Patents

Literature

69results about How to "Increase process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

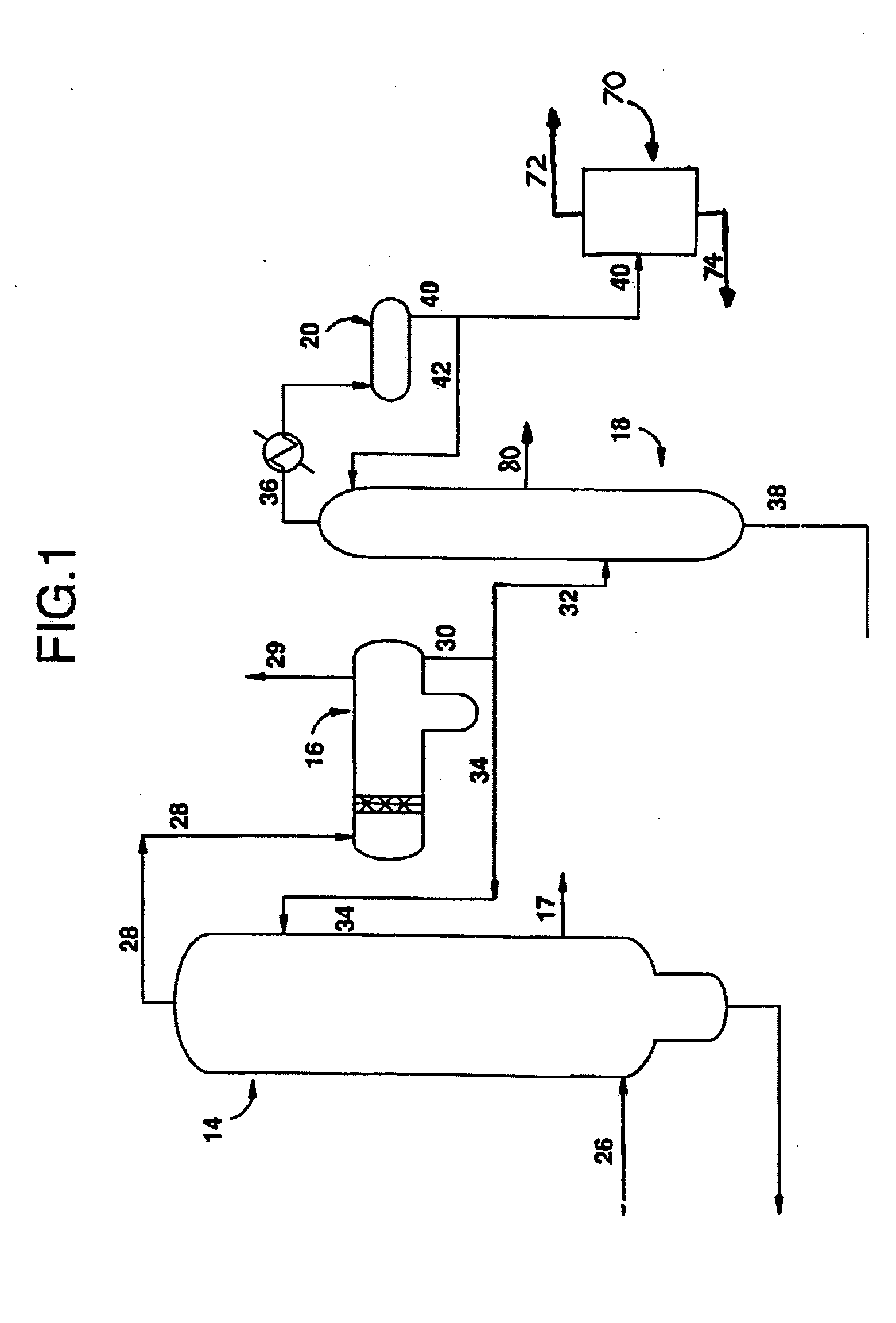

Process for the production of acetic acid

ActiveUS20060247466A1Increase processOrganic compound preparationCarboxylic preparation from carbon monoxide reactionProtein carbonylBoiling point

A process for the reduction and / or removal of permanganate reducing compounds formed by the carbonylation of methanol in the presence of a Group VIII metal carbonylation catalyst to produce acetic acid is disclosed. More specifically, a process for reducing and / or removing permanganate reducing compounds or their precursors from intermediate streams during the formation of acetic acid by said carbonylation processes is disclosed. In particular, a process in which a low boiling overhead vapor stream from a light ends column is subjected to a single distillation to obtain an overhead that is subjected to an extraction to selectively remove and / or reduce PRC's from the process is disclosed.

Owner:CELANESE INT CORP

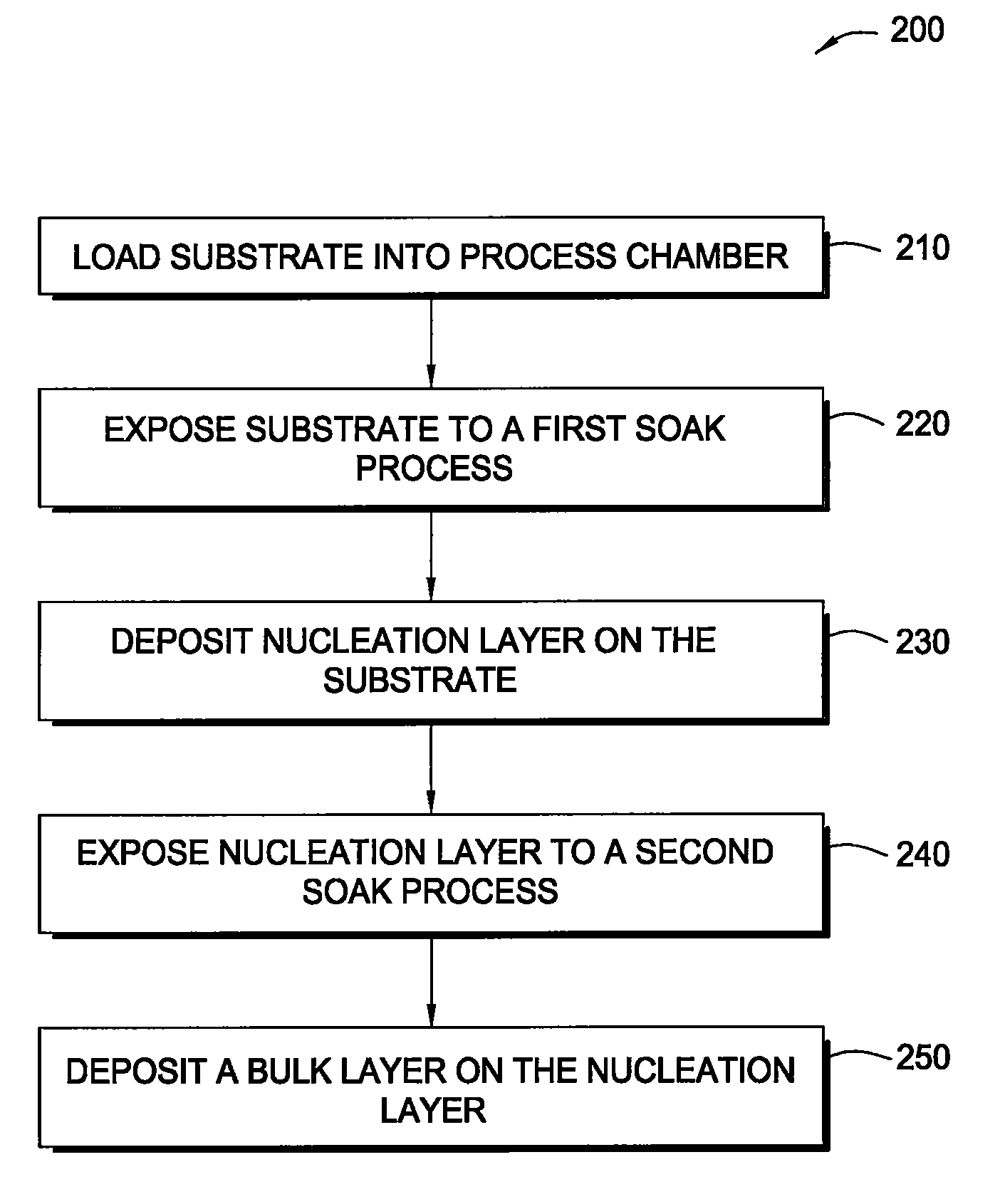

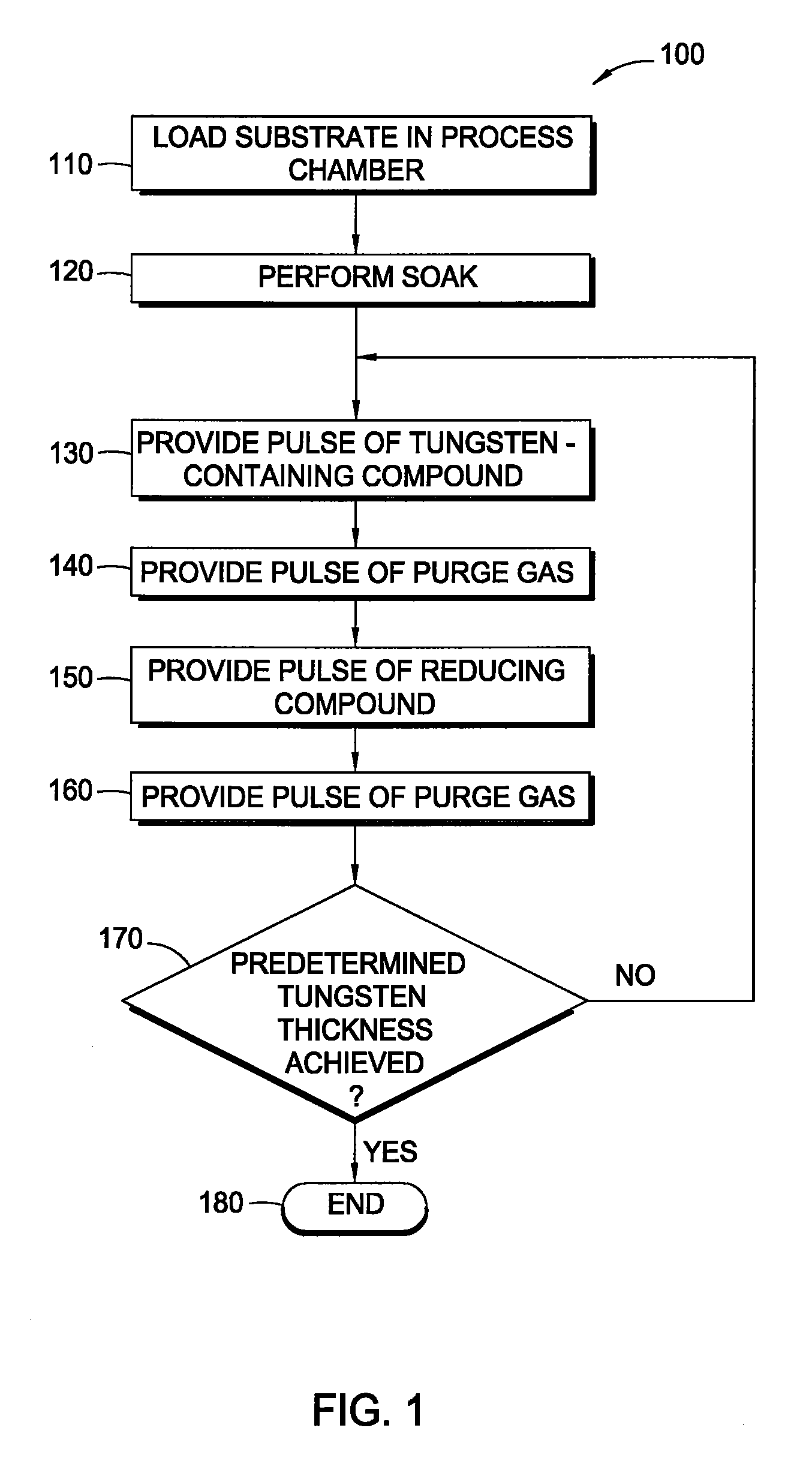

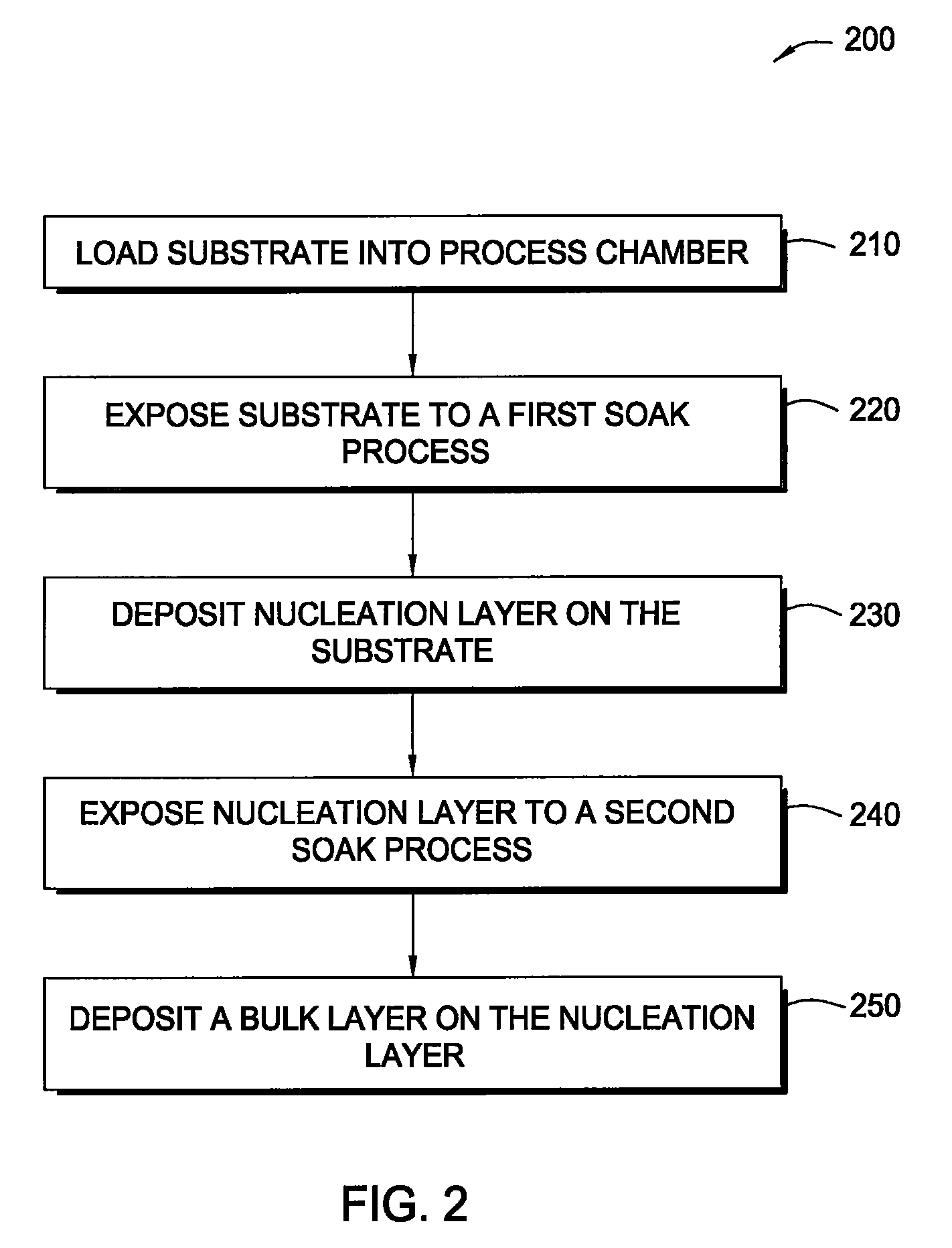

Atomic layer deposition of tungsten materials

ActiveUS20090053893A1Increase processImproved conductivity and surface uniformitySolid-state devicesSemiconductor/solid-state device manufacturingTungsten filmDiborane

Embodiments of the invention provide an improved process for depositing tungsten-containing materials. The process utilizes soak processes and vapor deposition processes, such as atomic layer deposition (ALD) to provide tungsten films having significantly improved surface uniformity and production level throughput. In one embodiment, a method for forming a tungsten-containing material on a substrate is provided which includes positioning a substrate within a process chamber, wherein the substrate contains an underlayer disposed thereon, exposing the substrate sequentially to a tungsten precursor and a reducing gas to deposit a tungsten nucleation layer on the underlayer during an ALD process, wherein the reducing gas contains a hydrogen / hydride flow rate ratio of about 40:1, 100:1, 500:1, 800:1, 1,000:1, or greater, and depositing a tungsten bulk layer on the tungsten nucleation layer. The reducing gas contains a hydride compound, such as diborane, silane, or disilane.

Owner:APPLIED MATERIALS INC

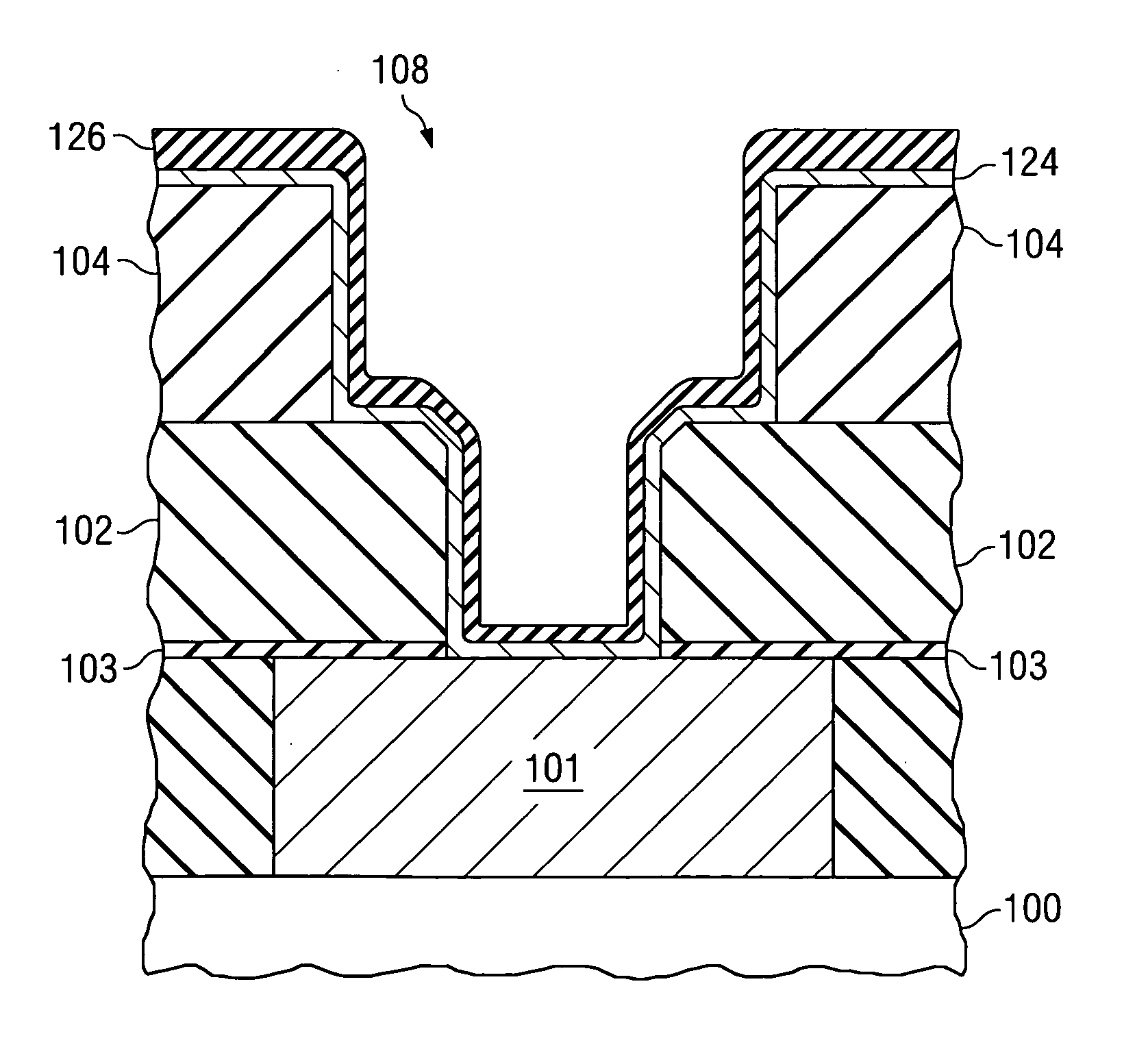

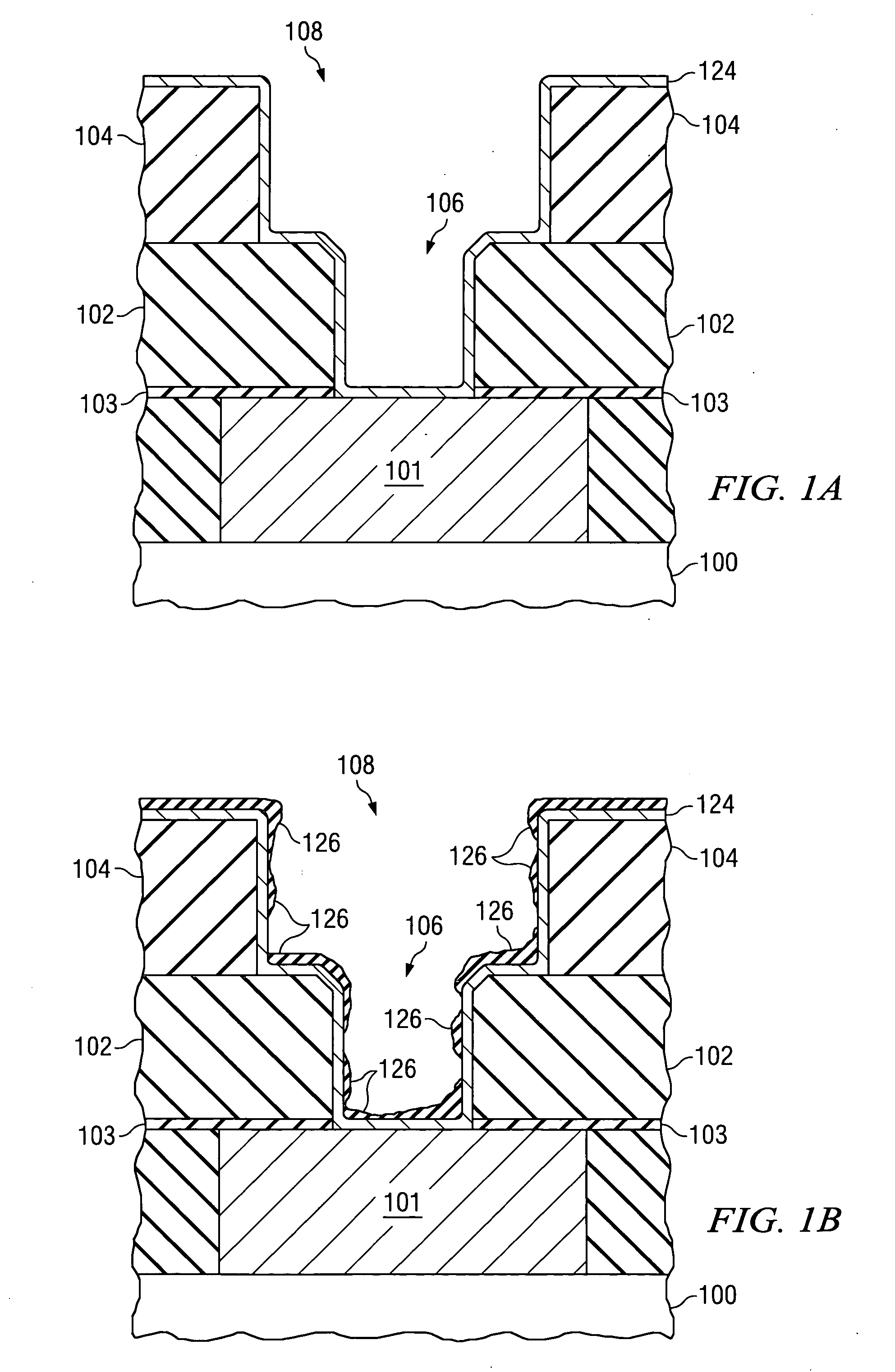

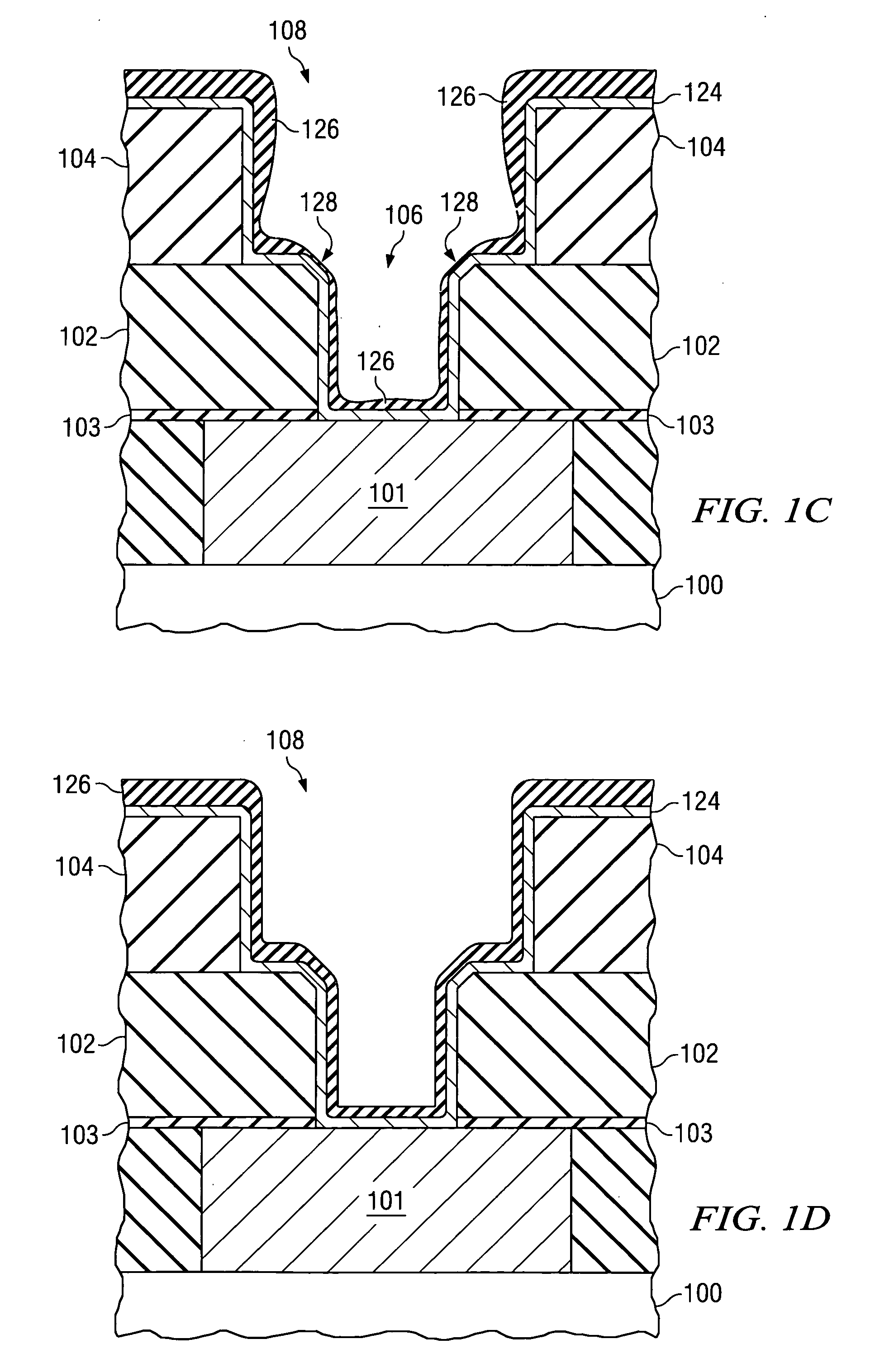

HSQ/SOG dry strip process

InactiveUS20060024958A1Minimizes CDIncrease processSemiconductor/solid-state device manufacturingDielectricIon energy

A spin-on dielectric (120) strip process. Instead of a wet strip, a dry strip process is used to remove the spin-on dielectric (120). In a via-first dual damascene method, a via (116) may be patterned and etched and the via (116) is filled with the spin-on dielectric (120). Then, the trench is patterned and etched while the spin-on dielectric (120) protects the bottom of the via (116). Finally, the spin-on dielectric (120) is removed using a dry strip process with a low ion energy plasma.

Owner:TEXAS INSTR INC

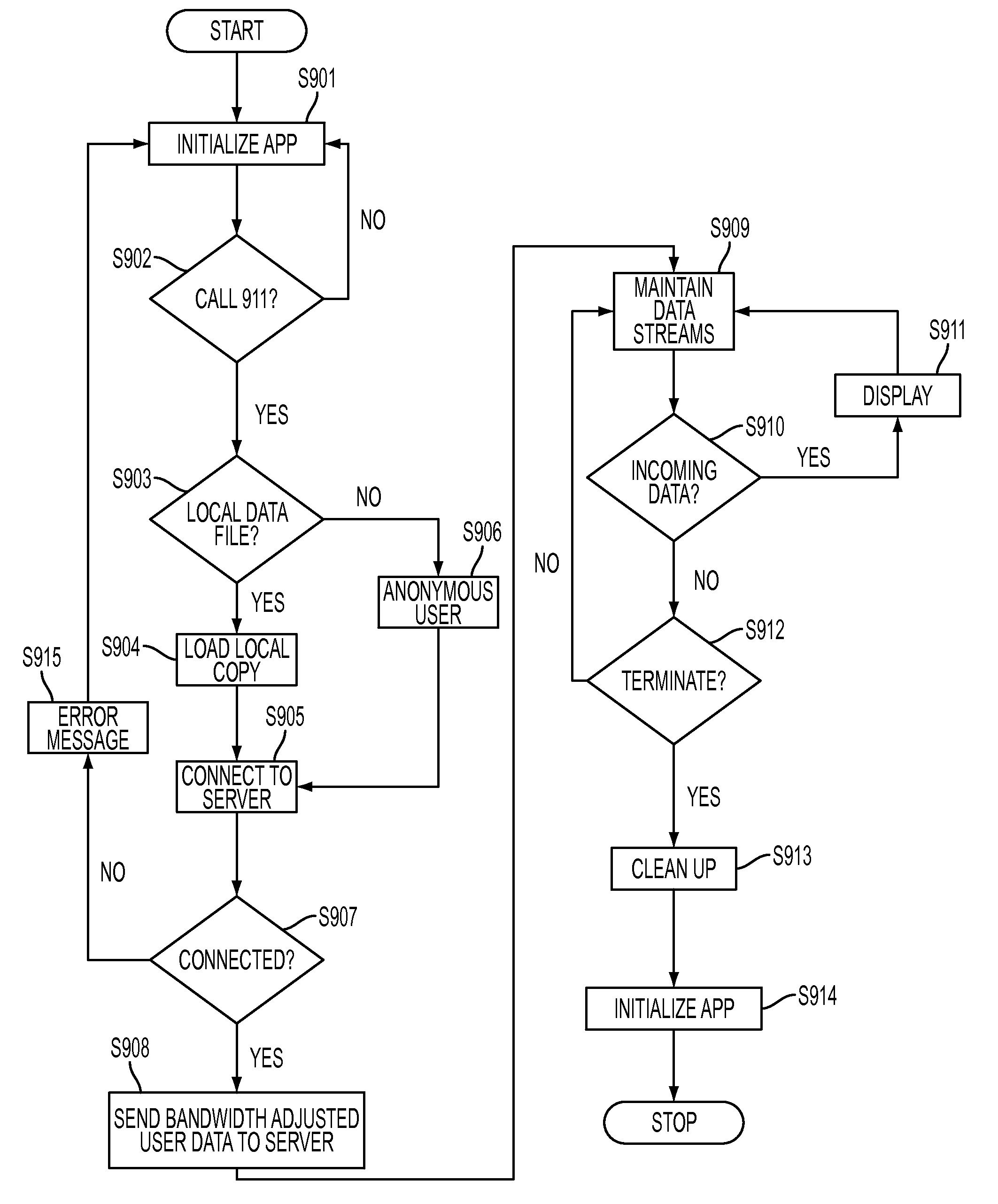

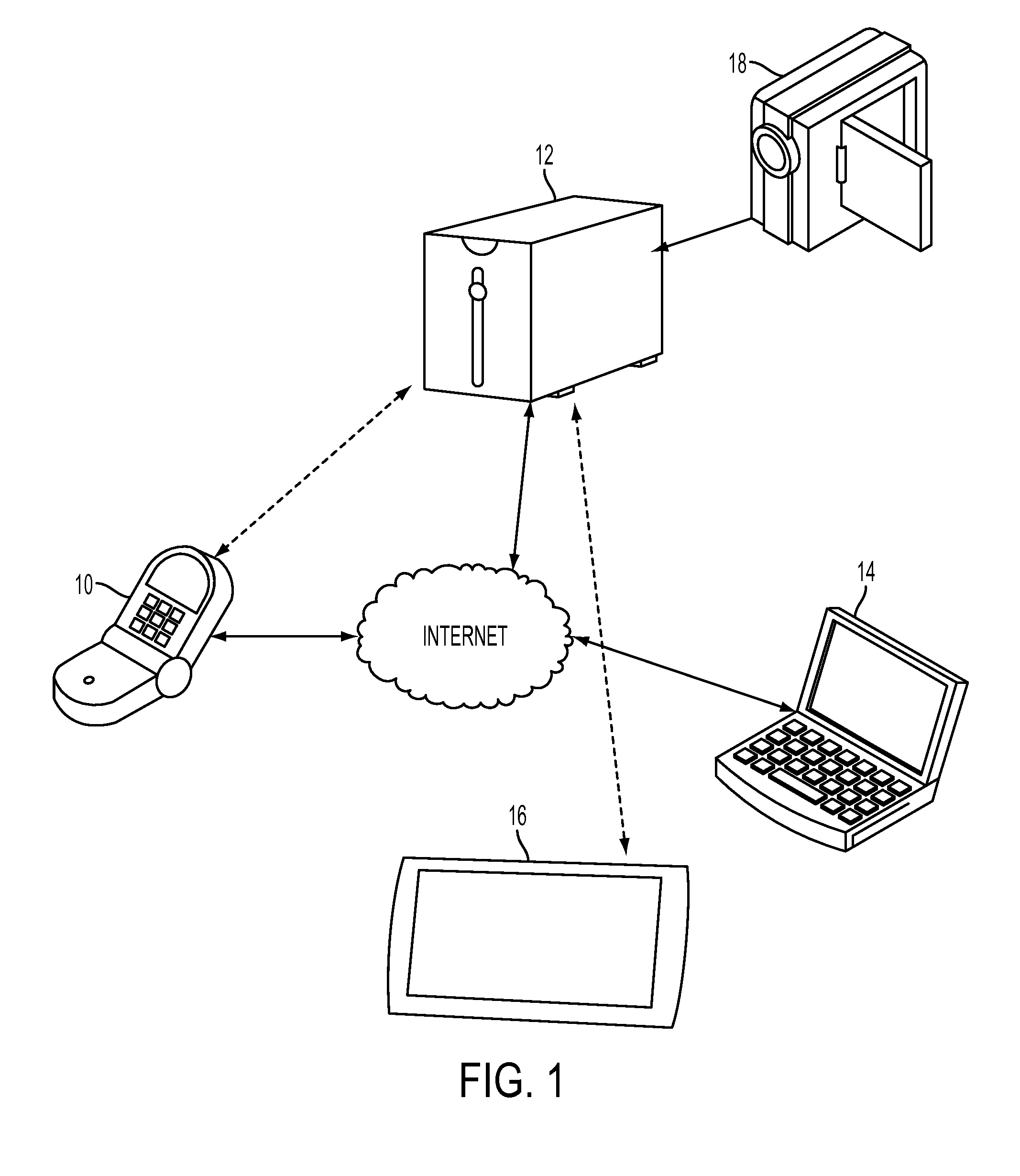

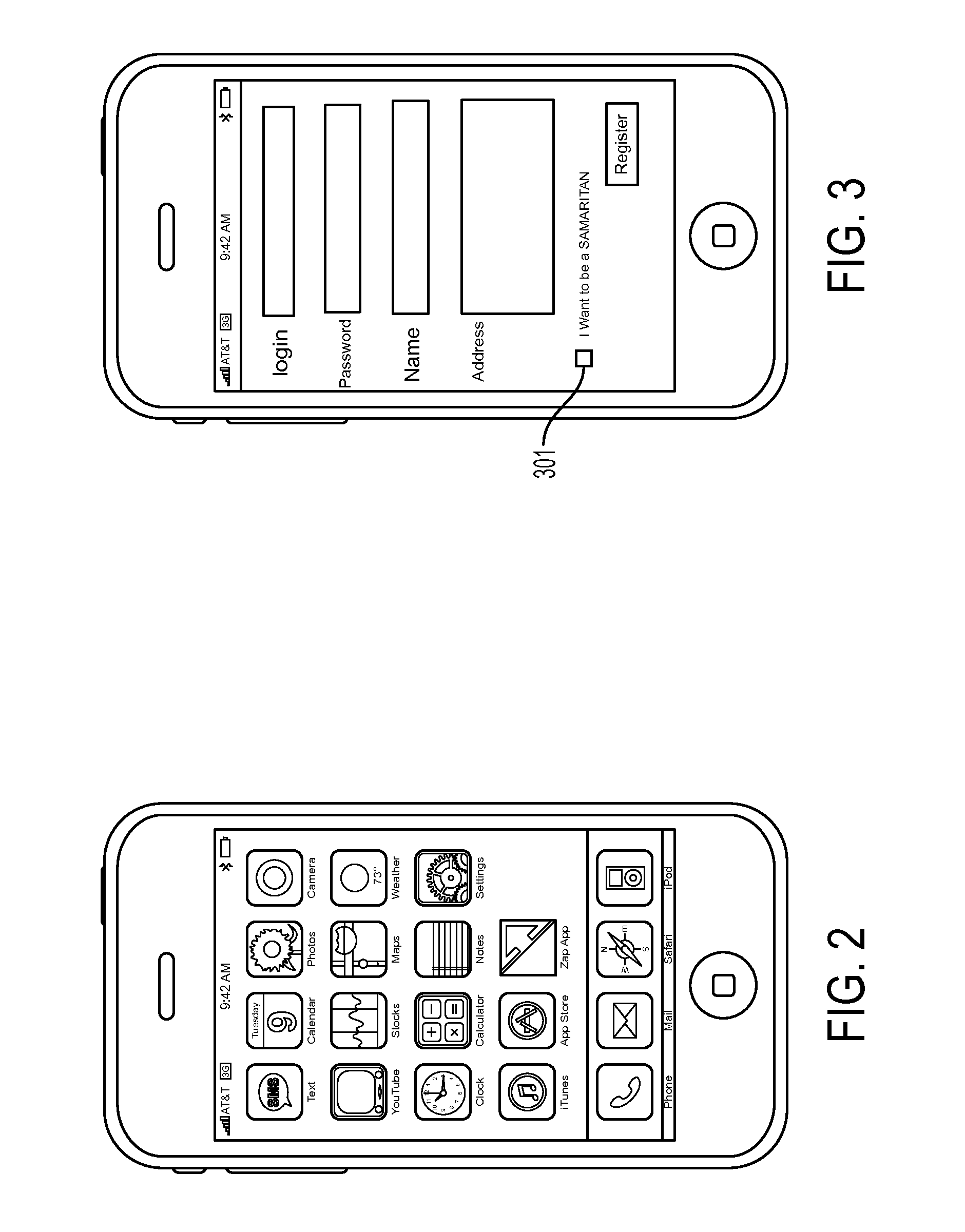

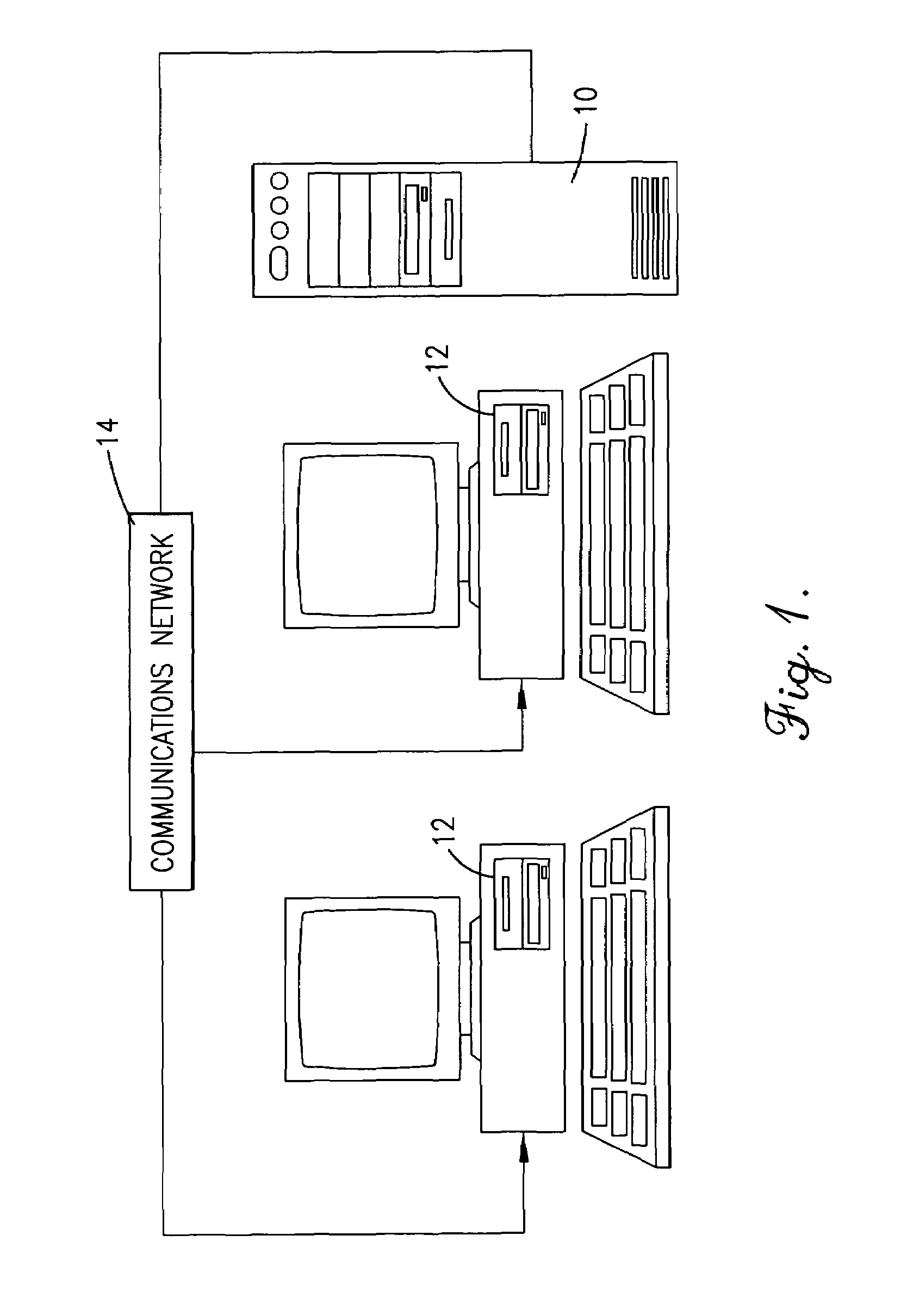

System and method for reporting and tracking incidents with a mobile device

ActiveUS20130005294A1Increase processSpeed up the processTelephonic communicationClosed circuit television systemsFirst responderSoftware

A novel system and method for enhancing people's personal safety and incident reporting is presented, wherein mobile devices are used to report and / or record both “911” type situations and non-emergency situations. Users of the invention can record, transmit, stream, upload and / or send information from a threatening situation to a dispatcher at an emergency management office or facility and to the user's safety group. The dispatcher can assess the situation and, if the situation warrants action, then the information can be forwarded to the appropriate first responders. The system geo-locates the user and allows integration of camera feeds in the user's vicinity. The inventive system and method enables a user to contact a dispatcher and also to alert the user's safety group. Four pieces of software facilitate video, audio, images and / or text medium of communication between the user-in-distress and the dispatcher, first responders and the user's safety group.

Owner:ZAP GROUP

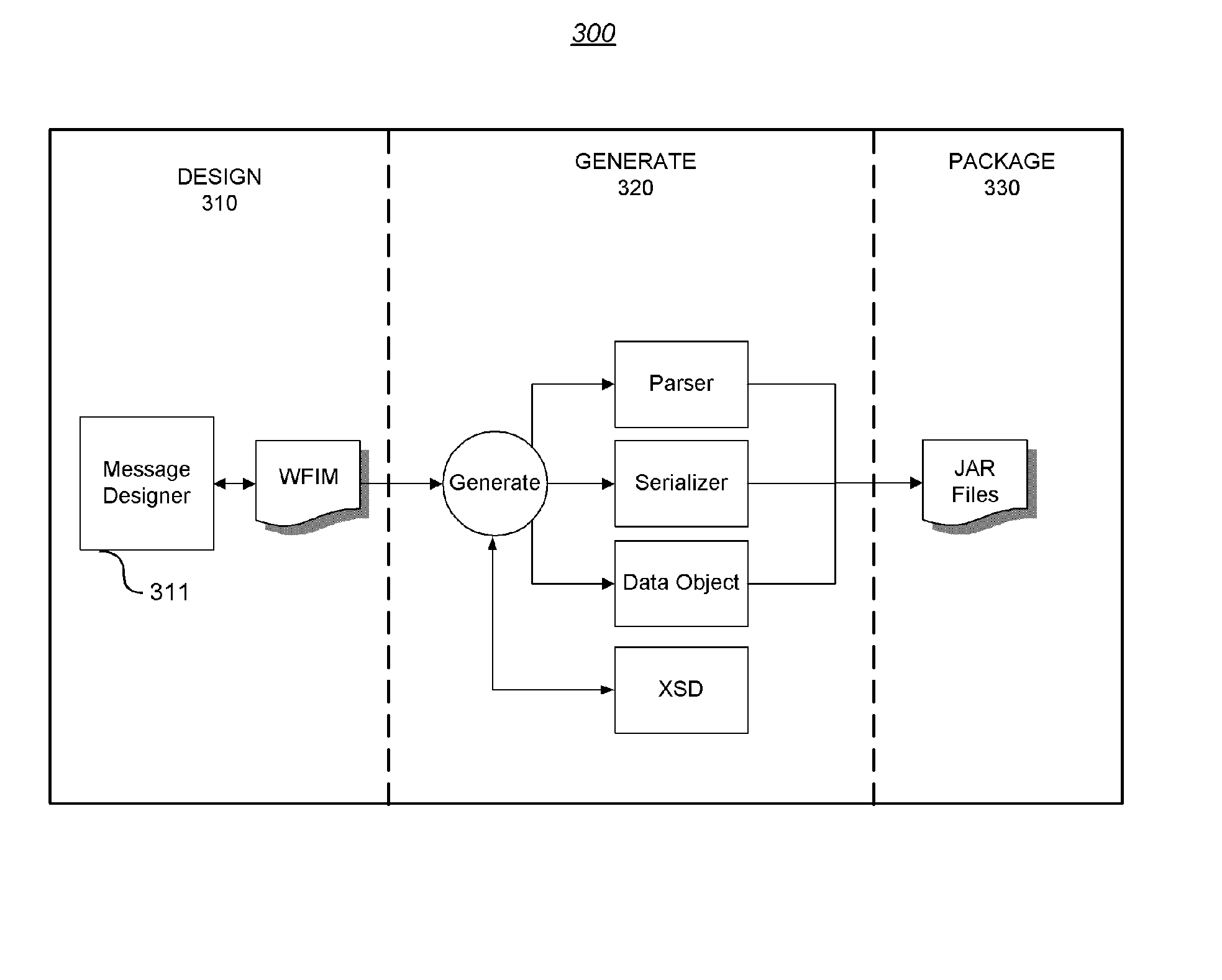

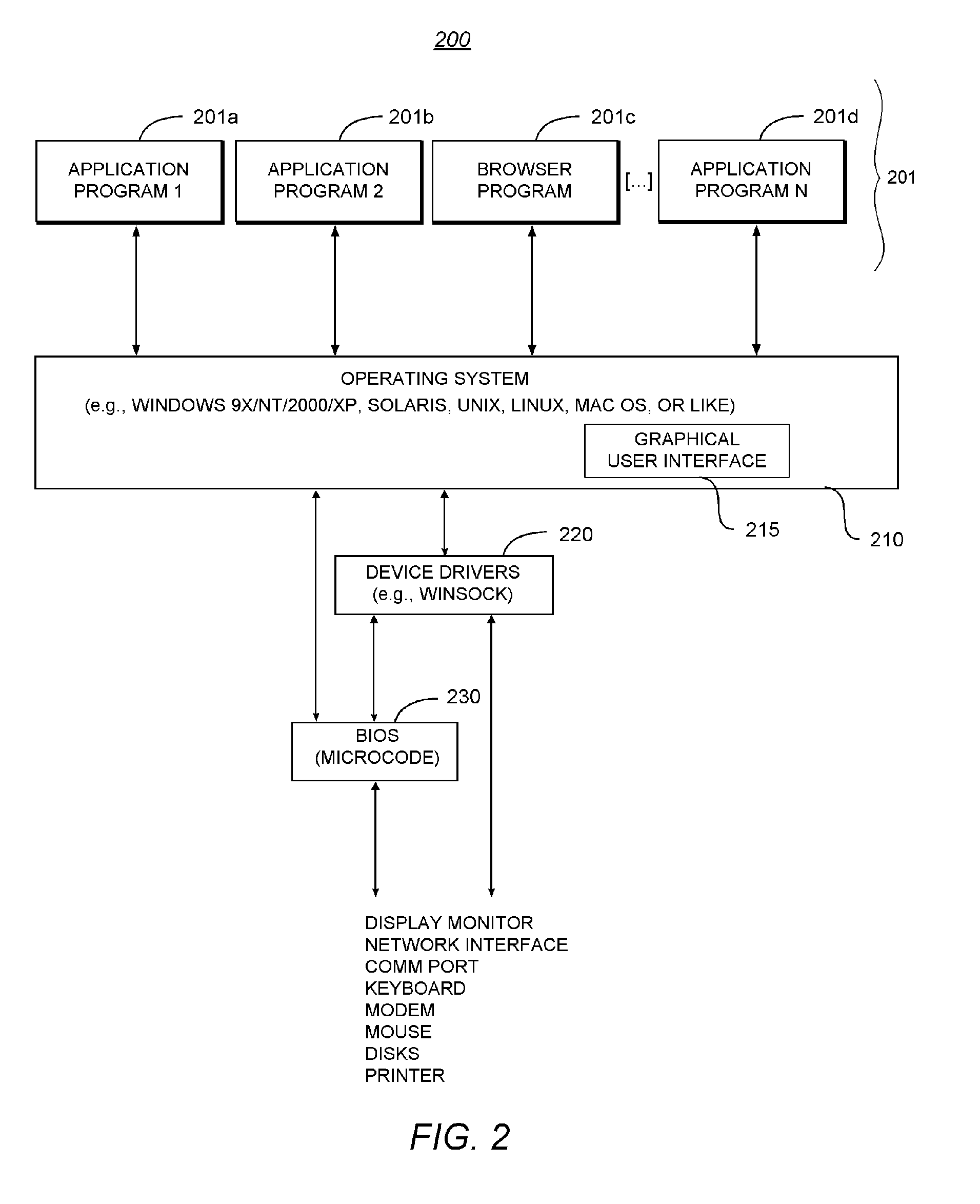

Development System with Methodology Providing Optimized Message Parsing and Handling

ActiveUS20070044069A1Increase processOptimized handlingCompiler constructionSpecific program execution arrangementsMetadataMessage type

Owner:SYBASE INC

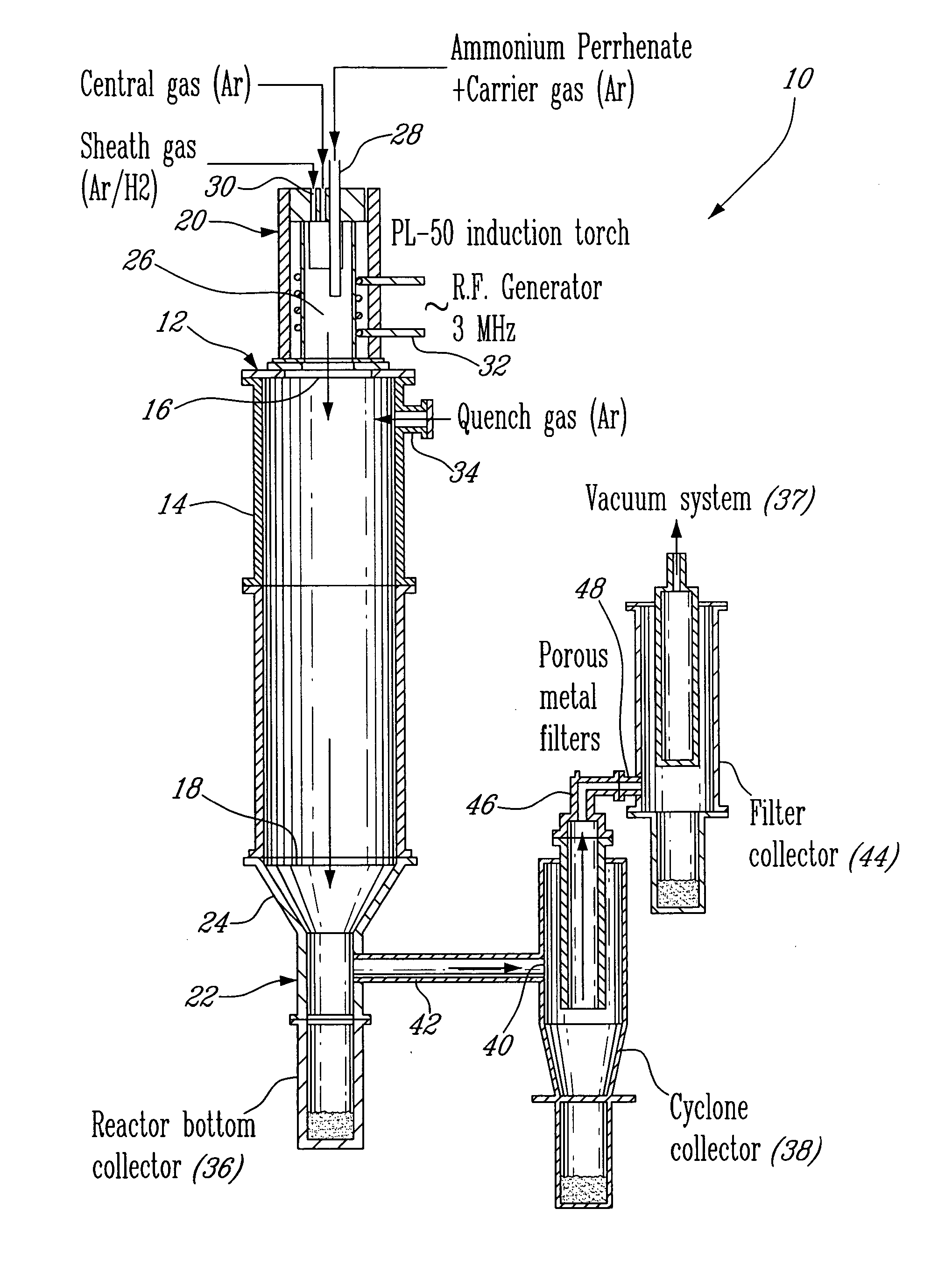

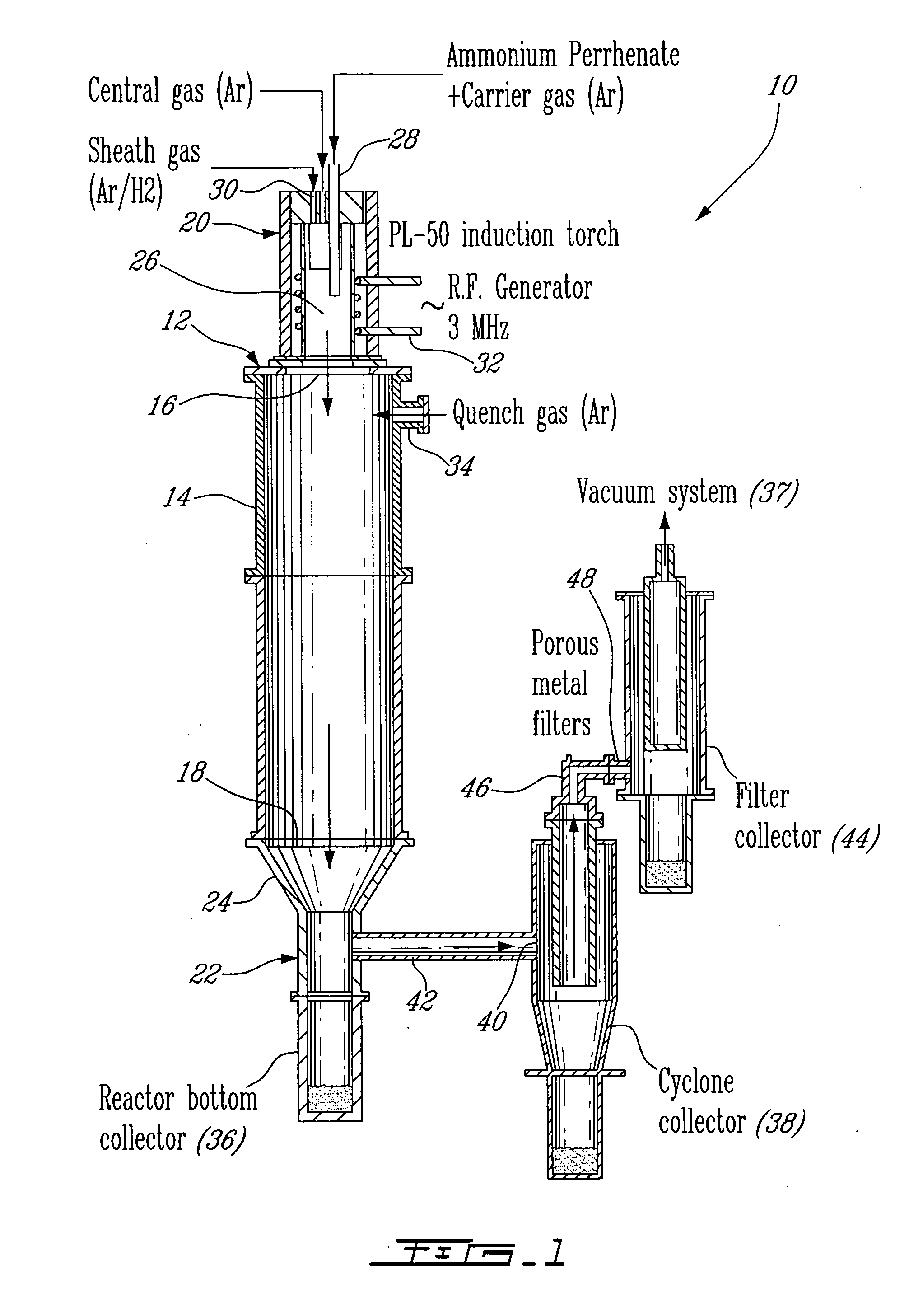

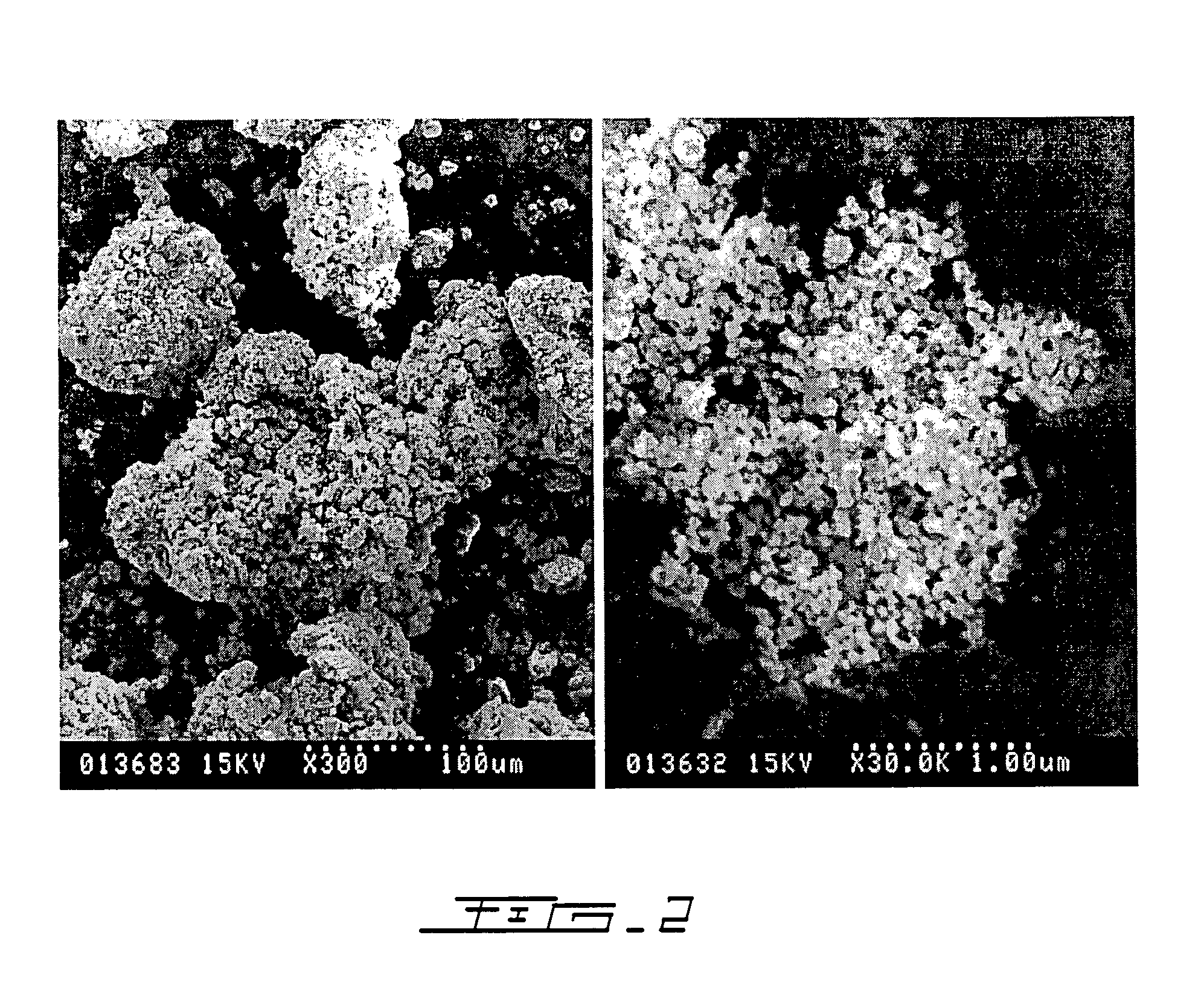

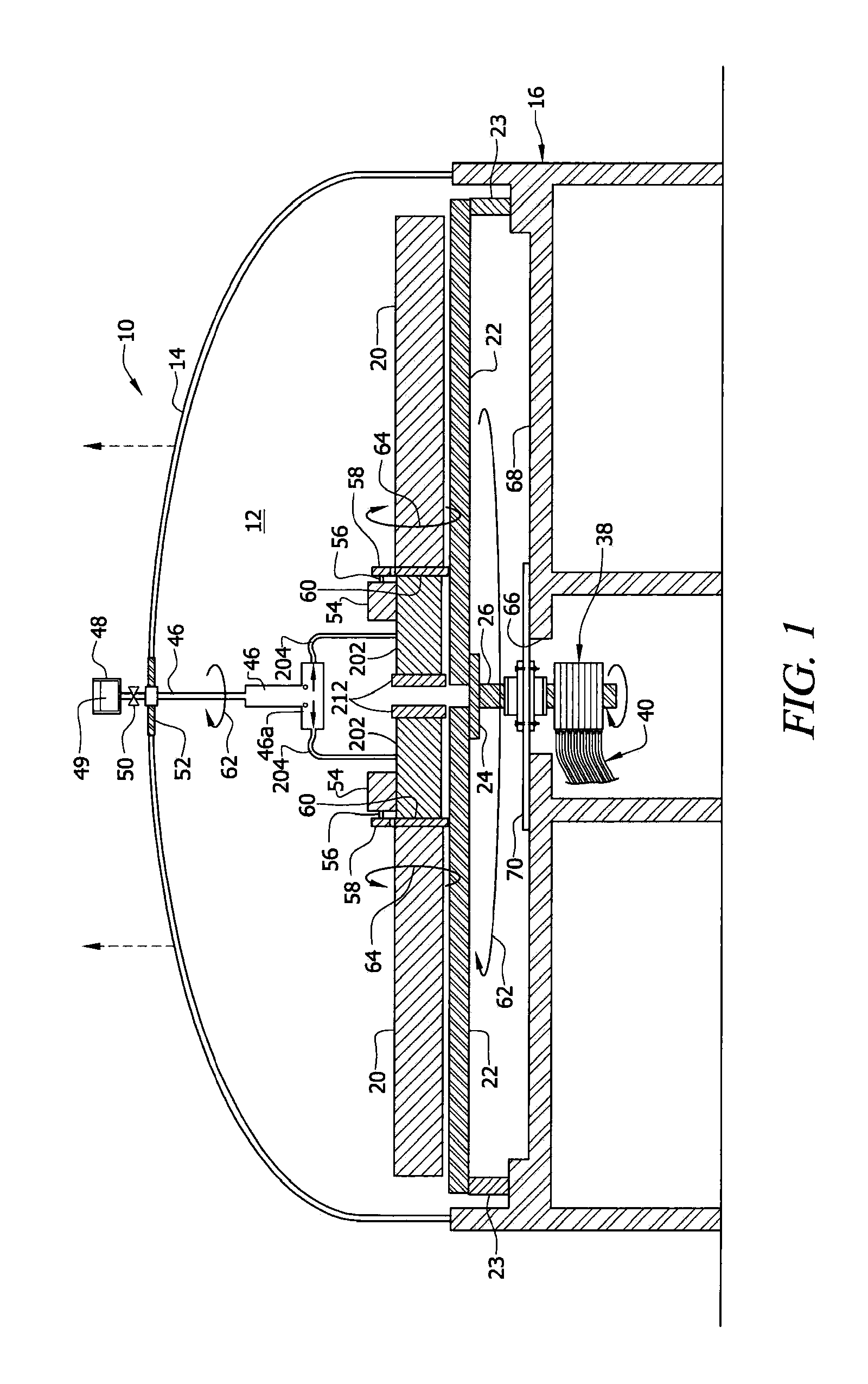

Process for plasma synthesis of rhenium nano and micro powders, and for coatings and near net shape deposits thereof and apparatus therefor

The process for the synthesis of rhenium powders comprises the injection of ammonium perrhenate powder through a carrier gas in a plasma torch of a plasma reactor operated using a mixture including hydrogen as the plasma gas, yielding metallic rhenium under the following chemical reaction: 2 NH4ReO4+4 H2→2 Re+N2↑+8 H2O↑. The reactor is provided with a quench zone for cooling the metallic rhenium so as to yield rhenium nano and micro powders.

Owner:TEKNA PLASMA SYST INC

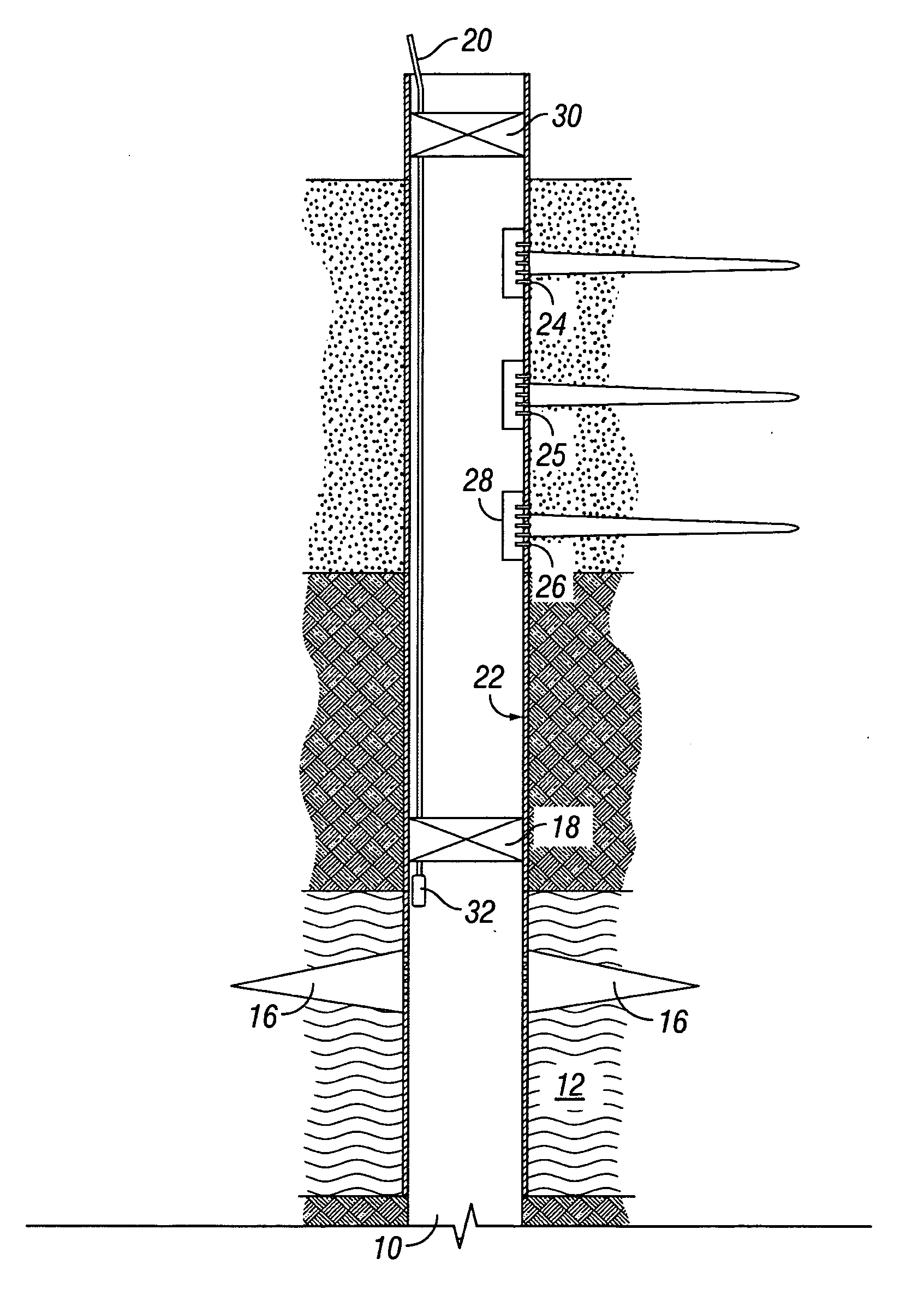

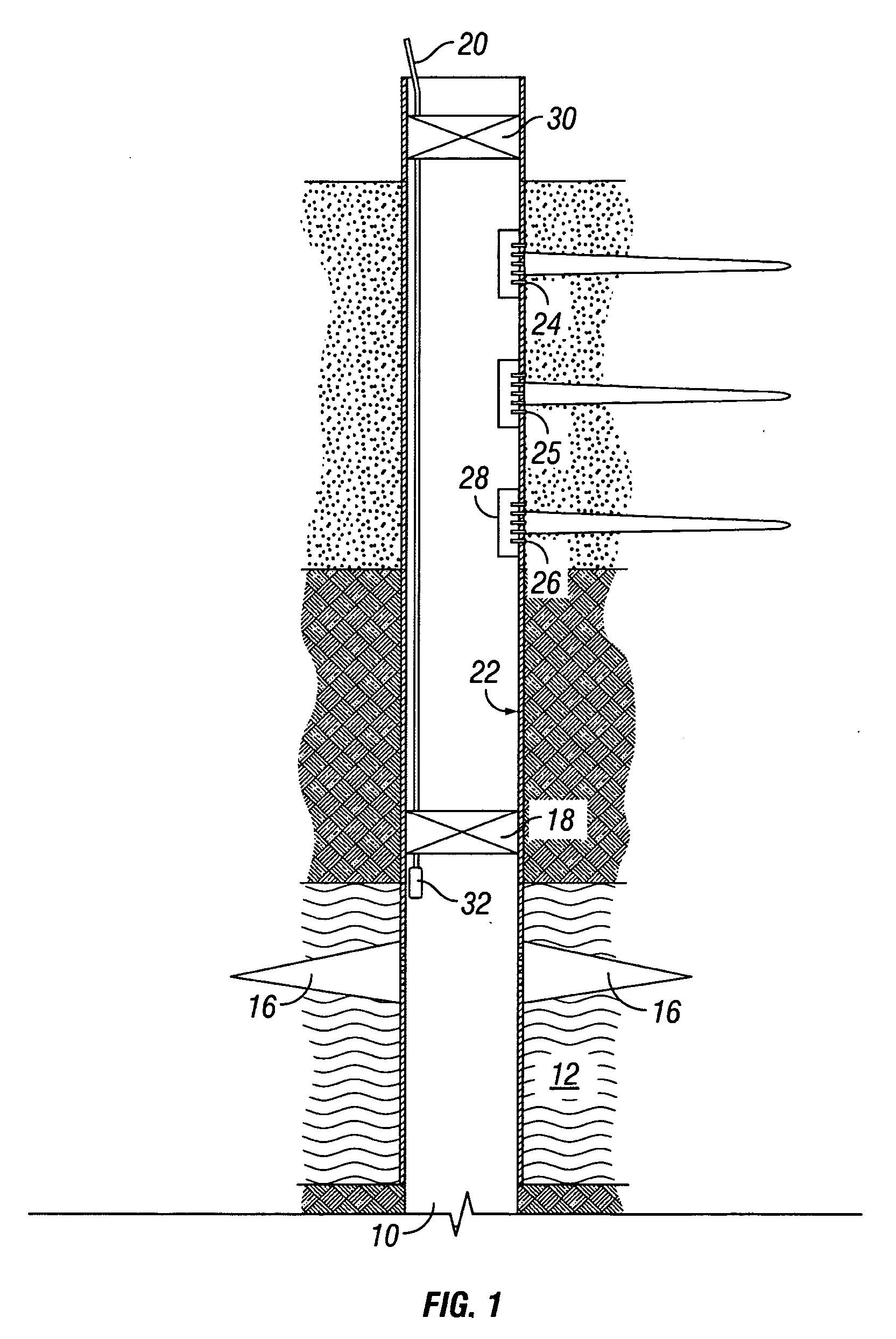

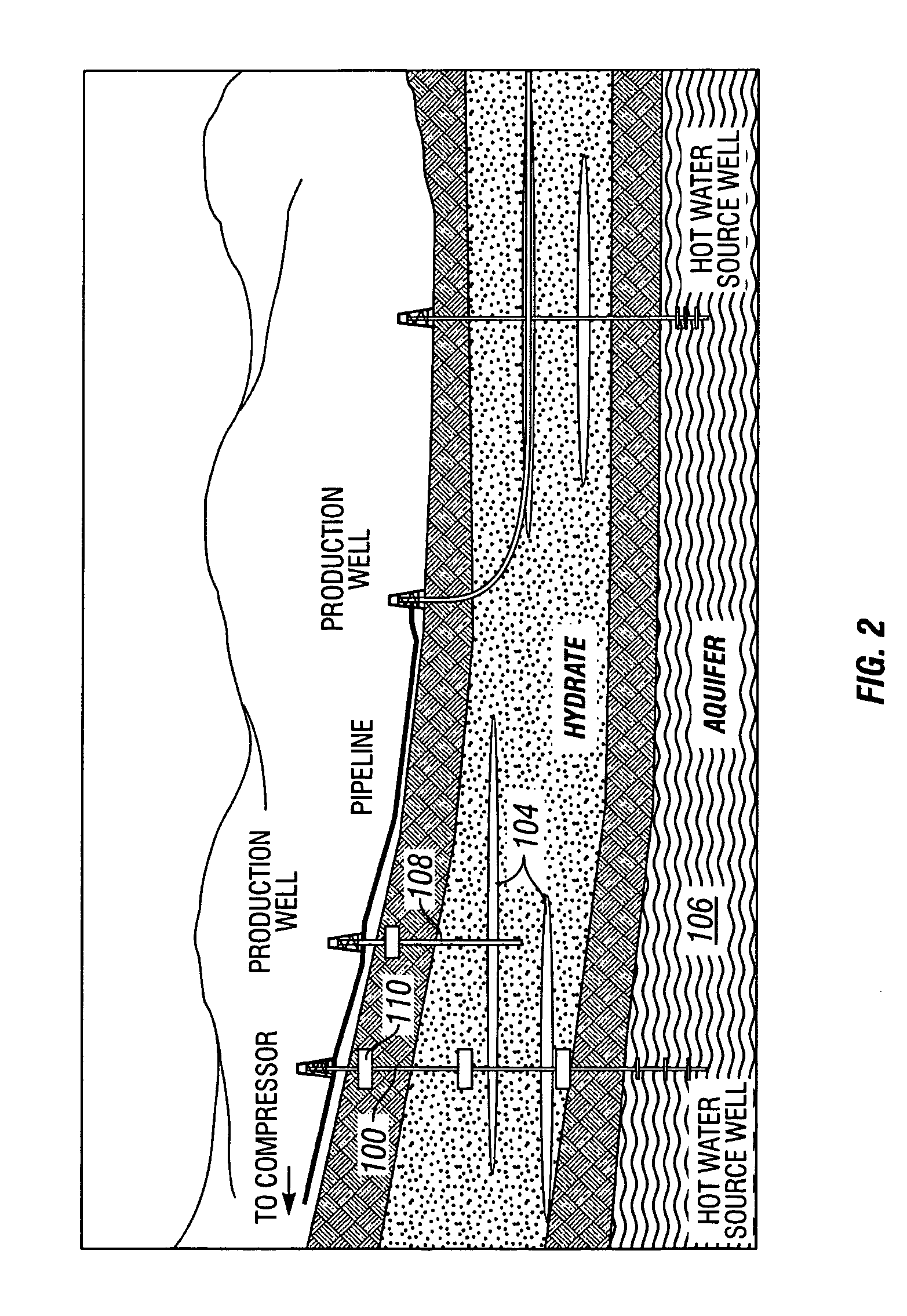

Method for exploitation of gas hydrates

InactiveUS20060032637A1Prevent methane leakageIncrease processSurveyConstructionsEnvironmental geologyStreamflow

A method and apparatus for producing gas from a hydrate formation includes the use of at least one wellbore which penetrates the hydrate formation and further extends into an aquifer below the hydrate formation. The aquifer provides relatively warm water which may be produced up and into the hydrate formation thereby causing the release of gas from the hydrate. Suitable flow control and monitoring equipment may be included to control the flow of water produced from the aquifer and gas produced from the hydrate formation.

Owner:SCHLUMBERGER TECH CORP

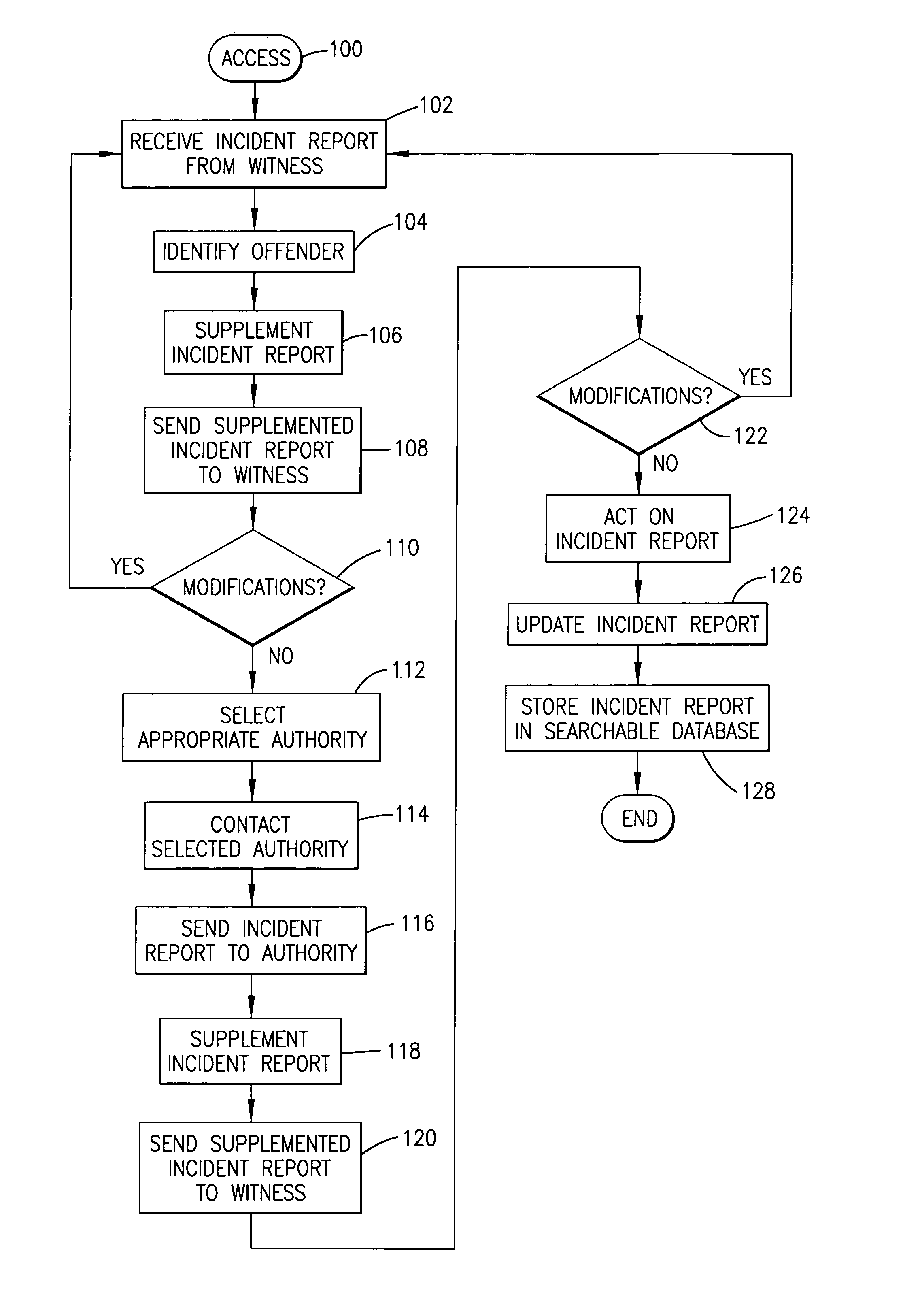

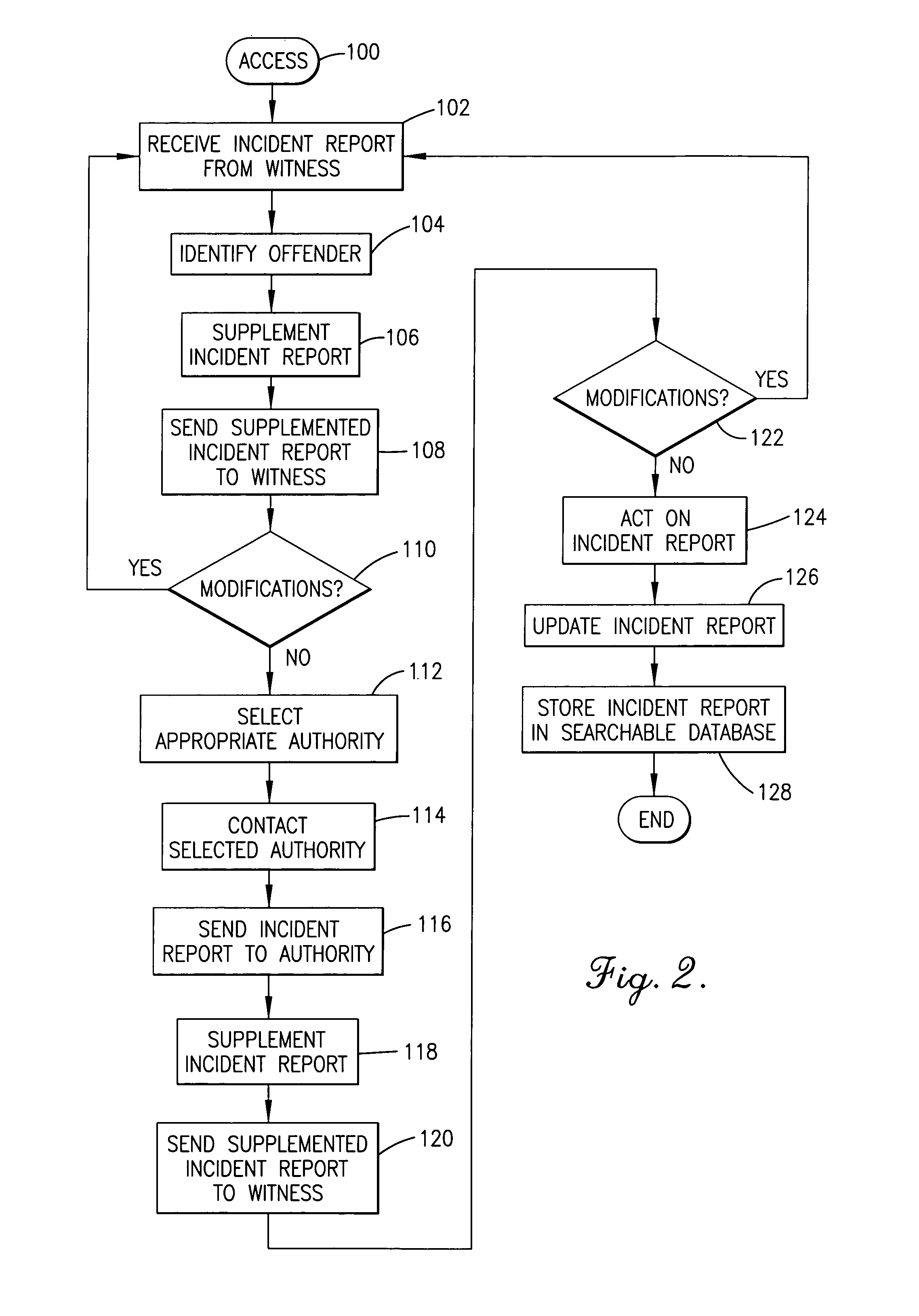

Incident reporting system and method

A computer-based method of collecting and processing incident reports received from witnesses who observe incidents such as criminal acts and legal violations. The method automates the collection and processing of the incident reports and automatically sends the incident reports to the appropriate authority so that the observed incidents can be acted on in an appropriate manner.

Owner:SLOO MARSHALL A

Process for removal of carbonyl sulfide from hydrocarbons

InactiveUS6843907B1Increase processHydrocarbonsAdsorption purification/separationSorbentCarbonyl sulfide

The invention comprises a process for removal of carbonyl sulfide from a hydrocarbon, which comprises contacting a hydrocarbon stream containing carbonyl sulfide with an adsorbent and then regenerating the adsorbent by passing a heated gas, containing a hydrolyzing agent. The adsorbent that is regenerated by using this process retains at least 70% of its capacity for adsorption of sulfur as compared to fresh adsorbent.

Owner:UOP LLC

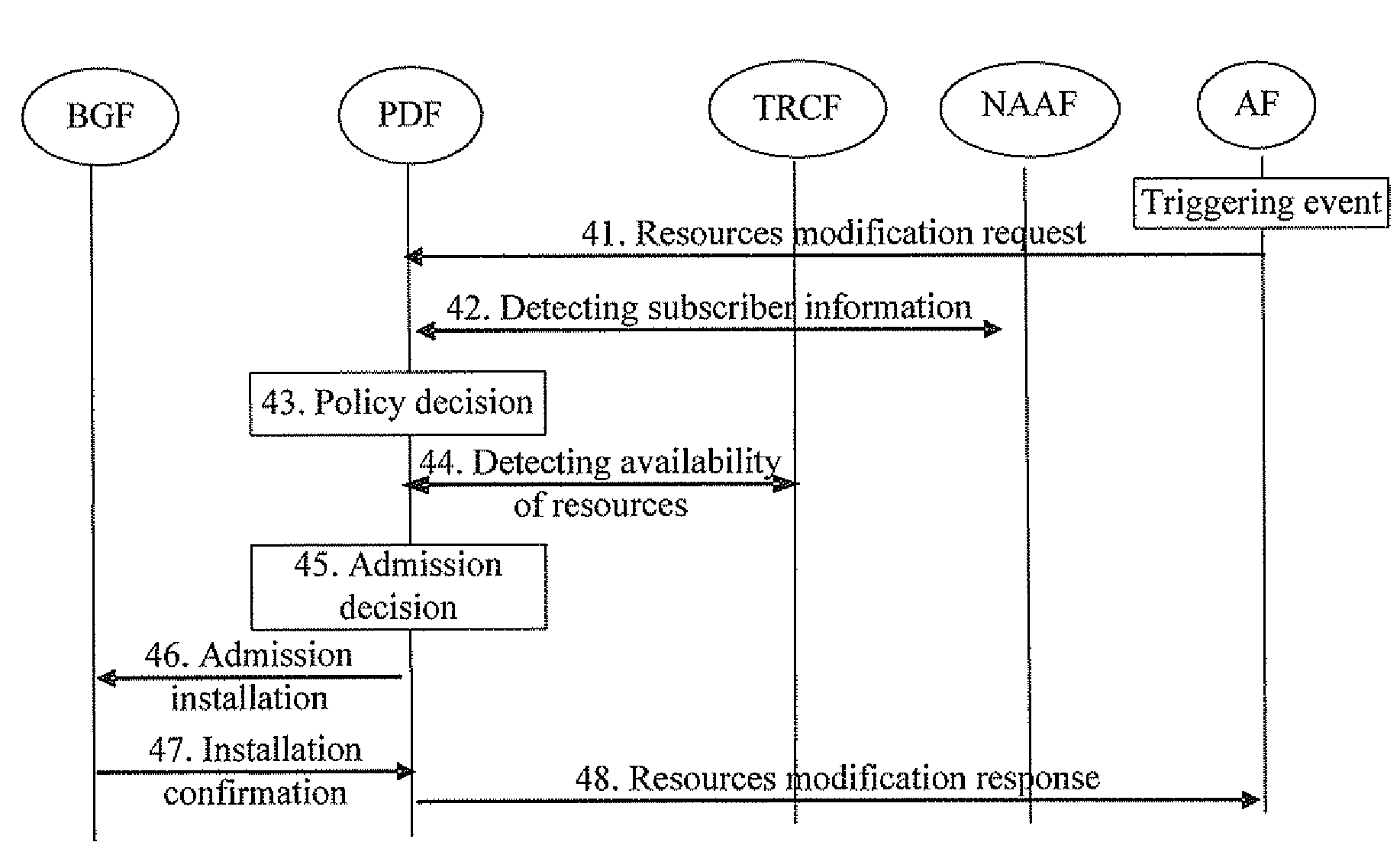

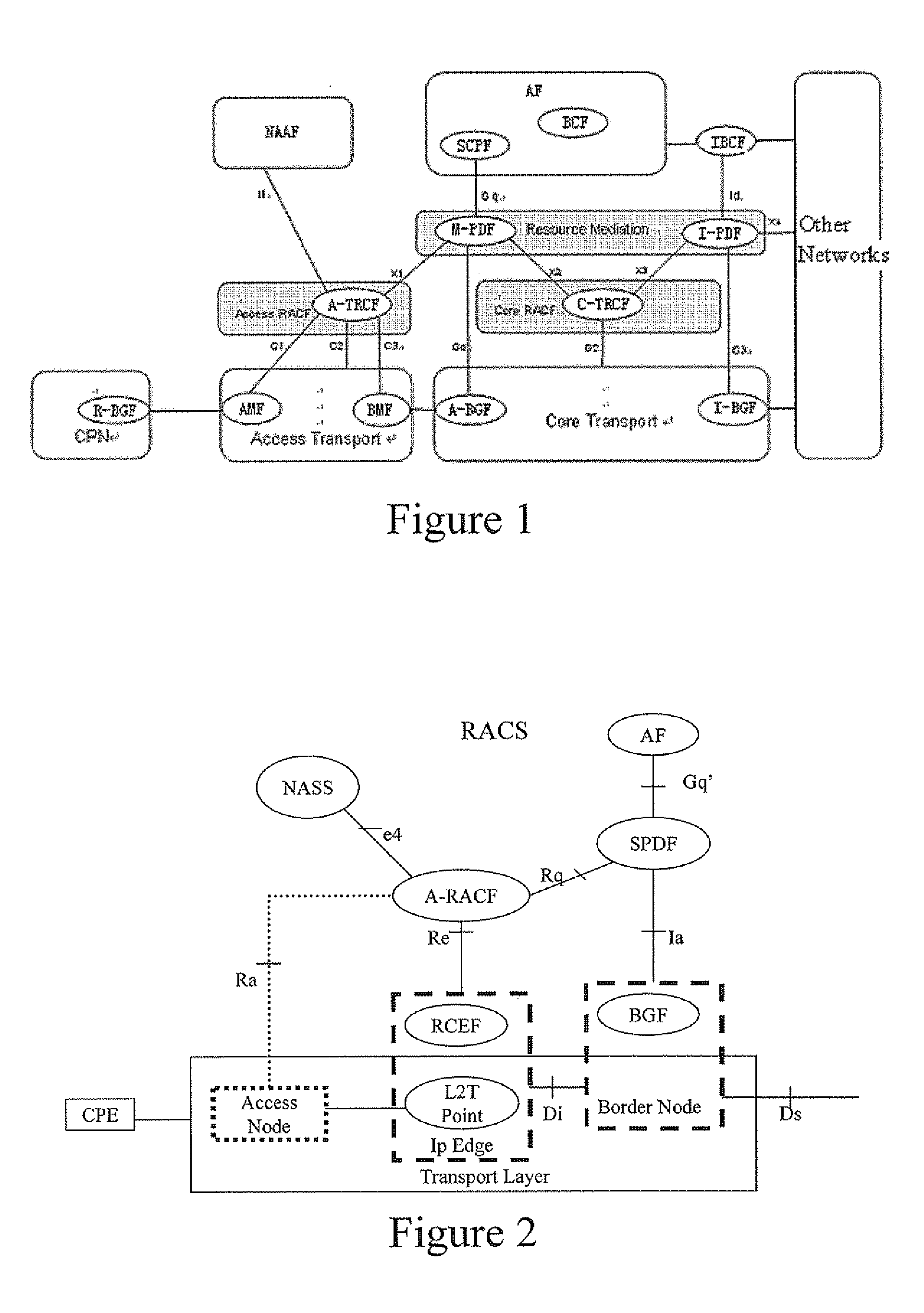

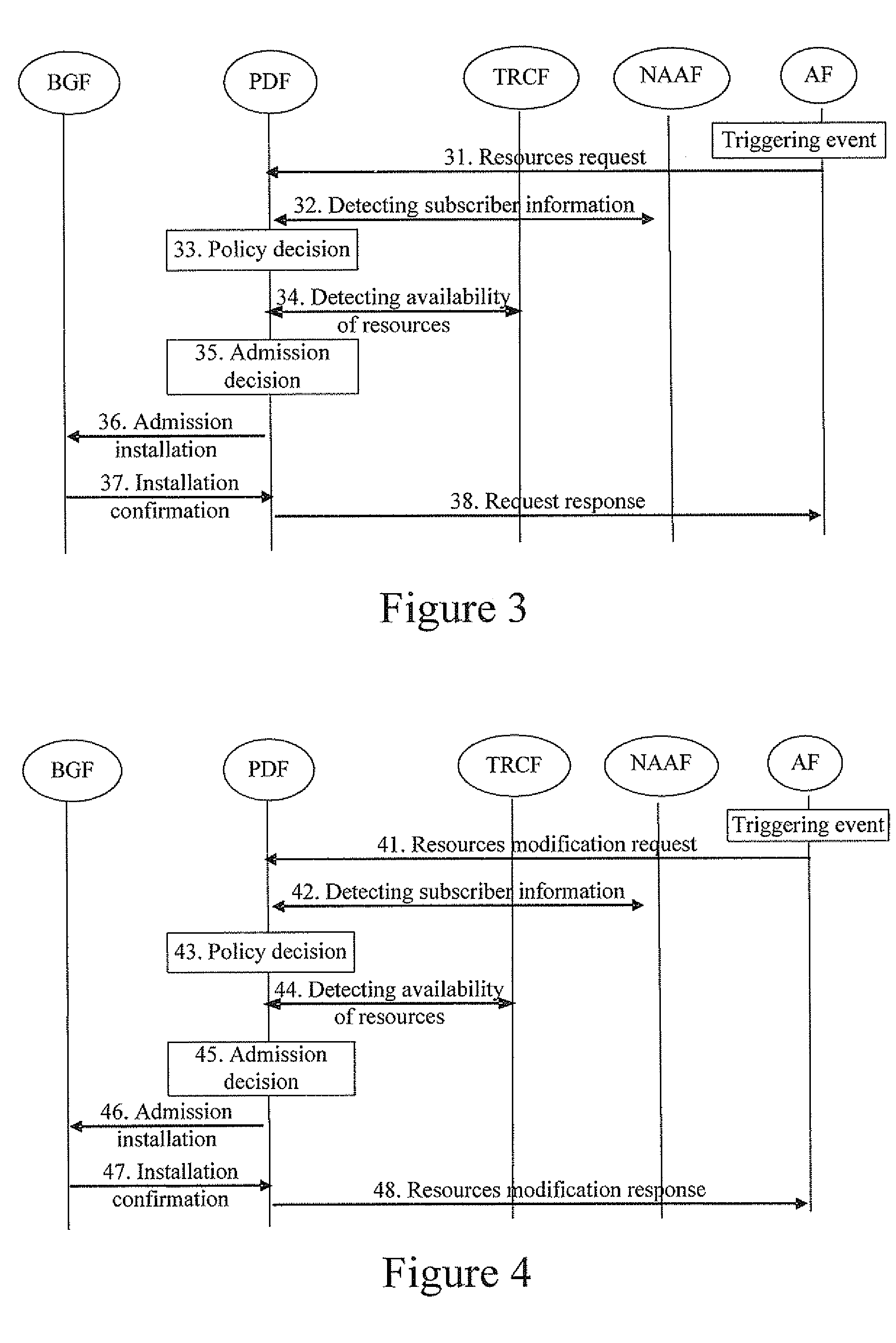

Method for Implementing Resources Reservation in a Proxy-Requested Mode in Next Generation Network

ActiveUS20080256237A1Simple processIncrease processNetwork traffic/resource managementDigital computer detailsTraffic volumeTraffic capacity

A method for implementing resources reservation in a proxy-requested mode in an NGN, includes: an AF entity sending a resources request message carrying resources requirement parameters information on behalf of a user to a resources mediation PDF; the resources mediation PDF making an admission decision according to network operation policy rules, subscriber configuration files, and availability of transport resources; if the corresponding resources request is admitted, the resources mediation PDF sending an admission installation command to a BGF, setting and keeping corresponding admission decision parameters information in the BGF; the BGF forwarding subscriber traffic entering networks according to the admission decision parameters information to ensure QoS class requested by the user. According to the present invention, terminals with various QoS negotiation capabilities are supported, and QoS requirement parameters of the media flows are negotiated or are determined by the AF entity according to the media flows and service operation policies.

Owner:HUAWEI TECH CO LTD

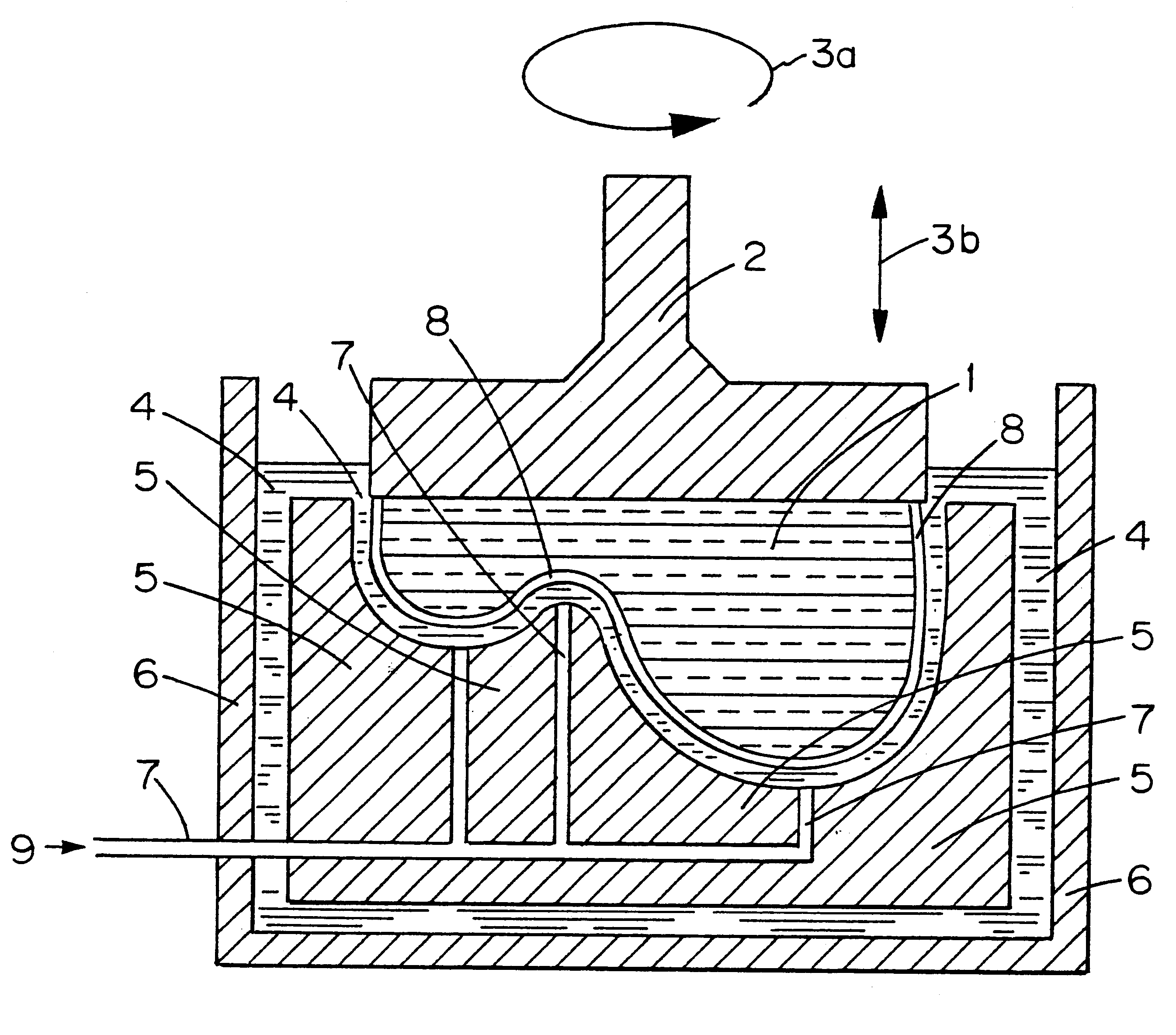

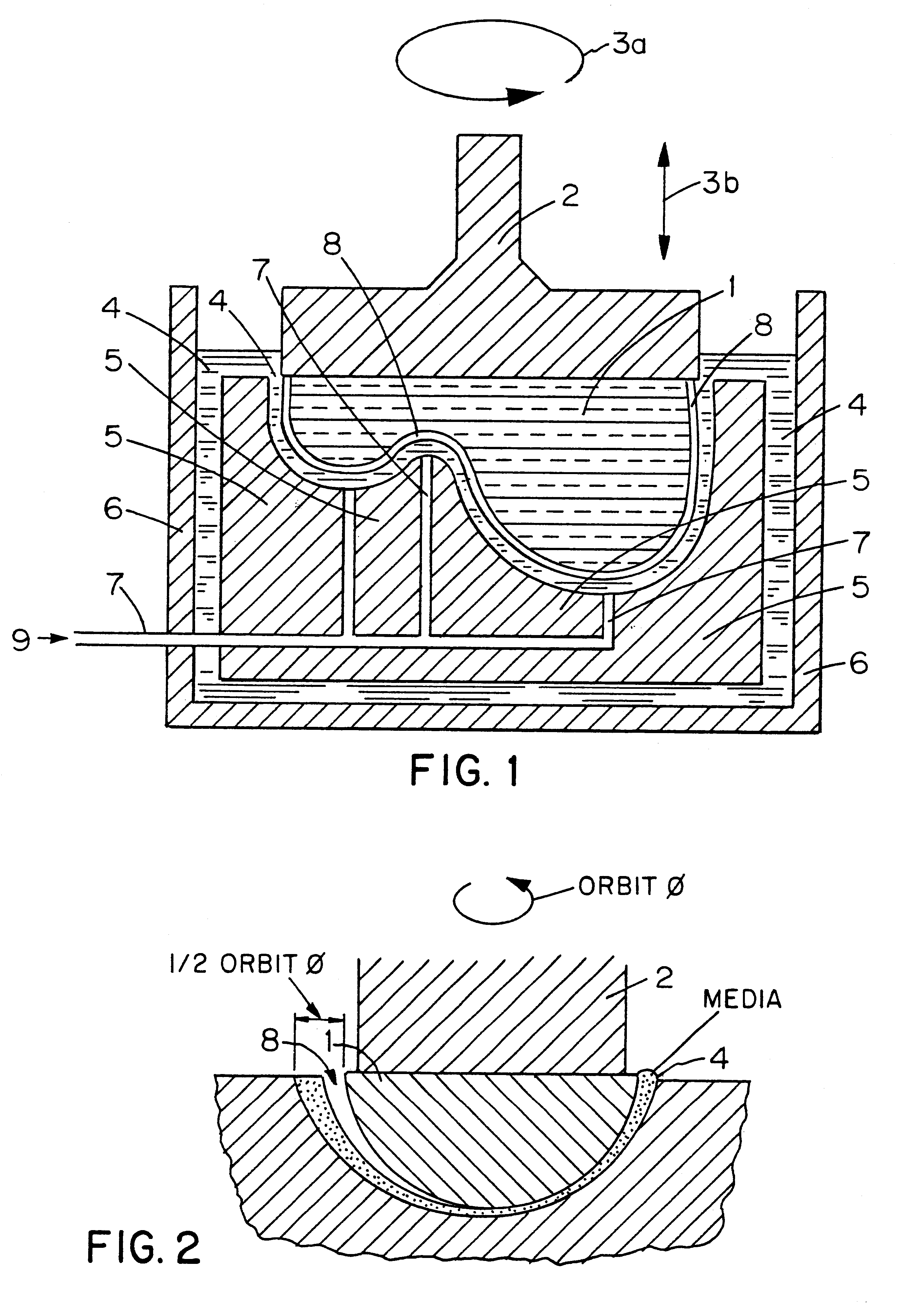

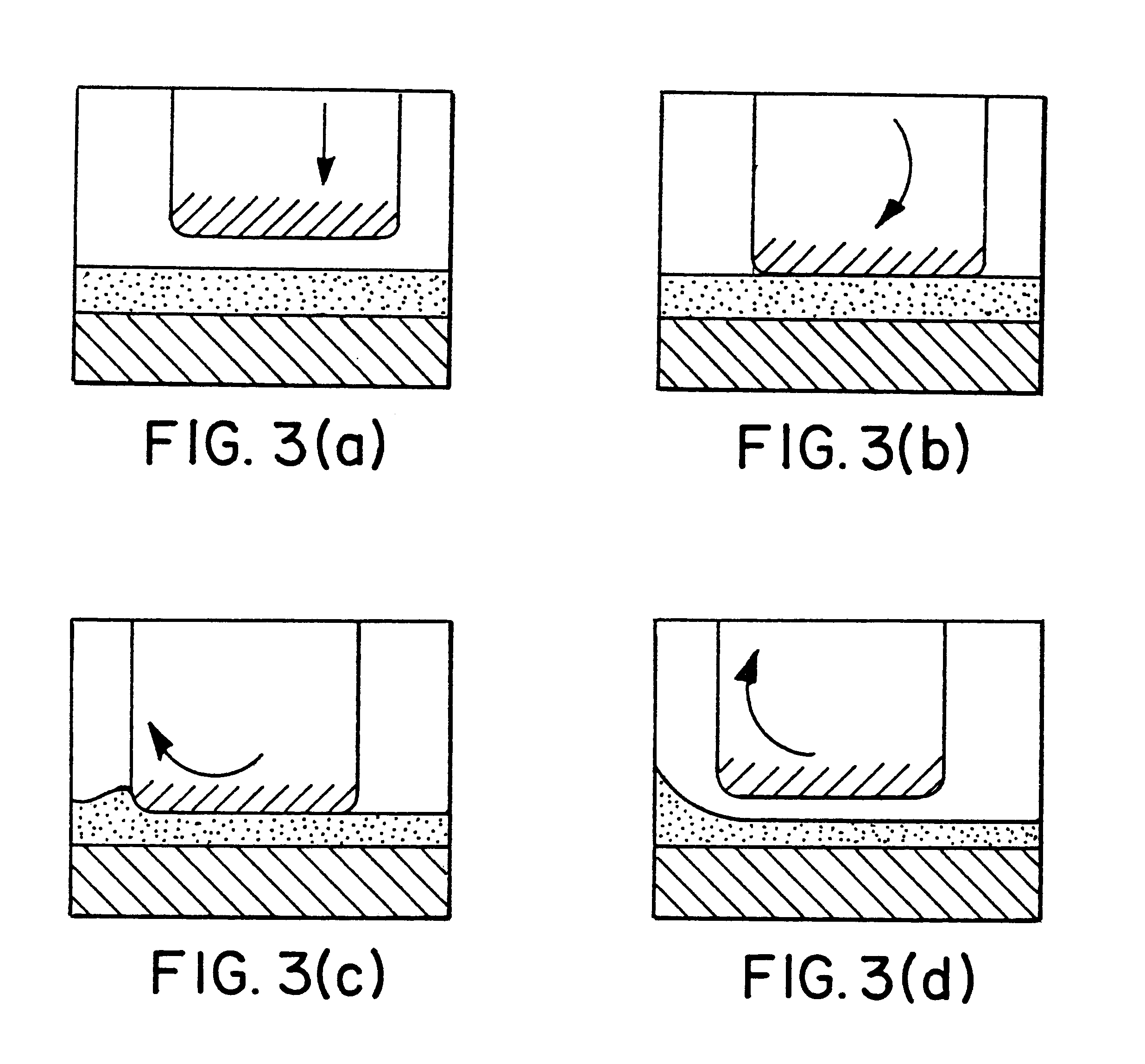

Abrasive polishing method using a visco-elastic abrasive medium

InactiveUS6273787B1Increase processMaximized depth of cutEdge grinding machinesPigmenting treatmentSiloxaneStrain rate

The present invention is based on the practice of abrasive machining with no sealed working chamber by the employment of a visco-elastic abrasive medium, behaving predominantly as an elastic solid at the applied strain of the orbital working motion, and applying orbital or other relative working motion to produce strain rates which bring the medium into a predominantly elastic deformation and often near, but not to exceed, the compressive stress limit at the strain rate employed. The preferred visco-elastic abrasive medium is a rheopectic poly(boro-siloxane) filled with viscosity increasing stiffening agents and high loadings of the abrasive of choice and relatively minor amounts of plasticizers. The system is operated in an open chamber under applied strain rates such that at least about 50%, particularly about 50 to 99%, and preferably about 80 to 95%, of the deflection of the medium tinder the conditions of operation occurs by elastic deformation and is elastically recovered, and less than 50%, particularly about 1 to 50%, preferably about 5 to 20%, of the deflection of the medium occurs by fluid or plastic flow.

Owner:EXTRUDE HONE CORP

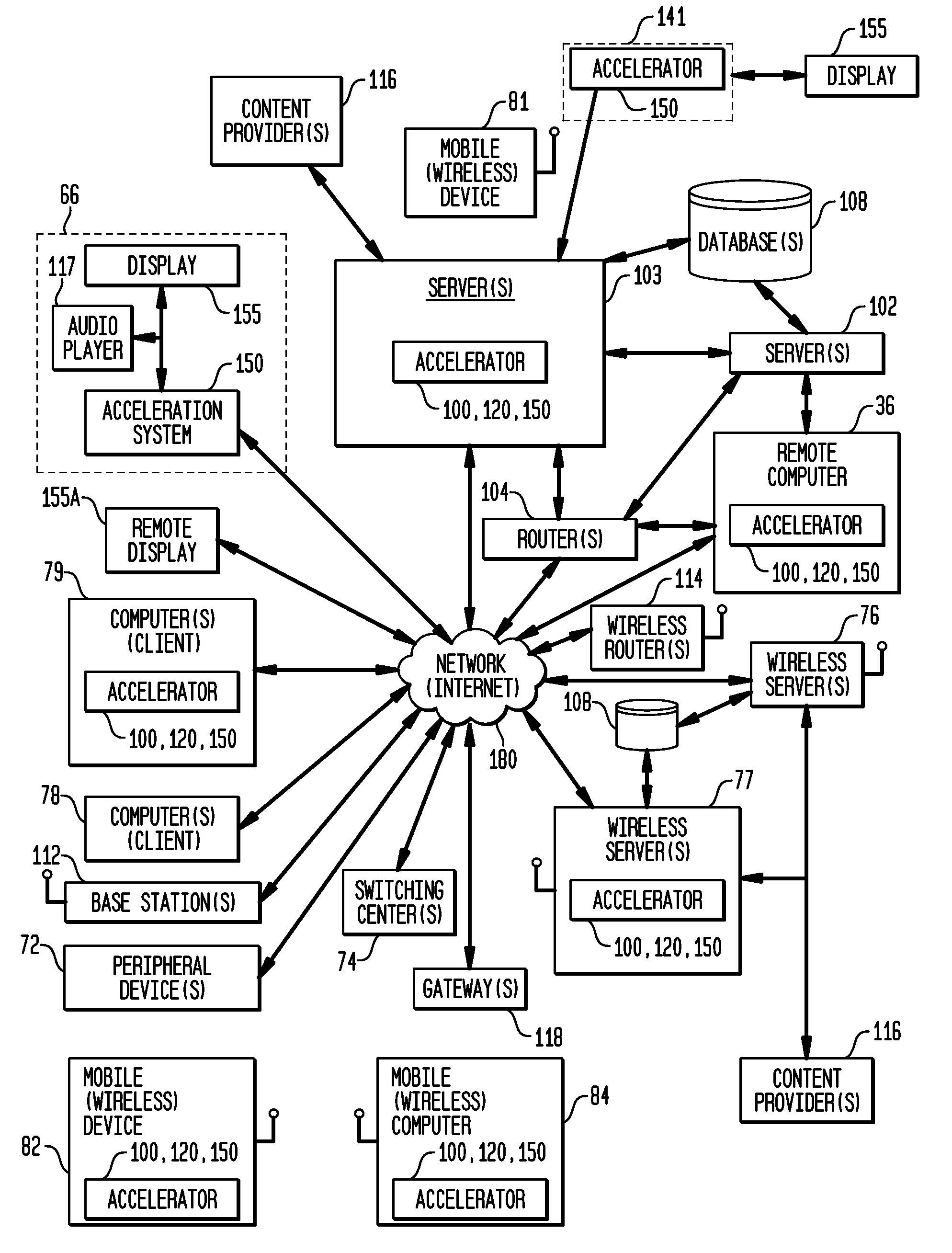

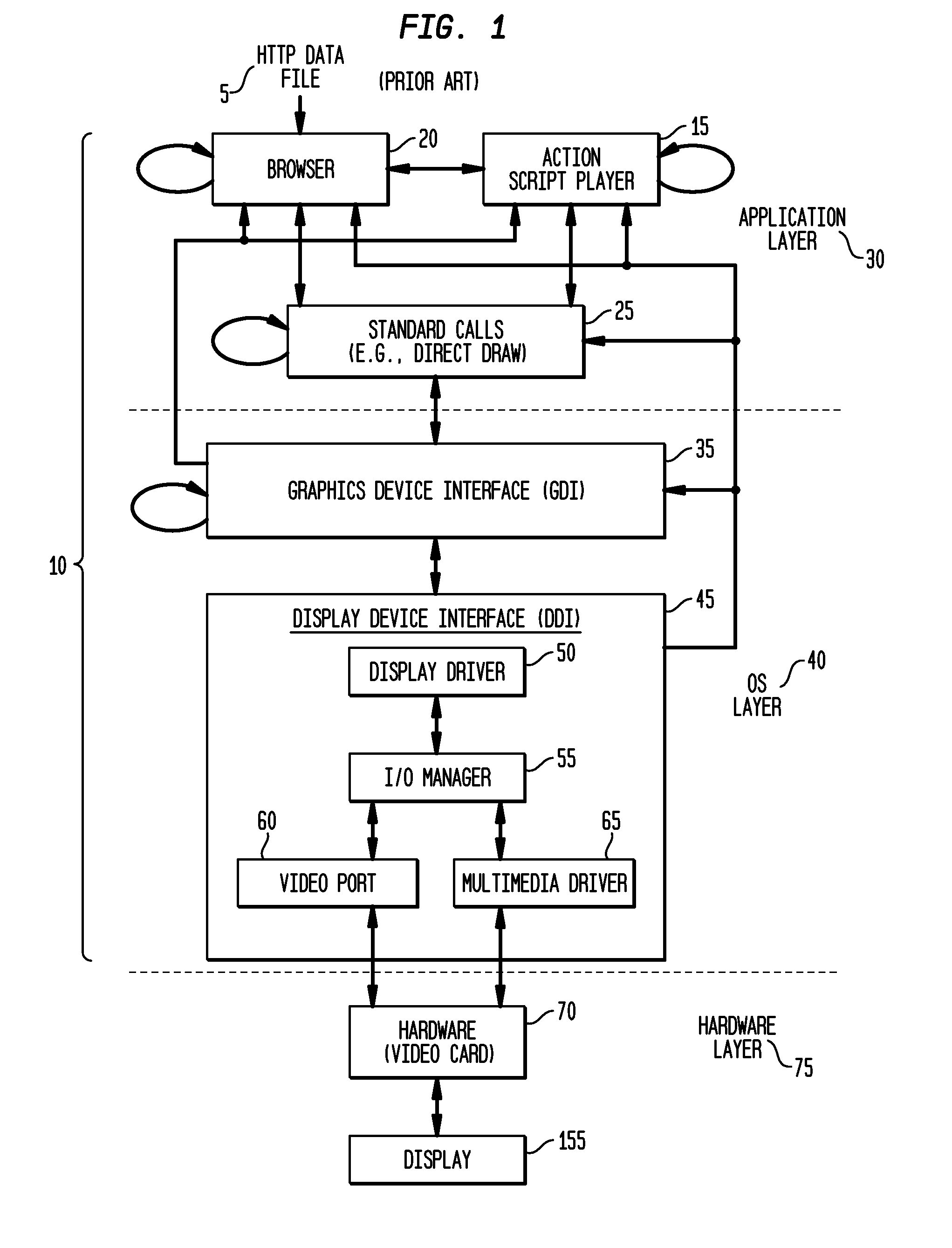

Media Action Script Acceleration Apparatus

ActiveUS20100153692A1Increase processIncrease conversionsDrawing from basic elementsCathode-ray tube indicatorsAction CodeGraphics

Exemplary apparatus, method, and system embodiments provide for accelerated hardware processing of an action script for a graphical image for visual display. An exemplary apparatus comprises: a first memory; and a plurality of processors to separate the action script from other data, to convert a plurality of descriptive elements of the action script into a plurality of hardware-level operational or control codes, and to perform one or more operations corresponding to an operational code of the plurality of operational codes using corresponding data to generate pixel data for the graphical image. In an exemplary embodiment, at least one processor further is to parse the action script into the plurality of descriptive elements and the corresponding data, and to extract data from the action script and to store the extracted data in the first memory as a plurality of control words having the corresponding data in predetermined fields.

Owner:LEONOVUS USA

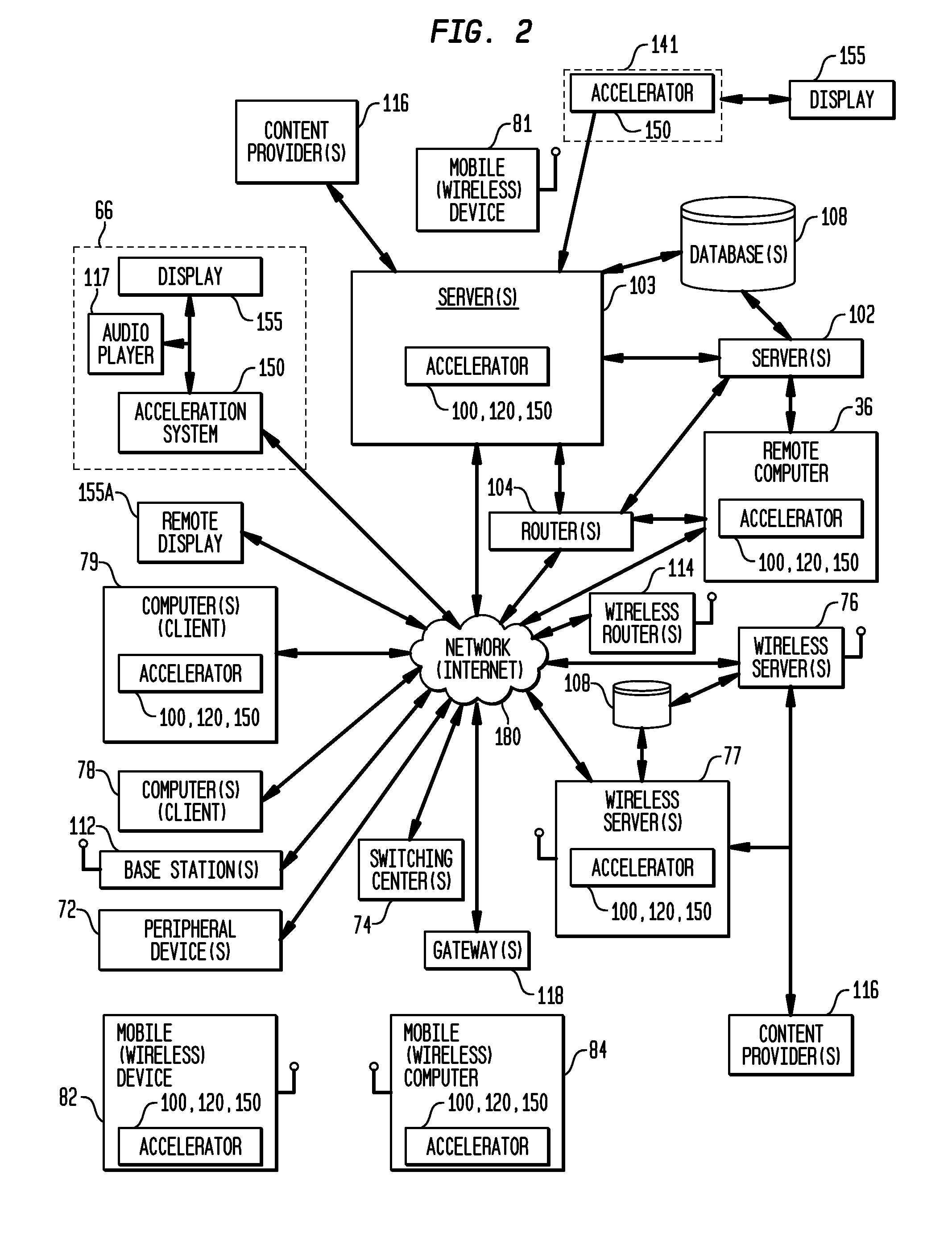

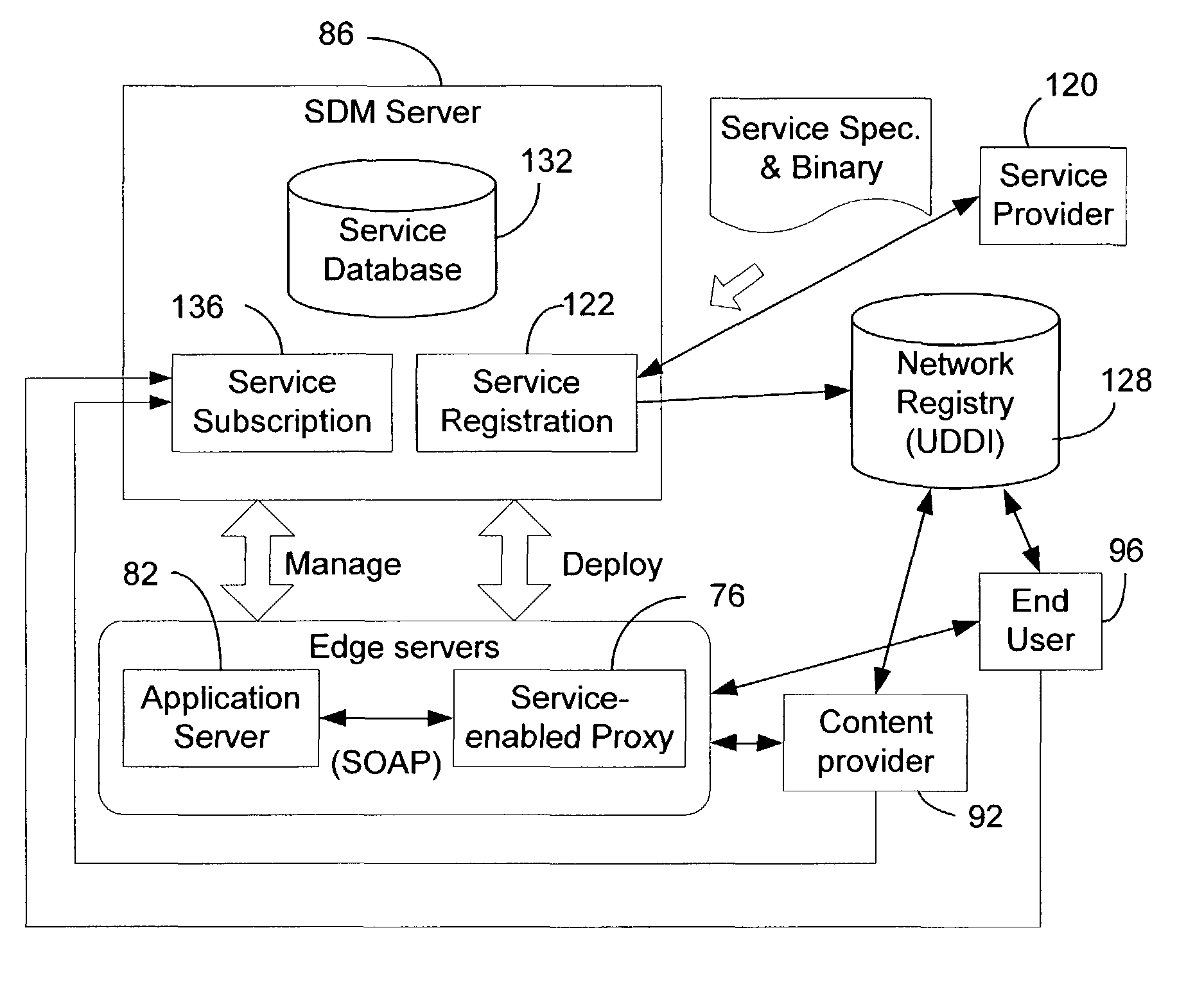

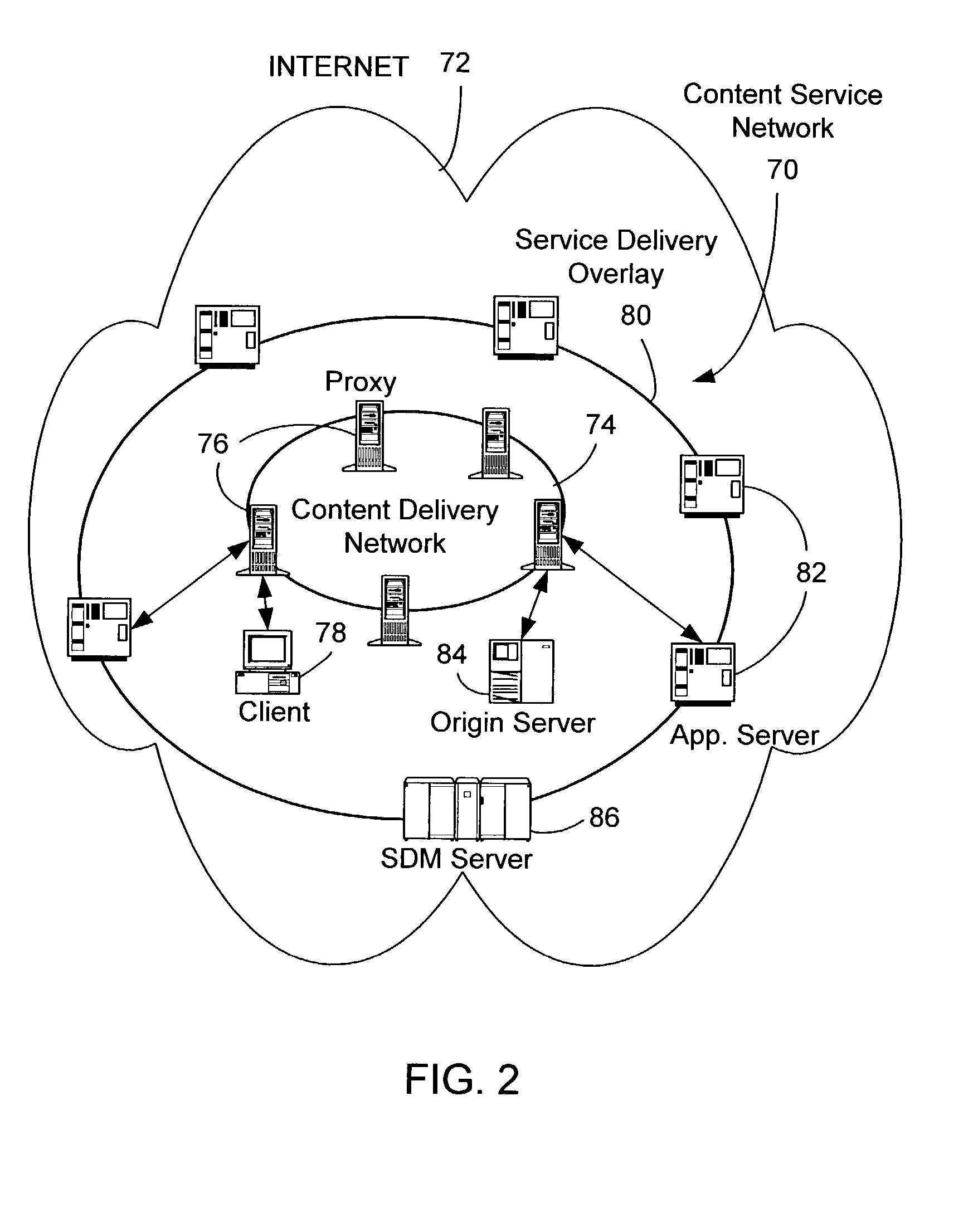

System and method for providing content-oriented services to content providers and content consumers

ActiveUS7809813B2Increase processDigital computer detailsWebsite content managementMessage passingApplication server

A content service network for providing content-oriented services over the Internet or similar networks comprises a service delivery overlay having a plurality of application servers and a content delivery network overlay having a plurality of service-enabled proxies in content delivery paths between content providers and content consumers. The service delivery overlay and the content delivery network collaborate to provide content-oriented processing, such as adaptive video delivery, content personalization, language translation, etc. The content service network accepts subscriptions from content providers and content consumer. For each subscription, service instructions including service binding data for binding the subscribed services with the subscriber's identity are generated and distributed to the service-enabled proxies. When a service-enabled proxy detects that a message passing therethrough requires a subscribed service, it retrieves service instructions for the service and renders the service either by making a remote call to an application service or by invoking a local execution module.

Owner:ROVI TECH CORP

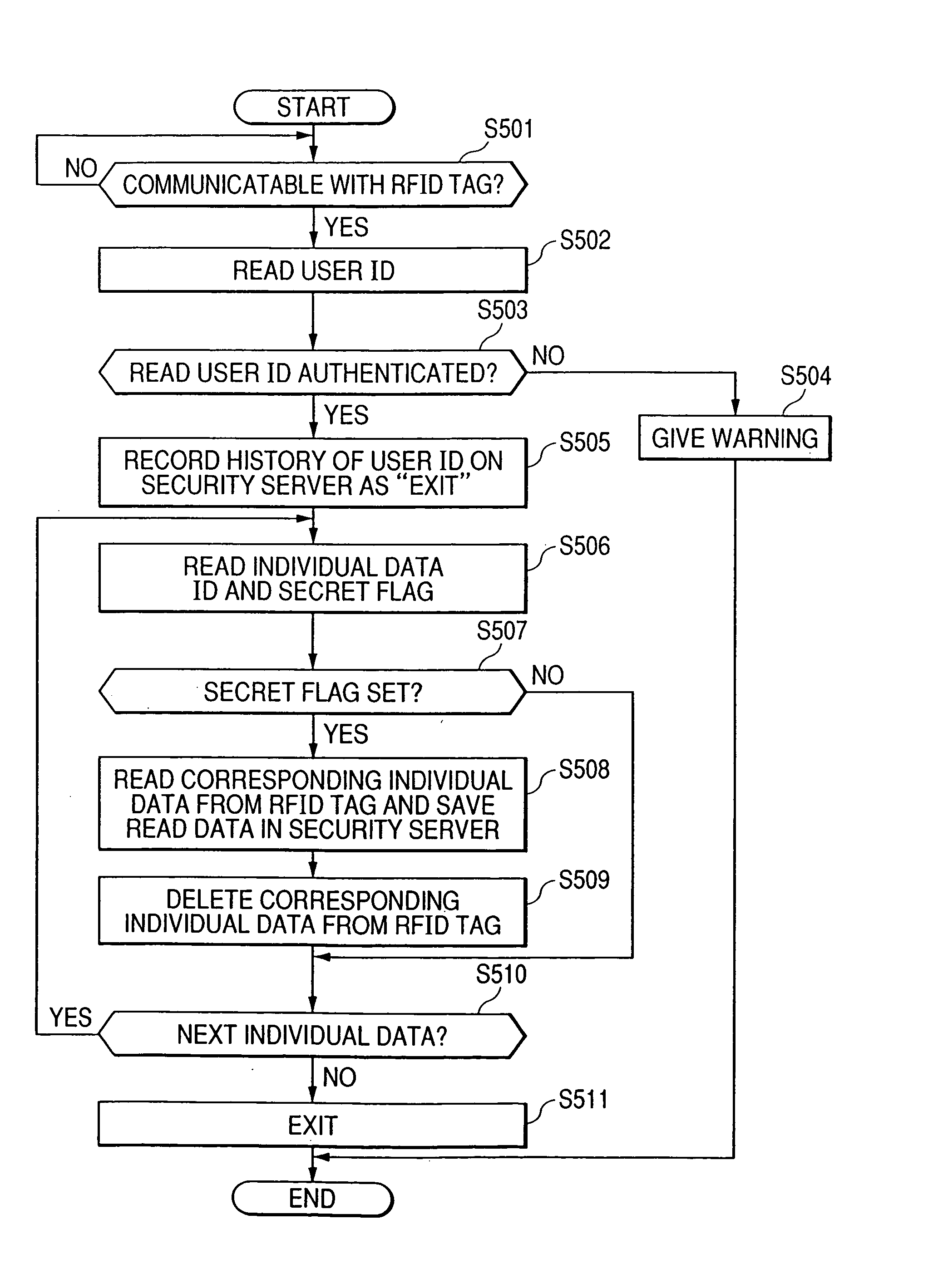

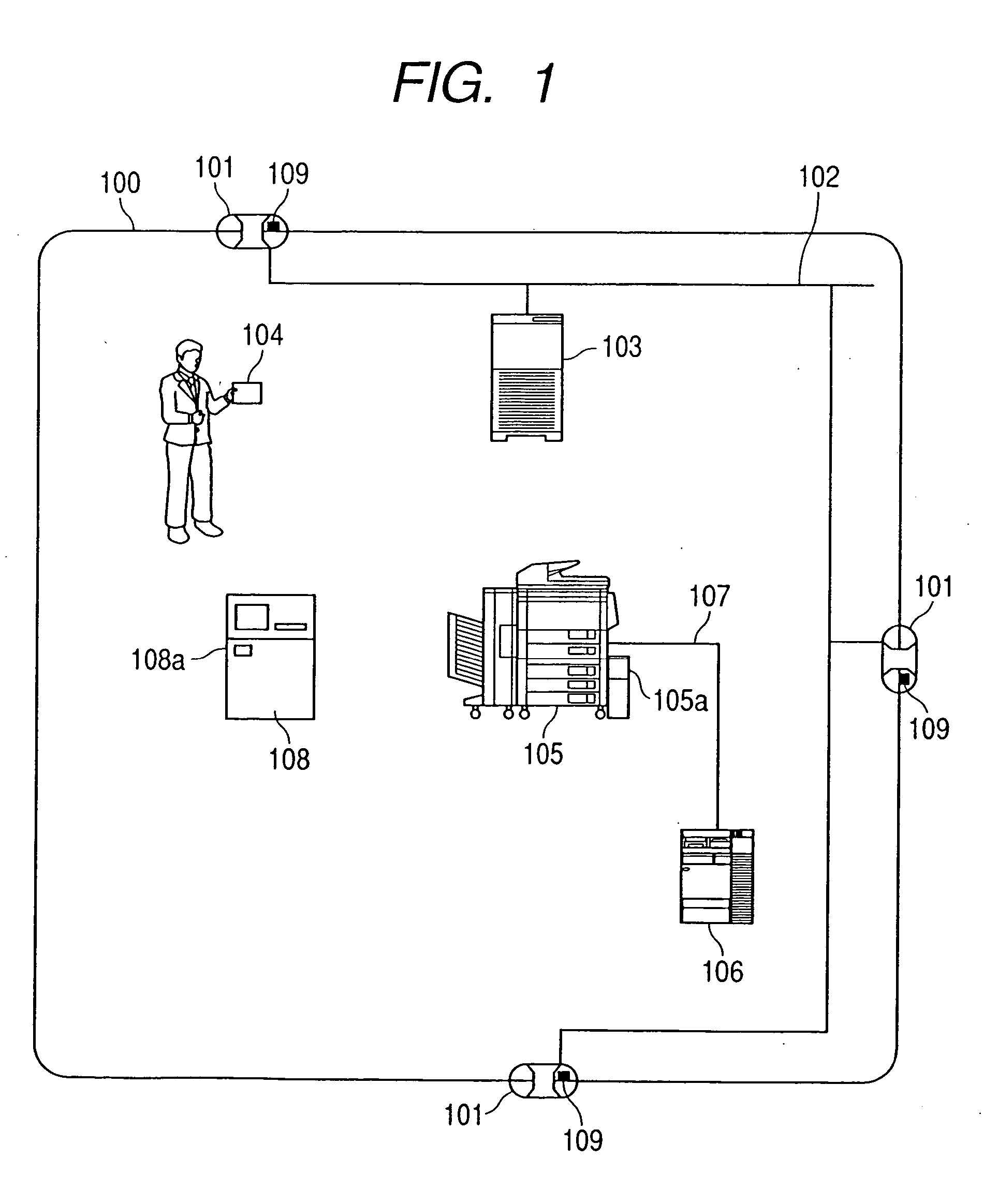

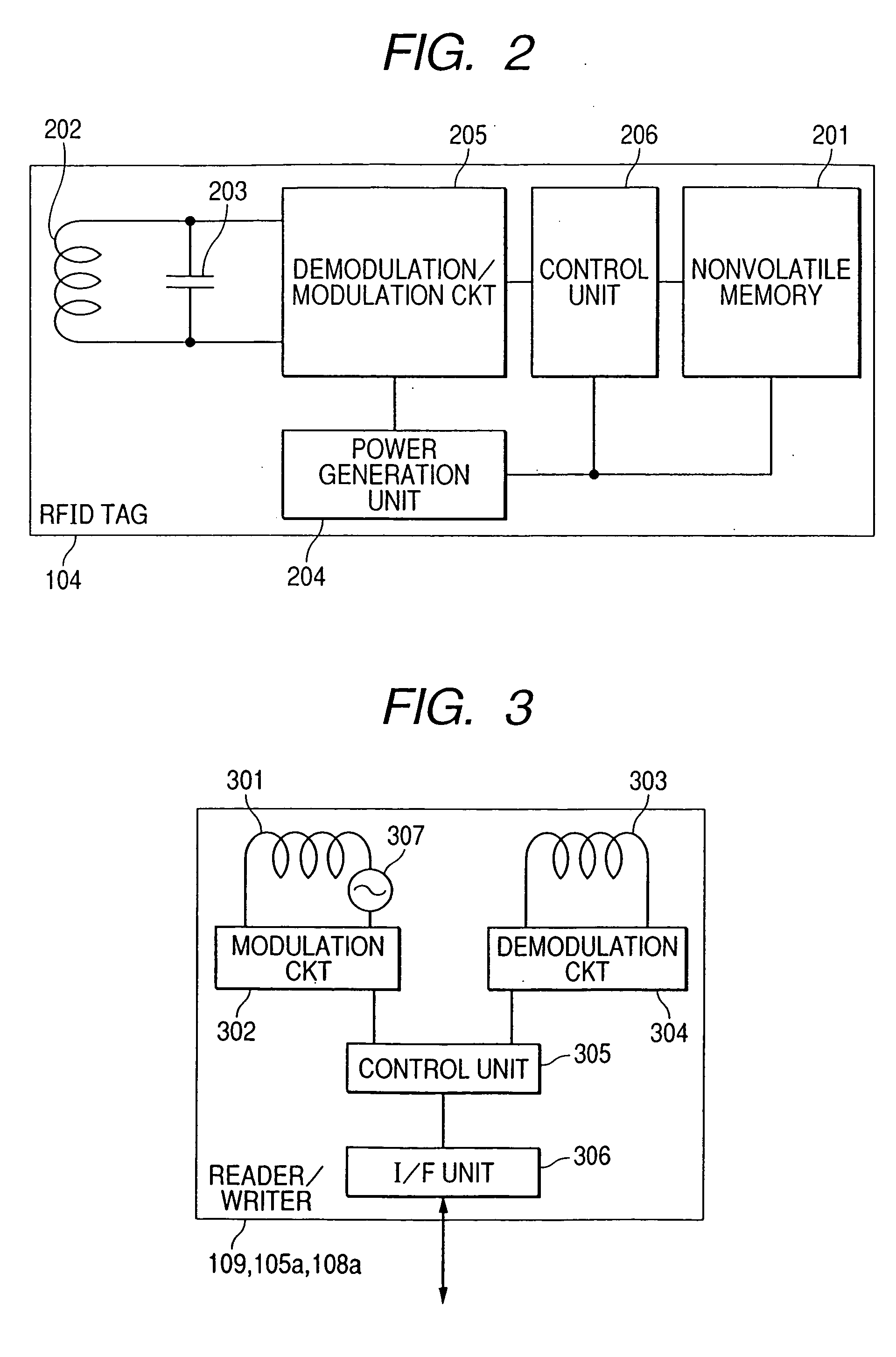

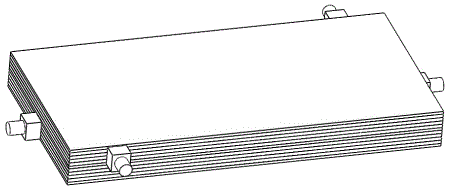

Information processing apparatus and information processing method

InactiveUS20060015739A1Increase processExtended processing methodDigital data processing detailsUnauthorized memory use protectionComputer hardwareInformation processing

An information processing apparatus having a security server and a reader / writer includes a demodulator of the reader / writer for reading information from an RFID tag, a modulator of the reader / writer for writing information into the RFID tag and also writing area information indicating whether the RFID tag exists in a secret area, a memory for storing the information read from the RFID tag by the demodulator and the information written into the RFID tag by the modulator, and a controller for controlling the demodulator and the modulator. When the area information read from the RFID tag by the demodulator indicates that the RFID tag exists in a predetermined area, the controller precludes from reading predetermined information stored in the RFID tag, and controls the modulator so as to write the area information indicating that the RFID tag does not exist in the predetermined area.

Owner:CANON KK

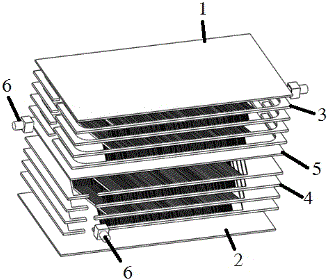

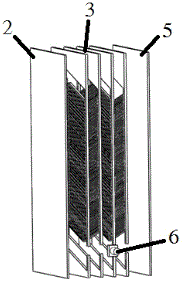

Micro-channel heat exchanger

InactiveCN105486129AIncrease processOptimizing Flow PathsHeat exchanger casingsStationary plate conduit assembliesFusion weldingEngineering

A micro-channel heat exchanger comprises an upper cover plate, a lower cover plate, a transverse heat exchange structure, a longitudinal heat exchange structure, a middle partition plate and working medium inlet / outlet units. The upper cover plate, the middle partition plate and the lower cover plate are sequentially arranged in parallel, and a transverse heat exchange piece unit is arranged between the upper cover plate and the middle partition plate; a longitudinal heat exchange piece unit is arranged between the middle partition plate and the lower cover plate; and the transverse heat exchange piece unit and the longitudinal heat exchange piece unit are each provided with one inlet / outlet working medium unit; the transverse heat exchange structure at least comprises a transverse heat exchange unit, and the longitudinal heat exchange structure at least comprises a longitudinal heat exchange unit. The flow process of each flow way can be designed to be the same, and a diffusion fusion welding structure can be adopted for connection of partition plates. According to the heat exchanger, multilayer cross flow, uniform heat exchange and flow disturbance can be achieved, the heat exchange efficiency of the heat exchanger can be further improved, and the running cost is reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

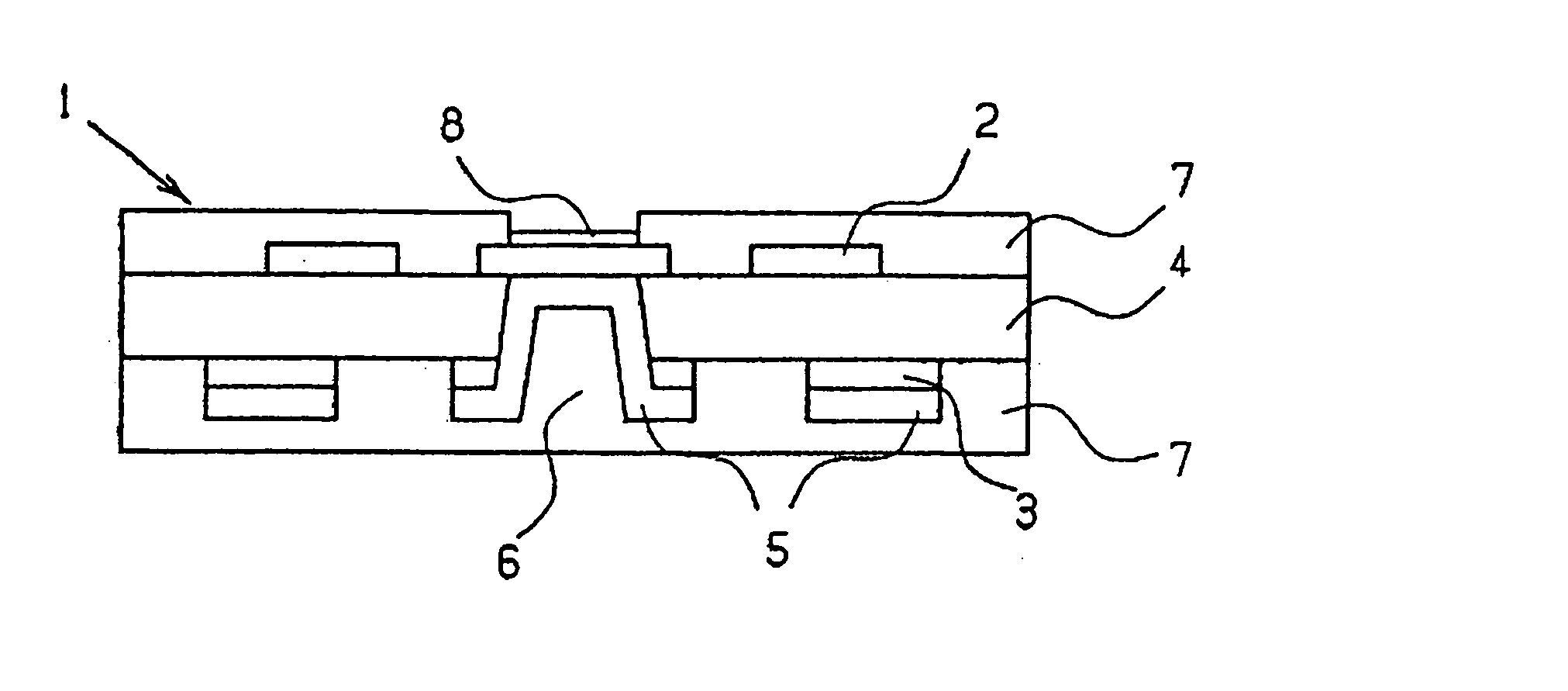

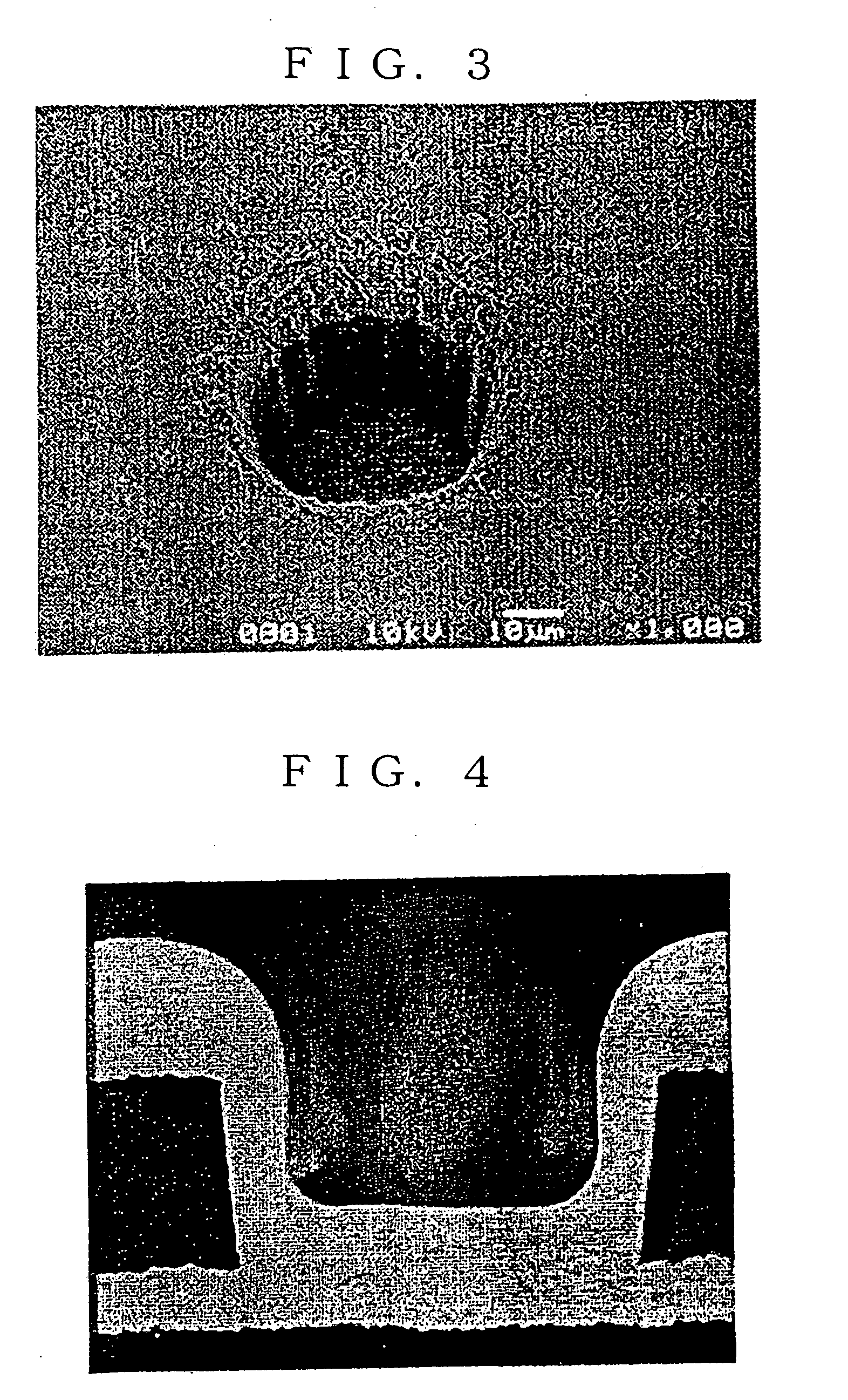

Production of via hole in flexible circuit printable board

InactiveUS20050162835A1Increase processProduced in advancePrinted circuit aspectsInsulating layers/substrates workingPolyimide membraneAbrasive

A flexible circuit printable board can be favorably produced by a process composed of steps of forming in a polyimide film having a metal coat on each surface side a via hole penetrating at least one metal coat and the polyimide film; and applying a mixture of liquid and abrasive grains under pressure onto the via hole, whereby smoothing an edge of the via hole and cleaning the via hole.

Owner:UBE IND LTD

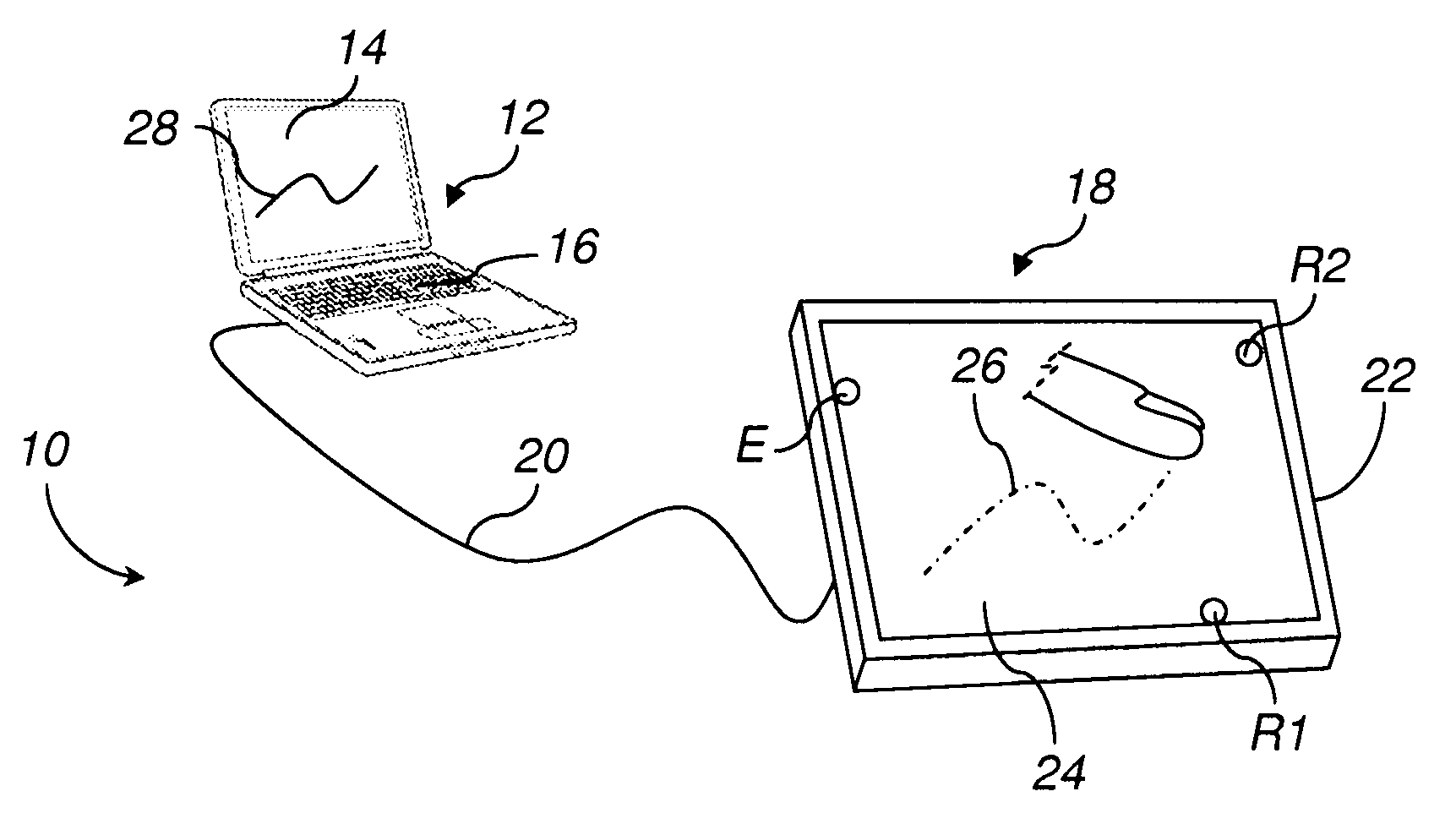

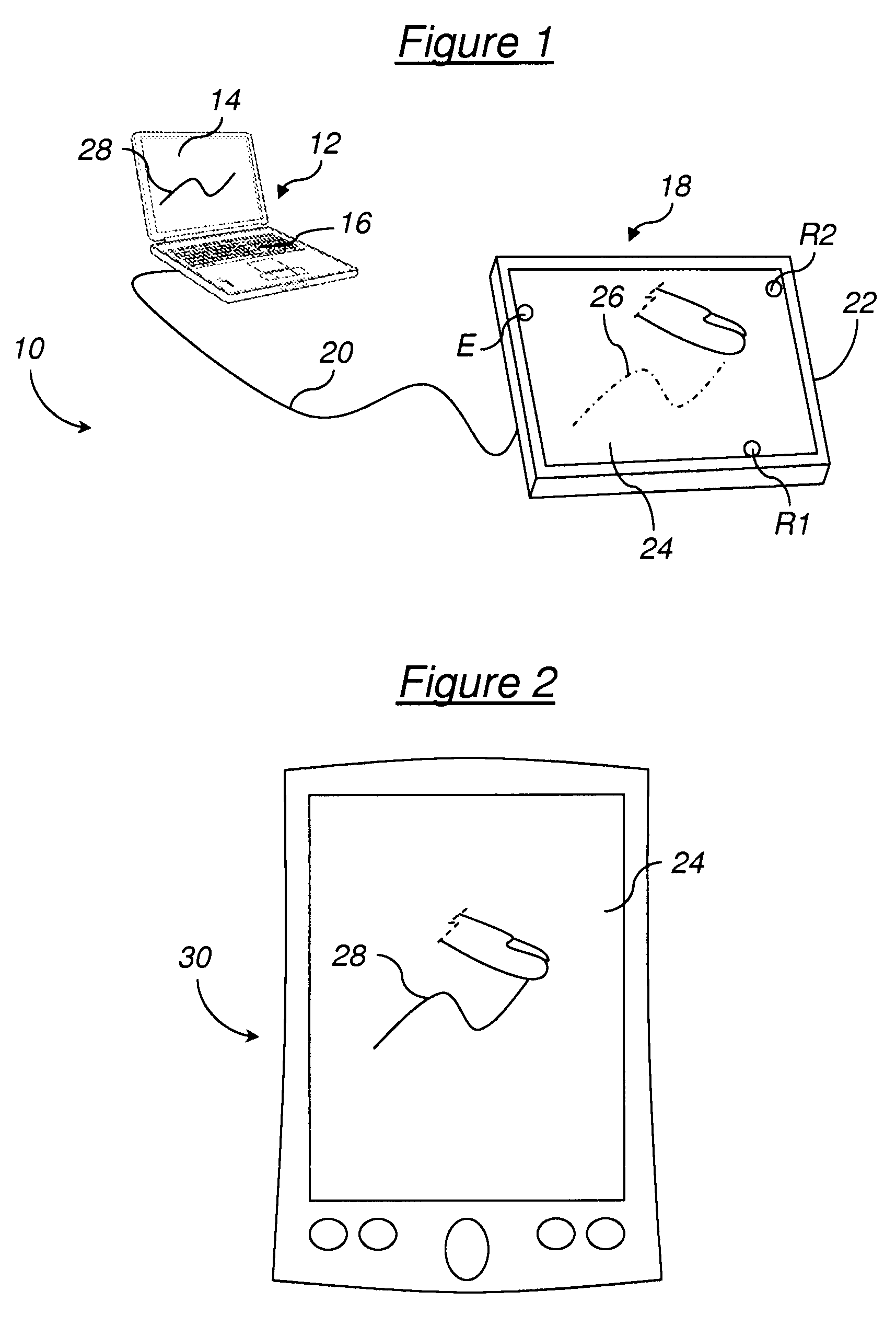

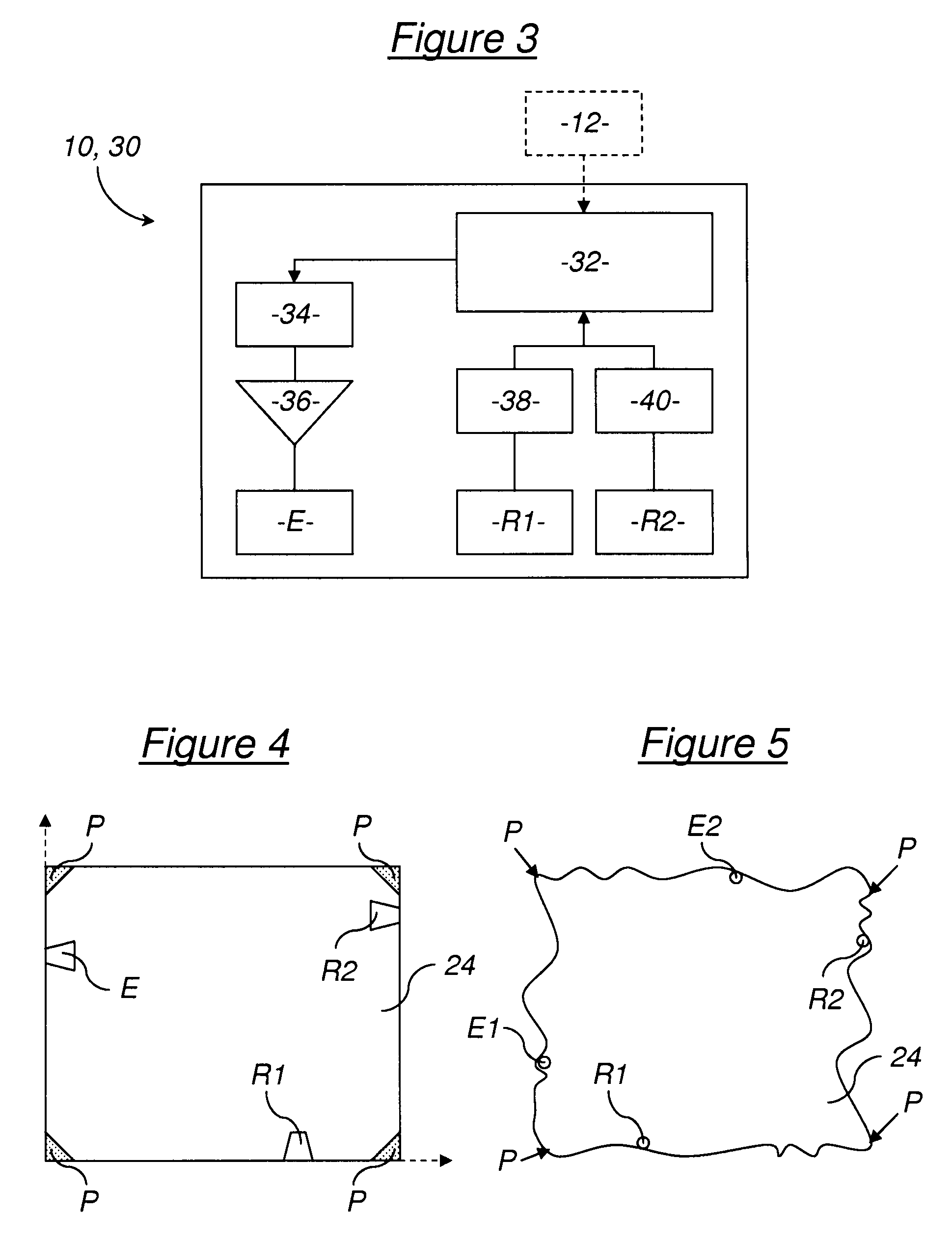

Method and device for locating at least one touch on a touch-sensitive surface of an object

InactiveUS8913039B2Obtained quicklyIncrease processCathode-ray tube indicatorsInput/output processes for data processingRadiationLight spectrum

This method for locating at least one touch on a touch-sensitive surface of an object comprises the following steps:monitoring (100) of at least one touch by propagating (102), in the touch-sensitive surface of the object, elastic mechanical waves from at least one transmitting point of the object, and by detecting (104) said elastic mechanical waves in at least one reception point of the object, in order to obtain at least one sensed signal, andlocating (200) at least one touch on the touch-sensitive surface of the object by comparing certain spectral characteristics of the sensed signal to a set of reference characteristics.The monitoring step (100) comprises measuring (104, 106) the sensed signal during a time interval (t3) starting during a transient phase of the propagation of the transmitted waves, for supplying, to said at least one reception point, information on radiation interfered with by said at least one touch.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

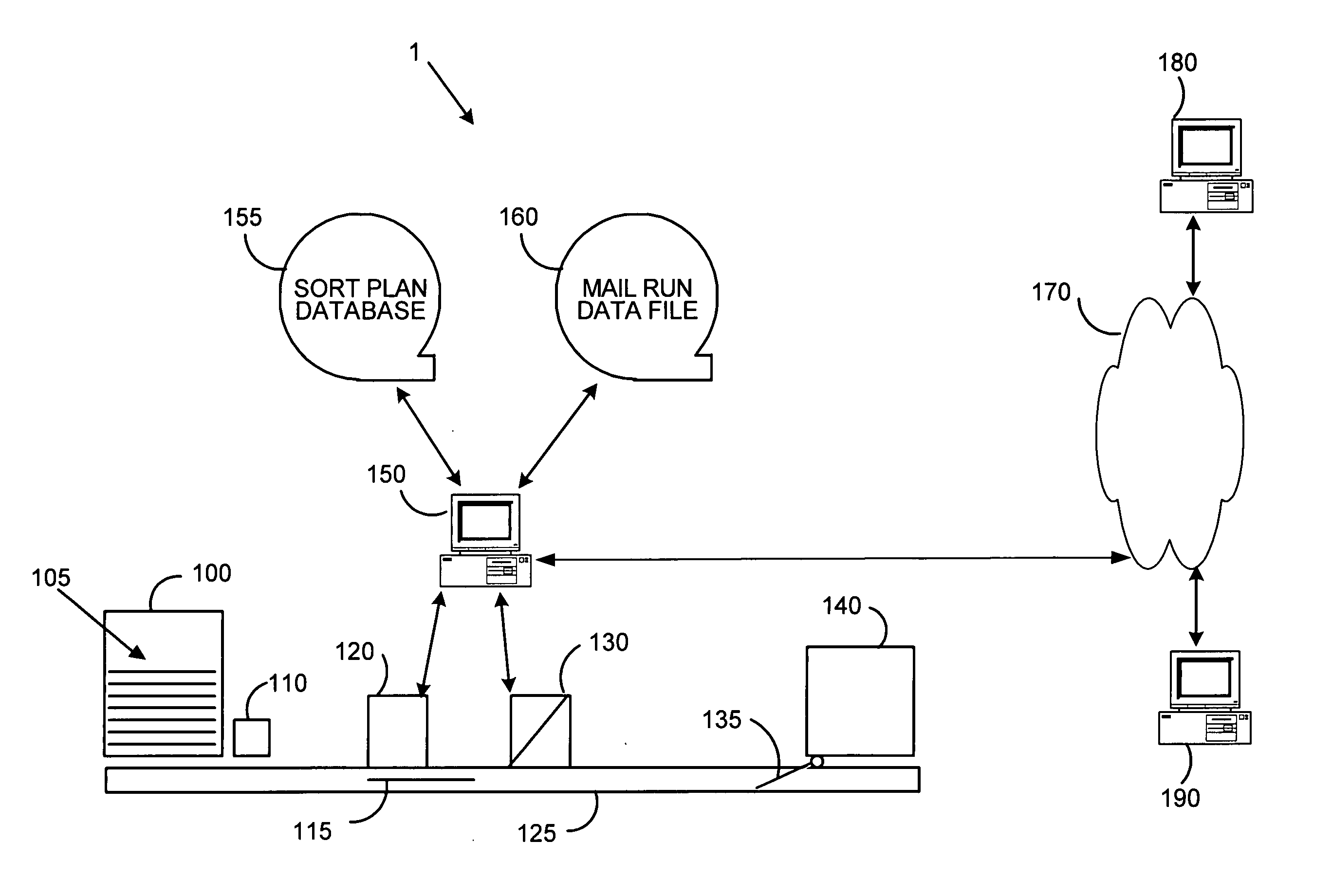

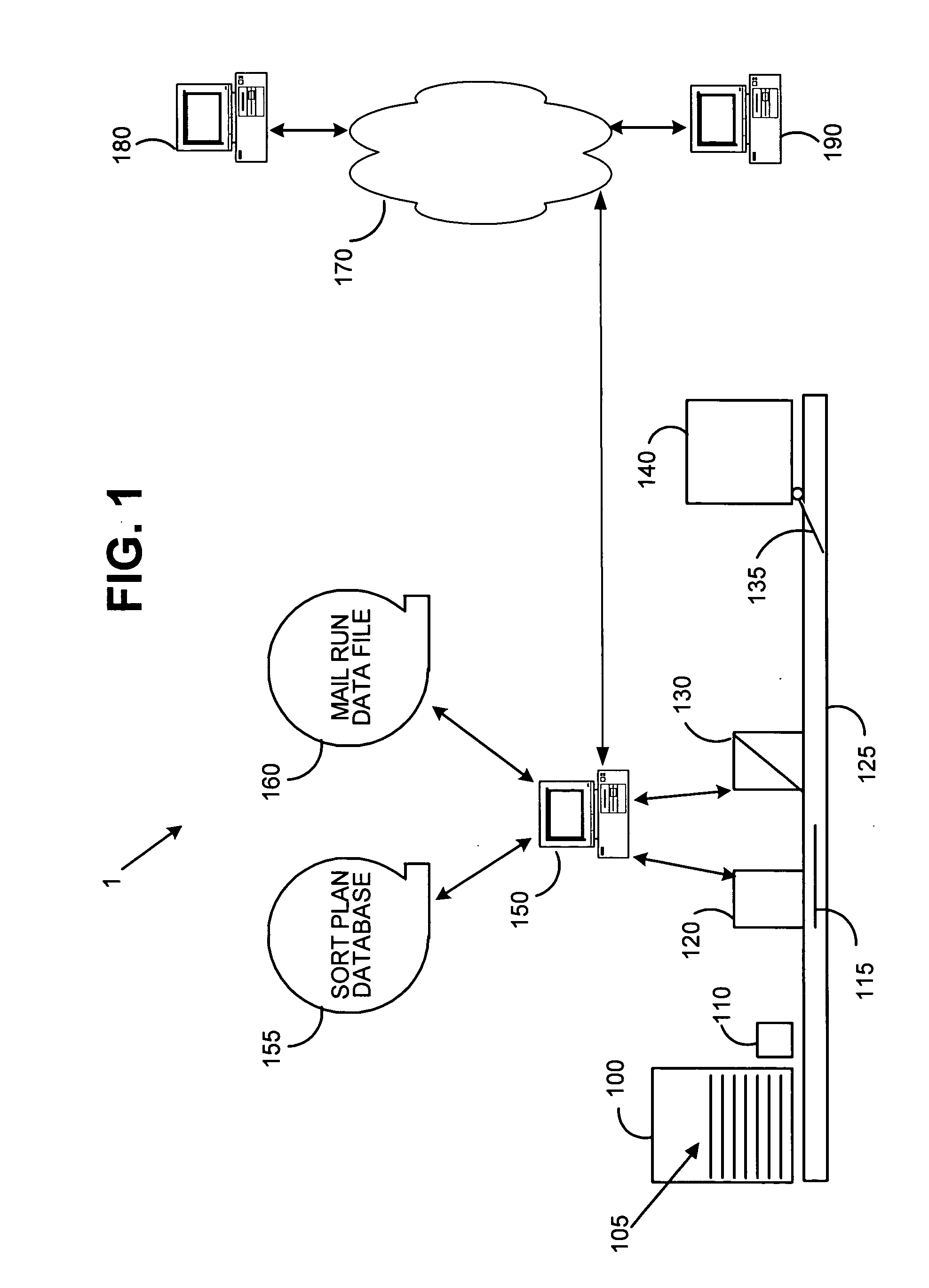

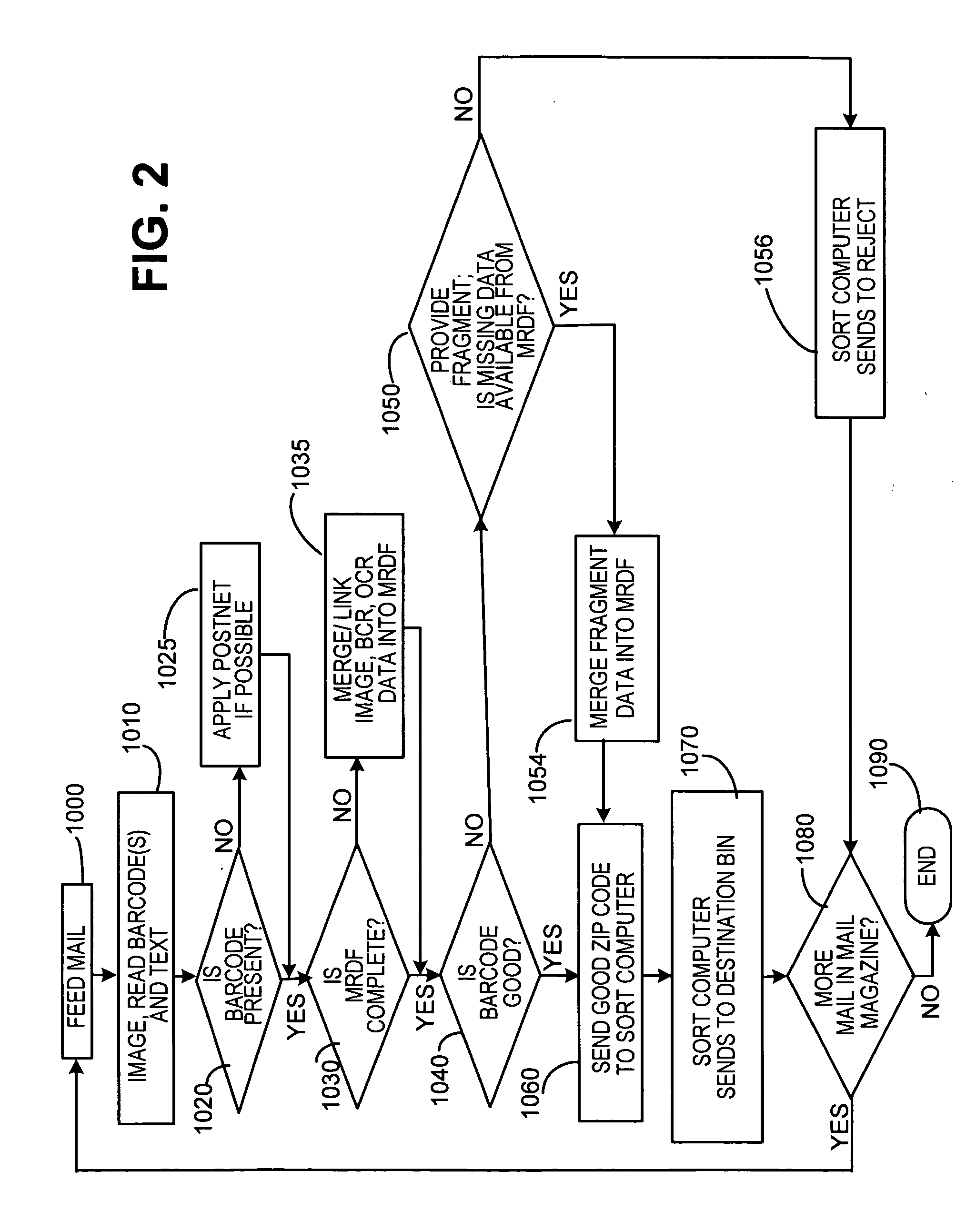

Method for enhancing mail piece processing system

ActiveUS20060131378A1Increase processReduce numberDigital data processing detailsCommerceHandling systemWorld Wide Web

A method for processing mail pieces having information thereon includes scanning the mail piece information and storing scanned mail piece information. Stored information is accessed when a scanned mail piece information is incomplete to obtain previously stored complete mail piece information. The previously stored complete mail piece information is employed in processing the mail piece with the incomplete information. The information may be a code or text that is scanned and stored during the processing of the mail. Fragmentary information from various sources on the scanned mail piece may be combined to access a previously stored mail piece record. The accessed information may be displayed.

Owner:DMT SOLUTIONS GLOBAL CORP

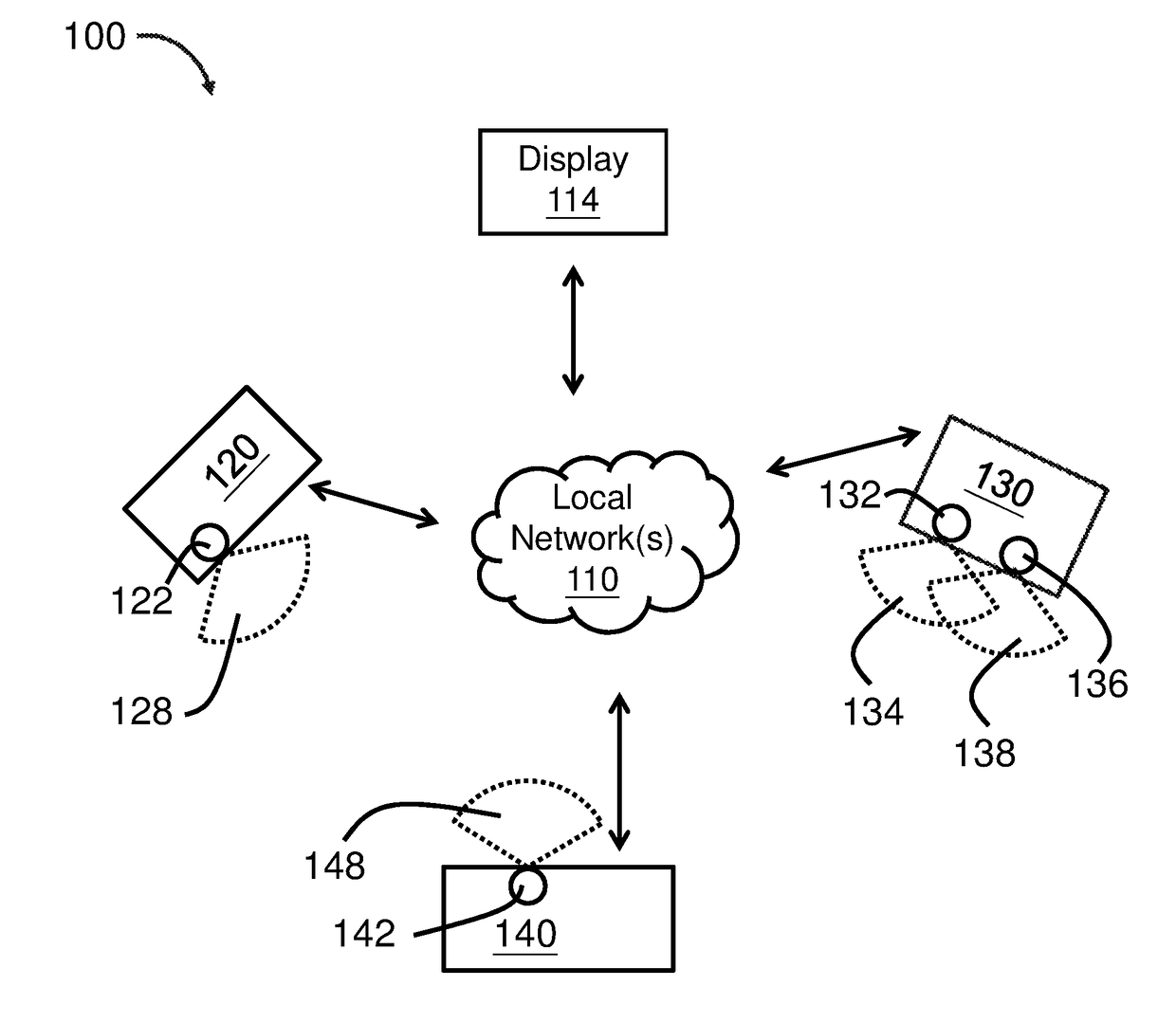

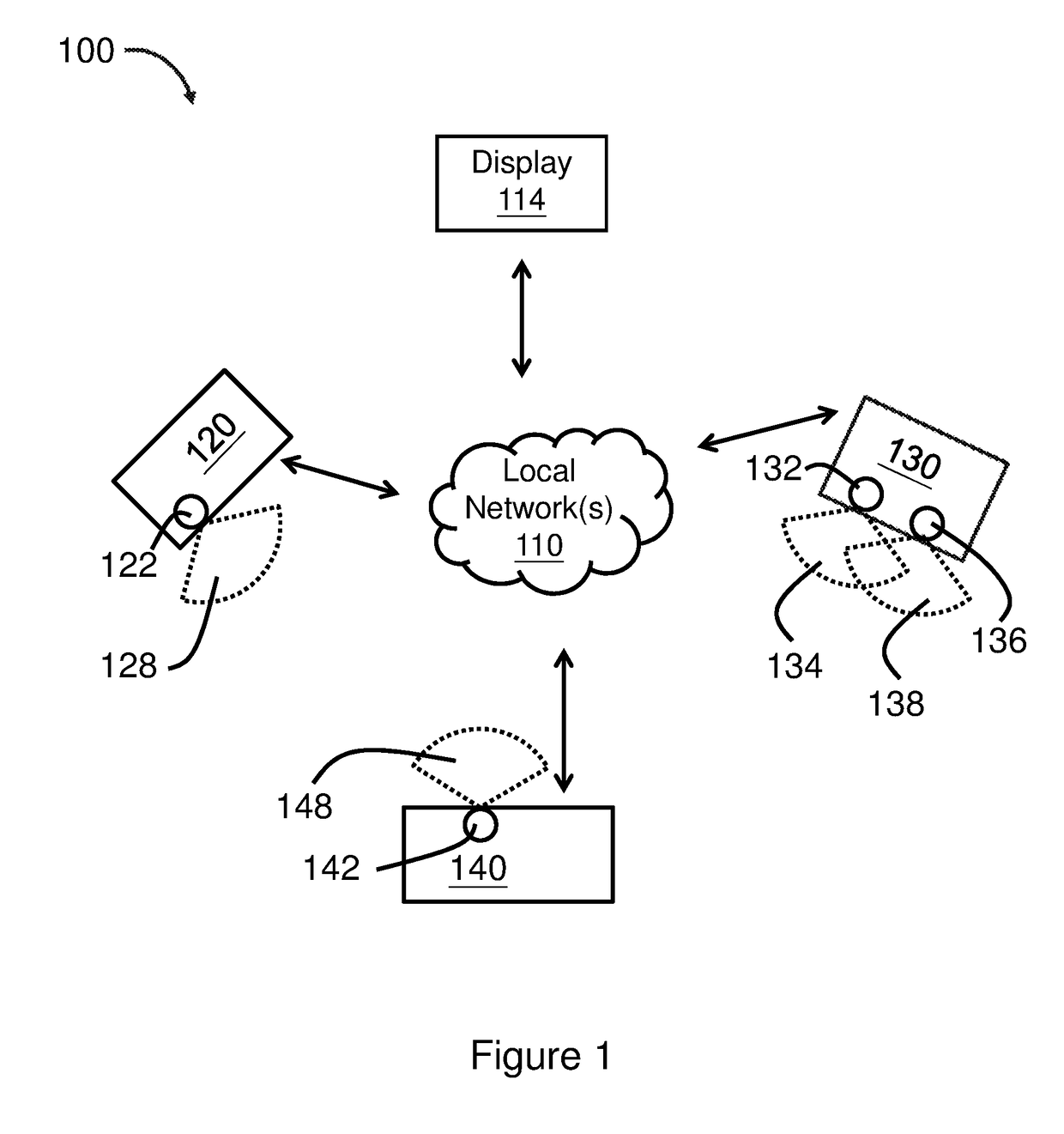

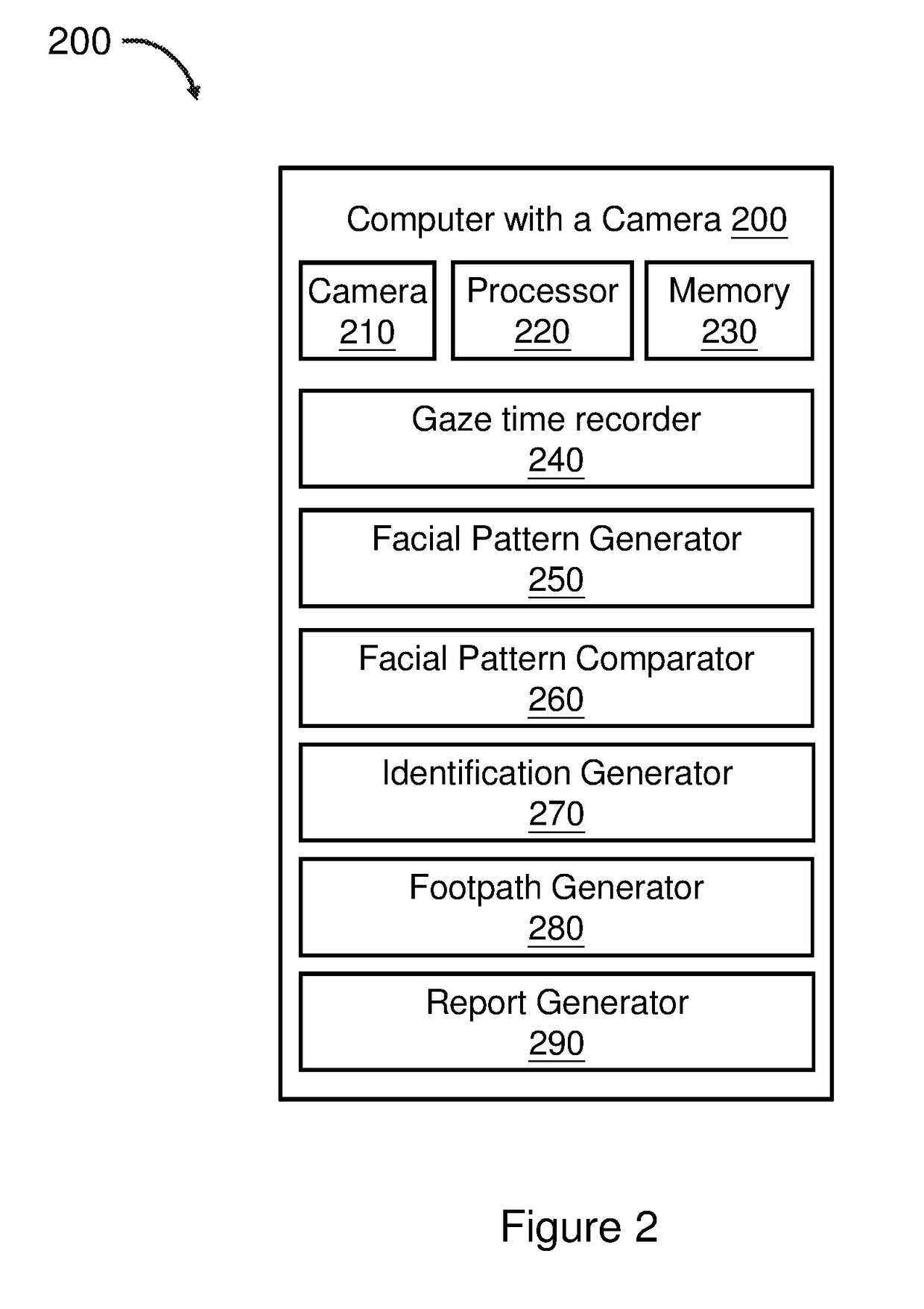

Expedite processing of facial recognition of people in a local network

ActiveUS20170308919A1Increase processSpeed up the processImage enhancementMarket predictionsLocal area networkImage capture

A method that expedites processing of facial recognition from facial images captured by different cameras in a local area network (LAN). The method generates a first facial pattern for a first facial image of a person and a first facial identification that is unique to the first facial pattern. A second facial pattern is generated from a second facial image and compared, by a computer in the LAN, with the first facial pattern to determine whether the first facial image and the second facial image are both from the same person. A second facial identification of the second facial pattern is generated when the second facial image is determined to be different from the first person. If the second facial pattern is determined to be the same as the first facial pattern generated from the first facial image of the first person, the second facial pattern is assigned the first facial identification. The first and second facial patterns and their facial identifications are shared among the computers in the LAN to expedite processing of facial recognition.

Owner:INREALITY LTD

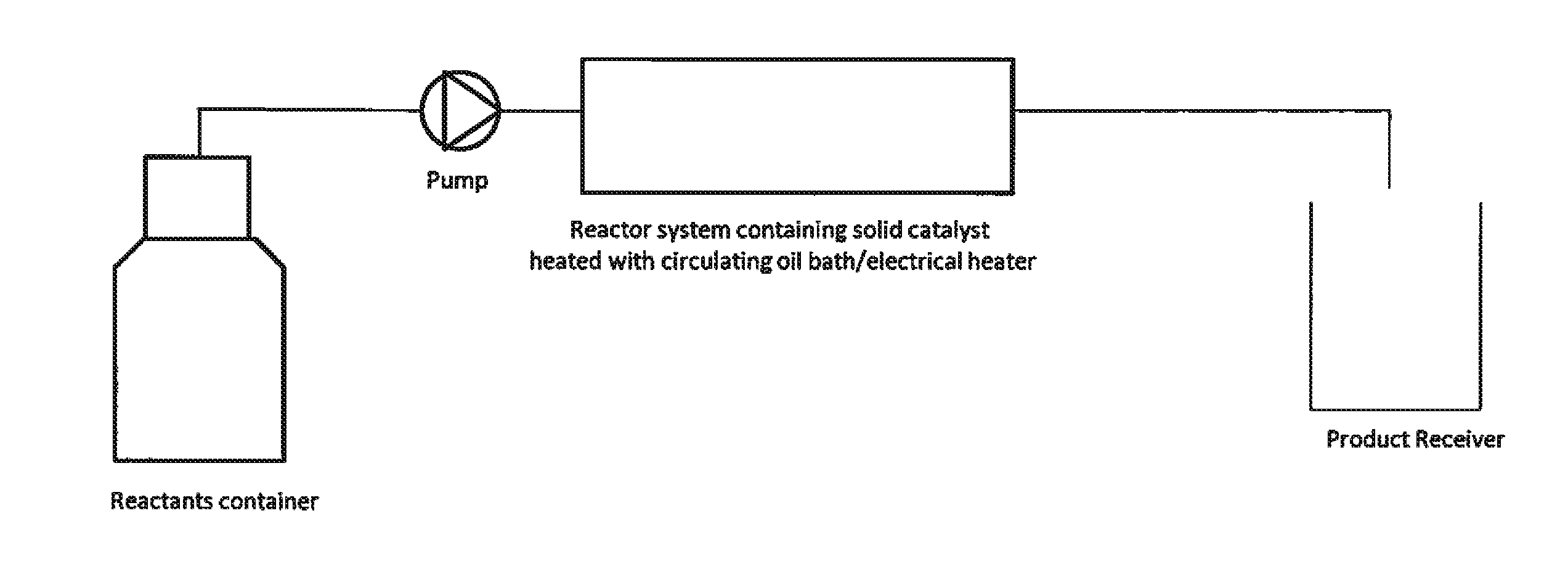

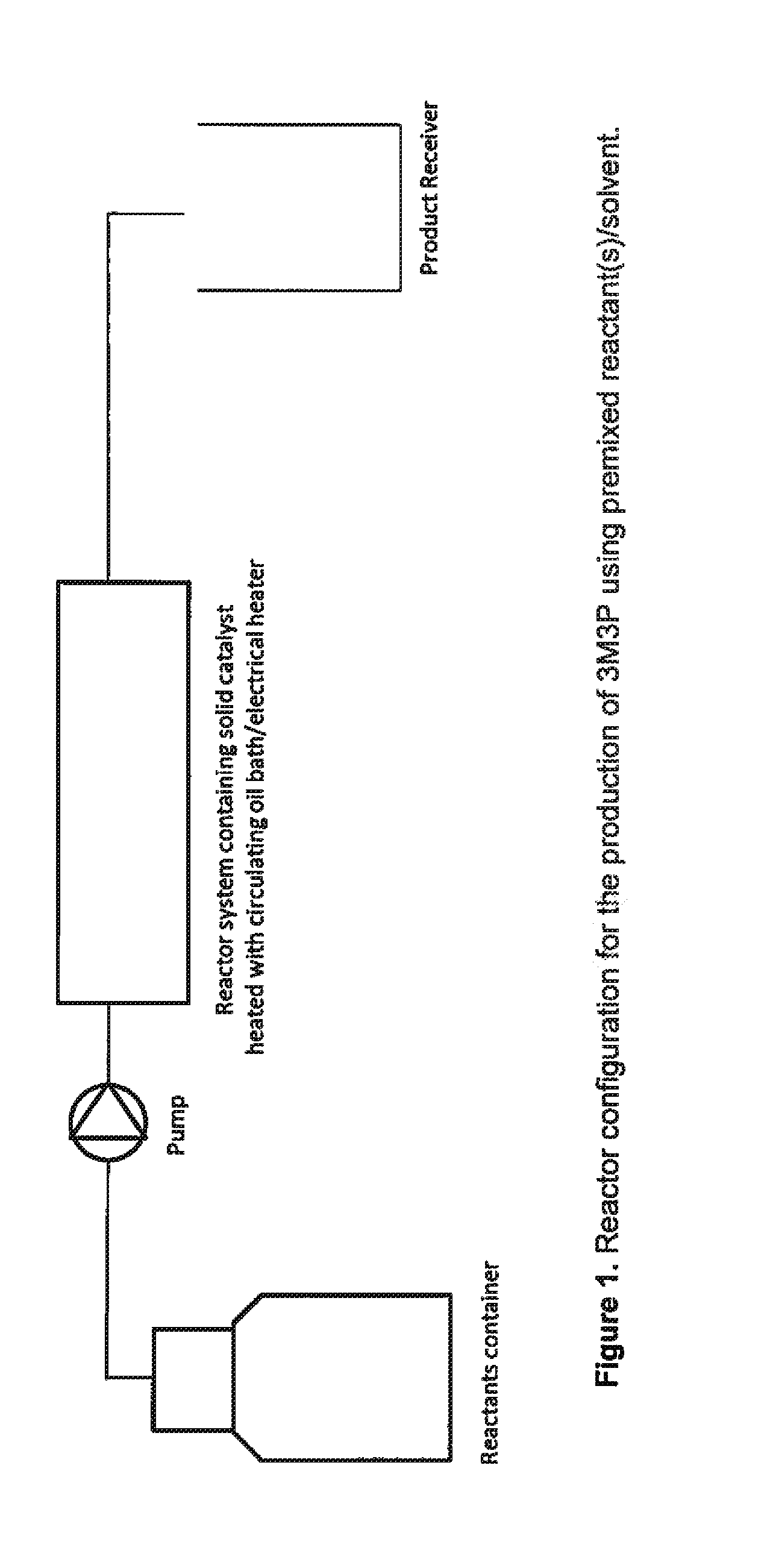

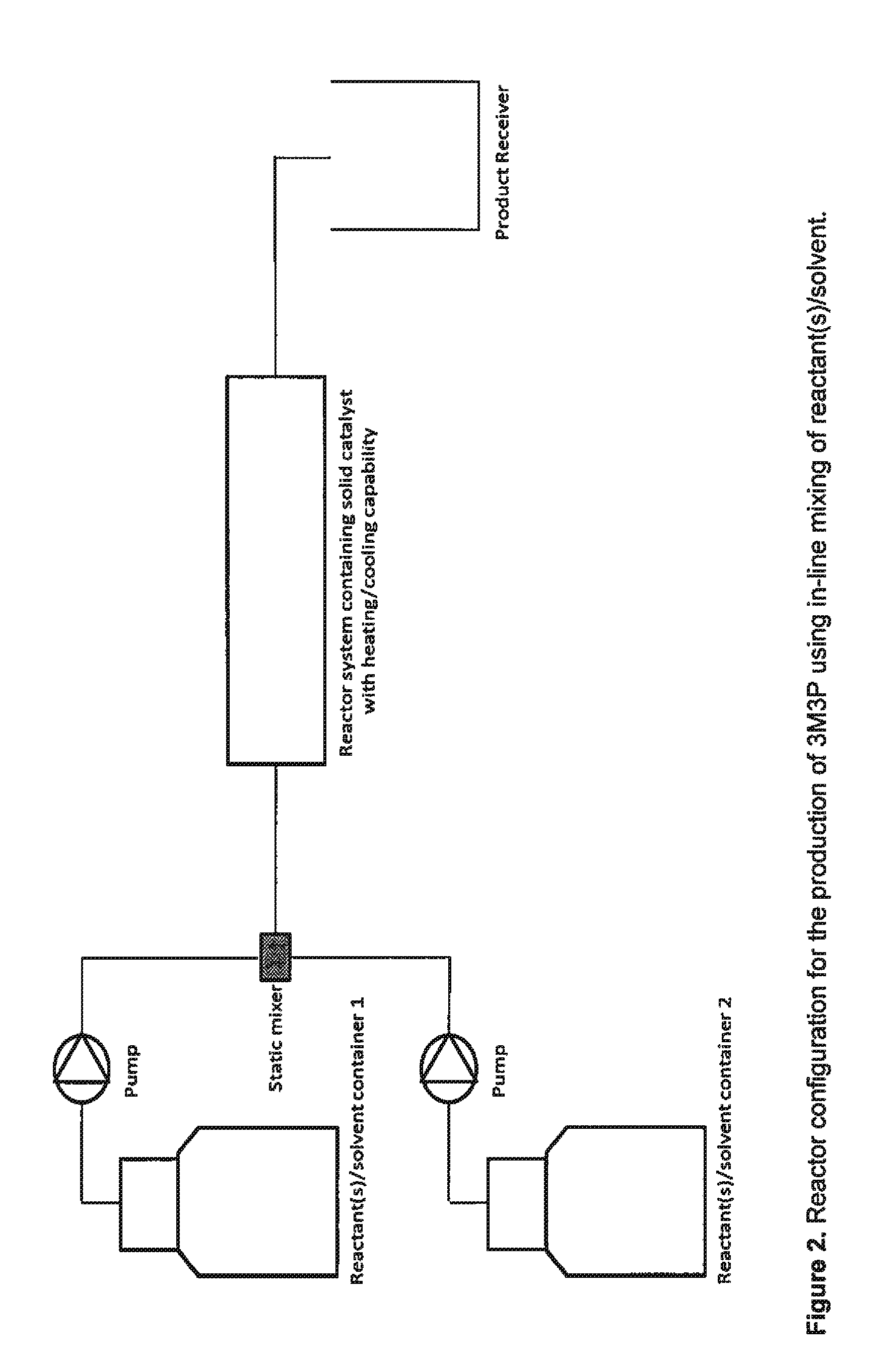

Green process for producing 3-methyl-3-pentene-2-one

ActiveUS20150133694A1Increase processSpeed up the processOrganic compound preparationCarbonyl compound preparation by condensationChemistryPentene

The present invention relates to an improved and sustainable process for producing 3-methyl-3-pentene-2-one which is used in the synthesis of fragrance ingredients for perfumery applications.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Supplement composition and method of use for enhancement of anti-inflammation process

InactiveUS20060292250A1EnhancementIncrease processBiocideCarbohydrate active ingredientsSodium hyaluronateUrtica dioica leaf extract

A supplement composition for enhancement of anti-inflammation process is provided, which contains nettle leaf extract, hops extract, and turmeric rhizome extract. The supplement composition further includes hyaluronic acid, sodium salt, glucosamine sulfate, and chondroitin sulfate. Further provided is a method of using the supplement composition for enhancement of anti-inflammation process.

Owner:SURACELL

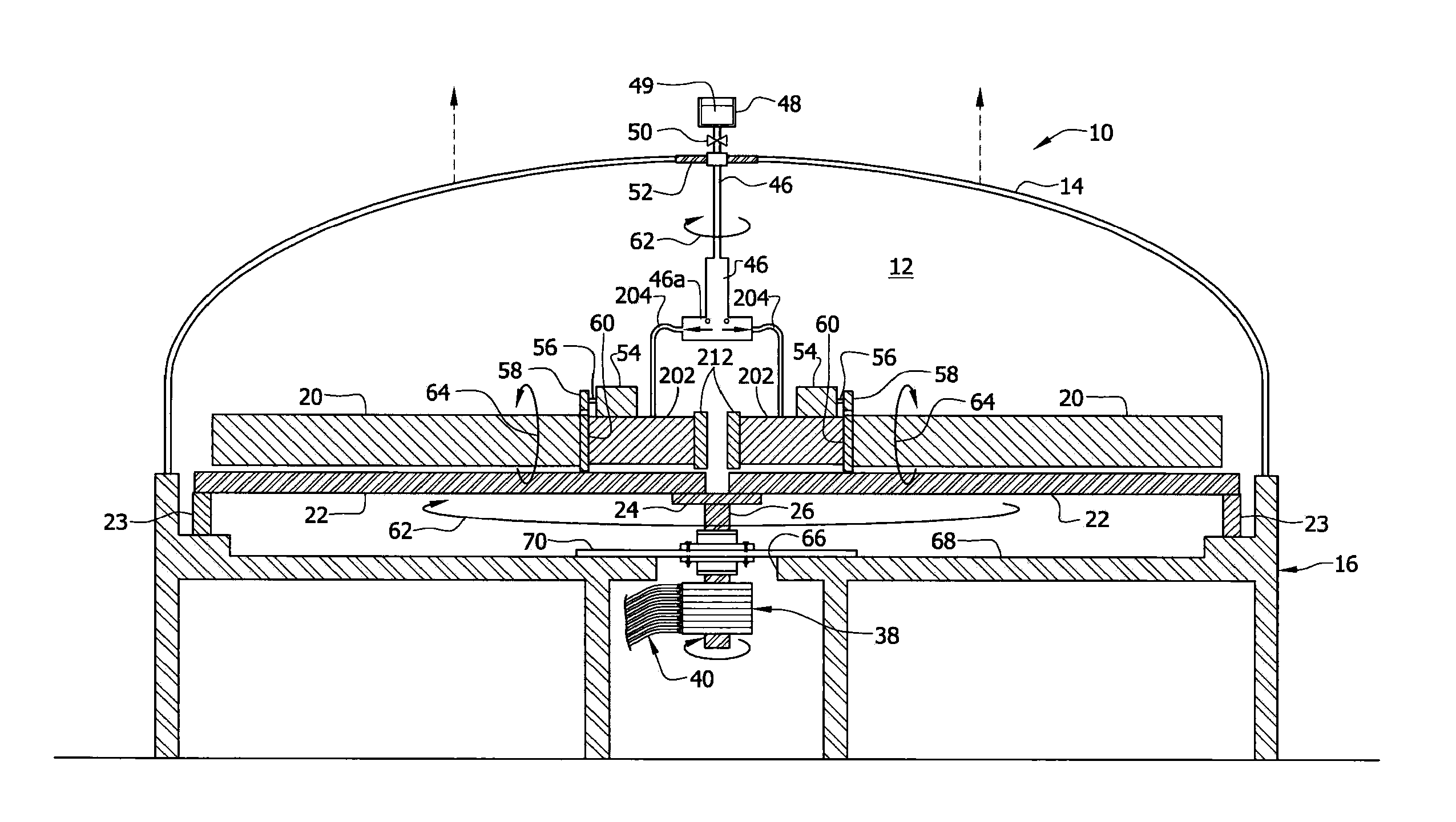

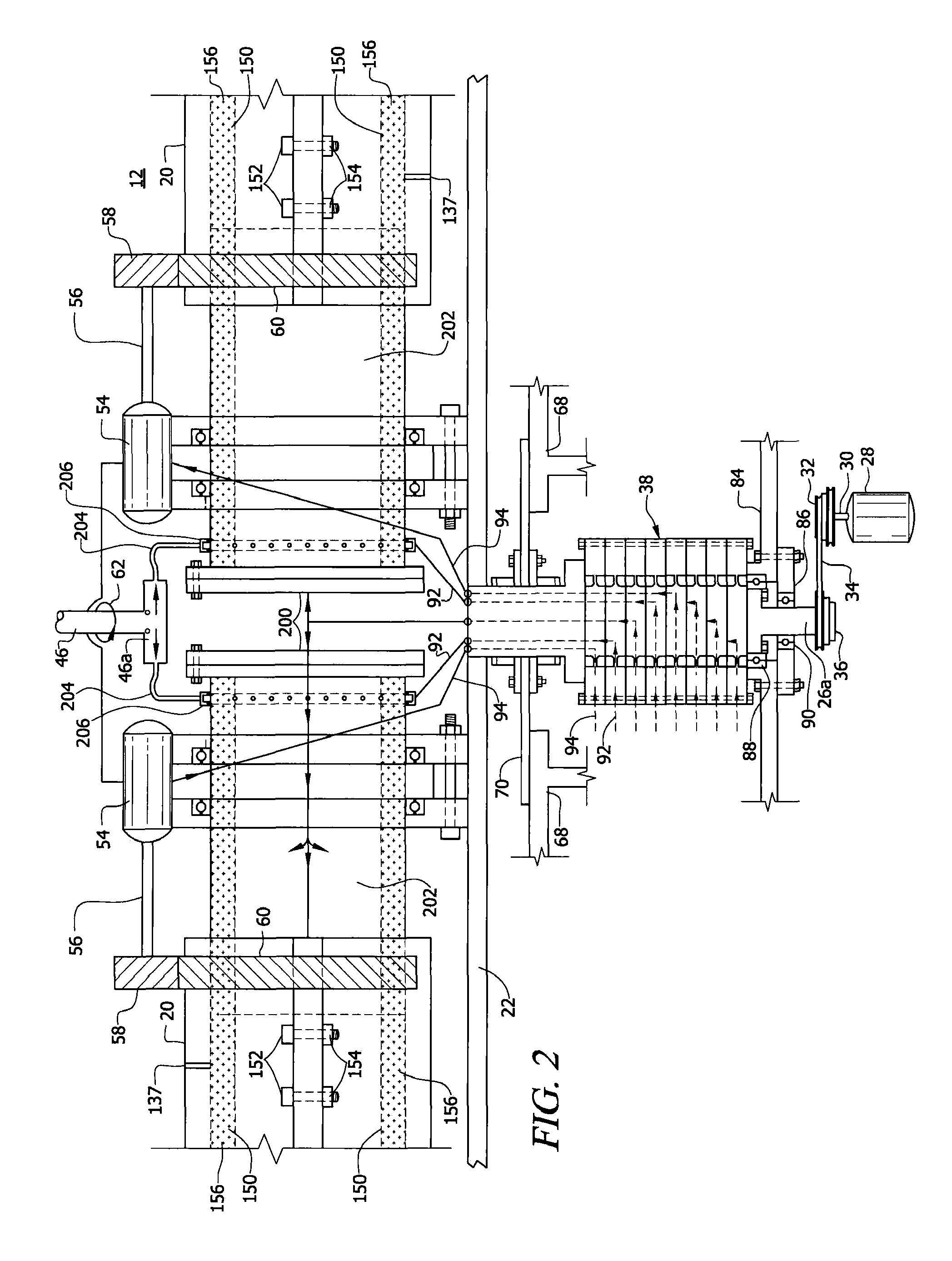

Low pressure vacuum resin infusion system

ActiveUS8029263B1Increase processEnhances thoroughness and speedTailstocks/centresConfectioneryFiber architectureEngineering

A mold assembly includes a support table mounted for rotation within a vacuum chamber. A plurality of hollow part molds is radially disposed about an axis of rotation of the support table. Each part mold has fiber architecture disposed between an inflatable bladder and internal walls of the part mold. A first motor rotates the support table and resin is urged by centrifugal force to flow along the length of each part mold until the fiber architecture is thoroughly impregnated with resin. A second motor spins each part mold about an axis of rotation of the part mold to ensure that the resin migrates radially outwardly relative to the interior wall surface of each part mold. The resulting product is a monolithic, seamless part having no voids.

Owner:QUENNEVILLE MARC A +1

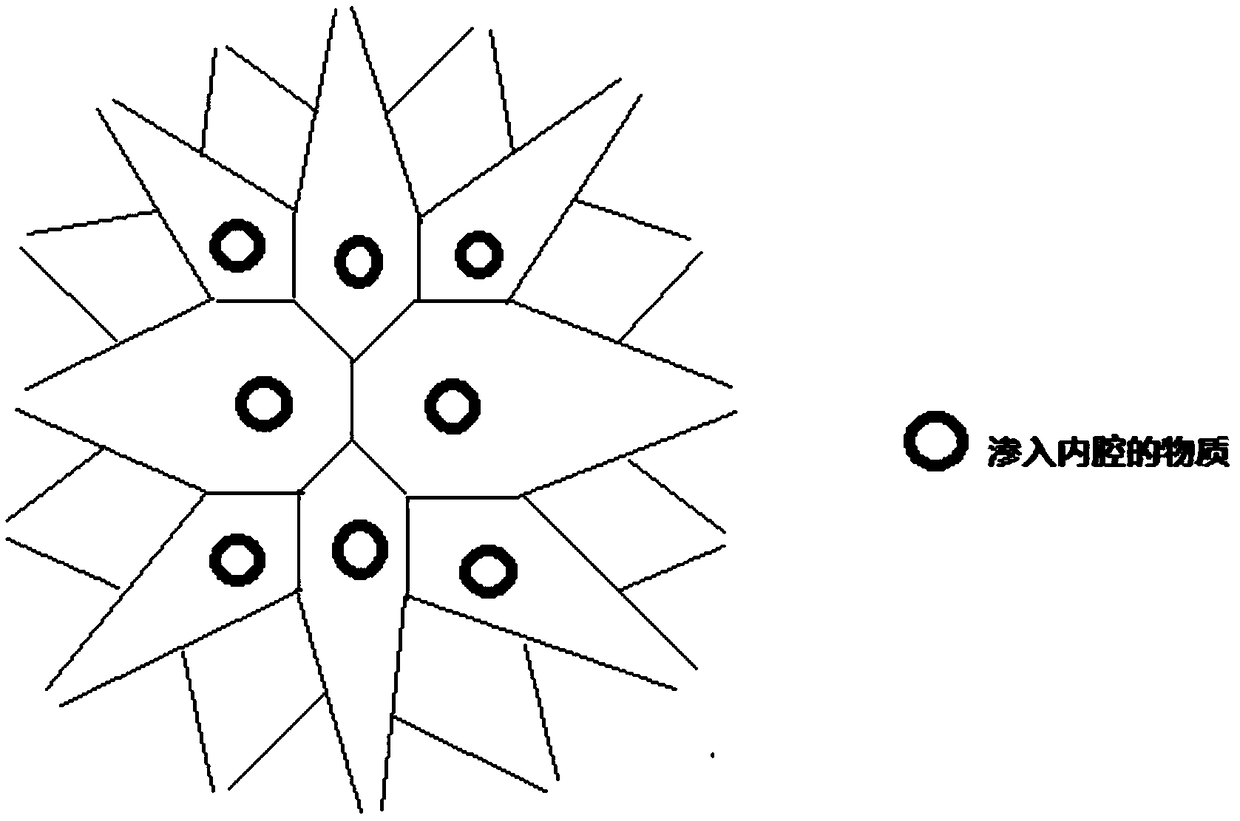

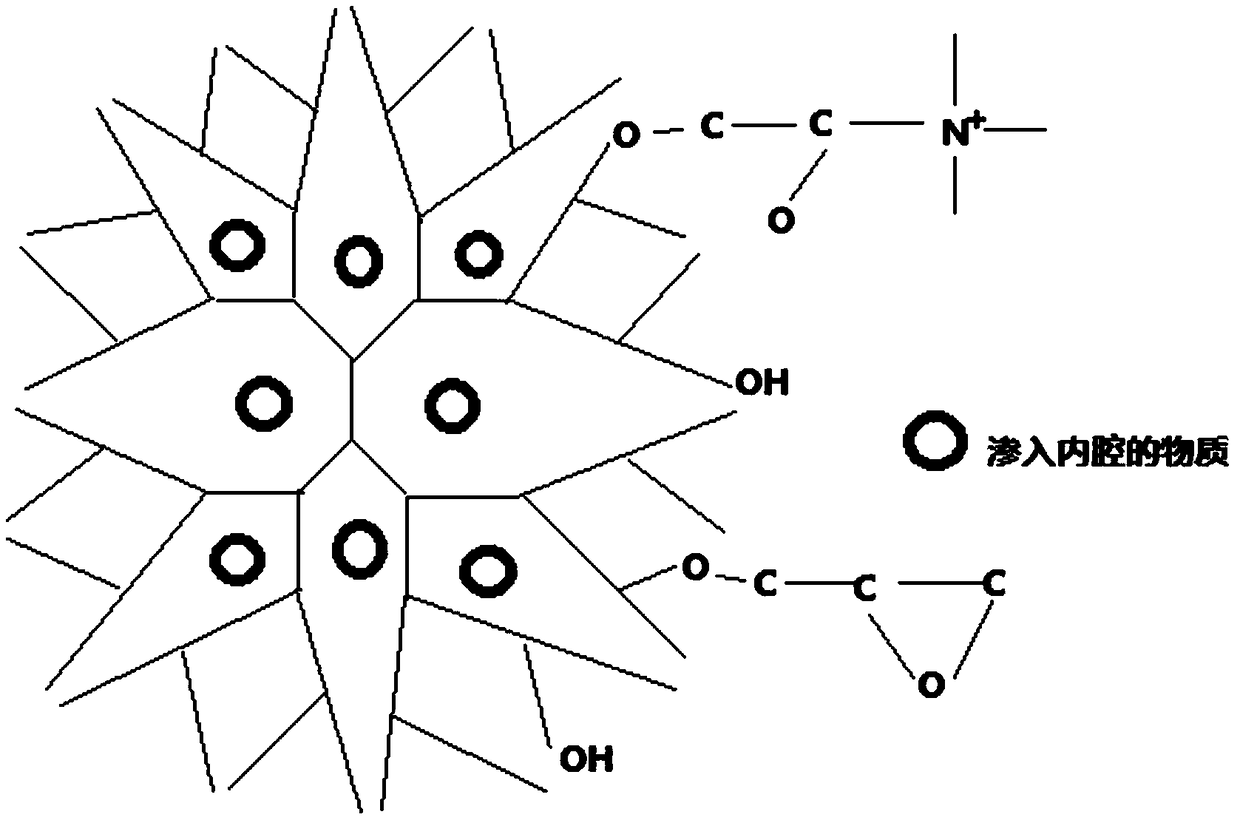

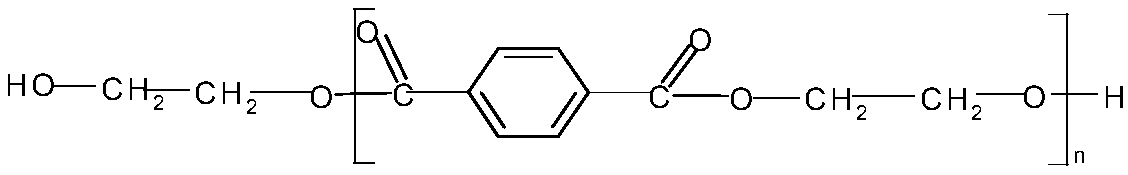

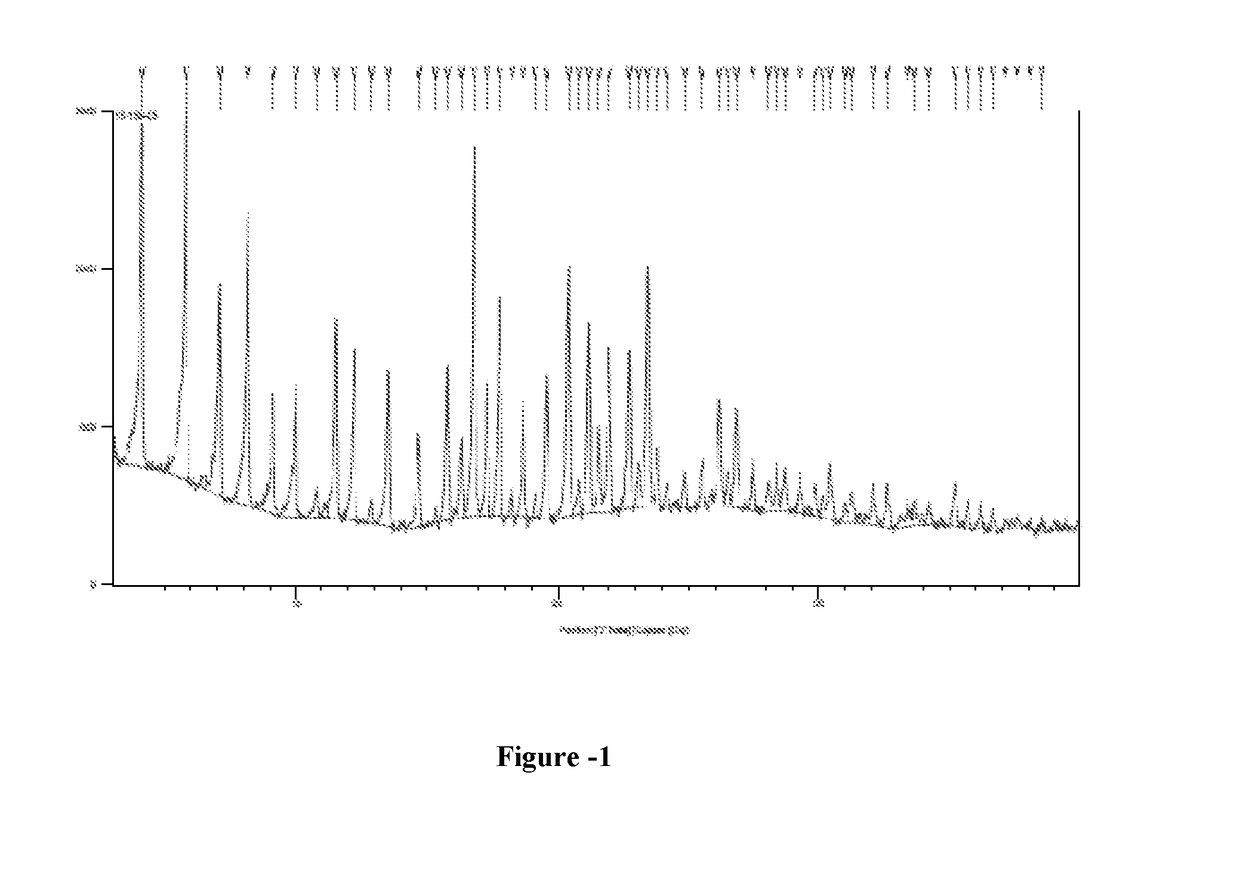

Multifunctional finishing agent based on hyperbranched polyester derivative as well as preparation and application thereof

InactiveCN109322164AIncrease processEasy to operateBiochemical fibre treatmentLight resistant fibresCompound sCooking & baking

The invention relates to a multifunctional finishing agent based on hyperbranched polyester derivative as well as preparation and application thereof. The finishing agent is prepared from a hyperbranched polyester derivative solution for wrapping a functional agent. The preparation comprises the steps: preparing the hyperbranched polyester derivative solution; then adding the functional agent, stirring and dispersing to make the functional agent permeate into an inner cavity of the polyester to form a functional compound and preparing into a mixed solution; dipping or padding the polyester fabric by the solution and performing pre-baking and baking treatment. The multifunctional finishing agent disclosed by the invention has the advantages that a finishing method is easy and practical to operate, raw materials and a technological process are friendly to the environment and the human body, and a padding and baking mode is utilized to finish hyperbranched polyester and the functional agent to the fabric; thus, not only are moisture absorption and quick dryness of the polyester fabric enhanced, but also the fabric has effects of intelligently adjusting temperature, resisting bacteria,retarding flame, resisting static electricity and the like; furthermore, the polyester fabric has excellent washing resistance, and requirements of people for multifunctional fabrics are met.

Owner:DONGHUA UNIV

Process for recovering used lubricating oils using clay and centrifugation

A process for recovering used lubricating oils, and oils recovered using the process. In a first embodiment (for used industrial oils), the used lubricating oil is mixed with clay in a reactor. The mixture is preferably heated to between 80 and 200 degrees Celsius. The temperature should not be too great, to avoid “cracking” the oil (i.e., breaking molecular chains in the oil). After a certain period of time, the mixture is pumped through filters. Cakes of clay and contaminants remain in the filters, while the oil emerges without the contaminants. A second embodiment (for removing ash or soot, very fine carbon particles and other organic compounds from used motor oils) is the same as the first embodiment, except that before the mixture is passed through the filters, a centrifuge is used to remove most of the clay contaminated with soot, so that it will not block the filters.

Owner:MARTIN DE JULIAN PABLO +2

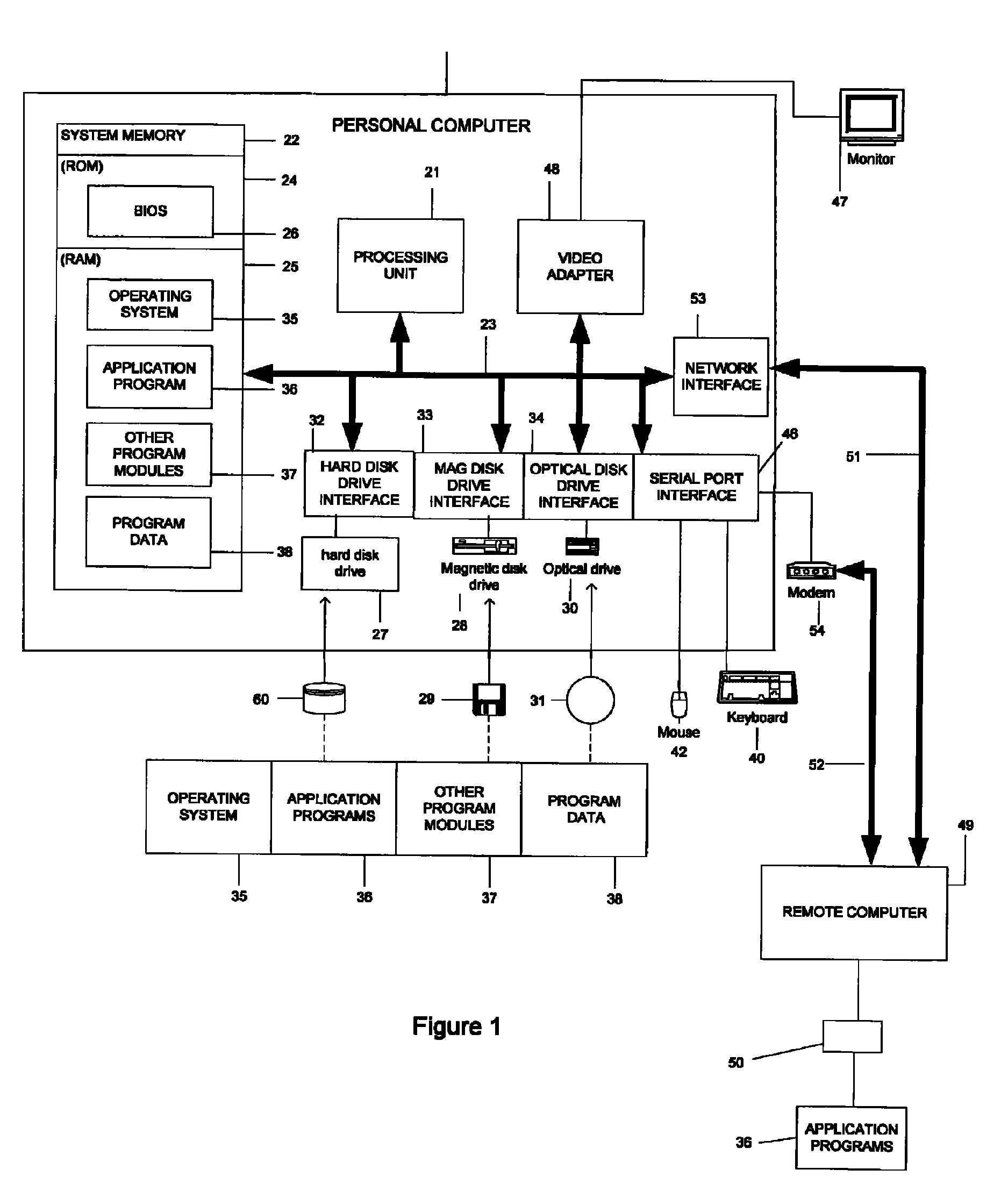

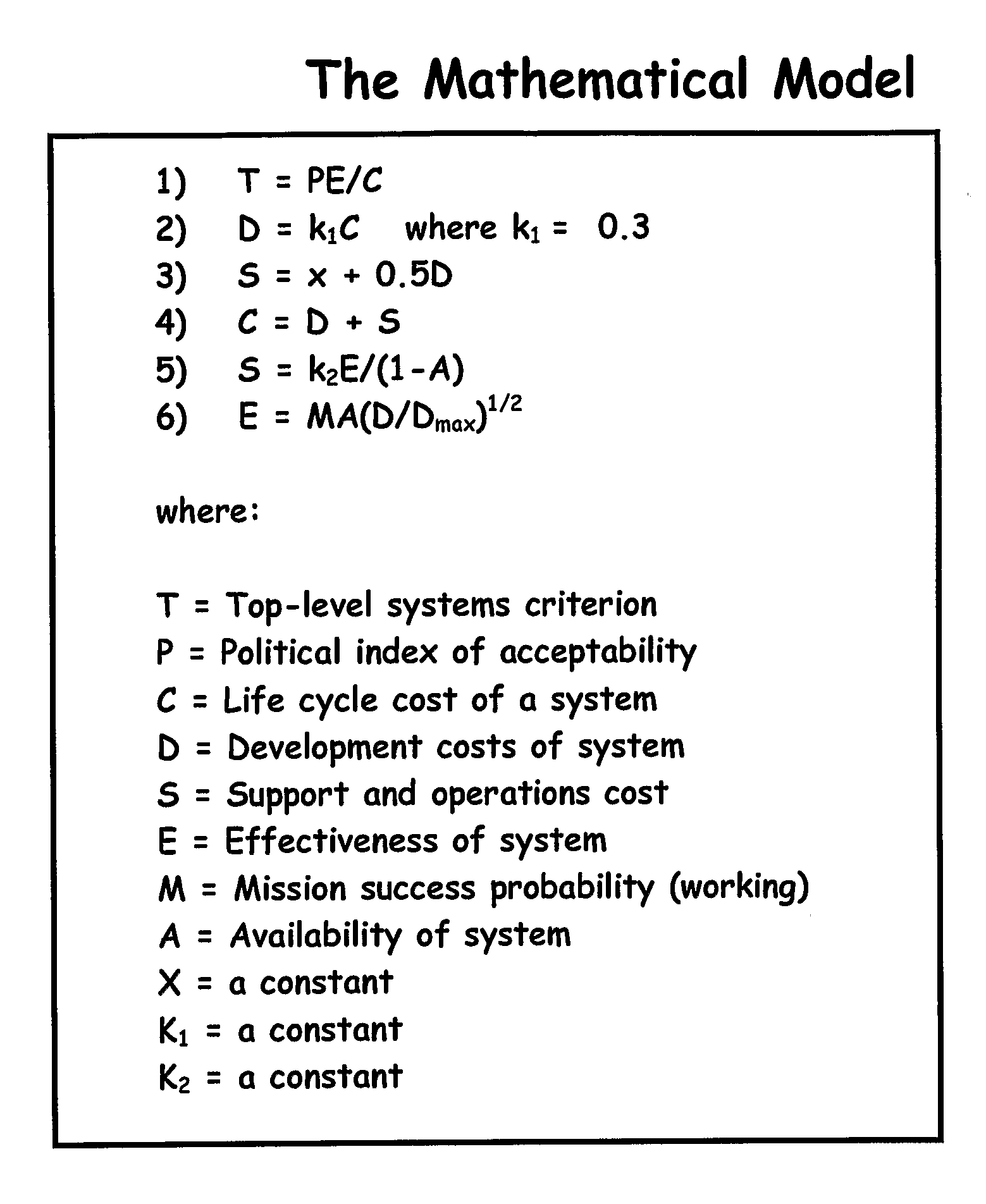

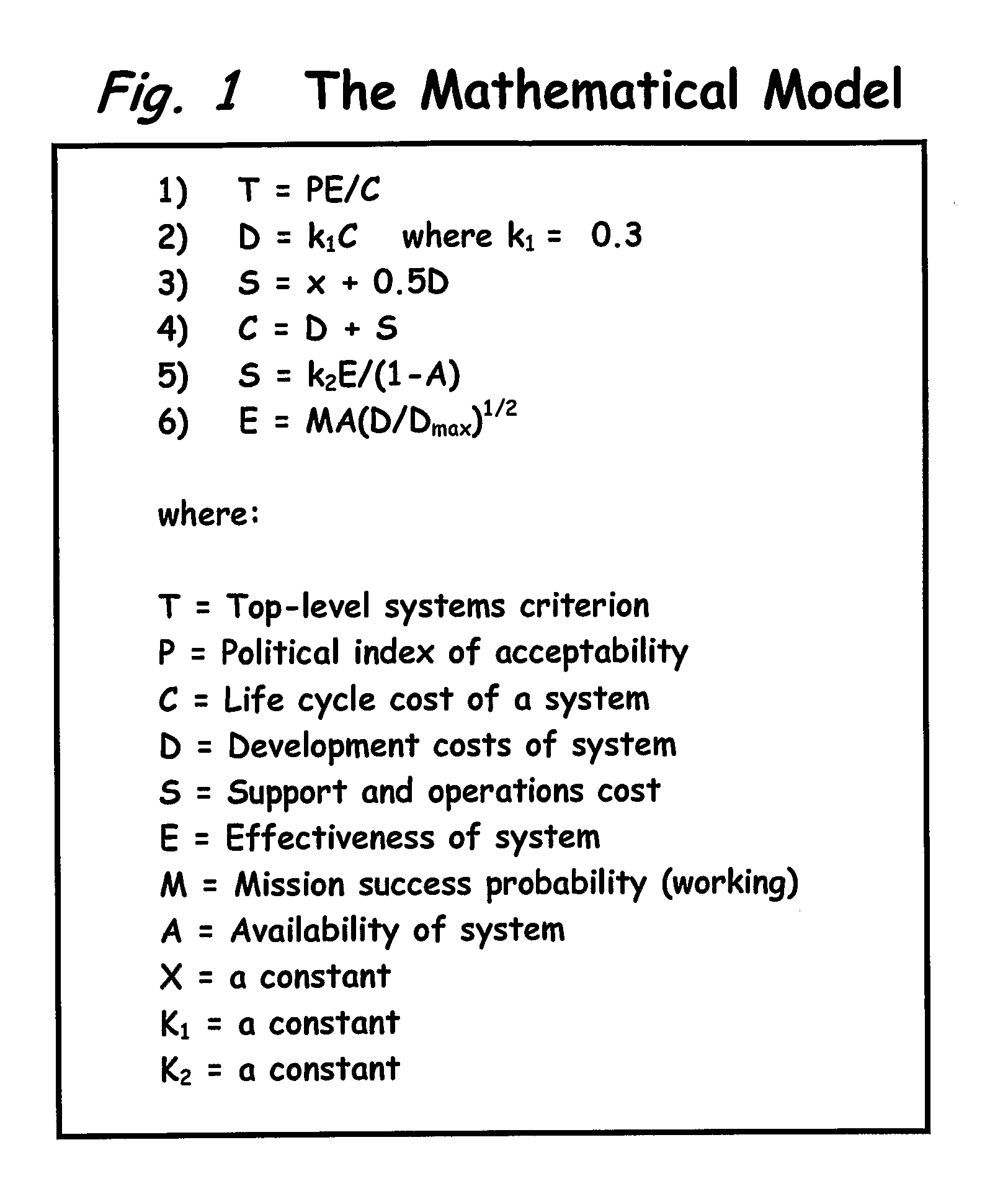

Computer Program Product & Computer with Program to Execute a Well-Posed Mathematical Method

InactiveUS20080140364A1Increase processIncrease powerComputation using non-denominational number representationComplex mathematical operationsComputer programMathematical model

A computer determines whether a proposed mathematical model and computational requests made upon the model are well posed. The computer includes a program that determines whether the model is consistent and suggests at least one alternative consistent model if the proposed model is inconsistent. The program also determines whether a computational request is allowable and suggests at least one alternative allowable computational request if an initial computational request is unallowable.

Owner:FRIEDMAN GEORGE

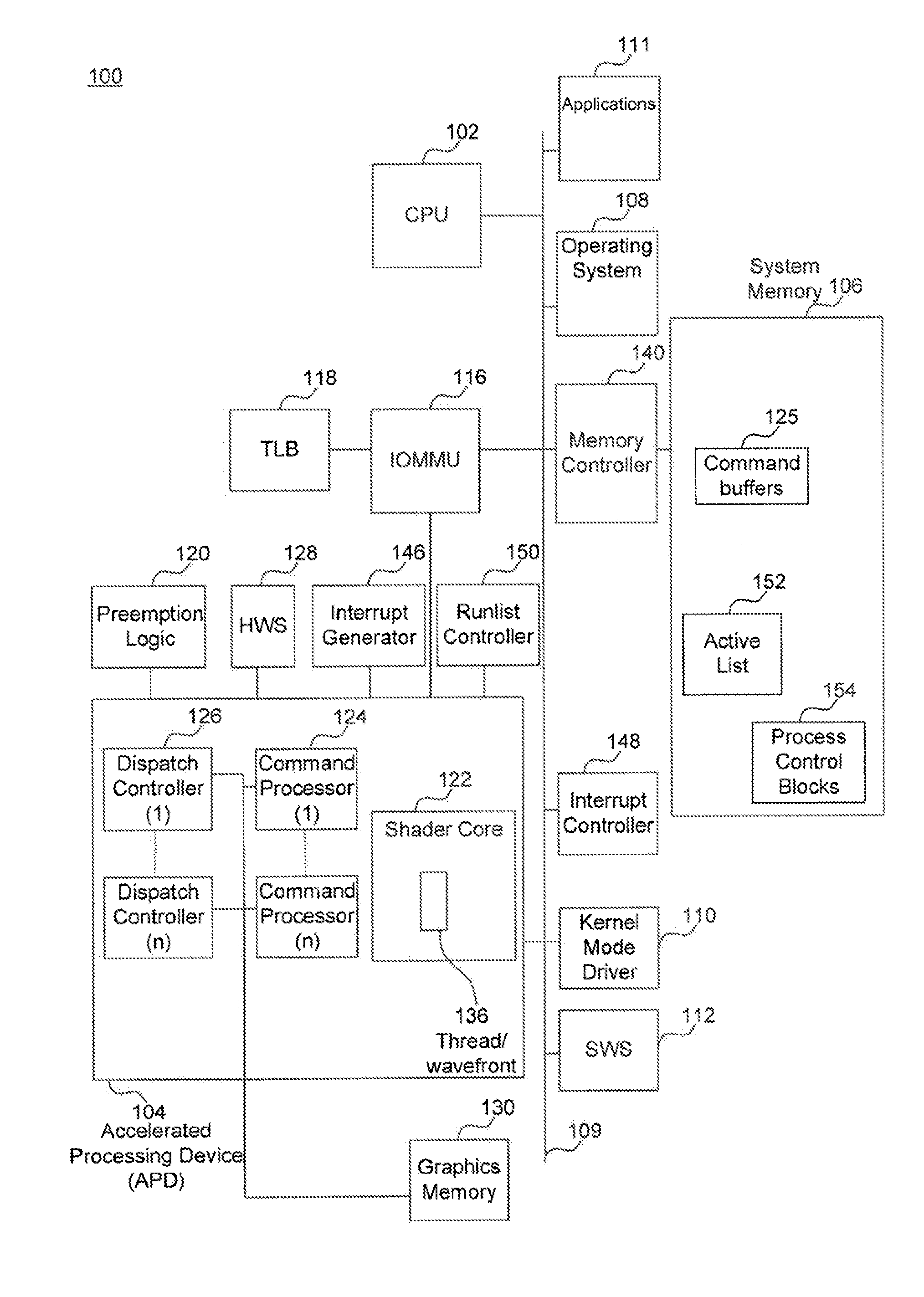

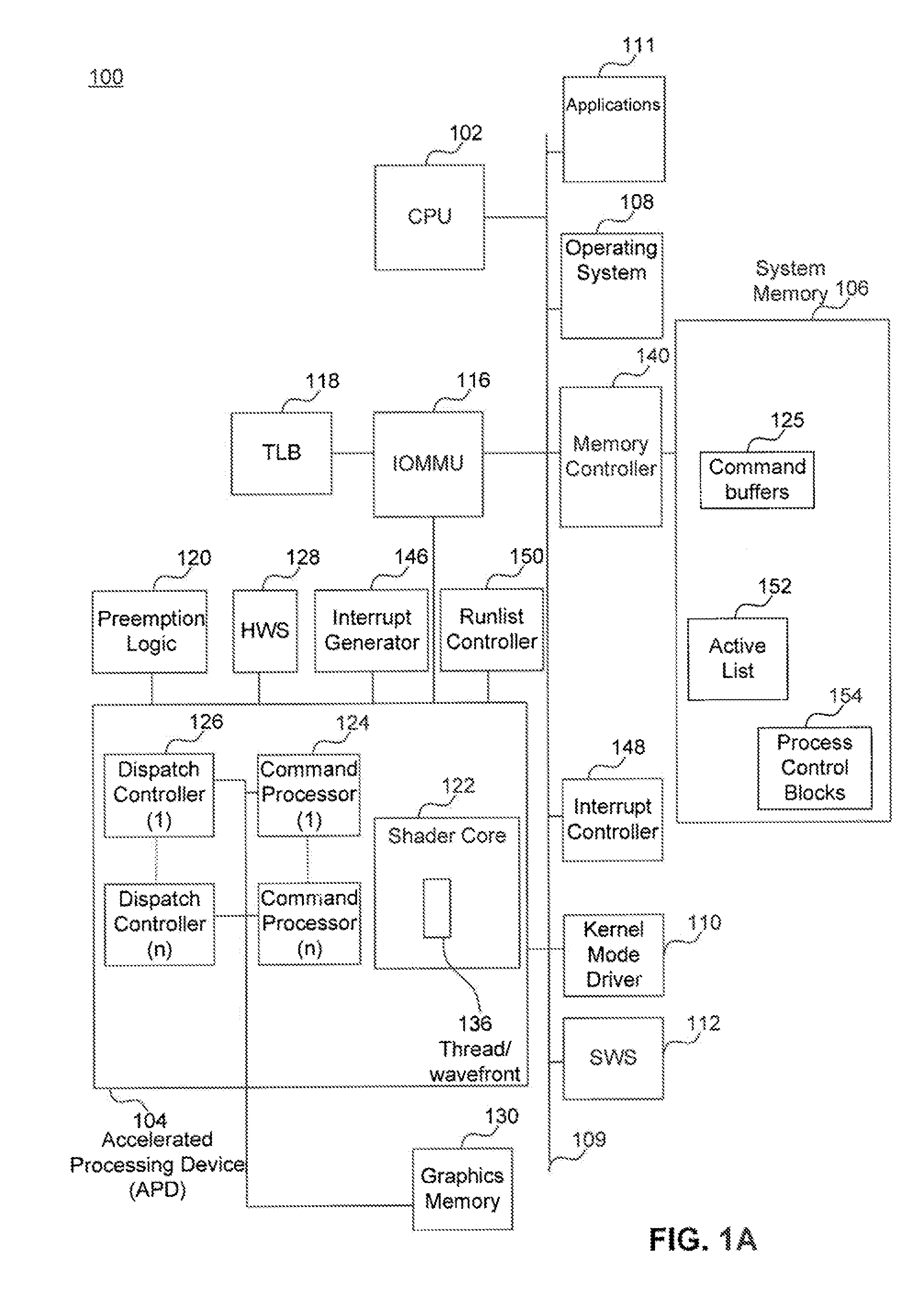

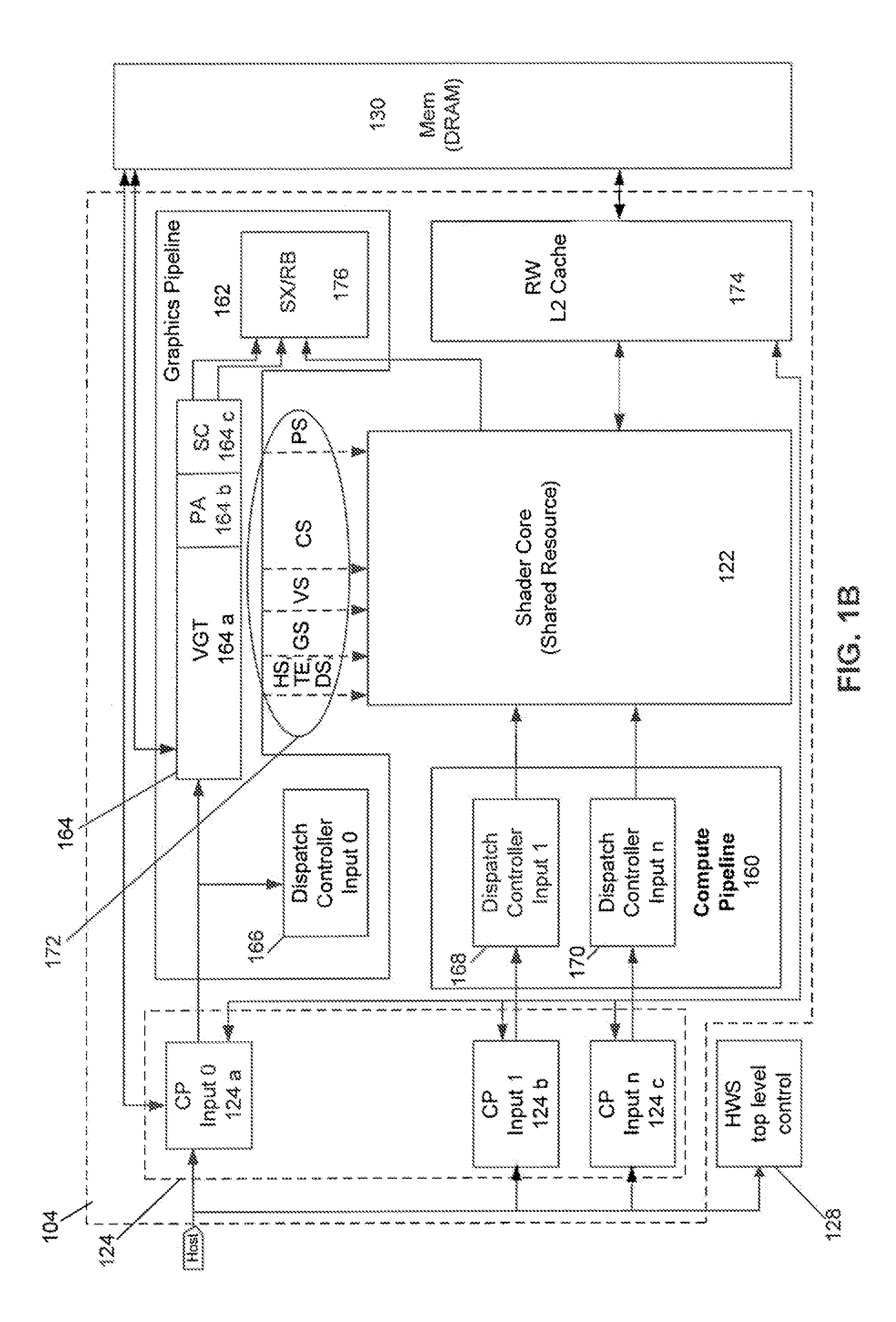

Computer System Interrupt Handling

ActiveUS20120179851A1Increase processDesign optimisation/simulationProbabilistic CADRAID processing unitComputerized system

A system, method and article of manufacture for an accelerated processing device (APD) to request a central processing unit (CPU) to process a task, comprising enqueuing a plurality of tasks on a queue using the APD, generating a user-level interrupt and transmitting to the CPU the plurality of tasks in the queue using an interrupt handler associated with a CPU thread.

Owner:ADVANCED MICRO DEVICES INC

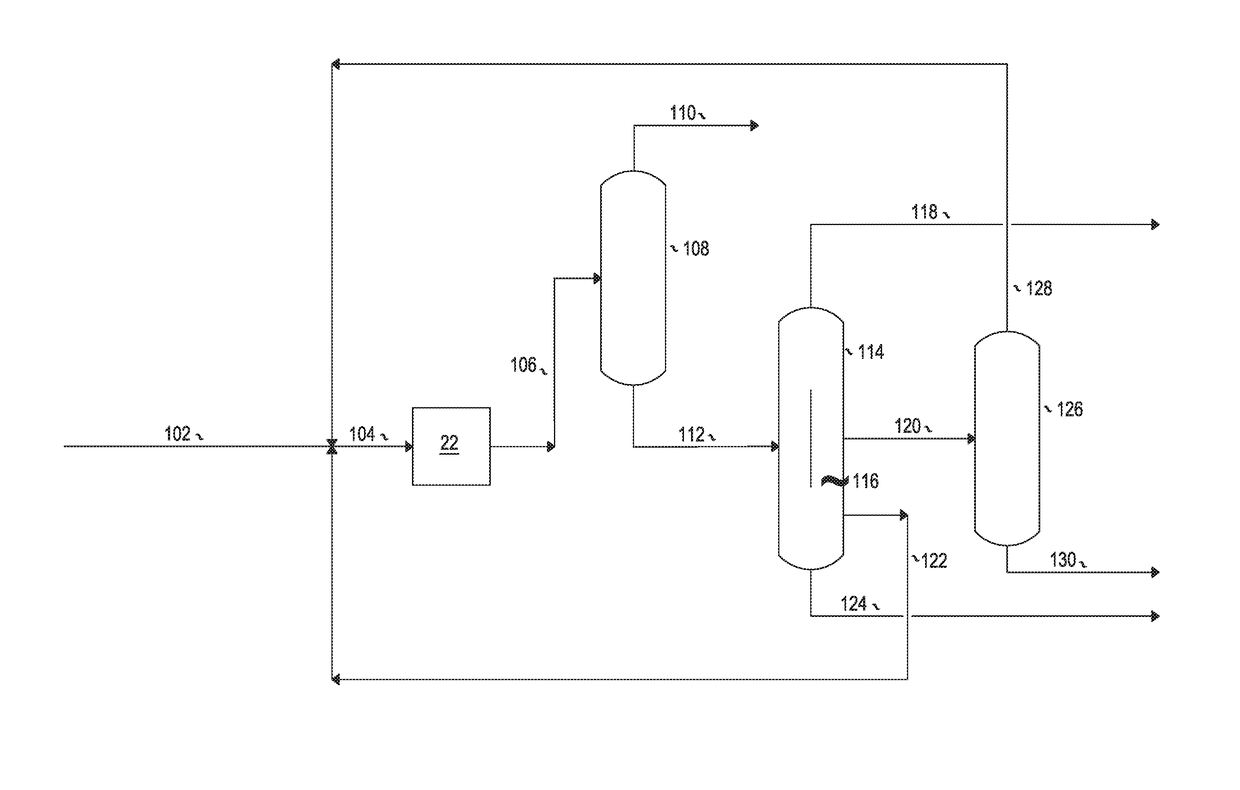

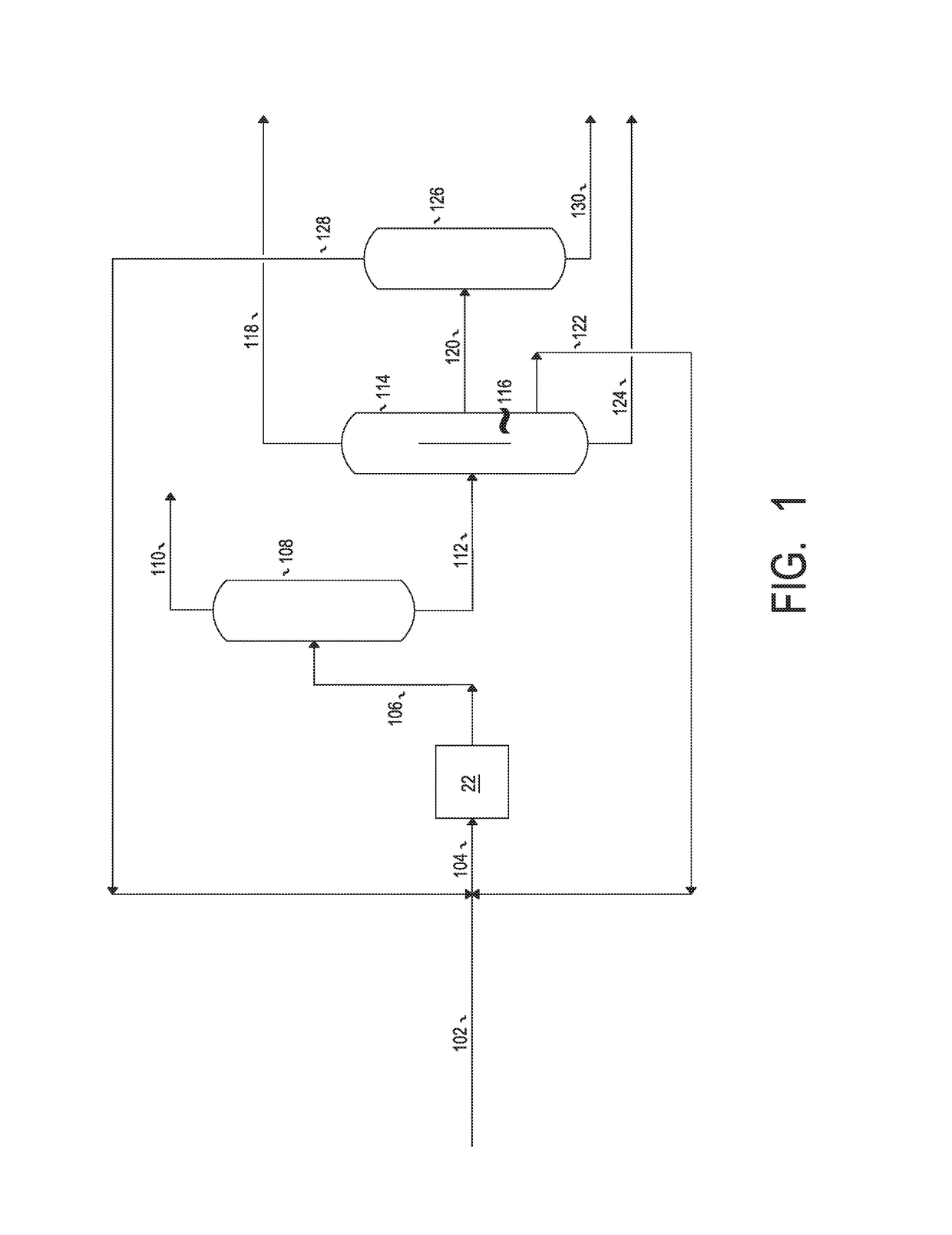

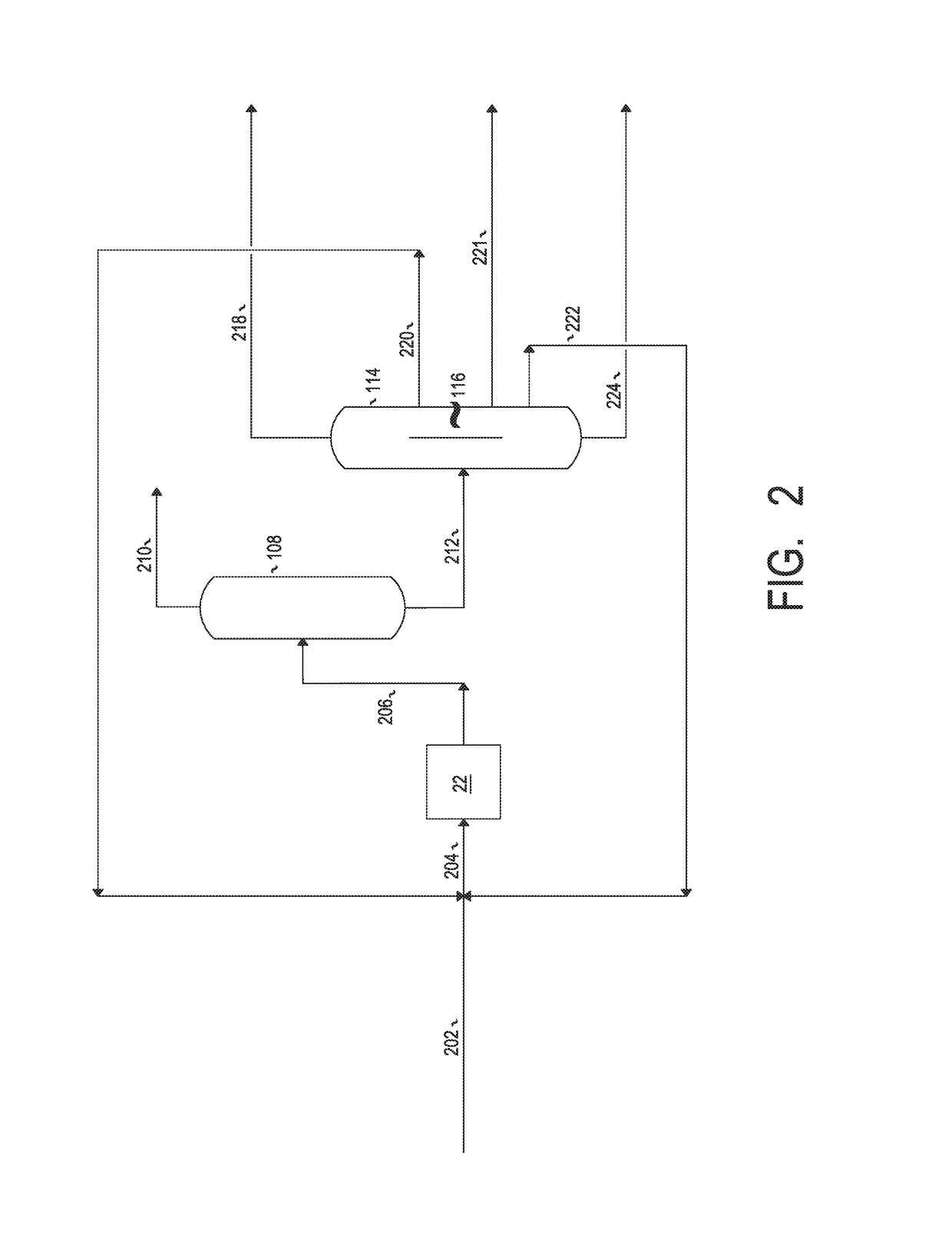

Energy efficient methods for isomerization of a C5-C6 fraction with dividing wall fractional distillation

ActiveUS10118875B1Increase processEliminate needHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonChemistrySeparation process

This invention relates to a method of separating an isomerization zone effluent mixture comprising between 5 and 7 carbon atoms into high octane isomerate product streams and low octane streams which may be recycled to the isomerization zone. The separation process makes use of a dividing wall column to efficiently perform the separation of isopentane and high octane multibranched paraffins from low octane straight chain and single branched paraffins.

Owner:KOCKLER DAVID NORBERT

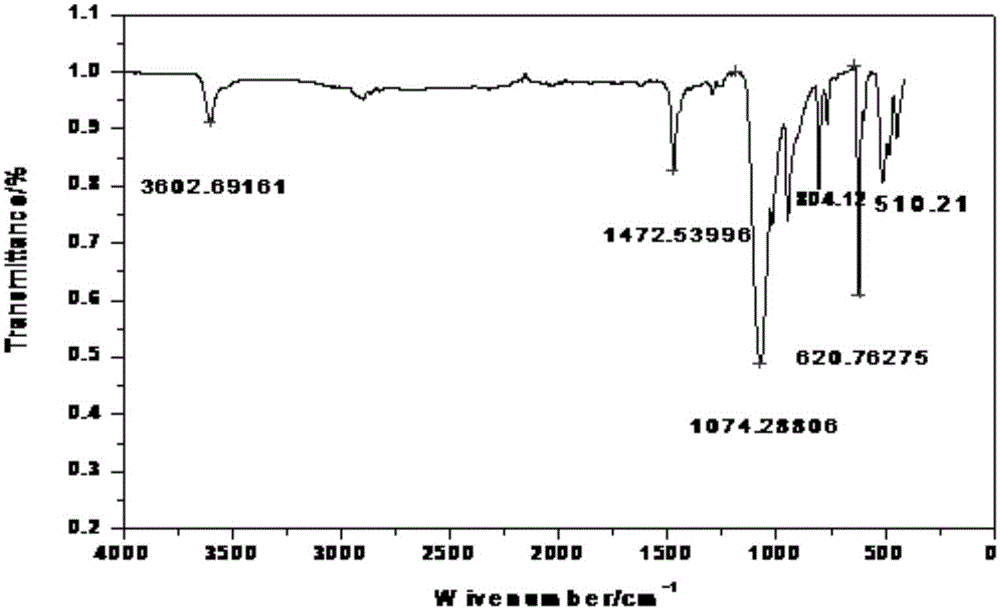

Copper-containing complex catalyst and preparation method and application thereof

InactiveCN104646058AEasy to prepareIncrease processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventDiamine

The invention relates to a copper-containing complex catalyst and a preparation method and application thereof. The preparation method comprises the following steps: adding water into copper carbonate, dripping perchloric acid to generate reaction, evaporating a blue solution after reaction is completed so as to be concentrated to obtain crystals, and finally obtaining copperperchlorate hydrate; adding the copperperchlorate hydrate and organic diamine into a solvent, stirring, performing heating backflow reaction under the temperature of 50-80 DEG C for 5-8 hours, and performing filtering, washing and drying to obtain a product. Compared with the prior art, the preparation method for the catalyst is simpler, and the catalysis activity is relatively high; pollution cannot be generated.

Owner:SHANDONG NORMAL UNIV

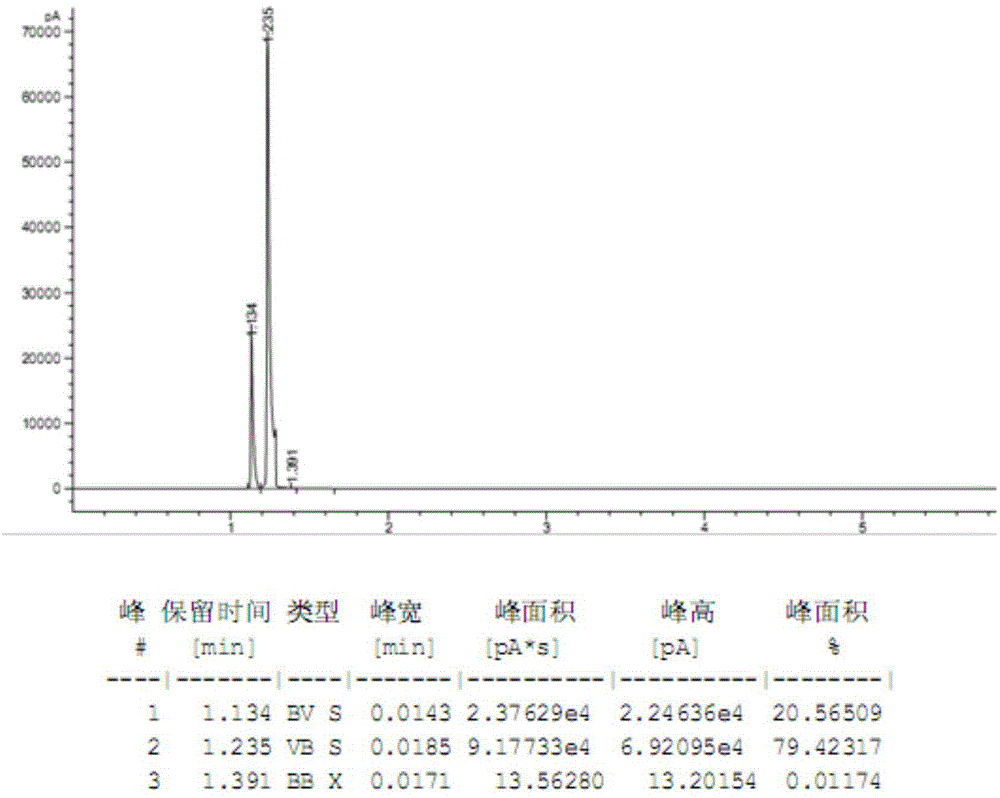

Process for the preparation of sugammadex and its intermediates

The present application provides an improved process for the preparation of sugammadex which comprises the halogenation of γ-cyclodextrin in a suitable organic solvent to give 6-per-deoxy-6-per-halo-γ-cyclodextrin, wherein halo is bromo or chloro, reacting the halogenated γ-cyclodextrin with 3-mercaptopropionic acid in the presence of alkoxide base to obtain sugammadex of formula I. This application also provides isolation of 6-per-deoxy-6-per-chloro-γ-cyclodextrin as a crystalline compound and its use for the preparation of sugammadex of formula (I).

Owner:FRESENIUS KABI IPSUM SRL

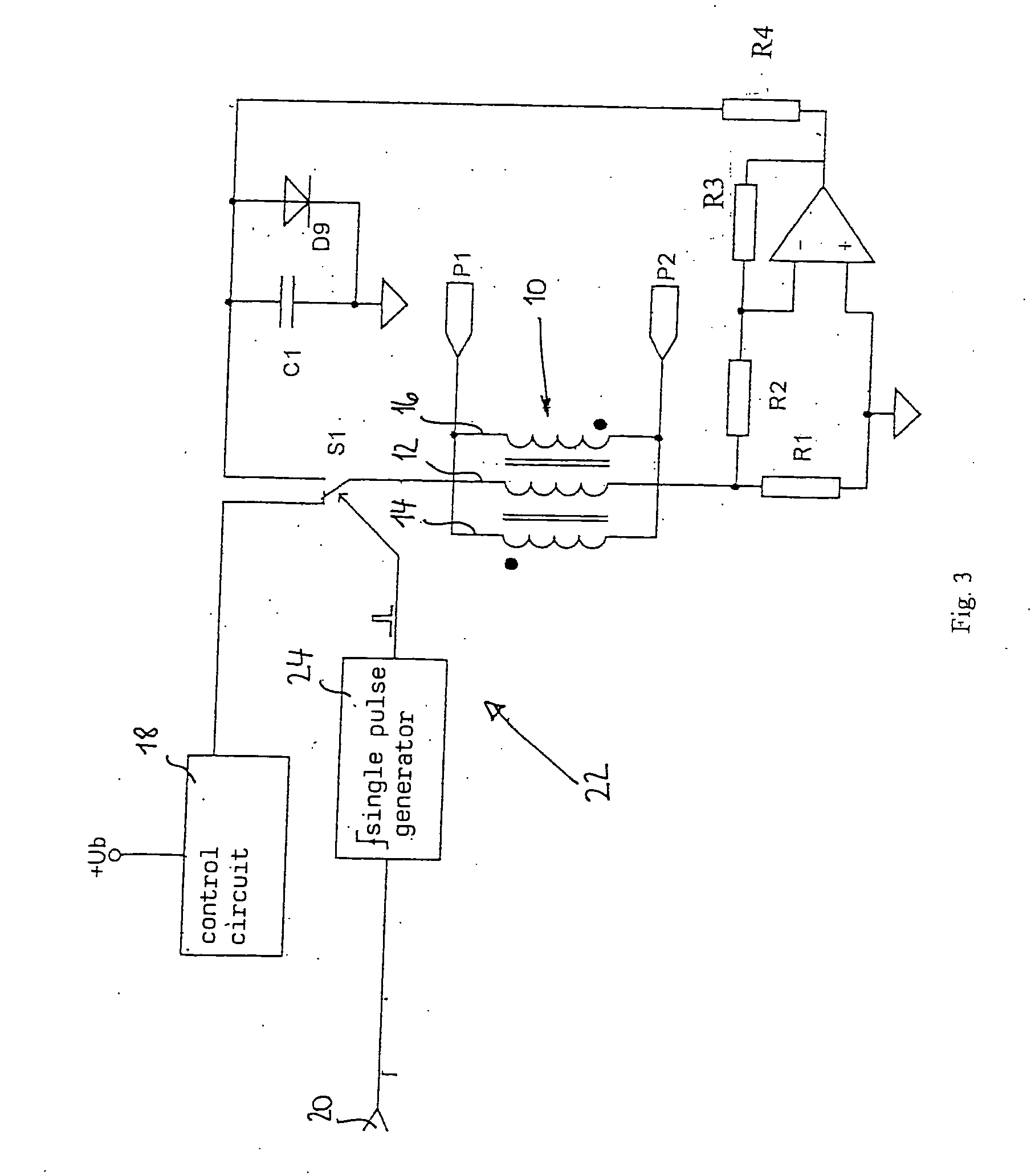

Means for controlling a coil arrangement with electrically variable inductance

InactiveUS20050013084A1High efficiencyIncrease processVariable inductancesTransformers/inductances circuitsMagnetic coreInductor

The invention relates to a special control for current-controlled inductors which allows inductance to be varied at a considerably faster rate than is the case in the prior art. The control presented in the invention can be employed for coil arrangements which carry at least one control winding and at least two working windings on a ferro or ferromagnetic core material. The accelerated change in inductance is achieved by means of a demagnetizing inverse voltage impulse which is generated by a special part of the circuit.

Owner:MINEBEA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com