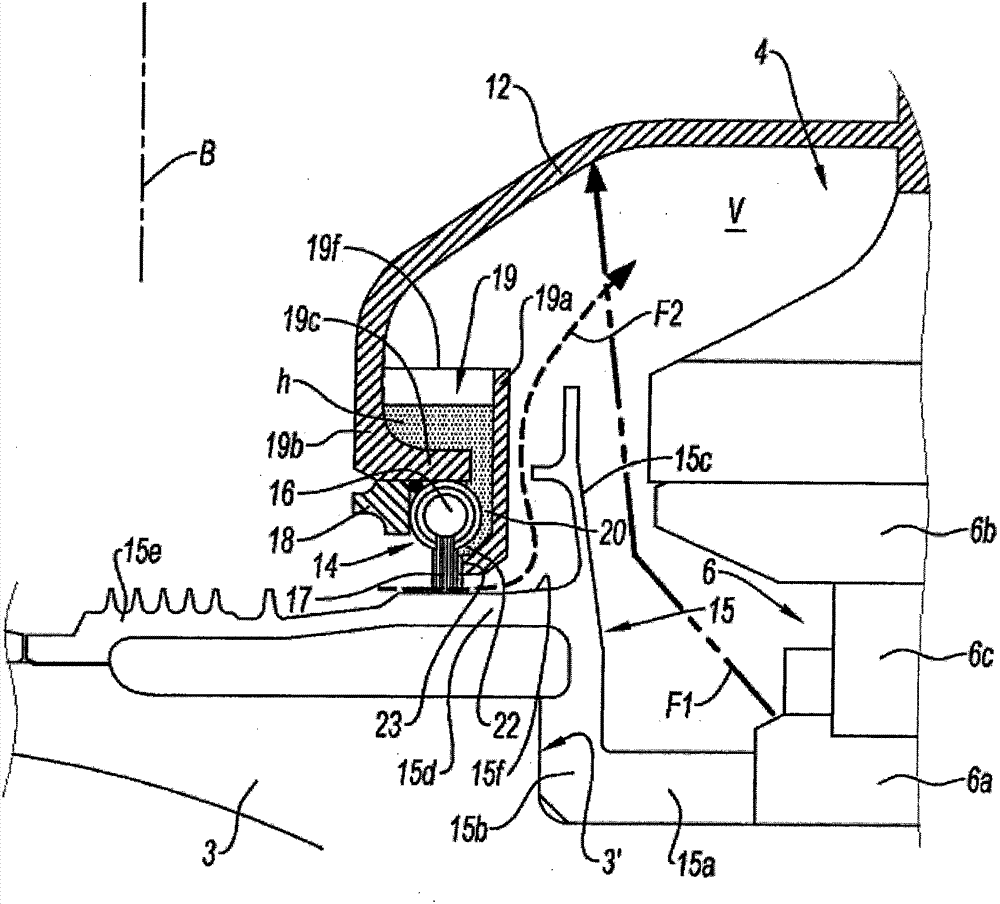

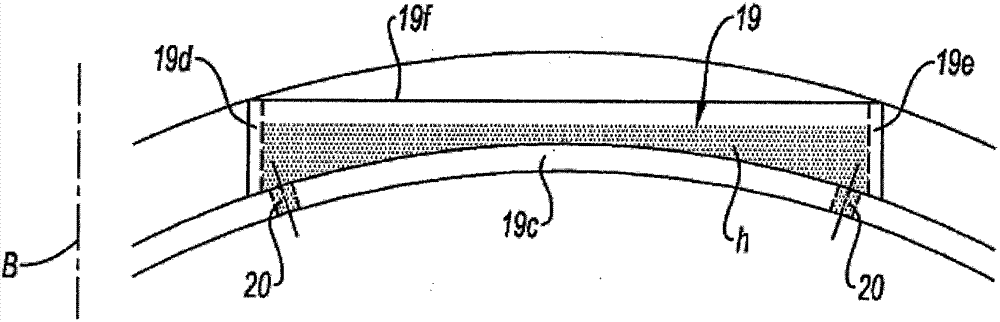

[0034] The turbojet engine 1 has an "upstream oil casing" 4 near the upstream end of the high pressure core, containing bearings and gear components, and a "downstream oil casing" 5, containing bearings and gear components, ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com