Sensor orthogonal calibration method for oil drilling measurement

A technology of drilling measurement and calibration method, which is applied in the field of petroleum drilling engineering, can solve the problems that the 3 sensitive axes cannot be strictly orthogonal, and the electrical performance of the 3-axis sensitivity is symmetrical, so as to improve the precision, reduce the workload and realize the temperature compensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

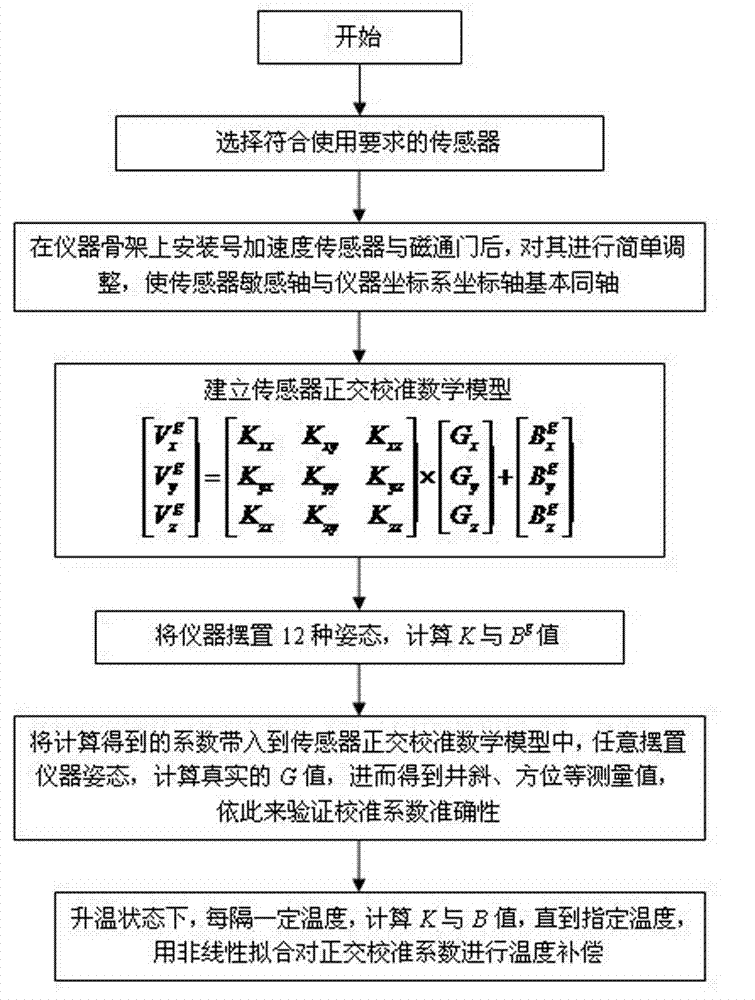

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] A sensor orthogonal calibration method for oil drilling measurement, the program compiled by the algorithm is run on the computer, and the orthogonal calibration method is:

[0019] Step 1: Select the acceleration sensor and fluxgate that meet the requirements of use. At room temperature, the bias value of the acceleration sensor is less than 15mg, and the bias value of the fluxgate is less than 3nT;

[0020] Step 2: After installing the acceleration sensor and the fluxgate on the instrument frame, make simple adjustments to make the sensitive axis of the sensor and the coordinate axis of the instrument coordinate system basically coaxial;

[0021] The third step: establish the sensor orthogonal calibration mathematical model,

[0022]

[0023] V g is the output voltage value of each meter, K is the scale factor, G is the acceleration due to gravity in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com