Electronic device and heat radiating system thereof

A technology for electronic devices and heat dissipation systems, which is applied in the direction of electrical components, electrical digital data processing, and structural components of electrical equipment. It can solve problems such as shortened working life, inability to dissipate heat, and high operating temperature, and achieve improved flow paths and heat dissipation conditions. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

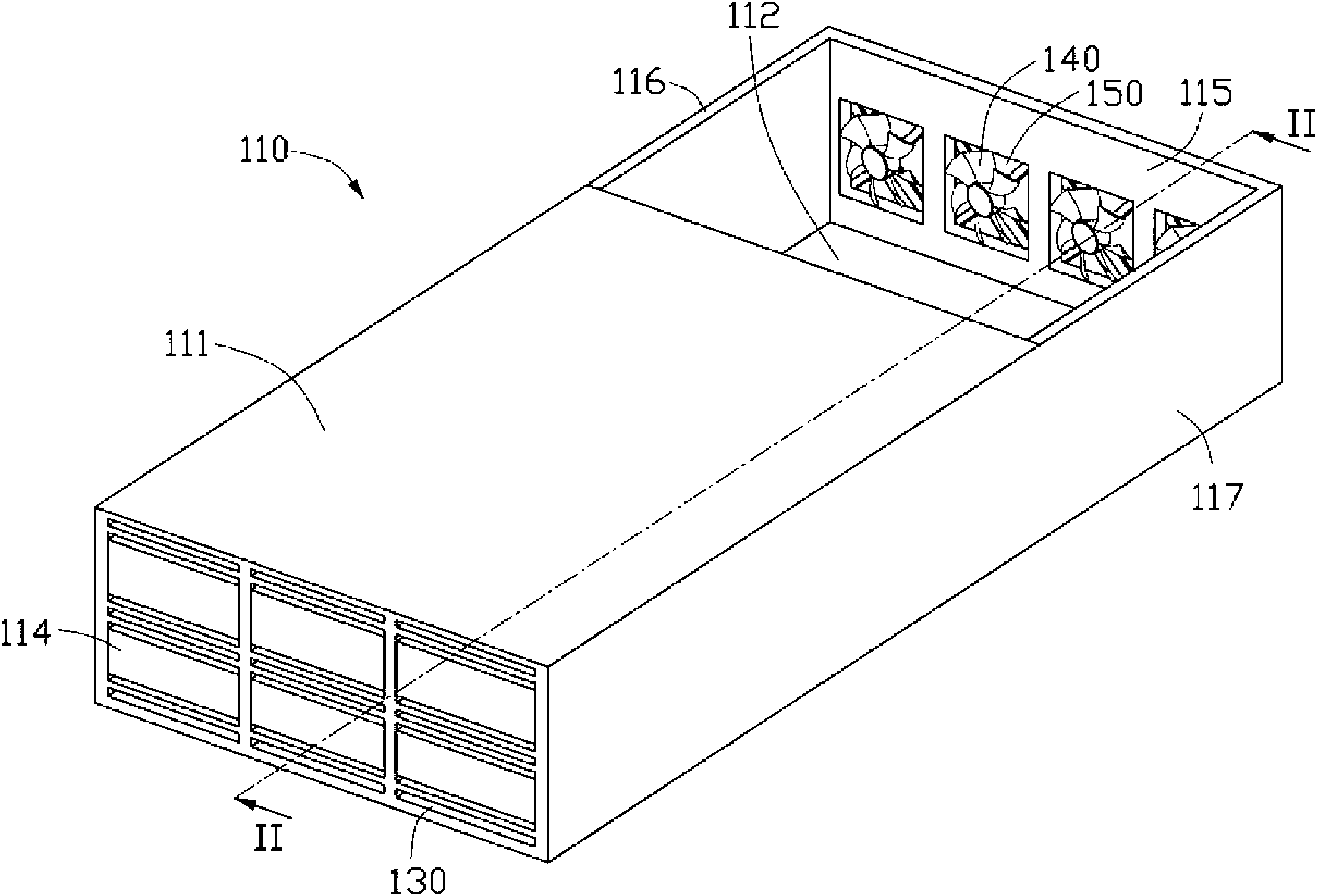

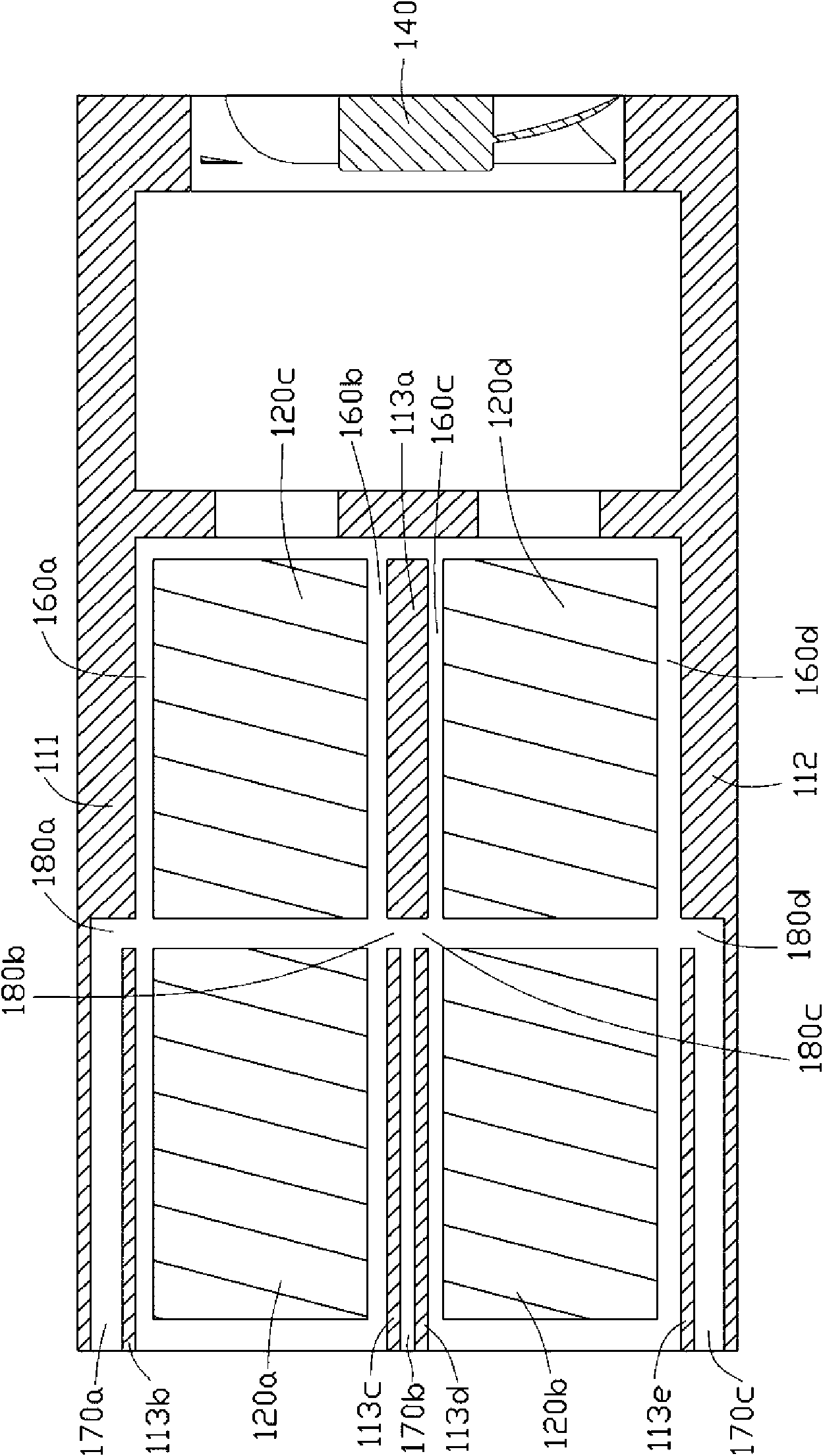

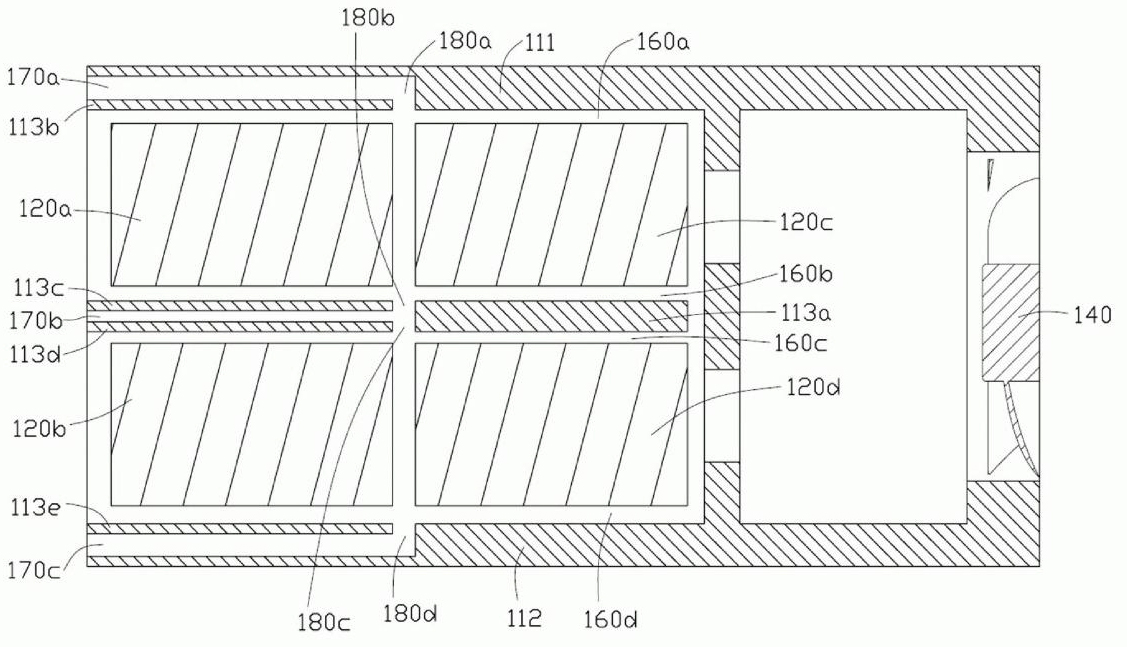

[0019] Please refer to figure 1 and figure 2 The electronic device of the present invention includes a cooling system and several electronic devices 120a-120d, the cooling system includes a case 110, several fans 140 and several first partitions 113b-113e, the case 110 includes a board, a front Plate 114, a rear plate 115, side plates 116 and 117, the plate body includes a top plate 111 ( figure 1 The middle portion is cut away to show the fan 140), a bottom plate 112 parallel to the top plate 111, and a second partition 113a.

[0020] A number of air inlets 130 are provided on the front panel 114 of the chassis 110, and a cooling fluid, such as external cold air, can enter the interior of the chassis 110 through the air inlets 130 to cool the electronic devices 120a-120d. To dissipate heat.

[0021] A plurality of air outlets 150 are opened on the rear panel 114, and each fan 140 is fixed at each corresponding air outlet 150, for passing the heated fluid flowing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com