Temperature self-compensating fiber grating rod force sensor and using method thereof

A fiber grating and force sensor technology, which is applied in the direction of force measurement, instrumentation, and the use of optical devices by measuring the change of optical properties of materials when they are stressed, can solve problems such as cross-sensitivity of fiber grating sensors, and achieve light weight, Simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

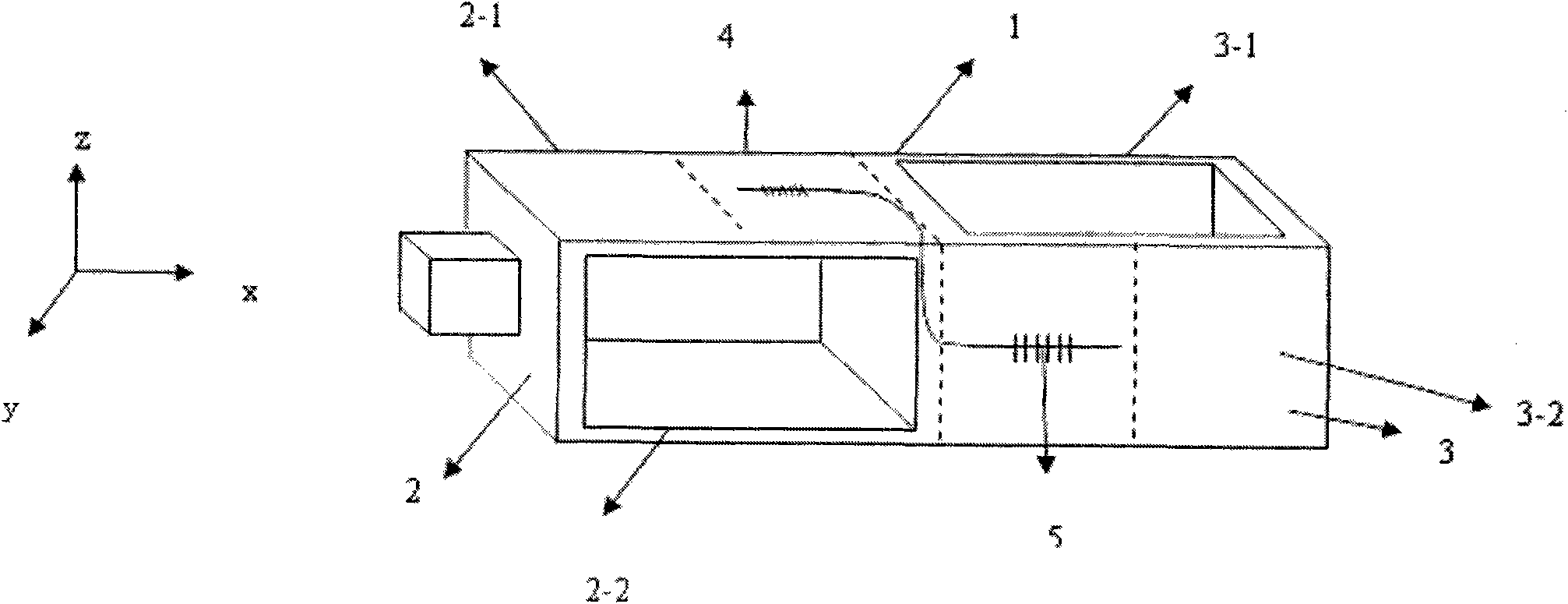

Examples

Embodiment 2

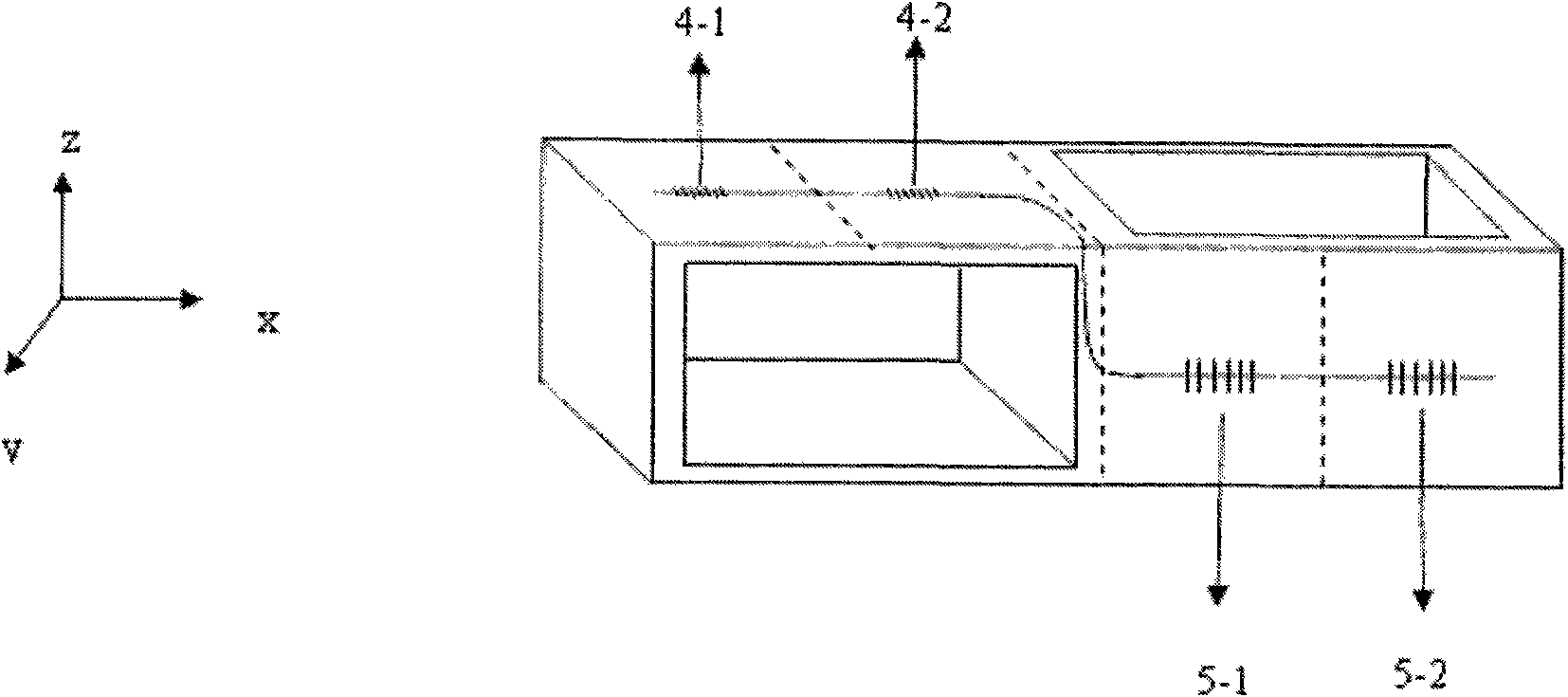

[0049] Embodiment 2: see attached figure 2 , the difference from Example 1 is that the first FBG strain sensor 4 and the second FBG strain sensor 5 are bare fiber Bragg gratings, and the first FBG strain sensor 4 consists of two bare FBG strain sensors 4 -1, 4-2 connected in sequence and pasted on the central axis of the surface, the second fiber grating strain sensor 5 is composed of two bare fiber Bragg gratings 5-1, 5-2 connected in sequence and pasted on the surface on the central axis. When the rod force sensor is bent and deformed, the center wavelength drift of the first fiber Bragg grating strain sensor 4 takes the average value of the center wavelength drift of the bare fiber Bragg grating 4-1, 4-2; the center wavelength of the second fiber Bragg grating strain sensor 5 The drift is the average value of the center wavelength drift of the bare fiber Bragg gratings 5-1 and 5-2.

Embodiment 3

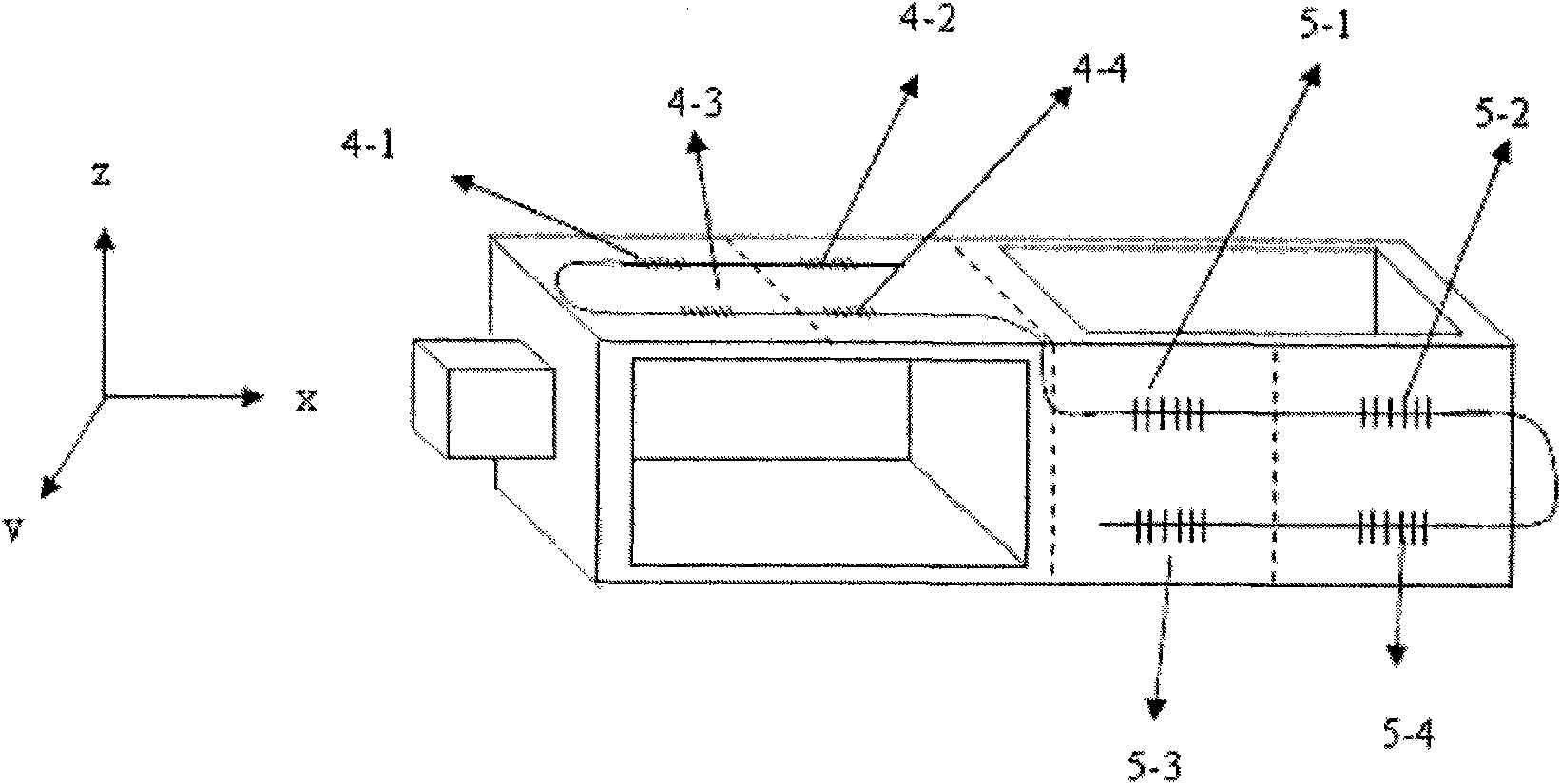

[0050] .Embodiment 3: see attached image 3 , the difference from Example 1 is that the first FBG strain sensor 4 and the second FBG strain sensor 5 are bare long-period fiber gratings, and the first FBG strain sensor 4 is composed of four bare long-period optical fibers The gratings 4-1, 4-2, 4-3, and 4-4 are sequentially connected to form and pasted on the surface, arranged in two rows up and down, and parallel to the upper and lower sides of the surface. The second fiber grating strain sensor 5 is composed of two bare long-period fiber gratings 5-1, 5-2, 5-3, 5-4 sequentially connected and pasted on the central axis of the surface. When the rod force sensor is bent and deformed, the center wavelength drift of the first fiber Bragg grating strain sensor 4 is the average value of the center wavelength drift of the bare fiber Bragg grating 4-1, 4-2, 4-3, 4-4; The center wavelength shift of the fiber Bragg grating strain sensor 5 is the average value of the center wavelength s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com