Battery pack heat exchange system and electric vehicle

A heat exchange system and battery pack technology, applied in electric vehicles, electric vehicle charging technology, batteries, etc., can solve the problems of unfavorable single battery temperature uniformity control, poor cooling/heating effect, etc., to improve the uniformity of temperature distribution , good heat exchange effect, guarantee the effect of cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

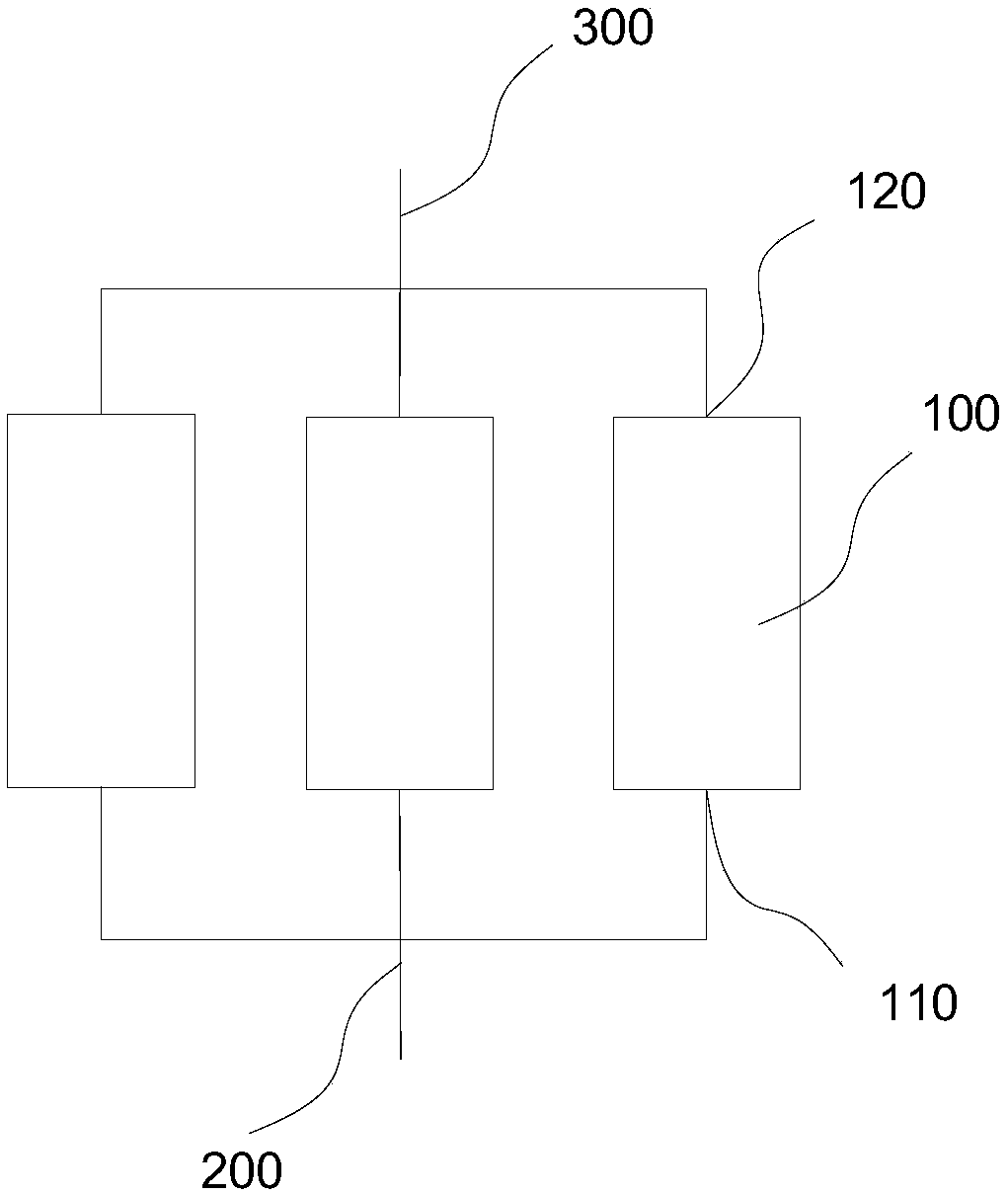

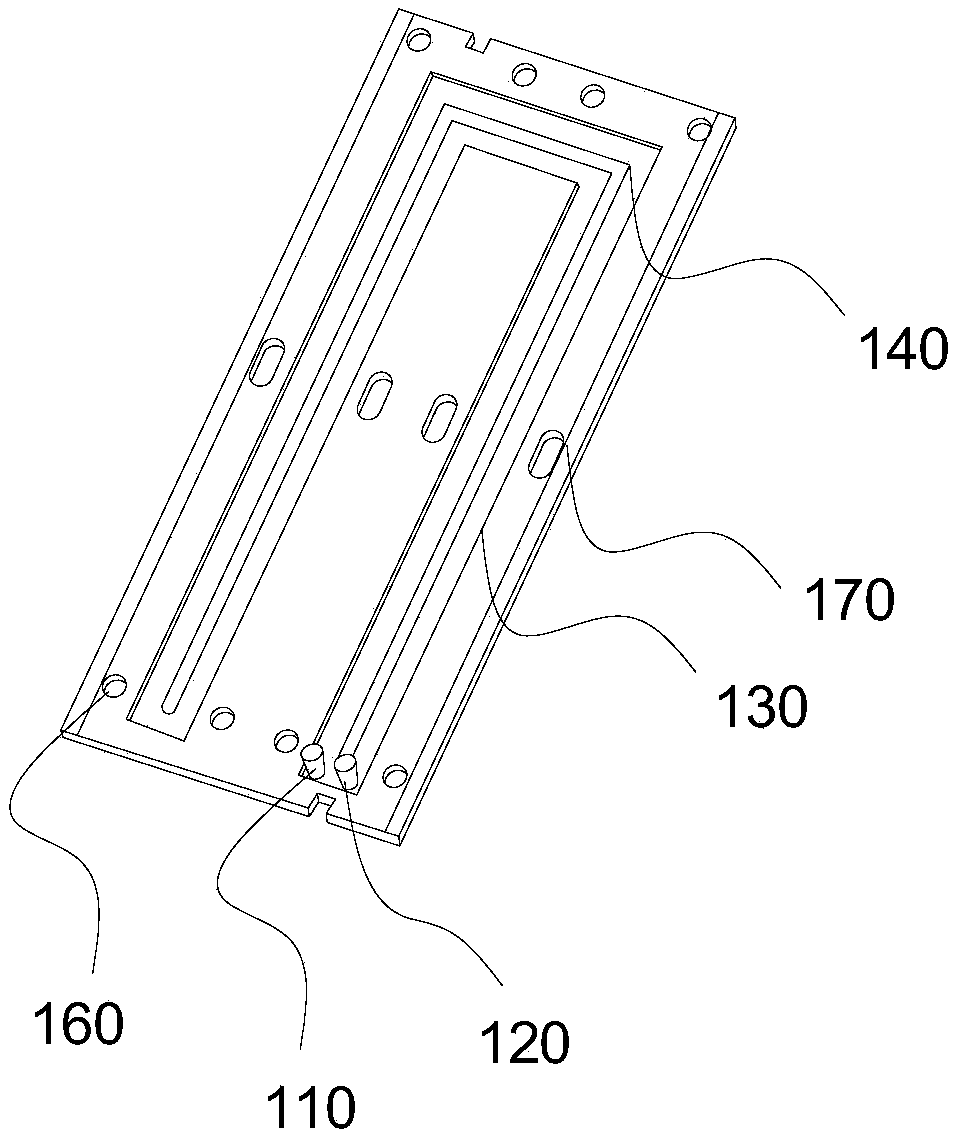

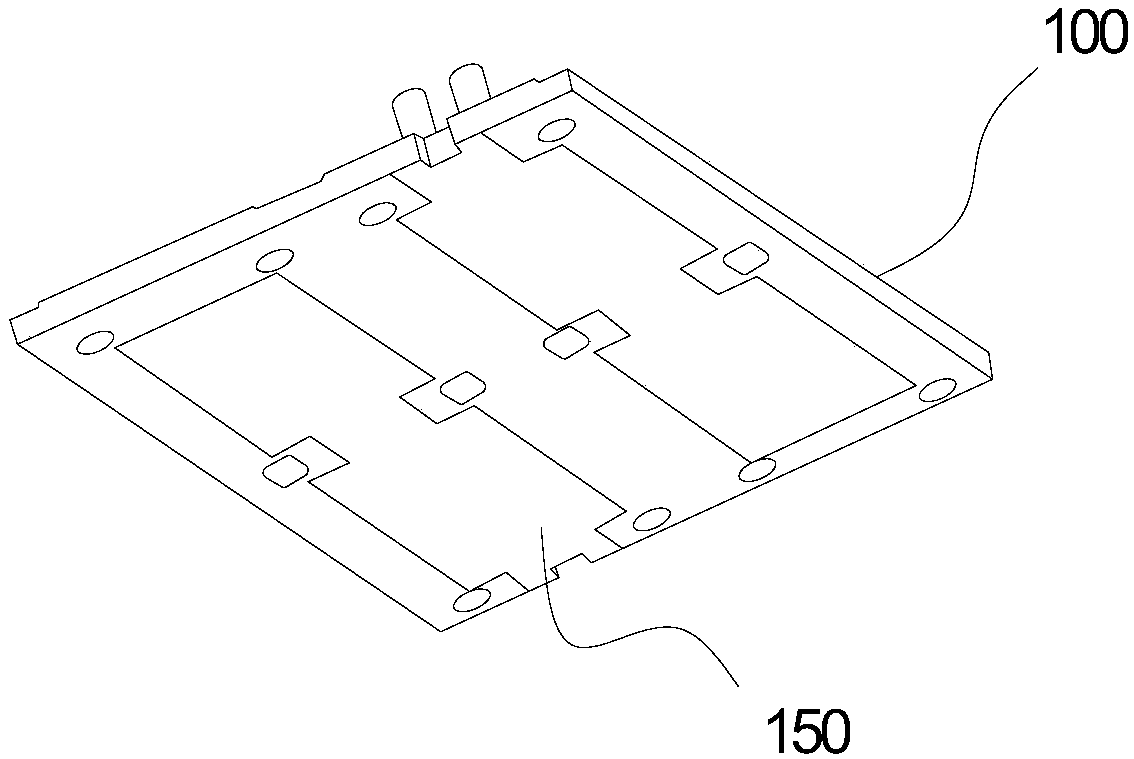

[0038] figure 1 Schematic diagram of the structure of the battery pack heat exchange system provided in Embodiment 1 of the present invention; figure 2 It is a structural schematic diagram of the first viewing angle of the heat exchange device 100 in the battery pack heat exchange system provided by Embodiment 1 of the present invention; image 3 It is a schematic structural diagram of the second viewing angle of the heat exchange device 100 in the battery pack heat exchange system provided by Embodiment 1 of the present invention.

[0039] Such as figure 1 As shown, a battery pack heat exchange system is provided in this embodiment, and the battery pack heat exchange system includes a plurality of heat exchange devices 100, a main water inlet pipe 200 and a main water outlet pipe 300;

[0040] A plurality of heat exchange devices 100 are provided in one-to-one correspondence with a plurality of batteries in the battery pack;

[0041] Each of the heat exchange devices 100 ...

Embodiment 2

[0064] Figure 4 A schematic structural diagram of a battery pack heat exchange system provided in another embodiment 2 of the present invention; Figure 4 As shown, the battery pack heat exchange system provided in this embodiment is a further improvement on the battery pack heat exchange system provided in Example 1, and the technical solution described in Example 1 also belongs to this embodiment.

[0065] Specifically, as Figure 4 As shown, a battery pack heat exchange system is provided in this embodiment, and the battery pack heat exchange system includes a plurality of heat exchange devices 100, a main water inlet pipe 200 and a main water outlet pipe 300;

[0066] A plurality of heat exchange devices 100 are provided in one-to-one correspondence with a plurality of batteries in the battery pack;

[0067] Each of the heat exchange devices 100 includes a water inlet 110 and a water outlet 120; a plurality of the water inlets 110 are connected to the main water inlet p...

Embodiment 3

[0075] This embodiment provides an electric vehicle, the electric vehicle includes the battery pack heat exchange system described in Embodiment 1 or Embodiment 2, which improves the uniformity of temperature distribution between the single cells and ensures that the battery is at the optimum temperature. Working within the temperature range, thus ensuring the cruising range, safety and life of the electric vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com