Multifunctional finishing agent based on hyperbranched polyester derivative as well as preparation and application thereof

A technology of hyperbranched polyester and finishing agent, applied in the fields of biochemical fiber treatment, fiber treatment, textile and paper making, etc., can solve the problems of long process, different performance of finishing agents, poor stability, etc., and achieve long process, environment-friendly and human-friendly , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

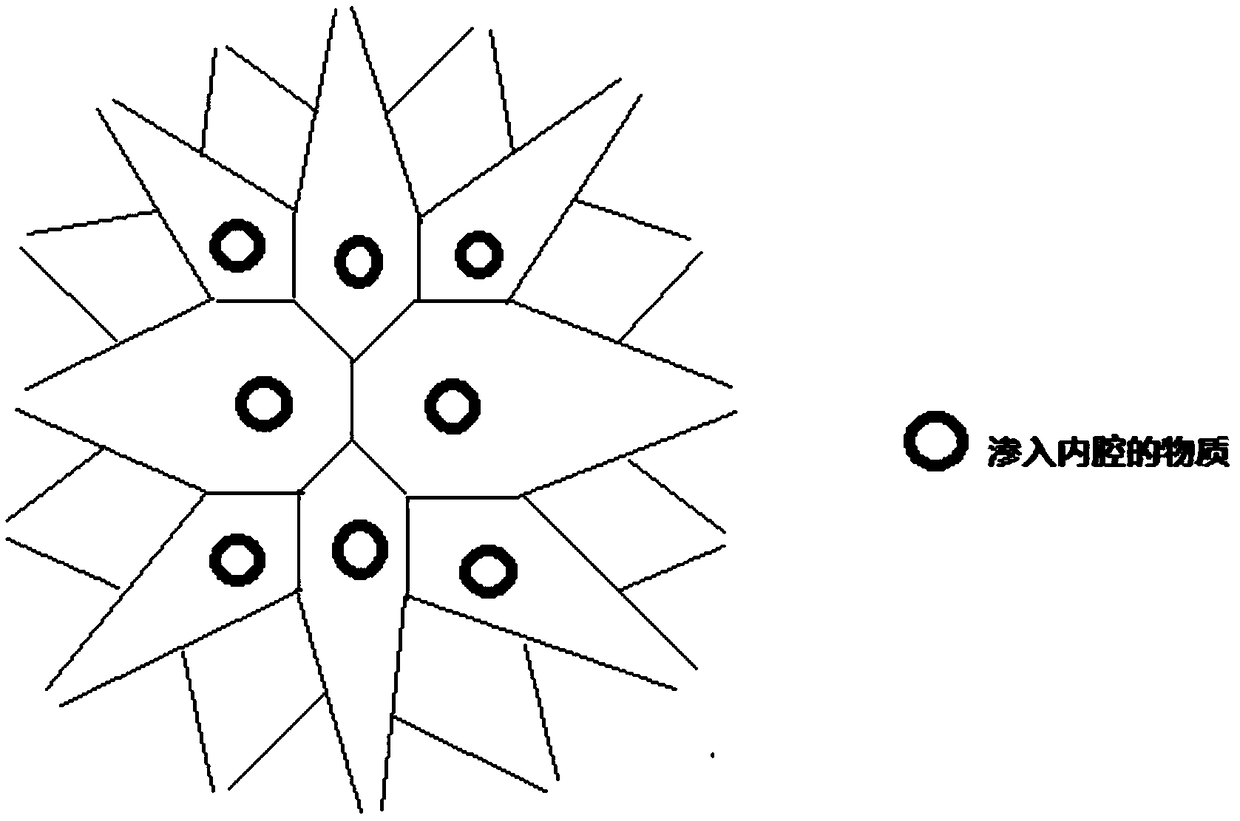

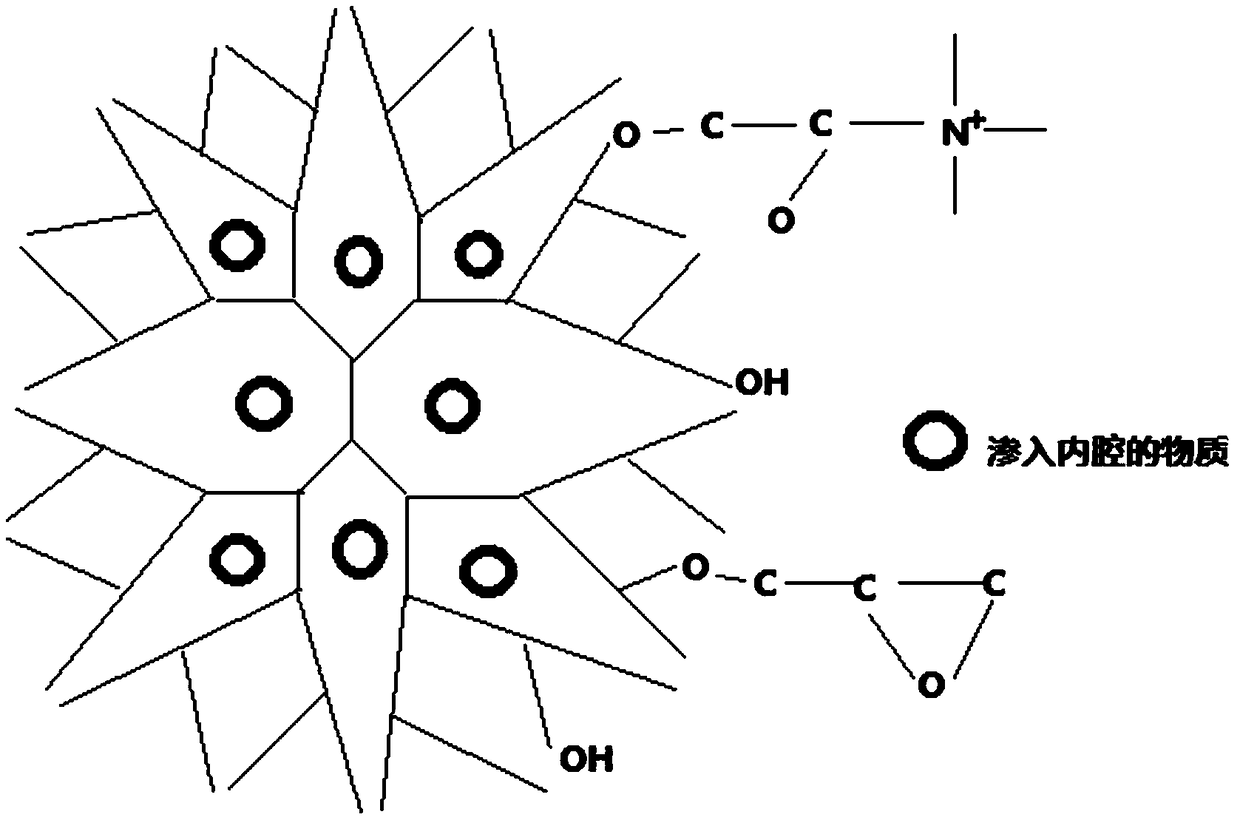

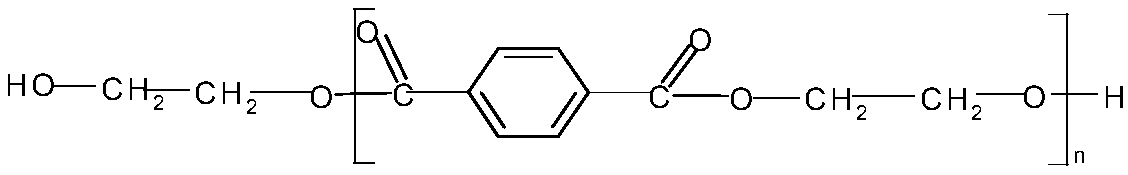

[0034] (1) hyperbranched polyester derivatives, the branched end has dozens of polar functional end groups and fiber linking groups; it is equipped with a hyperbranched polyester treatment solution with a concentration of 0.5% made of deionized water green solvent;

[0035] (2) In the hyperbranched polyester treatment solution, trichlorazine, an antibacterial functional auxiliary agent that can enter the inner cavity of the branched polyester, is added. The molar ratio of functional additives and hyperbranched polyester is 2:1, and the treatment time is 120min.

[0036] (3) Padding the polyester fabric with the above solution, and curing and fixing the fabric to give the fabric multifunctionality. The time for immersing the polyester fabric in the solution is 10 minutes, the padding method is two dipping and two rolling, the excess rate is 70%, the pre-baking temperature is 80 °C, the pre-baking time is 10 min, the baking temperature is 150 °C, and the baking time is 1 min , ...

Embodiment 2

[0038] (1) hyperbranched polyester derivatives, the branched end has dozens of polar functional end groups and fiber linking groups; it is equipped with a hyperbranched polyester treatment solution with a concentration of 1% made of deionized water green solvent;

[0039] (2) In the hyperbranched polyester treatment liquid, n-octadecane, a phase-change cooling and thermal insulation functional auxiliary agent that can enter the inner cavity of the branched polyester, is added. The molar ratio of functional additives and hyperbranched polyester is 4:1, and the treatment time is 120min.

[0040] (3) Padding the polyester fabric with the above solution, and curing and fixing the fabric to give the fabric multifunctionality. The time for immersing the polyester fabric in the solution is 30 minutes, the padding method is two dipping and two rolling, the excess rate is 70%, the pre-baking temperature is 80 °C, the pre-baking time is 10 min, the baking temperature is 150 °C, and the ...

Embodiment 3

[0042] (1) hyperbranched polyester derivatives, the branched end has dozens of polar functional end groups and fiber linking groups; it is equipped with a hyperbranched polyester treatment solution with a concentration of 1% made of deionized water green solvent;

[0043] (2) In the hyperbranched polyester treatment solution, tetrakismethylol acetate phosphorus, a flame-retardant functional auxiliary agent that can enter the inner cavity of the branched polyester, is added. The molar ratio of functional additives and hyperbranched polyester is 6:1, and the treatment time is 120min.

[0044] (3) Padding the polyester fabric with the above solution, and curing and fixing the fabric to give the fabric multifunctionality. The time for immersing the polyester fabric in the solution is 30 minutes, the padding method is two dipping and two rolling, the excess rate is 70%, the pre-baking temperature is 80 °C, the pre-baking time is 10 min, the baking temperature is 180 °C, and the bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com