Production of via hole in flexible circuit printable board

- Summary

- Abstract

- Description

- Claims

- Application Information

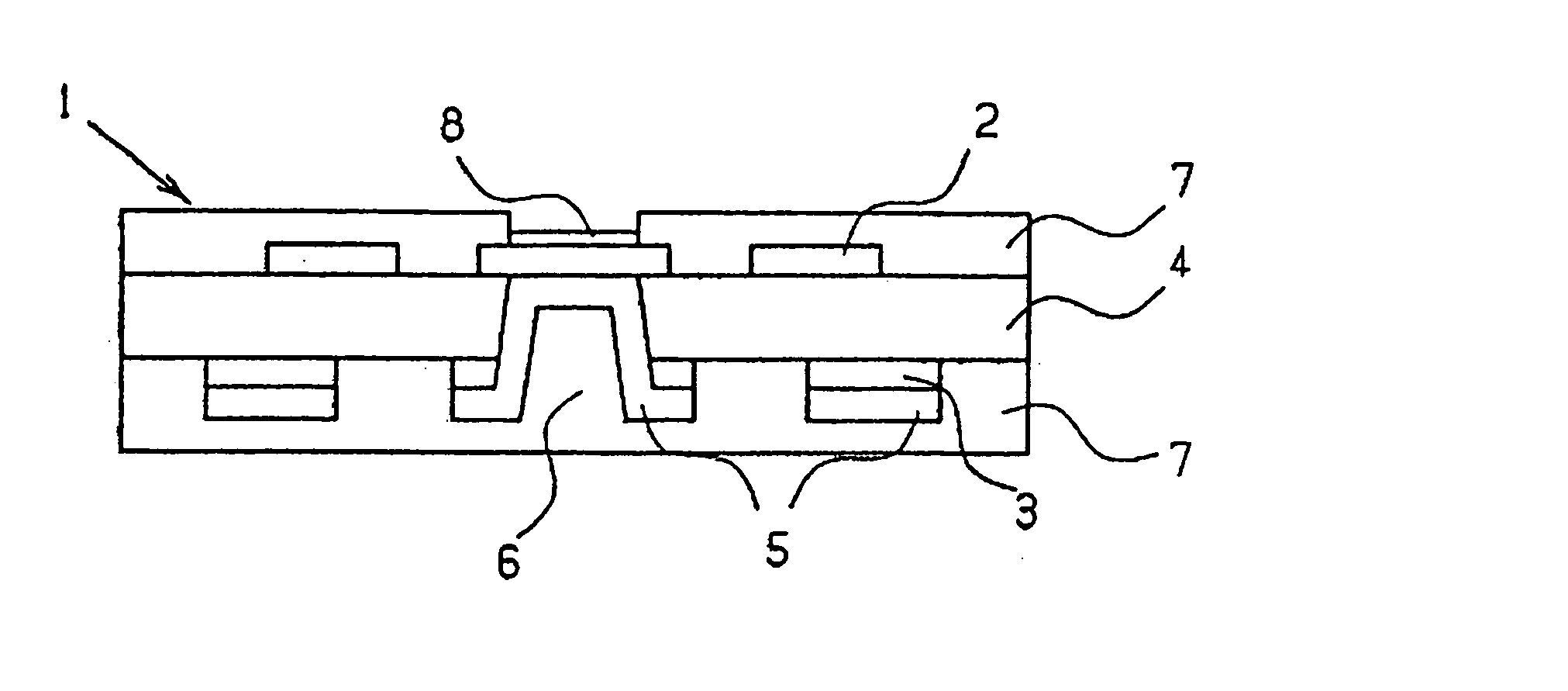

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0067] A metal-coated composite (trade name Upicel N, available from Ube Industries, Ltd.) composed of a three layer polyimide film (thickness: 25 μm) having a thermoplastic surface on each surface side and an electrolytic copper foil (thickness: 9 μm, trade name USLPR2, available from Nippon Electrolytic Co., Ltd.) which was placed on each of the thermoplastic surfaces under pressure and heating is exposed to a UV-YAG laser (Model 5320 available from ESI, wavelength 355 μm), to form simultaneously holes in one copper layer and in the polyimide film. To the holes were subsequently applied a mixture of water and alumina grains (alumina content: 16 vol. %) under an air pressure of 0.2 MPa using a wet-blasting apparatus (available Mako Co., Ltd.), whereby metal flashes and dust in the holes were removed.

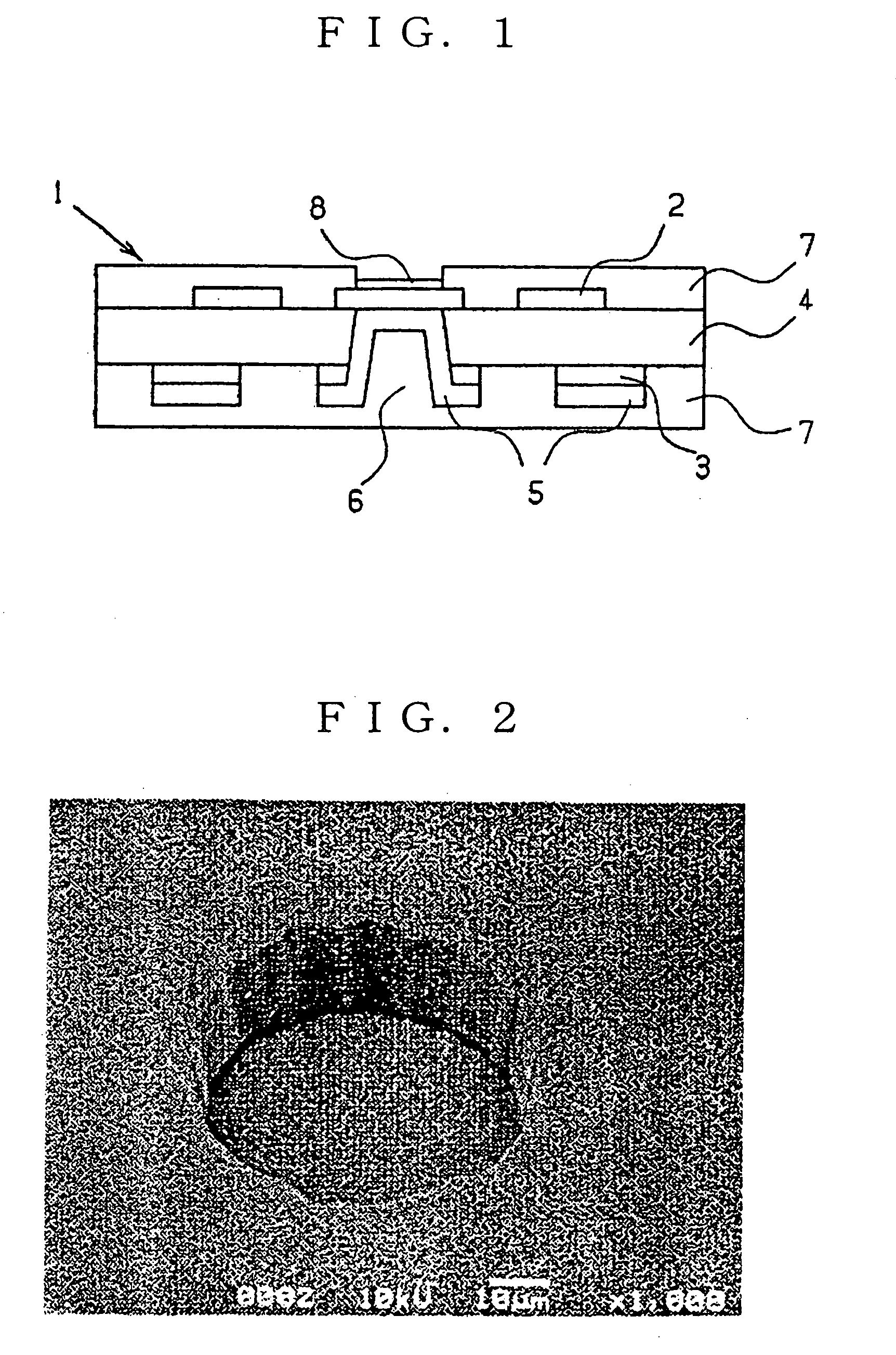

[0068]FIG. 2 shows a section of the hole having been subjected to the above-mentioned wet-blasting.

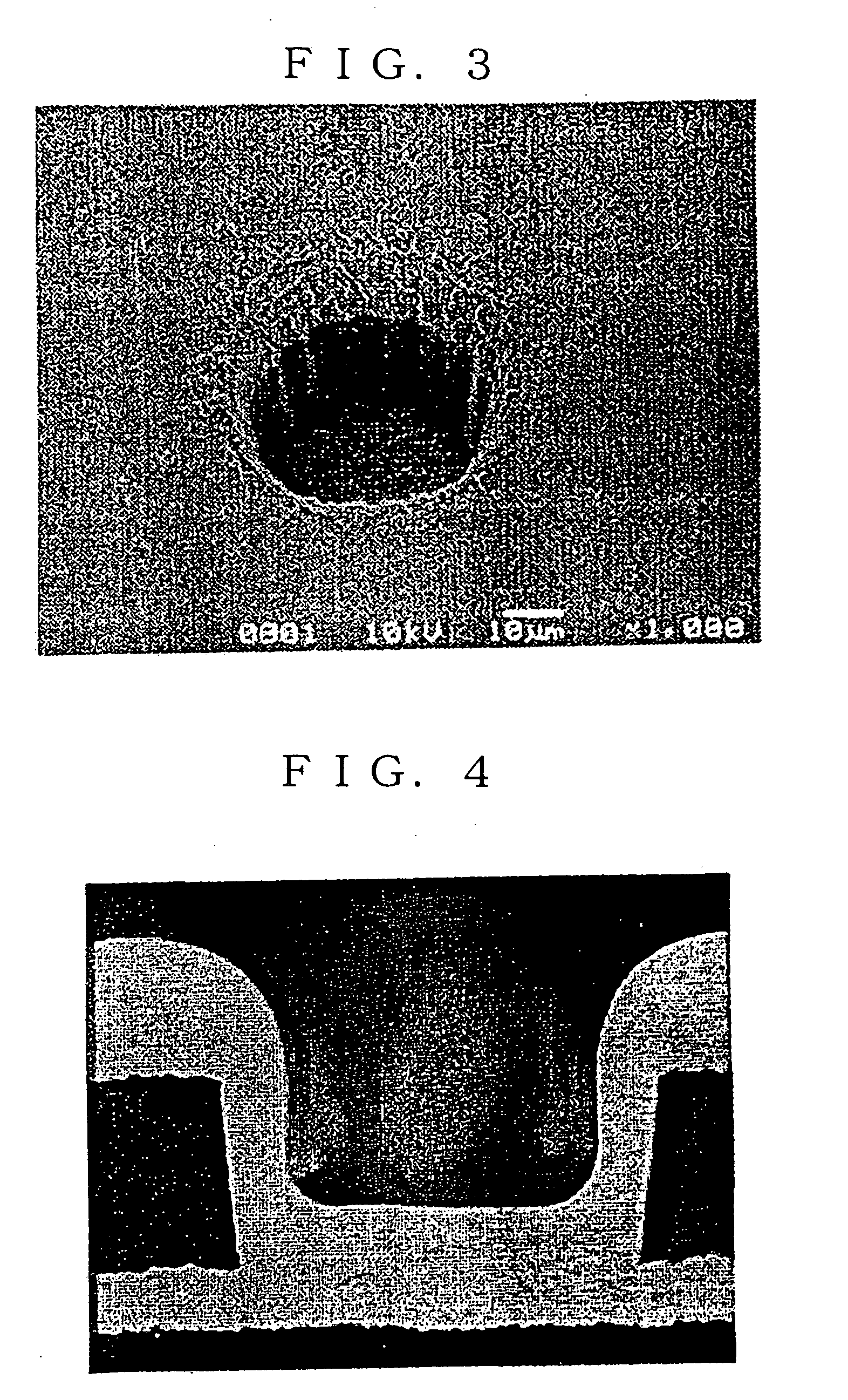

[0069]FIG. 3 shows a section of the hole before having been subjected to the wet-bla...

example 2

[0081] The procedures of Example 1 were repeated except for producing through-holes in the metal-coated polyimide composite film by means of a punch. Thus produced through-holes were then subjected to wet-blasting in the same manner as in Example 1, to give via holes and copper foil having thereon a copper plated layer having a thickness of 12 μm.

[0082] Then, the procedures of Example 1 were repeated to produce a flexible circuit printed board. In the flexible circuit printed board, the copper foils were firmly connected to the copper plated layer, so that no separation was observed at their interfaces when it was heated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Photosensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com