An optical fiber coating device with a start-up auxiliary function

A technology of coating device and auxiliary function, applied in the field of optical fiber coating device, can solve the problems of optical fiber coating outer diameter fluctuation, optical fiber processing scrap, difficult to control, etc., to reduce optical fiber scrap, reduce scrap, improve qualification rate and production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

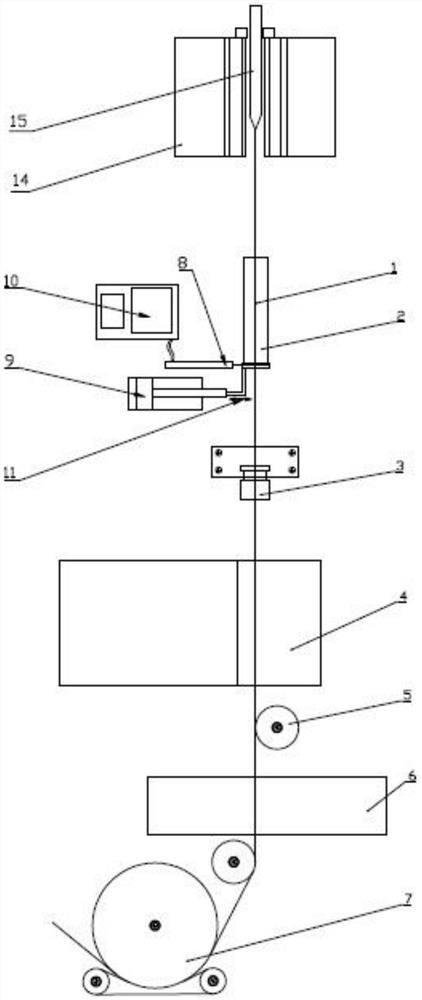

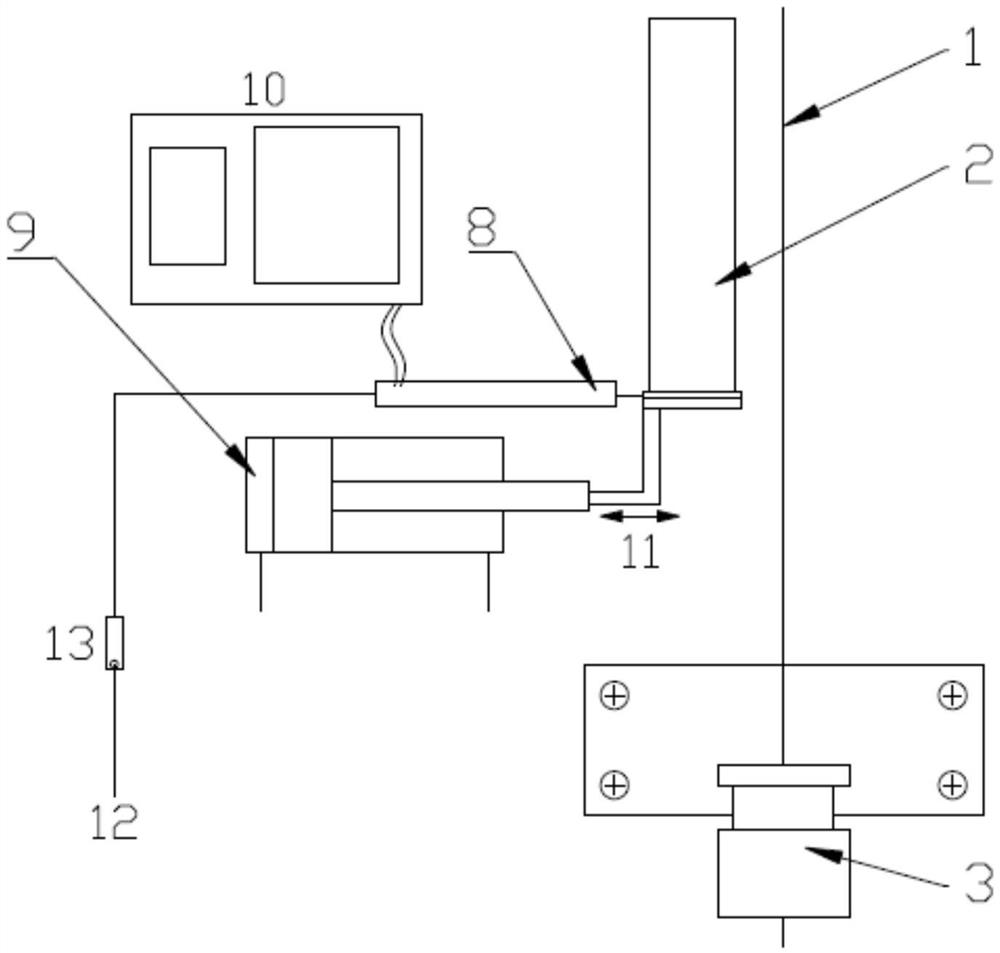

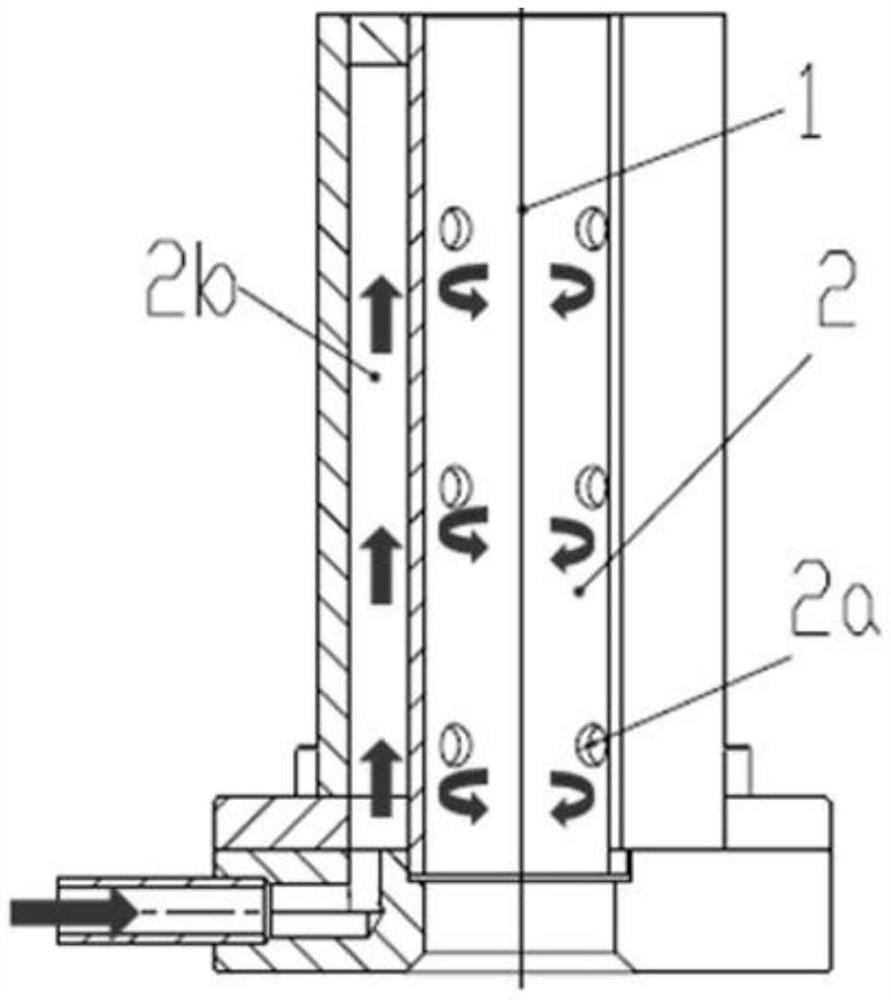

[0019] An example of the present invention is figure 1 As shown, it includes a coater 3, an ultraviolet curing device 4, a measuring device 6 and a traction mechanism 7 arranged sequentially below the drawing outlet of the wire drawing furnace 14, and a guide wheel is arranged between the ultraviolet curing device, the measuring device and the traction mechanism 5. Between the drawing outlet of the drawing furnace and the coater, an optical fiber auxiliary heating device is provided relative to the drawing track of the optical fiber 1. The auxiliary heating device includes a heating tube 2 and a hot air source connected to the heating tube. The heating The tube wall has a hollow airtight ring cavity 2b, and the inner wall of the hollow airtight ring cavity is evenly distributed with air outlet holes 2a along the upper, lower and circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com